Efficient nano composite catalyst capable of converting CO2 to cyclic carbonate and preparation method thereof

A cyclic carbonate and nanocomposite technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor stability, high catalyst preparation cost, and difficulty in recycling. and other problems, to achieve the effects of stable structure, wide range of substrates, and resistance to salt and alkali specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

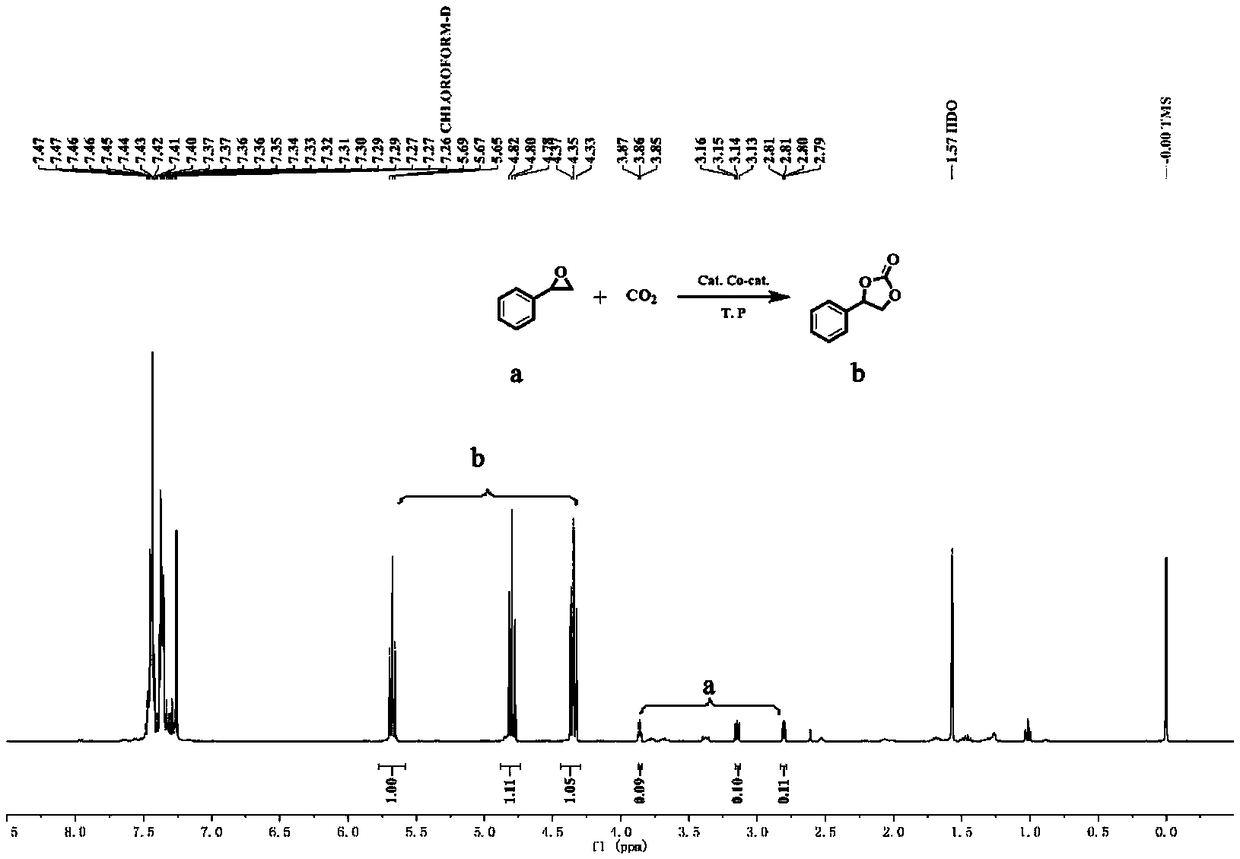

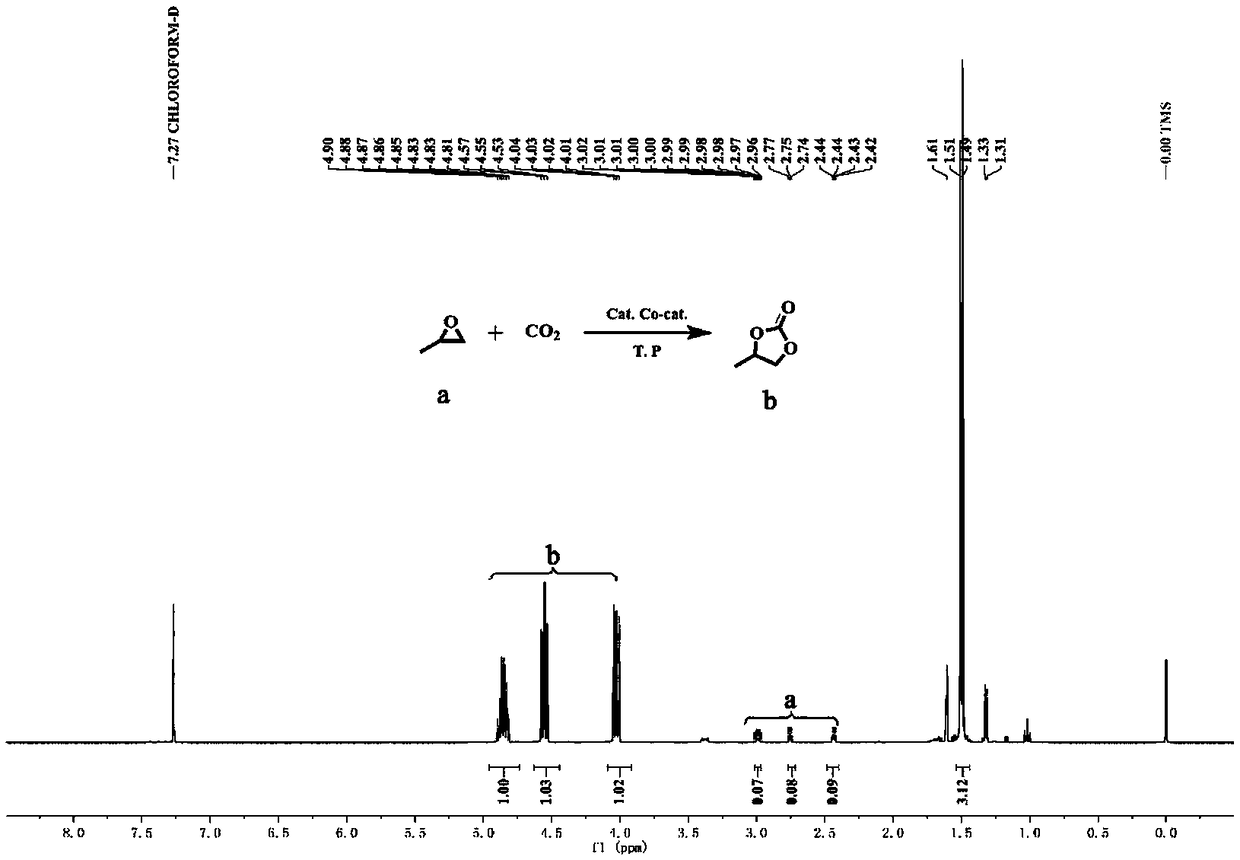

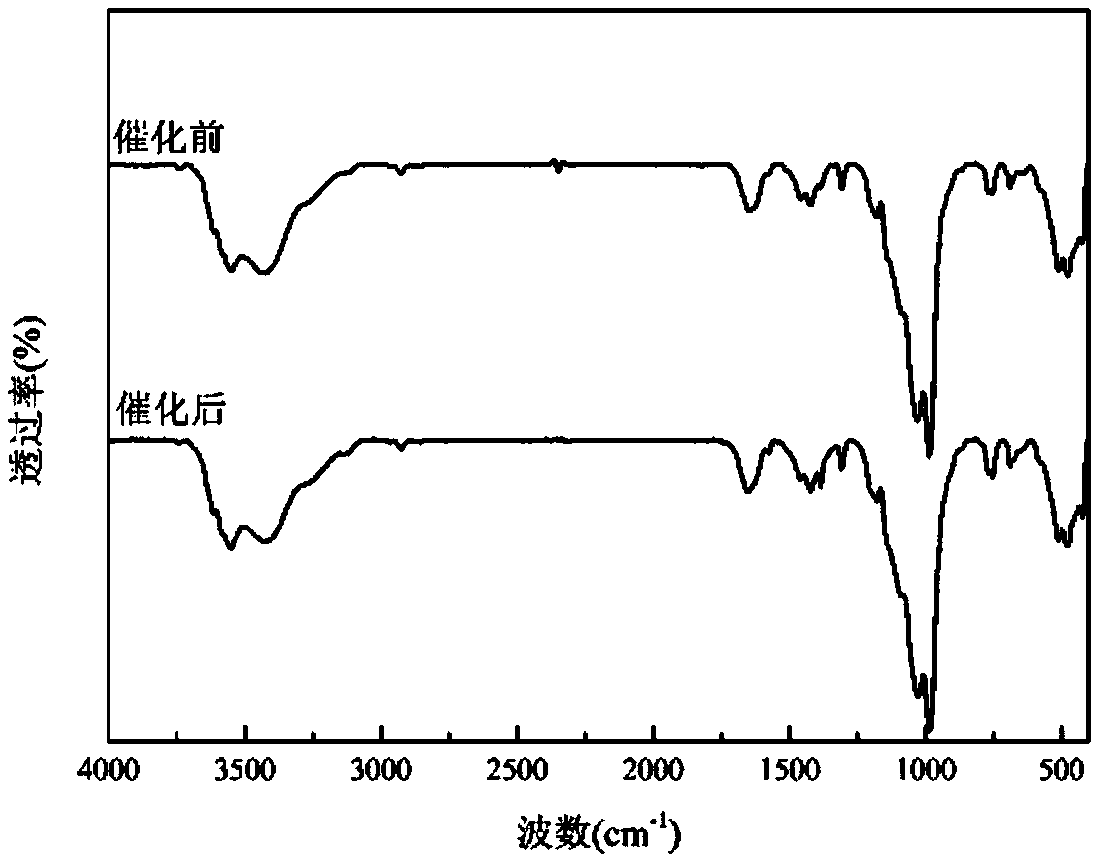

Examples

preparation example Construction

[0034] The present invention provides a method using CO 2 The preparation method of the efficient nanocomposite catalyst that is converted into cyclocarbonate comprises the following steps:

[0035] (1) crushing and screening natural attapulgite ore to remove impurities to obtain attapulgite powder;

[0036] (2) Dispersing the attapulgite powder into the first solvent, adding a modifier, stirring and reacting, followed by centrifugation, washing, and drying to obtain a solid powder;

[0037] (3) Dispersing the solid powder into a second solvent, adding an organic ligand and a metal salt, stirring to dissolve it completely, and then standing still to obtain a pre-product;

[0038] (4) placing the pre-product in a room temperature or high-temperature oven to allow it to fully react, and then centrifuging, washing, and drying the product to obtain the high-efficiency nanocomposite catalyst;

[0039] The metal salts are rare earth salts and / or transition metal salts.

[0040] T...

Embodiment 1

[0060] A use of CO 2 The preparation method of the efficient nanocomposite catalyst that is converted into cyclocarbonate comprises the following steps:

[0061] S1: Add 60g of attapulgite powder to a 1000ml two-necked bottle equipped with a mechanical stirring device, add 600ml of deionized water as a solvent, and then add 1.6g of NaPF 6 As a modifier; control the temperature at 25-55 ° C, mechanically stir and ultrasonically disperse for 4 hours, after the reaction is completed, cool down to room temperature, centrifuge the product, wash, and dry to obtain a solid powder;

[0062] S2: Take 1.2g of the above solid powder and put it into a single-necked bottle, add 100ml DMF, disperse it ultrasonically, and then add 0.002mol Tb(NO 3 ) 3 After mixing with 0.005mol trimesic acid, magnetic stirring is used to completely dissolve the mixture, and the mixture is placed in an oven at 65° C. for 24 hours at a constant temperature. After the reaction is completed, the product is cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com