Method for increasing crystallization temperature and crystallization rate of polymer

A technology of crystallization temperature and crystallization rate, which is applied in the field of polymer materials, can solve problems such as difficult industrialization, difficulty in finding compatibilizers, and complicated operation process, and achieves the effects of accelerated crystallization rate, increased crystallization temperature, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

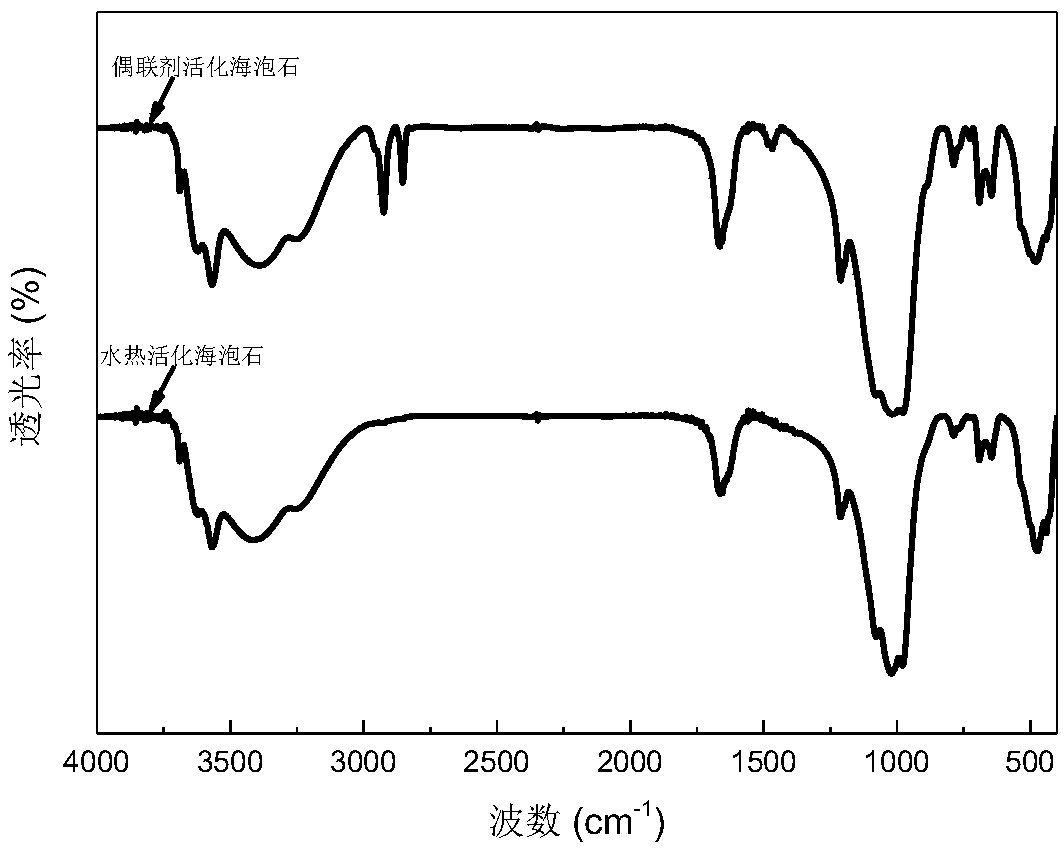

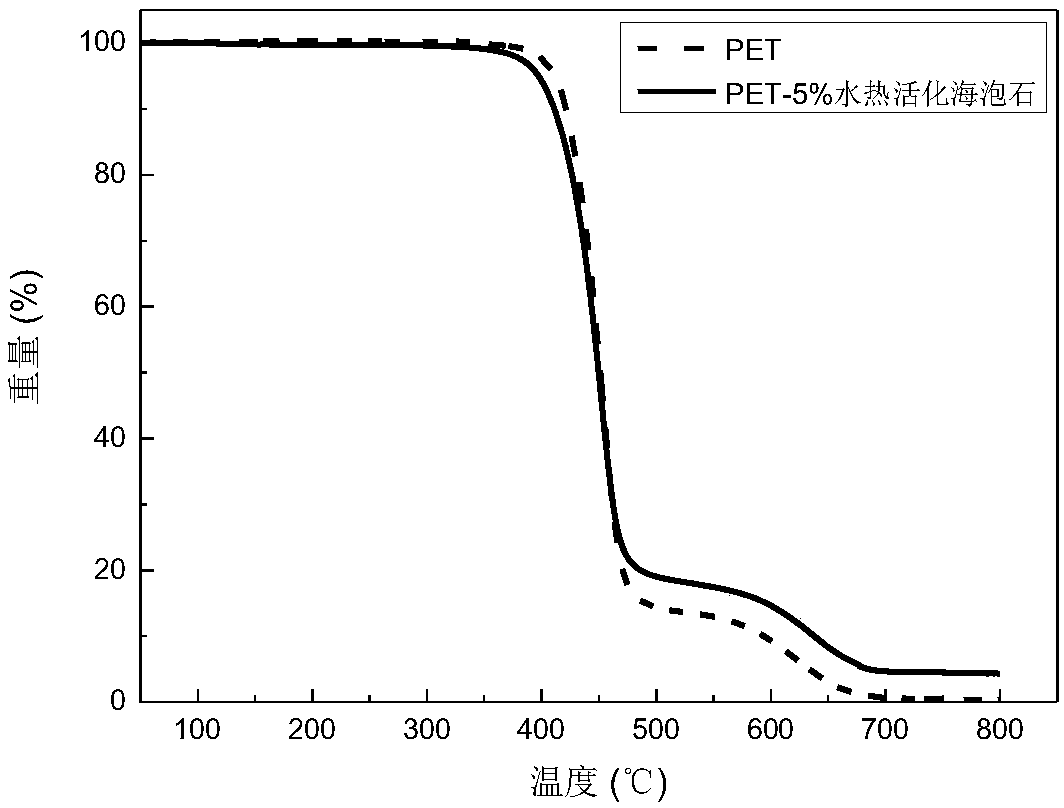

Embodiment 1

[0023] Mix 10 g of sepiolite and 200 g of distilled water into a beaker, put it into an autoclave, stir at 200° C. for 3 hours, filter with suction, dry, and pulverize to obtain activated sepiolite. The sepiolite was used as a nucleating agent, and a polyethylene terephthalate / sepiolite composite was prepared by a melt blending method. The blending conditions were 265°C, 50rpm, and 5min. The activated sepiolite and Polyethylene terephthalate is 1: 100 by mass ratio. Pure polyethylene terephthalate was also subjected to the same processing conditions as a reference sample. Differential scanning calorimetry (DSC) analysis showed that the crystallization temperature of the composite was 206.05°C, and that of pure polyethylene terephthalate was 169.15°C. It shows that the activated sepiolite can promote the crystallization of polyethylene terephthalate and is an efficient nucleating agent.

Embodiment 2

[0025] Method is with embodiment 1. Change the mass ratio of sepiolite to polyethylene terephthalate to 5:100. Through DSC analysis, it was found that the crystallization temperature of the composite was 212.77°C, and that of pure polyethylene terephthalate was 169.15°C. It shows that the activated sepiolite can promote the crystallization of polyethylene terephthalate and is an efficient nucleating agent.

Embodiment 3

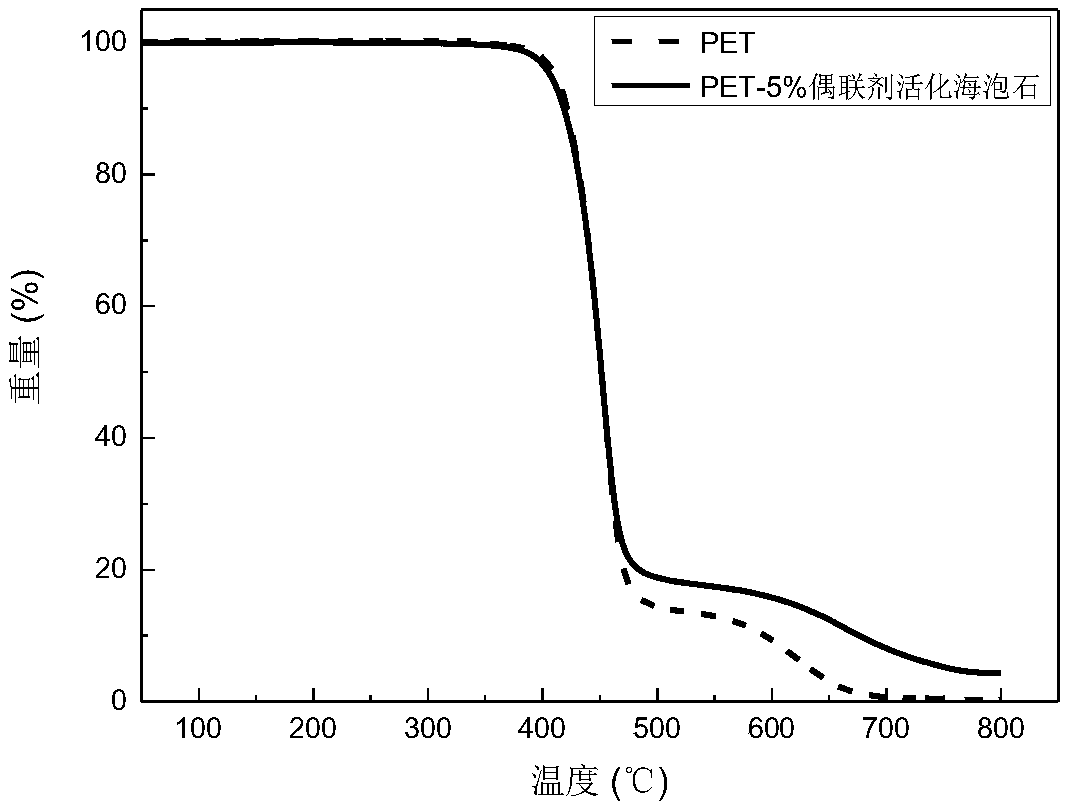

[0027] In a 500ml four-necked flask equipped with a mechanical stirrer, a condenser, and a thermometer, successively add 5g of finely ground sepiolite, 250mL of toluene, and 10mL of silane coupling agent, heat and stir under nitrogen protection until the toluene refluxes, and cool to At room temperature, wash repeatedly with anhydrous toluene, absolute ethanol and acetone respectively to remove unreacted coupling agent, and dry in vacuum to obtain activated sepiolite modified by silane coupling agent. The sepiolite was used as a nucleating agent, and the polyethylene terephthalate / sepiolite composite was prepared by the melt blending method. The blending conditions were 265°C, 50rpm, 5min, and the activated sepiolite The mass ratio with polyethylene terephthalate is 1: 100. Pure polyethylene terephthalate was also subjected to the same processing conditions as a reference sample. DSC analysis showed that the crystallization temperature of the complex was 214.9°C, and that of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com