Arsenic alkaline residue treatment system and method for treating arsenic alkaline residues by using arsenic alkaline residue treatment system

A disposal system and technology of arsenic-alkali slag, which is applied in the field of comprehensive resource utilization, can solve the problems of cost reduction and high processing cost, and achieve the effects of cost reduction, good processing effect and safe disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

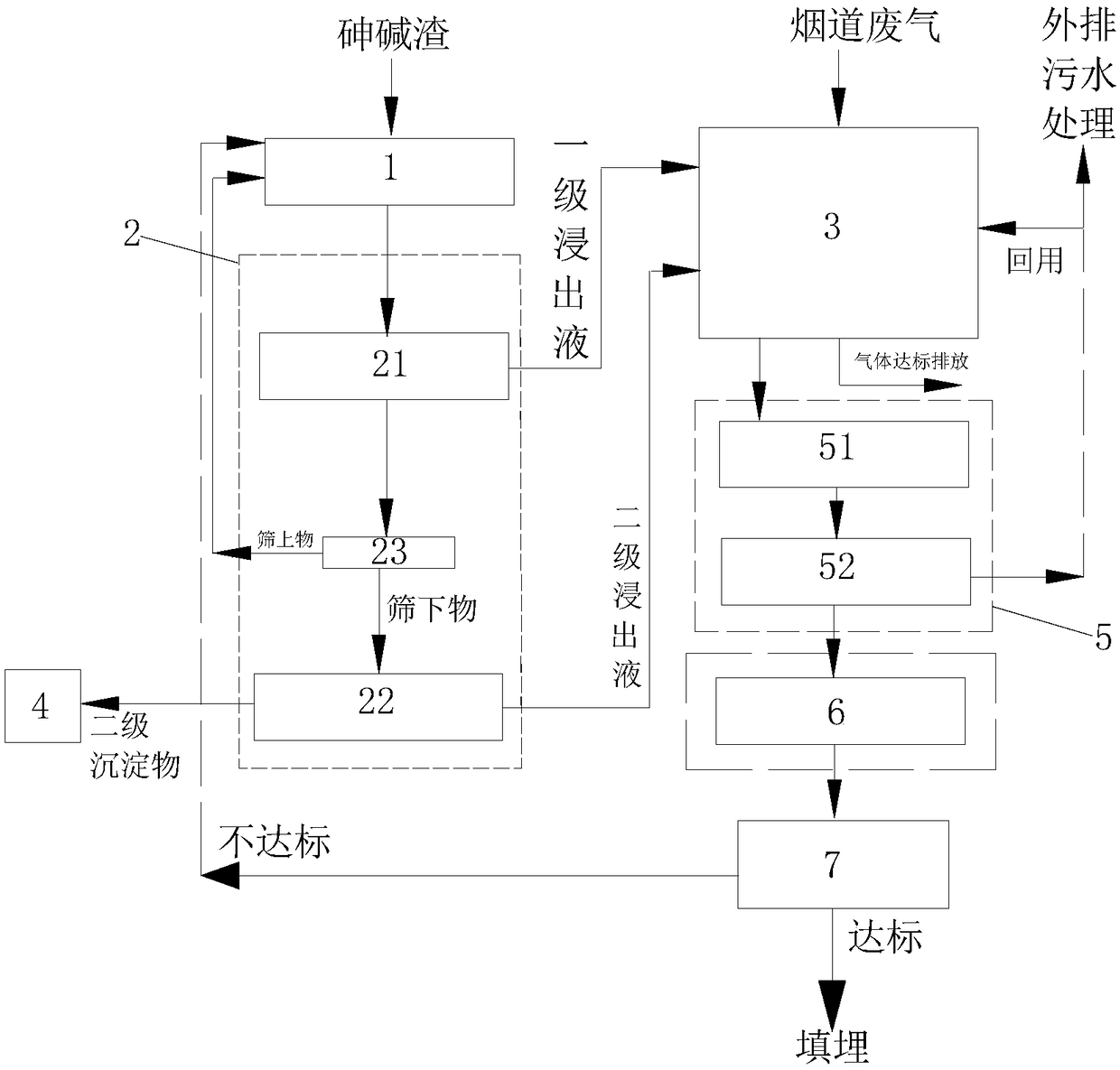

[0048] use figure 1 The shown arsenic-alkali slag disposal system performs arsenic-alkali slag treatment.

[0049] Send the original arsenic-alkali slag to the feeding pretreatment unit 1 for ball milling and crushing, with a solid-to-liquid ratio of 1:1 to obtain first-grade arsenic-alkali slag.

[0050] The primary arsenic-alkali slag is sent to the leaching unit 2, and is leached in the first leaching tank 21 using an acidic aqueous solution with a temperature of 20°C, containing sulfite ions, and a pH less than or equal to 6, to obtain a primary leachate and a primary precipitate. The primary leachate is input into the spray unit 3, the primary sediment is sieved by a grading sieve 23, the oversize is returned to the feeding pretreatment unit 1 for secondary ball milling and then circulated, and the undersize is input into the second leaching tank 22. Water at a temperature of 30° C. is used for leaching to obtain a secondary leachate and a secondary precipitate, and the ...

Embodiment 2

[0054] use figure 1 The shown arsenic-alkali slag disposal system performs arsenic-alkali slag treatment.

[0055] Send the original arsenic-alkali slag to the feeding pretreatment unit 1 for ball milling and crushing, with a solid-to-liquid ratio of 1:1 to obtain first-grade arsenic-alkali slag.

[0056] The primary arsenic-alkali slag is sent to the leaching unit 2, and is leached in the first leaching tank 21 with an acidic aqueous solution with a temperature of 30°C, containing sulfite ions, and a pH less than or equal to 6 to obtain a primary leachate and a primary precipitate. The primary leachate is input into the spray unit 3, the primary sediment is sieved by a grading sieve 23, the oversize is returned to the feeding pretreatment unit 1 for secondary ball milling and then circulated, and the undersize is input into the second leaching tank 22. Use water at a temperature of 20°C for leaching to obtain a secondary leachate and a secondary precipitate, and the secondar...

Embodiment 3

[0063] use figure 1 The shown arsenic-alkali slag disposal system performs arsenic-alkali slag treatment.

[0064] Send the original arsenic-alkali slag to the feeding pretreatment unit 1 for ball milling and crushing, with a solid-to-liquid ratio of 1:1 to obtain first-grade arsenic-alkali slag.

[0065] The primary arsenic-alkali slag is sent to the leaching unit 2, and is leached in the first leaching tank 21 using an acidic aqueous solution with a temperature of 25°C, containing sulfite ions, and a pH less than or equal to 6 to obtain a primary leachate and a primary precipitate. The primary leachate is input into the spray unit 3, the primary sediment is sieved by a grading sieve 23, the oversize is returned to the feeding pretreatment unit 1 for secondary ball milling and then circulated, and the undersize is input into the second leaching tank 22. Use water at a temperature of 25°C for leaching to obtain a secondary leachate and a secondary precipitate, and the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com