Transient heat transfer microscope and method thereof for micro-area thermal measurement

A technology of microscope and dark field microscope, which is applied in the direction of scattering characteristic measurement, color/spectral characteristic measurement, etc., and can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

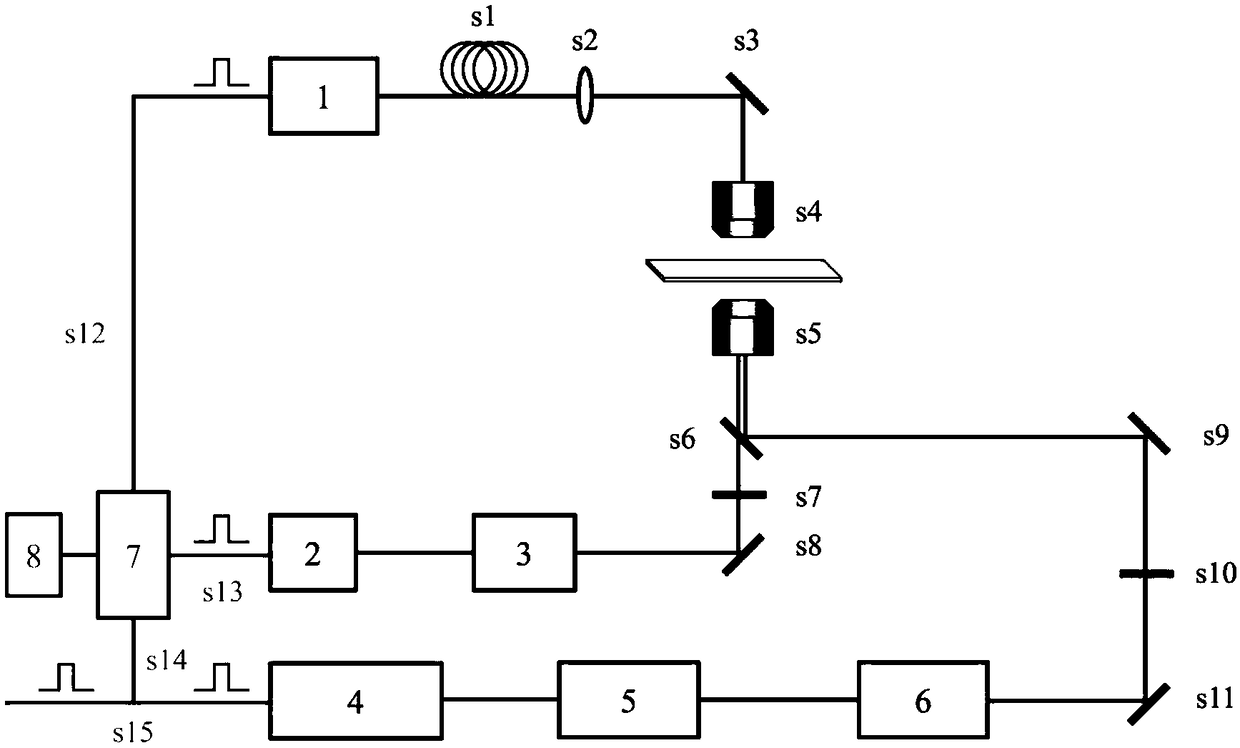

Method used

Image

Examples

Embodiment 1

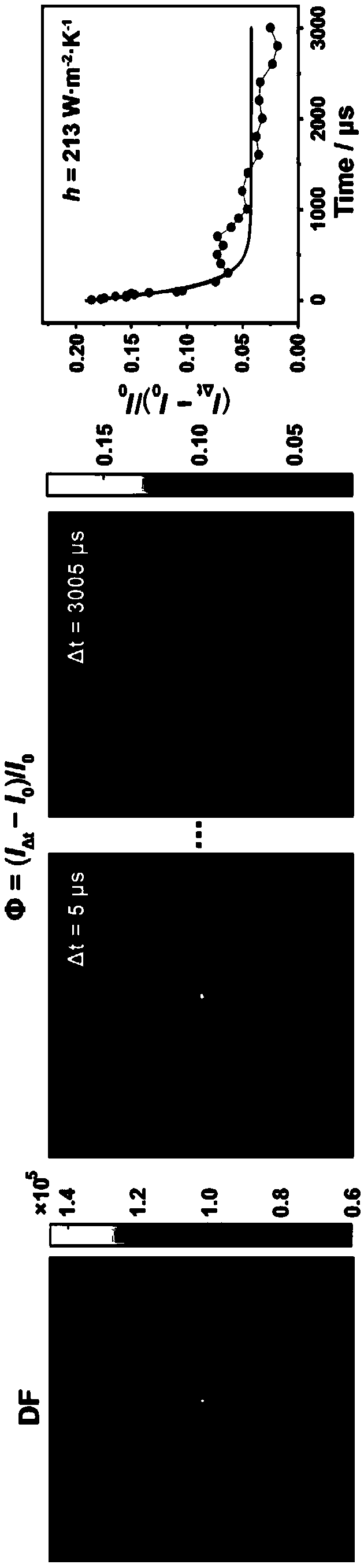

[0029] Determination of heat transfer in liquid media:

[0030] (1) Sample preparation:

[0031] Spread the nano-gold particle solution with a particle size distribution of 20-80nm on a clean glass plate for adsorption for 20 minutes, then wash off the nano-gold particle solution with ultrapure water and wash it with N 2 blow dry. Then, the heat transfer medium (glycerin) to be measured is dropped on the glass slide so that it wraps around the gold nanoparticles.

[0032] (2) Determination of medium heat transfer performance:

[0033]Fix the glass slide treated in step (1) on the stage of the transient heat transfer microscope. The nanosecond pulse laser 4, the optical parametric oscillator 5 and the frequency doubler 6 of the nanosecond pulse laser system are adjusted to a wavelength of 532nm to heat the liquid medium to be tested and the gold nanoparticles. Turn on the nanosecond pulse laser 4 at time t=0 to heat the liquid medium to be tested and the gold nanoparticles ...

Embodiment 2

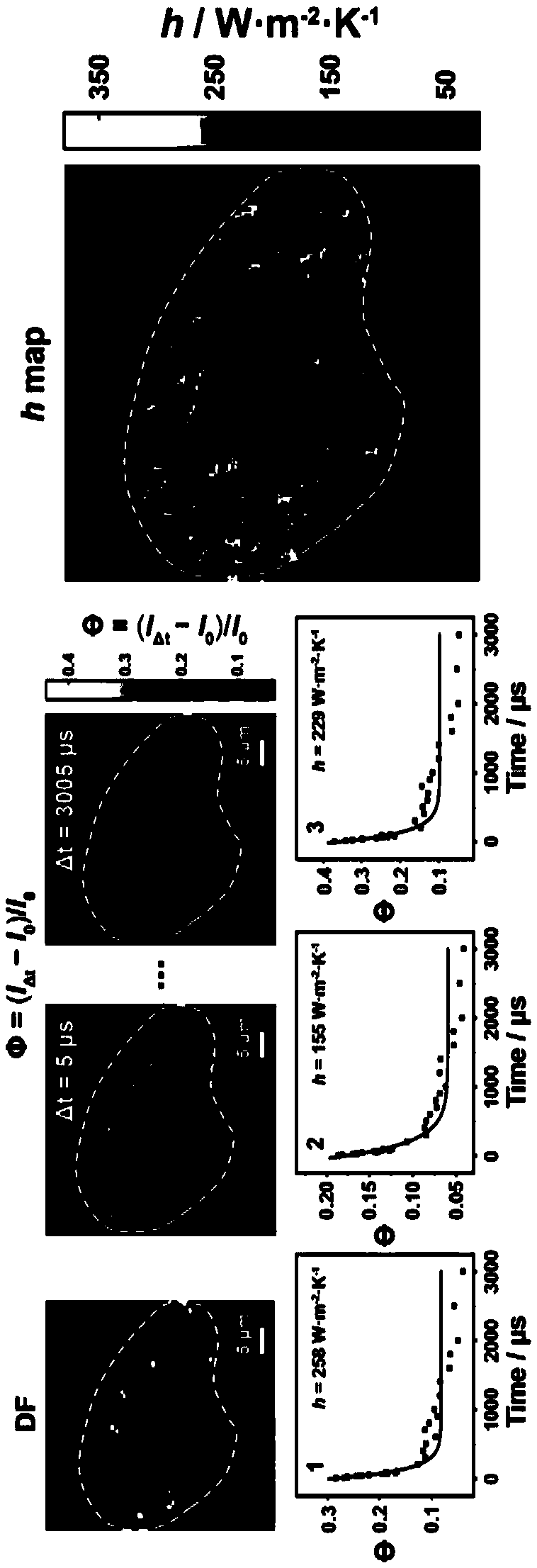

[0036] Measuring the heat transfer performance of the intracellular medium:

[0037] (1) Sample preparation:

[0038] The cells to be tested were grown adherently on a circular glass slide, and the polyethylene glycol (PEG) stabilized gold nanoparticles were mixed with the cells, then washed with sterile phosphate buffered saline (PBS), and finally placed on a circular glass slide. PBS solution was added dropwise on the slice to prevent the cells from drying out.

[0039] (2) Determination of heat transfer performance of intracellular medium:

[0040] Fix the circular glass slide treated in step (1) on the stage of the transient heat transfer microscope. The nanosecond pulse laser 4, the optical parametric oscillator 5 and the frequency multiplier 6 of the nanosecond pulse laser system are adjusted to a wavelength of 532nm to irradiate the cells to heat the cells and the gold nanoparticles in the cells. At time t=0, the nanosecond pulse laser 4 is turned on to heat the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com