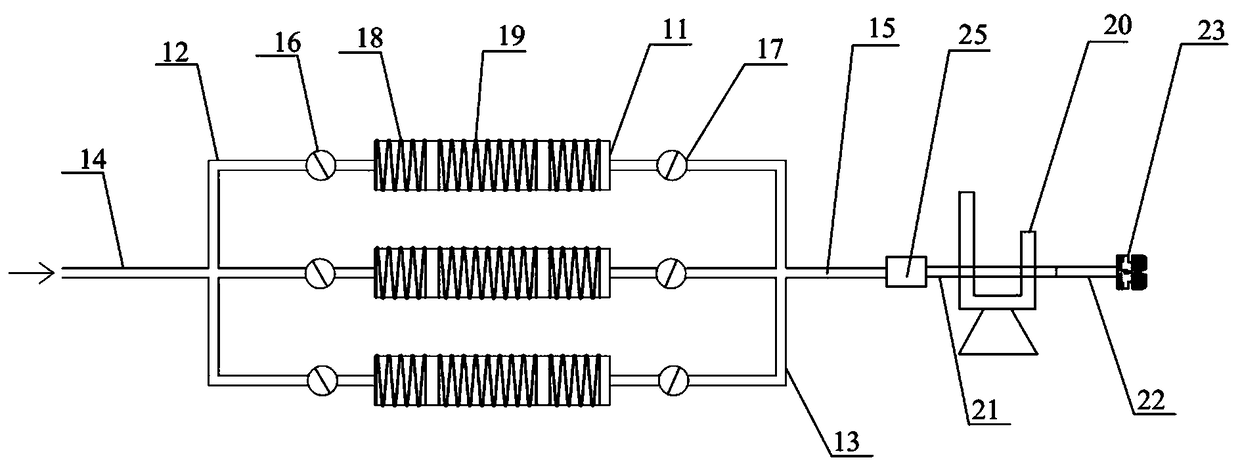

Post-mixing abrasive gas jet coal breaking device and coal breaking method thereof

A gas jet and post-mixing technology, applied in liquid/gas jet drilling, earthwork drilling, drilling equipment, etc., can solve the problems of drill pipe system wear, hidden safety hazards of underground workers, and obstruction of coal slag discharge, etc., to improve jet flow Impact force, improve coal breaking effect, and ensure the effect of action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

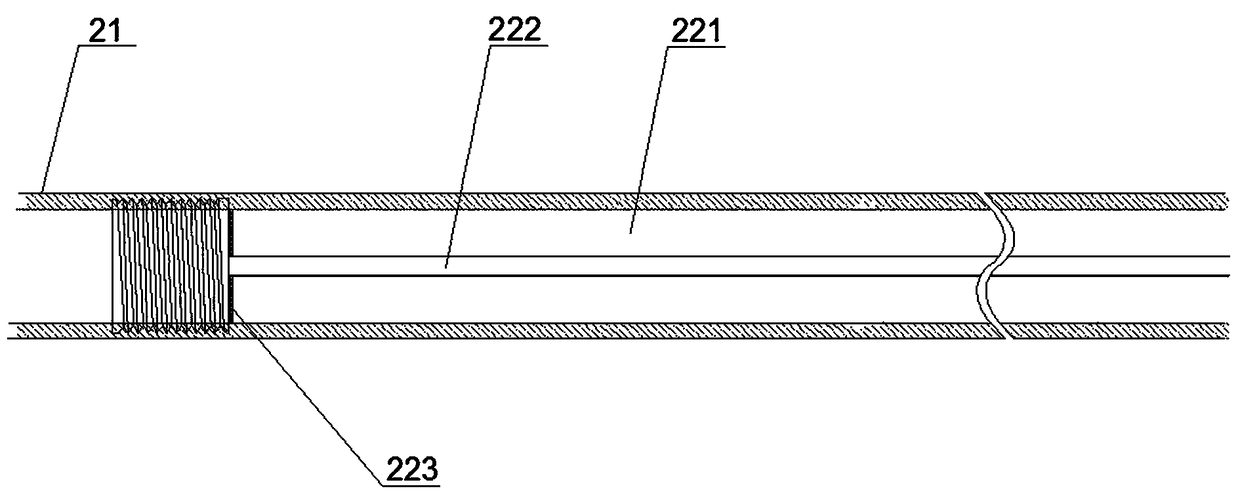

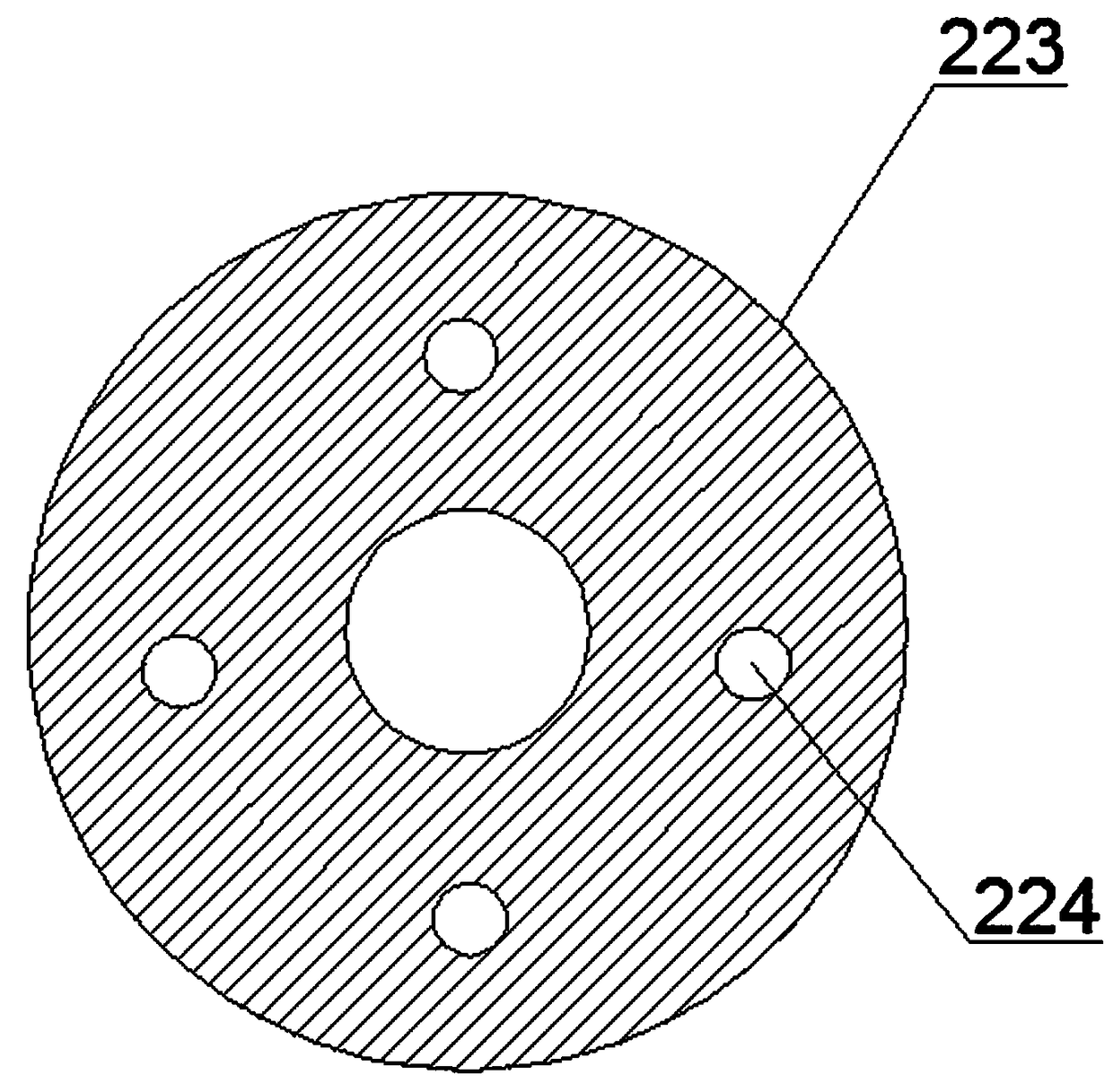

[0063] Embodiment 1: The opening pressure P of the first back pressure valve 235 is set z is 5Mpa, the opening pressure of the second back pressure valve 236 is set to P j 10Mpa, adjust the setting pressure of all the second pressure reducing valves 17 to 5Mpa. At this time, according to the opening characteristics of the back pressure valve, the first back pressure valve 235 is opened, the second back pressure valve 236 is closed, and the axial nozzle 233 Start the auxiliary drilling work. At this time, the drill bit of the drilling rig 20 is in a rotating state. With the advancement of the drill rod 21, the high-pressure abrasive gas jet ejected from the axial nozzle 233 can increase the drilling diameter to achieve the purpose of auxiliary drilling.

Embodiment 2

[0064] Embodiment 2: The opening pressure P of the first back pressure valve 235 is set z is 15Mpa, the opening pressure of the second back pressure valve 236 is set to P j to 8Mpa, adjust the setting pressure of all the second pressure reducing valves 17 to 8Mpa. At this time, the first backpressure valve 235 is closed, the second backpressure valve 236 is opened, and the radial spray nozzle 234 starts to slit. At this time, the drilling rig The drill bit of 20 is in static state, and along with the advancement of drill rod 21, the high-pressure abrasive gas jet flow that radial nozzle 234 sprays cuts out a slit in coal, reaches the purpose of slit.

Embodiment 3

[0065] Embodiment 3: The opening pressure P of the first back pressure valve 235 and the second back pressure valve 236 is set z ,P j are all 8Mpa, adjust the setting pressure of all the second pressure reducing valves 17 to 8Mpa, at this time, the first back pressure valve 235 and the second back pressure valve 236 are all opened, and the axial nozzle 233 and the radial nozzle 234 start simultaneously Work. First start the auxiliary drilling stage, the drill bit of the drilling rig 20 is in a rotating state, and the high-pressure abrasive gas jet ejected from the three-way nozzle is used to increase the diameter of the drilling hole during the advancement of the drill rod 21 to achieve the effect of auxiliary drilling. Then start the slotting stage. At this time, set the drilling machine 20 to a static state and push the rod. In the process of pulling back the rod, use the high-pressure abrasive gas jet ejected from the radial nozzle 234 to slot the coal to achieve the purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com