Preparation method of coconut shell extract/modified konjac glucomannan compound dye-fixing agent

A technology of konjac glucomannan and coconut shell, applied in the field of dyeing, can solve the problems of releasing formaldehyde and affecting human health, etc., and achieve the effects of preventing color fading, improving UV protection, and improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

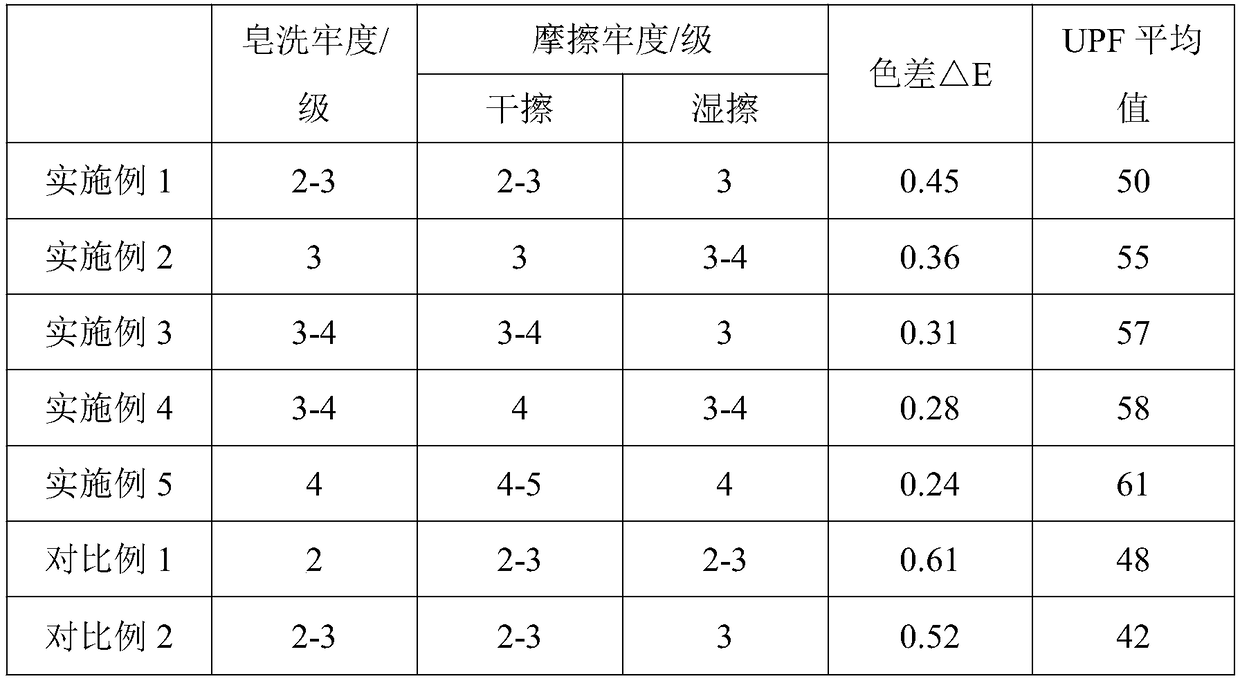

Examples

Embodiment 1

[0021] (1) Wash the coconut shell and dry it, crush it mechanically to powder, weigh 50g of powder, soak it overnight with 250mL 65wt% ethanol solution, and then perform ultrasonic extraction. The ultrasonic extraction power is 300w, the extraction time is 15min, and the extraction temperature is 60°C , to obtain the ethanol extract for subsequent use;

[0022] (2) Extract the ethanol extract with n-butanol solution. During each extraction, the volume ratio of the ethanol extract to n-butanol is 1:4, shake and stand for three times, and the extracts are combined to obtain n-butanol. The butanol extract is ready for use;

[0023] (3) Add the n-butanol extract to the rotary evaporator, adjust the vacuum indication value of the rotary evaporator to -0.08MPa, and the temperature is 70°C, add 0.2 times the volume of the n-butanol extract to deionized water, and observe When the solvent evaporates, stop the experiment to obtain the concentrated solution, and dry it at 60°C to obtai...

Embodiment 2

[0027] (1) Wash the coconut shell and dry it, crush it mechanically to powder, weigh 50g of powder, soak it overnight with 150mL 65wt% ethanol solution, and then perform ultrasonic extraction. The ultrasonic extraction power is 400w, the extraction time is 5min, and the extraction temperature is 80°C , to obtain the ethanol extract for subsequent use;

[0028] (2) Extract the ethanol extract with n-butanol solution. During each extraction, the volume ratio of the ethanol extract and n-butanol is 1:2. After shaking, stand still and extract three times altogether. The extracts are combined to obtain n-butanol. The butanol extract is ready for use;

[0029] (3) Add the n-butanol extract to the rotary evaporator, adjust the vacuum indicator value of the rotary evaporator to -0.08MPa, and the temperature is 70°C, add deionized water of 1 volume of the n-butanol extract, and observe When the solvent evaporates, stop the experiment to obtain the concentrated solution, and dry it at ...

Embodiment 3

[0033] (1) Clean the coconut shell and dry it, crush it mechanically to powder, weigh 50g of powder, soak it overnight with 210mL 65wt% ethanol solution, and then perform ultrasonic extraction. The ultrasonic extraction power is 330w, the extraction time is 13min, and the extraction temperature is 65°C , to obtain the ethanol extract for subsequent use;

[0034] (2) Extract the ethanol extract with n-butanol solution. During each extraction, the volume ratio of the ethanol extract and n-butanol is 1:3.5, shake and leave standstill, and extract three times altogether, and the extracts are combined to obtain n-butanol. The butanol extract is ready for use;

[0035] (3) Add the n-butanol extract to the rotary evaporator, adjust the vacuum indication value of the rotary evaporator to -0.08MPa, and the temperature is 70°C, add 0.4 times the volume of the n-butanol extract to deionized water, and observe When the solvent evaporates, stop the experiment to obtain the concentrated so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com