Cement ceiling board and preparation method thereof

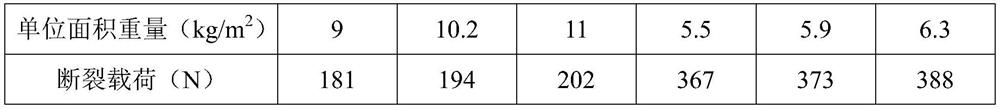

A ceiling slab and cement technology, applied in the field of building materials, can solve the problems of high weight per unit area of plates, restricting the application of cement-based materials, and high compressive strength, and achieve the effects of low weight per unit area, light weight and high breaking load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

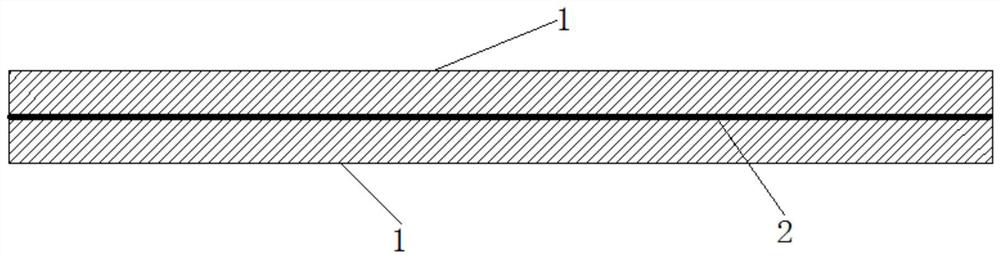

[0062] 1. A cement ceiling board, such as figure 1 As shown, the cement ceiling board is composed of cement board 1 and polypropylene fiber mesh cloth 2, wherein, the polypropylene fiber mesh cloth 2 is laid between the cement boards 1 to form three layers consisting of upper, middle and lower layers. Structurally composed of cement ceiling panels: the mesh size of the polypropylene fiber mesh cloth is 10mm×10mm, and the weight per unit area is 105g / m2 2 ; The cement is 42.5 Portland cement.

[0063] 2. The method for preparing the cement ceiling plate described in this embodiment includes the following steps:

[0064] (1) adding cement in a homogenizing tank according to a water-cement ratio of 3, stirring and mixing to obtain a cement slurry;

[0065] (2) Inject the cement slurry obtained in step (1) into the felt mold, when half of the slurry is injected, lay the polypropylene fiber mesh cloth on the surface of the slurry, and then continue to inject the remaining slurry ...

Embodiment 2

[0069] 1. A cement ceiling board, such as figure 1 As shown, the cement ceiling board is composed of cement board 1 and polypropylene fiber mesh cloth 2, wherein, the polypropylene fiber mesh cloth 2 is laid between the cement boards 1 to form three layers consisting of upper, middle and lower layers. The cement ceiling board composed of the structure; the mesh size of the polypropylene fiber mesh cloth is 10mm × 10mm, and the weight per unit area is 100g / m 2 ; The cement is 42.5R Portland cement.

[0070] 2. The method for preparing the cement ceiling plate described in this embodiment includes the following steps:

[0071] (1) adding cement into a homogenizing tank at a water-cement ratio of 2.0, stirring and mixing to obtain a cement slurry;

[0072] (2) Inject the cement slurry obtained in step (1) into the felt mold, when half of the slurry is injected, lay the polypropylene fiber mesh cloth on the surface of the slurry, and then continue to inject the remaining slurry ...

Embodiment 3

[0076] 1. A cement ceiling board, such as figure 1 As shown, the cement ceiling board is composed of cement board 1 and polypropylene fiber mesh cloth 2, wherein, the polypropylene fiber mesh cloth 2 is laid between the cement boards 1 to form three layers consisting of upper, middle and lower layers. The cement ceiling board composed of the structure; the mesh size of the polypropylene fiber mesh cloth is 10mm × 10mm, and the weight per unit area is 95g / m 2; The cement is 42.5 Portland cement.

[0077] 2. The method for preparing the cement ceiling plate described in this embodiment includes the following steps:

[0078] (1) adding cement into a homogenizing tank at a water-cement ratio of 4.5, stirring and mixing to obtain a cement slurry;

[0079] (2) Inject the cement slurry obtained in step (1) into the felt mold, when half of the slurry is injected, lay the polypropylene fiber mesh cloth on the surface of the slurry, and then continue to inject the remaining slurry int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com