Oxygen-nitrogen removal neon-helium separation and purification method

A technology for oxygen and nitrogen separation and helium gas, which is applied in cold treatment separation, liquefaction, solidification and other directions, can solve the problems of high operating pressure, complex equipment, low gas purity, etc., and achieves improved utilization, low system operating pressure and simplified process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

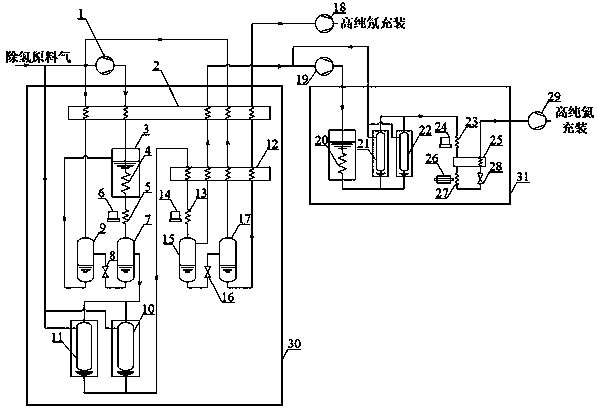

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] like figure 1 Shown, the implementation steps of the present invention are as follows:

[0028] Step 1, the raw material gas after the dehydrogenation and drying treatment is pressurized to 30 bar by the raw gas compressor 1, enters the neon refined refrigeration box 30, and enters the secondary heat exchanger 4 after being pre-cooled by the primary heat exchanger 2, The secondary heat exchanger 4 is placed in the primary liquid nitrogen Dewar 3, and the raw material gas state at the outlet of the primary liquid nitrogen Dewar 3 is a gas-liquid mixture with a temperature of about 80K. At this point, part of the nitrogen in the feed gas has been liquefied.

[0029] The 80K gas-liquid mixture enters the third-stage heat exchanger 5, and the nitrogen in the raw material gas is further liquefied. The cooling capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com