Device and method for sensitively detecting film penetration pressure value in film distillation process

A technology of sensitive detection and membrane distillation, applied in measurement devices, instruments, surface/boundary effects, etc., can solve the problems of inaccurate and sensitive description, hysteresis of wetting phenomenon, failure of membrane components, etc., and achieve easy observation, recording and detection methods Simple, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

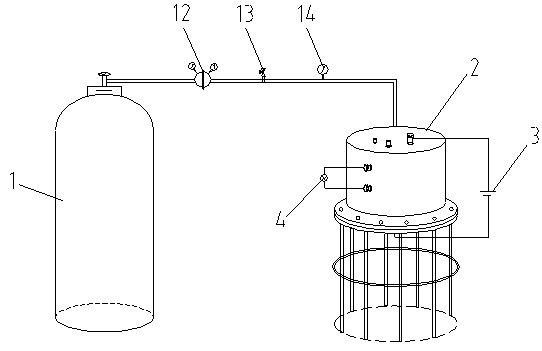

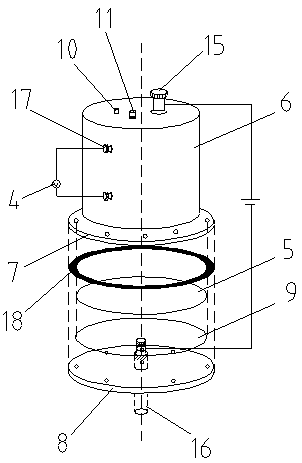

[0039] Example: see figure 1 , figure 2 , a device for sensitively detecting membrane percolation pressure value during membrane distillation process, comprising a gas storage tank 1, a membrane percolation test assembly 2, a DC power supply 3, a high-sensitivity electric bridge 4 and a diaphragm 5 to be tested. The membrane penetration test assembly 2 includes a metal accommodation cylinder with a closed upper end and an open lower end, and a bottom plate 8 that closes the lower end of the accommodation cylinder. A flange 6 is sheathed on the lower end of the outer side of the container, the flange 6 is made of metal, and is fixedly connected with the container; both the flange 6 and the container are made of metal, so they have good electrical conductivity performance, which is beneficial to the detection of electrical parameters in the detection process. During actual processing, the flange 6 is integrally formed with the containing cylinder, and the lower side of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com