Method for strengthening carbonation resistance of alkali-activated concrete

A technology of concrete and alkali excitation, applied in the field of enhancing the anti-carbonation ability of alkali-excited concrete, can solve the problems of reducing the compressive strength of alkali-excited concrete, affecting the durability of concrete, destroying the passivation film of steel bars, etc., and achieving significant environmental and social benefits. , Improve the anti-carbonization ability and avoid the effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

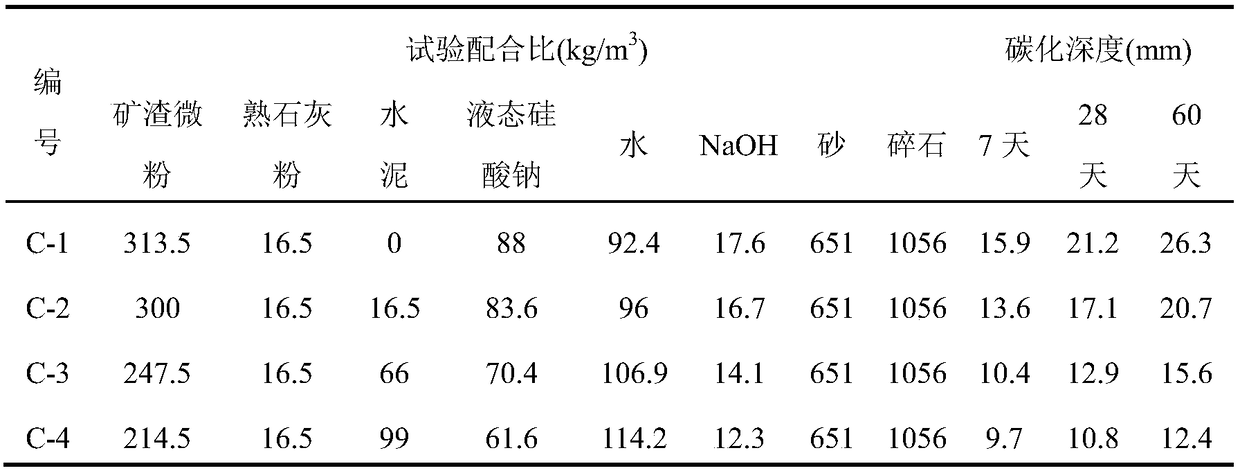

[0022] Embodiment 1: a kind of method that strengthens the anti-carbonation ability of alkali activated concrete, it is characterized in that: raw material composition and mass percentage thereof are as follows: take slag alkali activated concrete as example, cementitious material is blast furnace granulated slag micropowder 95% (dosage 313.5kg / m 3 ); ground slaked lime powder 5% (dosage 16.5kg / m 3 ); the fine aggregate is medium-coarse sand (dosage 651kg / m 3 ); the coarse aggregate is gravel (amount of 1056kg / m 3 ); liquid sodium silicate with a modulus of 2.75 (amount of 88 kg / m 3 ); caustic soda (NaOH dosage 17.6kg / m 3 ); water (dosage 92.4kg / m 3 ); with this as the control group, the accelerated carbonation test was carried out with reference to the standard GB / T 50082-2009 test method for long-term performance and durability of ordinary concrete. The carbonation test conditions were: CO 2 The mass fraction is 20%, the temperature is 20±2°C, and the humidity is 70±5%....

Embodiment 2

[0023] Embodiment 2: a kind of method that strengthens the anti-carbonation ability of alkali activated concrete, it is characterized in that: raw material composition and mass percentage thereof are as follows: take slag alkali activated concrete as example, cementitious material is blast furnace granulated slag micropowder 90% (dosage 300kg / m 3 ); ground slaked lime powder 5% (dosage 16.5kg / m 3 ); P.O 42.5 ordinary portland cement 5% (dosage 16.5kg / m 3 ); the fine aggregate is medium-coarse sand (dosage 651kg / m 3 ); the coarse aggregate is gravel (amount of 1056kg / m 3 ); liquid sodium silicate with a modulus of 2.75 (dosage 83.6kg / m 3 ); caustic soda (NaOH content 16.7kg / m 3 ); water (amount 106.9kg / m 3 );

Embodiment 3

[0024] Embodiment 3: a kind of method for enhancing the anti-carbonation ability of alkali-activated concrete is characterized in that: raw material composition and mass percentage thereof are as follows: taking slag alkali-activated concrete as example, cementitious material is blast furnace granulated slag micropowder 75% (dosage 247.5kg / m 3 ); ground slaked lime powder 5% (dosage 70.4kg / m 3 ); P.O 42.5 ordinary portland cement 20% (dosage 66kg / m 3 ); the fine aggregate is medium-coarse sand (dosage 651kg / m 3 ); the coarse aggregate is gravel (amount of 1056kg / m 3 ); liquid sodium silicate with a modulus of 2.75 (dosage 83.6kg / m 3 ); caustic soda (NaOH content 14.1 kg / m 3 ); water (dosage 96kg / m 3 );

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com