Portable rock-soil mechanics real-time loading test device matched with industrial CT (Computed Tomography) machine

A loading test device and technology of rock and soil mechanics, applied in the direction of measuring device, using stable tension/pressure to test material strength, scientific instruments, etc., can solve the problems of small ray energy, weak X-ray penetration, and crack evolution and development law Difficulties and other problems, to achieve the effect of small loss of ray energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

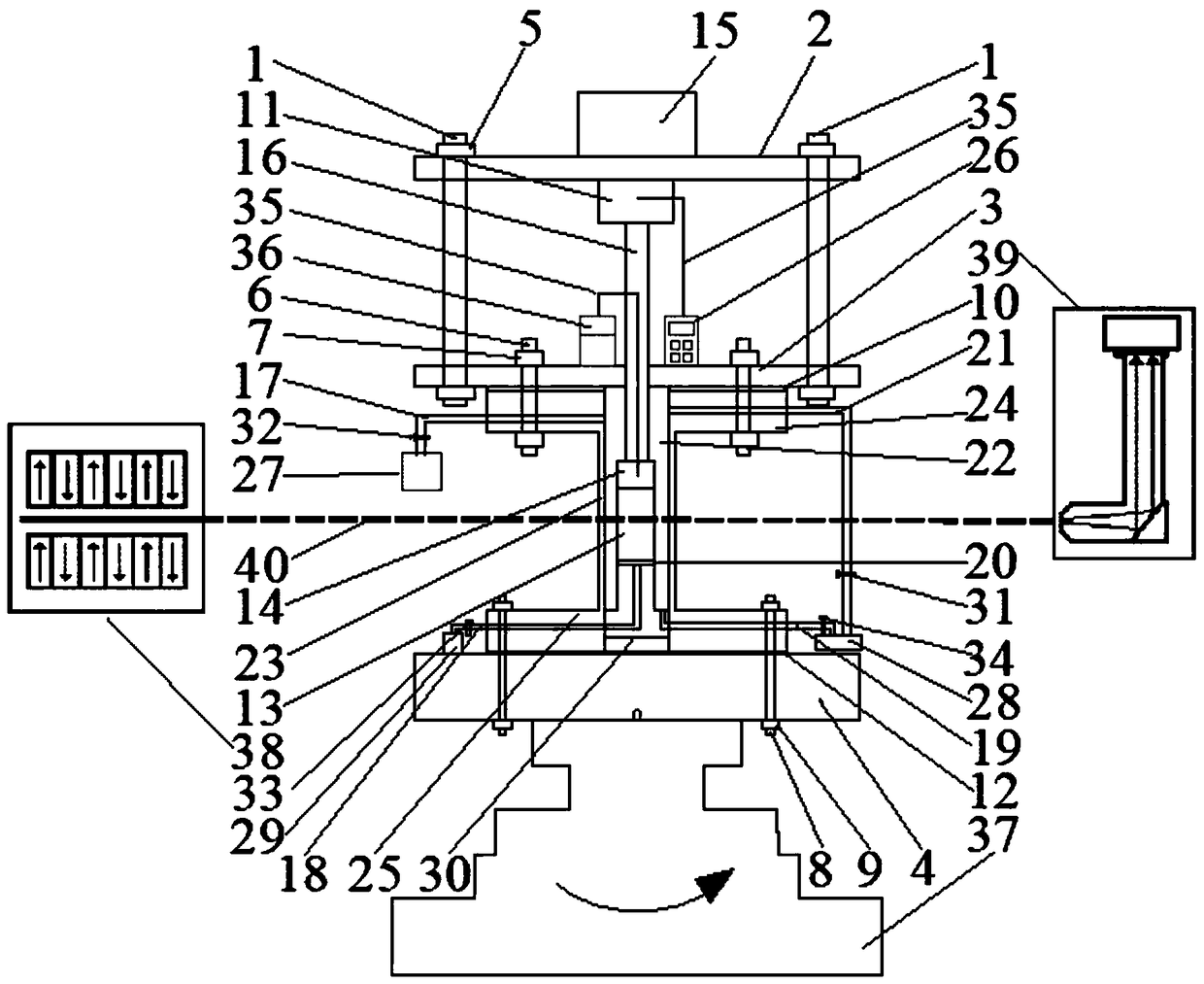

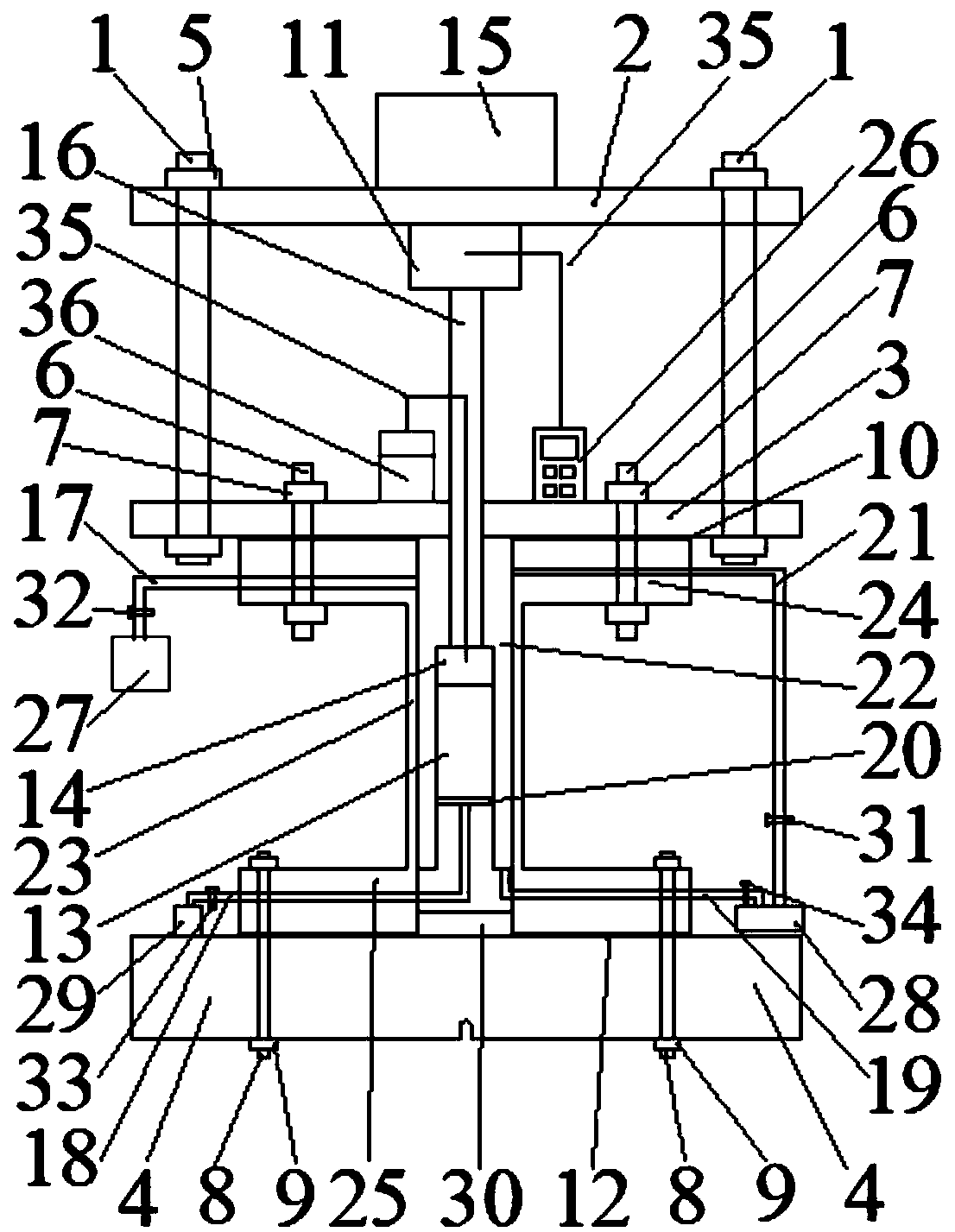

[0020] The invention provides a portable rock and soil mechanics real-time loading test device matched with an industrial CT machine.

[0021] like figure 2 As shown, the device includes an axial pressure system, a confining pressure system and a physical quantity measurement system,

[0022] The axial pressure system includes a rigid column 1, an upper beam 2, a lower beam 3, a column nut 5, a piston 15, a rigid dowel 16 and a data wire 35, and the rigid column 1, the upper beam 2 and the lower beam 3 are fixed by the column nut 5 , the piston 15 is connected to the rigid dowel 16 via the pressure sensor 11, and the rigid dowel 16 acts on the displacement sensor 14 to pressurize the sample 13;

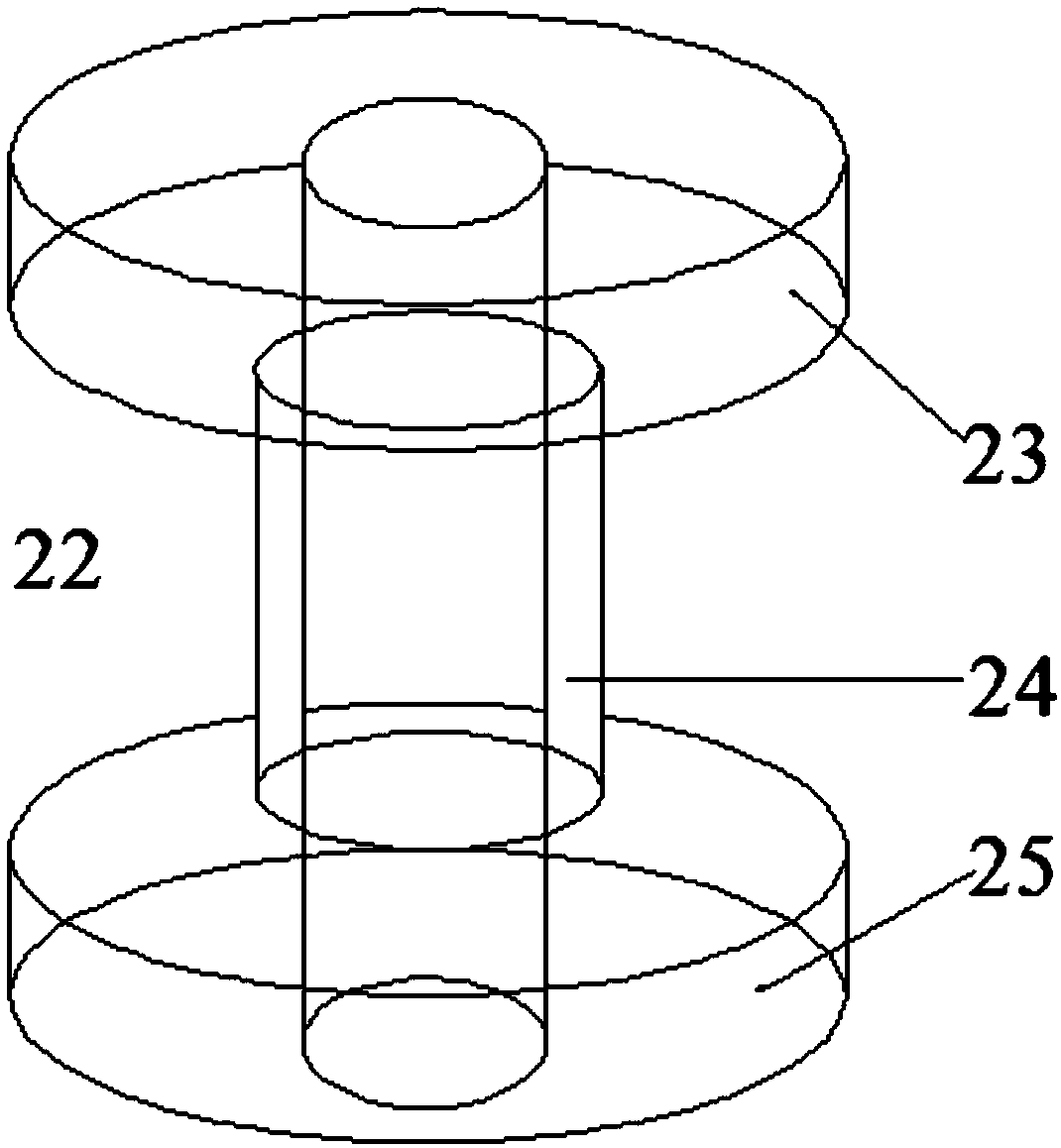

[0023] The confining pressure system includes a pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com