High-temperature-resistant and high-pressure-resistant high-alloy submerged arc welded steel pipe welding process

A welding process and high temperature resistant technology, which is applied in the submerged arc welding process of 2.25Cr-1Mo pearlitic heat-resistant alloy steel and the welding process of high alloy submerged arc welded steel pipes, can solve the problems of difficulty in welding and improve the welding seam. Quality, simple process, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0020] 2.25Cr-1Mo steel longitudinal submerged arc welded steel pipe production process, step 1: 2.25Cr-1Mo large-diameter longitudinal submerged arc welded steel pipe with a specification of φ1219×30×12000mm passes ultrasonic non-destructive testing, machining groove, JCOE forming, processing into "O" shape,

[0021] Step 2: The steel pipe adopts the double-sided X-shaped groove type with the inner groove larger than the outer groove; the blunt edge is 4-5mm; the double-sided X-shaped groove is easy to machine edge milling, which improves production efficiency;

[0022] Step 3: Preheat the steel pipe to 200°C before welding;

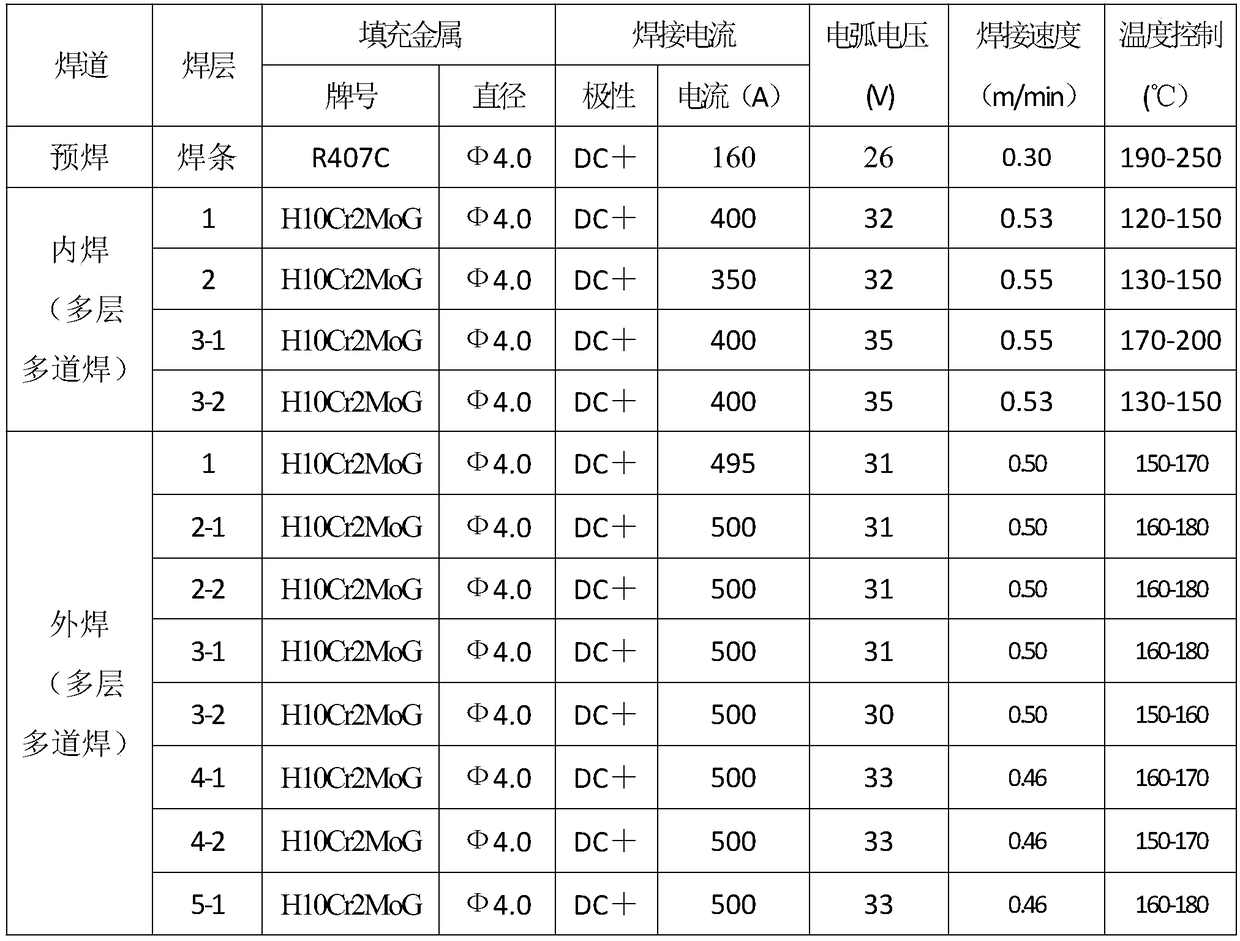

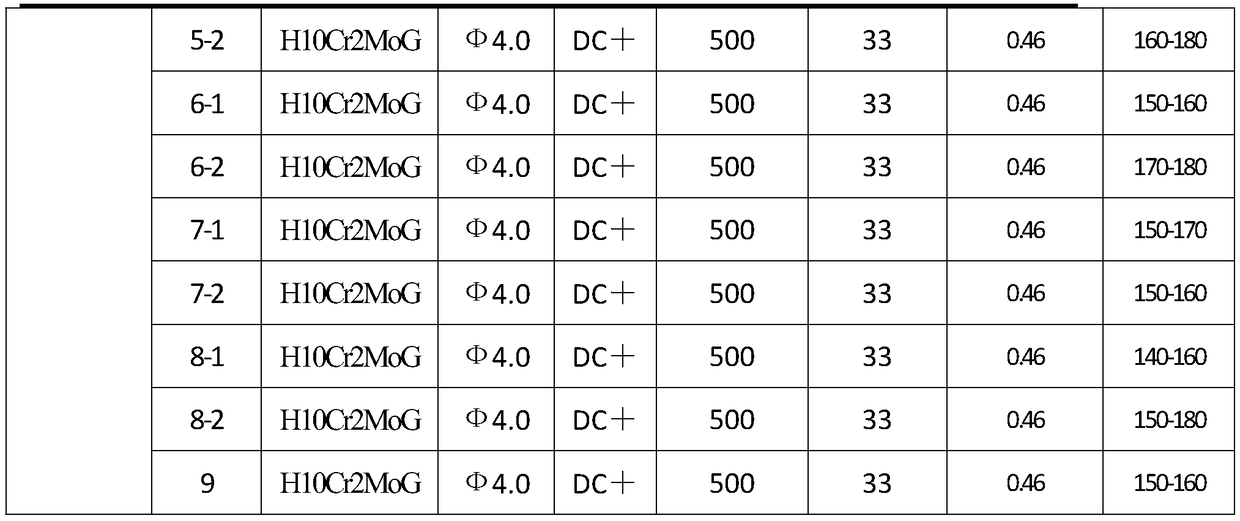

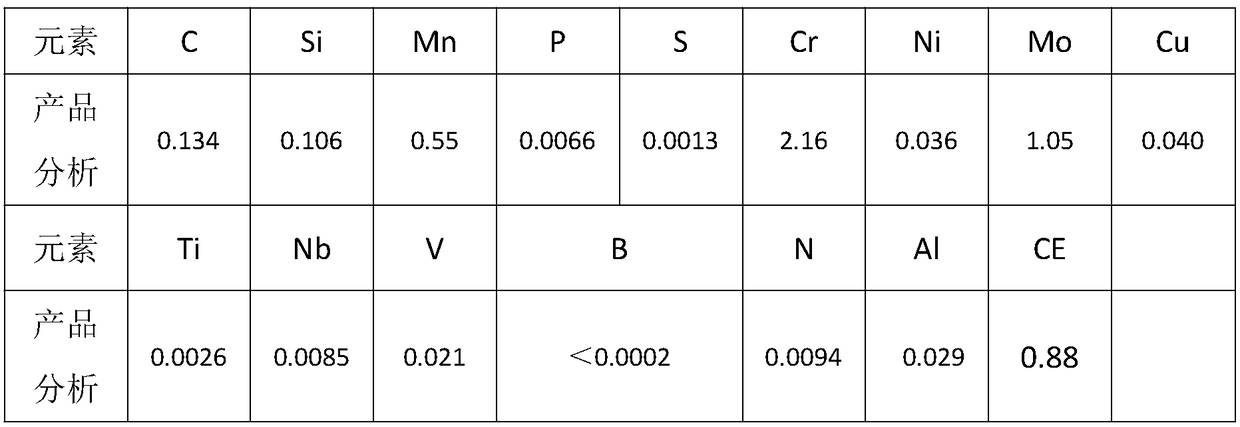

[0023] Step 4: Welding with straight seam submerged arc welding technolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com