Antibacterial massage health care insole fabric formed by three-dimensional three-dimensional weaving and its weaving method

A three-dimensional, fabric technology, applied in the field of textile and weaving, can solve problems such as poor foot feel elasticity, bacterial growth, poor comfort, etc., and achieve the effects of improving air permeability and softness, low production cost, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

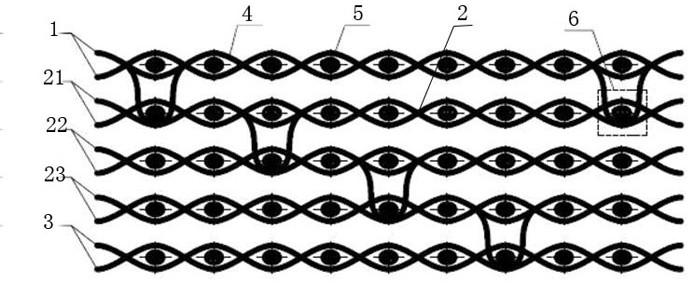

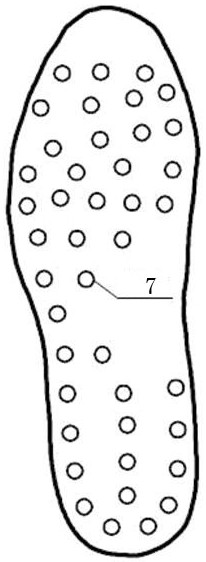

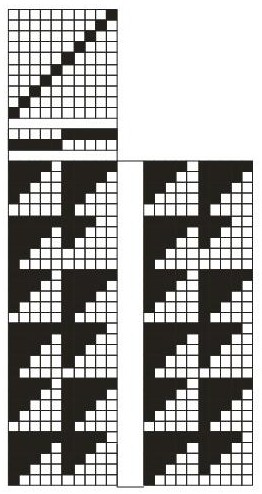

[0033]Such asFigure 1 to 3As shown, a three-dimensional stereo-shaped antibacterial massage health insole fabric is a plurality of layers of insole multilayer fabric using the "Upload" advice. Like the latitude and latitude density of each layer, all layered yarn raw materials are a hemp fiber yarn, each layer of fabric density. The insole fabric is woven on a common loom, and the gaunge is supplied or more through the shaft when weaving.

[0034]When weaving, the third layer of weft is used as a hemp nating yarn;

[0035]When weaving, each layer is tissue.

[0036]Three-dimensional stereo-shaped antibacterial massage method of healthcare insole fabric, including the following steps:

[0037]1 Insole thickness design: determine the thickness of the sole fabric, in this example: the sole thickness is 4mm;

[0038]2 Determination of the number of fabric layers:

[0039]Layer of fabric = insole thickness (mm) / 2 × yarn diameter (mm) * 0.75 = 4 / 2 * 0.518 * 0.75 = 5.15;

[0040]Therefore, the city's impleme...

Embodiment 2

[0052]A three-dimensional stereo-shaped antibacterial massage health insole fabric, including a multilayer fabric, said multi-layer fabric weaving, "upward" advice or "downward connection" advice; said multilayer The fabric includes an upper fabric 1, a plurality of intermediate fabric 2, and a lower layer fabric 3, the upper fabric 1, the intermediate layer fabric 2, and the lower layer fabric 3 are integral structures of a woven forming; the upper layer fabric 1, an intermediate layer fabric 2 and lower fabric 3 each include warp yarns 4 and weft yarns 5. The multilayer fabric is fabricated in a woven manner. The number of layers of the multilayer fabric of the present invention is determined according to the thickness of the insole and the thickness of the yarn.

[0053]The "upper receiving" advice is: when the first layer intermediate layer fabric 21 is woven, the warp yarn of the upper layer fabric 1 and the weft of the first layer intermediate layer fabric 21 forms the attachment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com