Preparation method of nano-nickel oxide

A nano-nickel oxide and nickel oxide technology, applied in the field of chemical science, can solve problems such as difficult shape control, complicated preparation process, and limited application development, and achieve excellent physical and chemical properties, simple experimental operation, and shortened preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

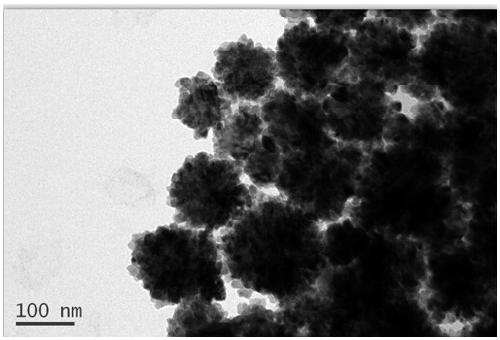

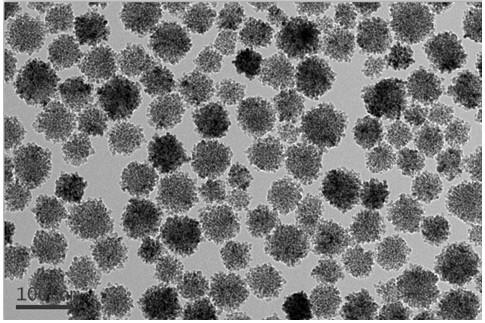

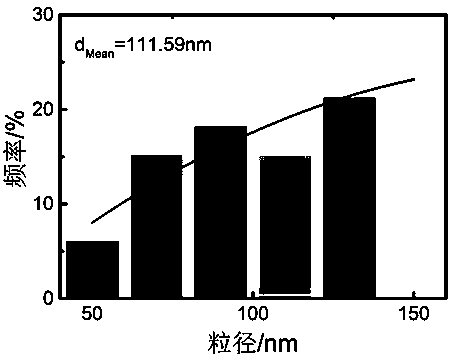

[0050] The preparation method of the nano-nickel oxide of the present embodiment comprises the following steps:

[0051] (1) Weigh 47.34 g of octadecene (62.5 mmol) and 16.98 g of oleic acid (20 mmol) at room temperature, mix, stir and heat to 50°C, add 6.94 g of nickel acetylacetonate, heat to 120°C and stir After 1 h, a uniform solution was formed and a light green mixed solution was obtained;

[0052] (2) Mix 1.6 g Tween-80 and 24.07 g oleylamine, and add it to the light green mixed solution obtained in step (1), heat and stir at a constant temperature of 120°C for 80 min to form a brown-red solution, and obtain the product the precursor of

[0053] (3) Transfer the precursor of the product obtained in step (2) to a high-temperature reaction kettle, heat it in an electric constant temperature blast drying oven at 200°C for 6 hours, then take it out and cool it to room temperature naturally to obtain a gray-green nickel oxide solution;

[0054] (4) Pour the centrifuge solu...

Embodiment 2

[0058] The difference between Example 2 and Example 1 is that in step (3), heat preservation at 200°C for 8 hours in an electric constant temperature blast drying oven, and other operating conditions are the same as in Example 1, and the obtained average particle size is 54.73nm of nickel oxide.

Embodiment 3

[0060] The difference between Example 3 and Example 1 is that in step (3), heat preservation at 200°C for 10 hours in an electric thermostatic blast drying oven, and other operating conditions are the same as in Example 1, and the obtained granules with an average particle size of 57.43nm Nickel oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com