Preparation method of spherical silicon dioxide nano-particles

A spherical silica and nanoparticle technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of high cost, inability to prepare silica with uniform sphericity and particle size, and increasing the difficulty of product separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

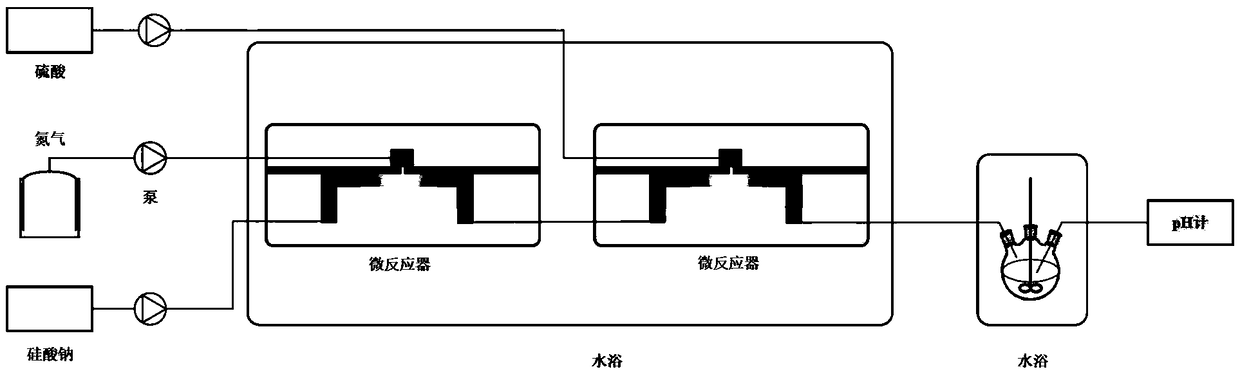

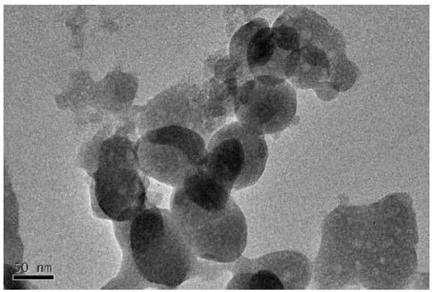

[0028] The invention provides a method for preparing spherical silica nanoparticles, comprising the following steps:

[0029] Disperse nitrogen vertically into the flowing sodium silicate solution through the microporous membrane to obtain the precursor solution;

[0030] The sulfuric acid solution is vertically dispersed in the flowing precursor solution through a microporous membrane, a precipitation reaction occurs, and aging is performed to obtain spherical silica nanoparticles;

[0031] The initial flow rate of the sulfuric acid solution through the microporous membrane is 5-30mL / min, and every 1-2min, the flow rate of the sulfuric acid solution through the microporous membrane increases once, each time the increase range is 0.1-10mL / min, The final flow rate is 12-40mL / min.

[0032] In the present invention, unless otherwise specified, all raw material components are commercially available components well known to those skilled in the art.

[0033] The invention vertica...

Embodiment 1

[0054] Place the membrane dispersion microreactor in a 70°C water bath;

[0055] Disperse nitrogen vertically through the microporous membrane in the membrane dispersion microreactor at a flow rate of 1000mL / min into a sodium silicate solution with a concentration of 1mol / L and a flow rate of 18mL / min to obtain a precursor solution;

[0056] The sulfuric acid solution of 1.2mol / L is vertically dispersed into the flowing precursor solution through the microporous membrane, and a precipitation reaction occurs. The flow rate of the solution increases by 1mL / min until the flow rate of the sulfuric acid solution reaches 15mL / min, and then no longer increases the flow rate of the sulfuric acid solution.

[0057] The product system obtained from the above precipitation reaction was aged in a stirred tank in a water bath at 70°C for 3 hours, centrifuged at a speed of 2000r / min for 10 minutes, and washed with water to obtain crude silica;

[0058] The crude silica was mixed with water...

Embodiment 2

[0062] Place the membrane dispersion microreactor in a water bath at 80°C;

[0063] Disperse nitrogen vertically through the microporous membrane in the membrane dispersion microreactor at a flow rate of 1000mL / min into a sodium silicate solution with a concentration of 1mol / L and a flow rate of 20mL / min to obtain a precursor solution;

[0064] The sulfuric acid solution of 1.2mol / L is vertically dispersed into the flowing precursor solution through the microporous membrane, and a precipitation reaction occurs. The flow rate of the solution increases by 1mL / min until the flow rate of the sulfuric acid solution reaches 15mL / min, and then no longer increases the flow rate of the sulfuric acid solution.

[0065] The product system obtained from the above precipitation reaction was aged in a stirred tank in a water bath at 80°C for 3 hours, centrifuged at a speed of 2000r / min for 10 minutes, and washed with water to obtain crude silica;

[0066] The crude silica was mixed with wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

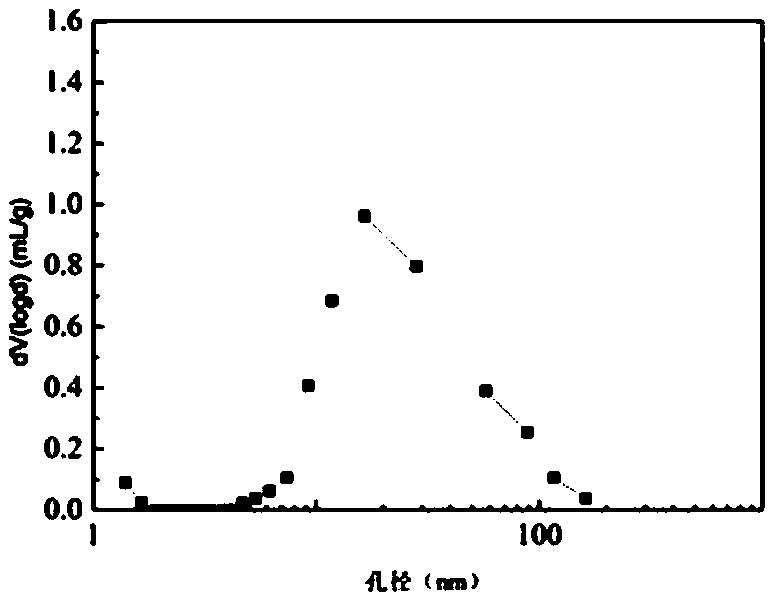

| Pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com