Synthetic process and equipment for calcium zincate as zinc-nickel battery negative electrode material

A negative electrode material, zinc-nickel battery technology, applied in battery electrodes, nickel accumulators, zinc compounds, etc., can solve the problems of large environmental pollution, large amount of alkaline waste liquid, waste of resources, etc., achieve high reaction rate, meet aging time , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

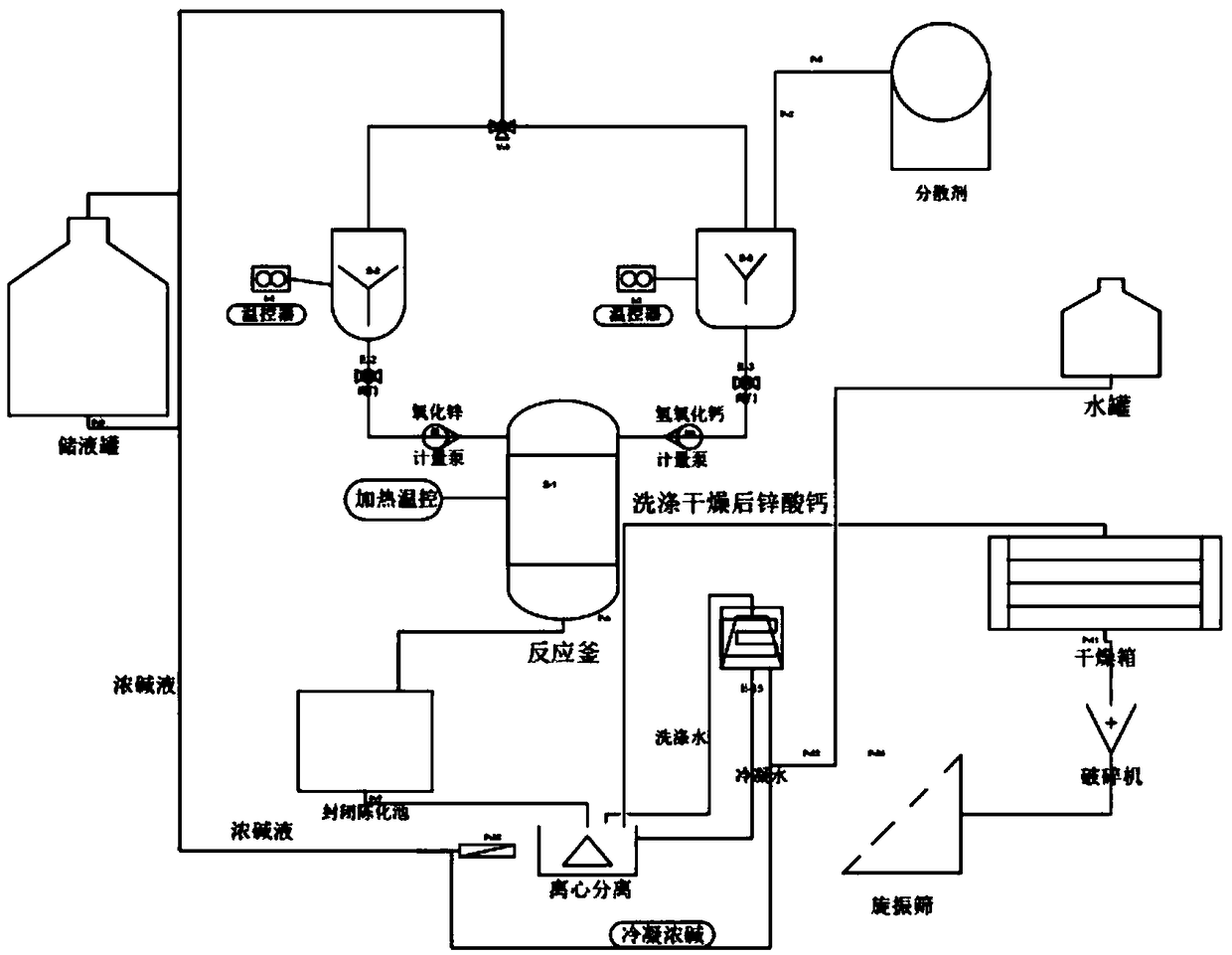

[0042]Embodiment 1: Provide a kind of zinc-nickel battery negative electrode material calcium zincate synthesis process and its equipment in this embodiment, described equipment adopts this zinc-nickel battery negative electrode material calcium zincate synthesis process:

[0043] The synthesis process of zinc-nickel battery negative electrode material calcium zincate comprises the following steps:

[0044] (1) Zinc oxide and acetic acid are mixed in a ratio of 1:2 by the reaction molar ratio, and after fully reacting, filter to remove impurities; then add a certain amount of sodium hydroxide solution, and the mixed reaction forms a zincate solution;

[0045] (2) react acetic acid and calcium hydroxide to generate calcium acetate solution, then add modified polycarboxylate dispersant 5040 dropwise, the amount of which is controlled at a solid content of 0.1-2%, and stir to form a mixed solution;

[0046] (3) Add the zincate solution prepared in step (1) dropwise to the mixed s...

Embodiment 2

[0049] Embodiment 2: Provide a kind of zinc-nickel battery negative electrode material calcium zincate synthesis process and its equipment in this embodiment, described equipment adopts this zinc-nickel battery negative electrode material calcium zincate synthesis process:

[0050] The synthesis process of zinc-nickel battery negative electrode material calcium zincate comprises the following steps:

[0051] (1) Zinc oxide and propionic acid are mixed in a ratio of 1:2 according to the reaction molar ratio, after fully reacting, filter to remove impurities; then add a certain amount of sodium hydroxide solution, and mix and react to form a zincate solution;

[0052] (2) Calcium hydroxide is added to a certain amount of water, and then the modified polycarboxylate dispersant 4010 is added dropwise, the amount of which is controlled at a solid content of 0.1-2%, to form a suspension;

[0053] (3) Add the suspension prepared in step (2) dropwise to the zincate solution prepared i...

Embodiment 3

[0056] Embodiment 3: Provide a kind of zinc-nickel battery negative electrode material calcium zincate synthesis process and its equipment in this embodiment, described equipment adopts this zinc-nickel battery negative electrode material calcium zincate synthesis process:

[0057] The synthesis process of zinc-nickel battery negative electrode material calcium zincate comprises the following steps:

[0058] (1) Zinc oxide and sodium hydroxide solution are mixed in a ratio of 1:2 by the reaction molar ratio, and mixed solution 1 is obtained after fully reacting;

[0059] (2) In the calcium hydroxide solution, drop a dispersant, which is a mixture of modified polycarboxylate dispersant 5040 and modified polyurethane dispersant 4010 in a weight ratio of 1:1 to form a mixed liquid two;

[0060] (3) Add the mixed solution 1 prepared in step (1) to the mixed solution 2 prepared in step (2); control the dropping rate to 0.5L / min~3L / min, while the reaction temperature is maintained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com