Antirust agent of steel part and preparation method

A technology of anti-rust agent and steel parts, applied in the field of anti-rust agent, can solve the problems of unstable anti-rust agent, difficult to preserve, pungent smell, etc., achieve the effect of small irritating smell, prolong shelf life, and not easy to deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

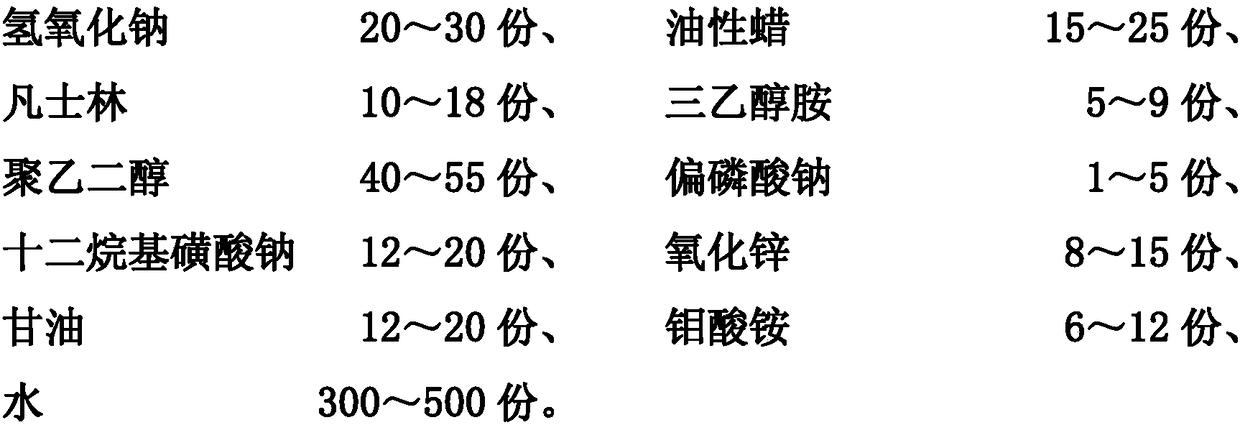

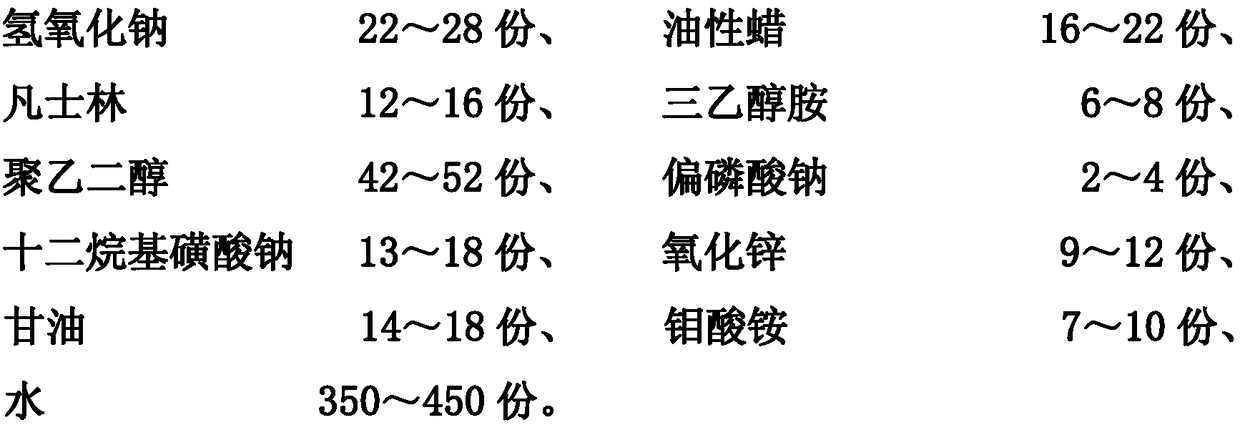

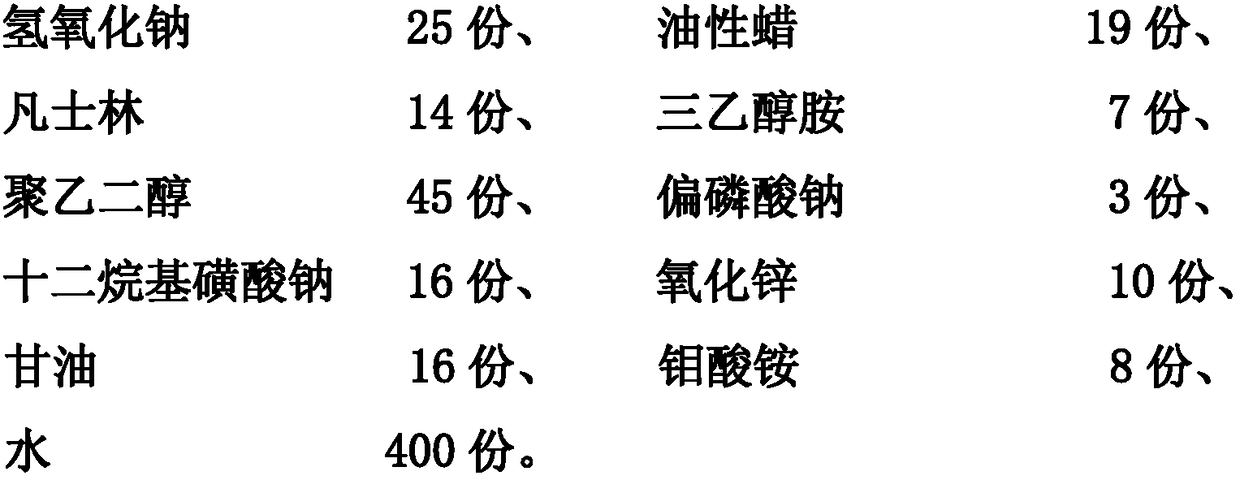

[0030] Example 1. A kind of antirust agent for steel parts, it is made from the following raw materials in proportion by weight,

[0031] Sodium hydroxide 25kg, oily wax 19kg,

[0032] Vaseline 14kg, triethanolamine 7kg,

[0033] Polyethylene glycol 45kg, sodium metaphosphate 3kg,

[0034] Sodium dodecyl sulfonate 16kg, Zinc oxide 10kg,

[0035] Glycerin 16kg, ammonium molybdate 8kg,

[0036] 400kg of water.

[0037] The preparation method of aforementioned antirust agent for steel parts is obtained in the following steps:

[0038] a. Mix the above raw materials to obtain product A;

[0039] b. Kneading and melting product A to obtain product B;

[0040] c. Knead and plasticize product B at a temperature of 180-185°C to obtain it.

Embodiment 2

[0041] Embodiment 2. A kind of antirust agent for steel parts, it is made with following raw material of proportioning by weight,

[0042] Sodium hydroxide 20kg, oily wax 15kg,

[0043] Vaseline 10kg, triethanolamine 5kg,

[0044] Polyethylene glycol 40kg, sodium metaphosphate 1kg,

[0045] Sodium dodecyl sulfonate 12kg, zinc oxide 8kg,

[0046] Glycerin 12kg, ammonium molybdate 6kg,

[0047] 300kg of water.

[0048] The preparation method of aforementioned antirust agent for steel parts is obtained in the following steps:

[0049] a. Mix the above raw materials to obtain product A;

[0050] b. Kneading and melting product A to obtain product B;

[0051] c. Knead and plasticize product B at a temperature of 180-185°C to obtain it.

Embodiment 3

[0052] Embodiment 3. A kind of antirust agent for steel parts, it is made with following weight kg proportioning raw material,

[0053] Sodium hydroxide 30kg, oily wax 25kg,

[0054] Vaseline 18kg, triethanolamine 9kg,

[0055] Polyethylene glycol 55kg, sodium metaphosphate 5kg,

[0056] Sodium dodecyl sulfonate 20kg, zinc oxide 15kg,

[0057] Glycerin 20kg, ammonium molybdate 12kg,

[0058] 500kg of water.

[0059] The preparation method of aforementioned antirust agent for steel parts is obtained in the following steps:

[0060] a. Mix the above raw materials to obtain product A;

[0061] b. Kneading and melting product A to obtain product B;

[0062] c. Knead and plasticize product B at a temperature of 180-185°C to obtain it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com