Automatic cleaning optical flow cell

A technology of automatic cleaning and flow cell, which is applied in the direction of material analysis, scientific instruments, and measuring devices through optical means. It can solve problems such as easy generation of air bubbles, inability of motors to resist corrosion and high temperature, and drift of measurement baselines. It achieves simple structure and design. ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

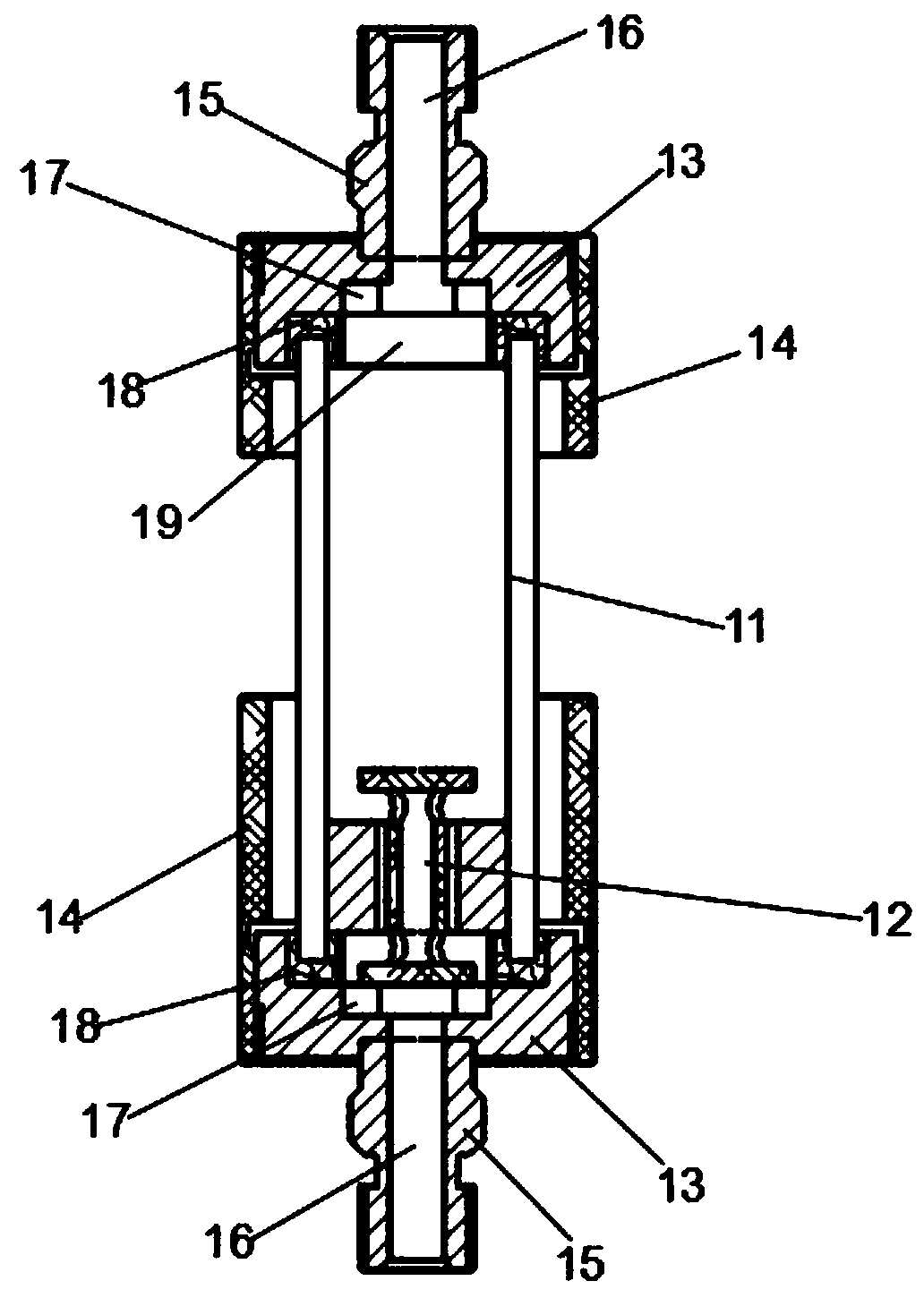

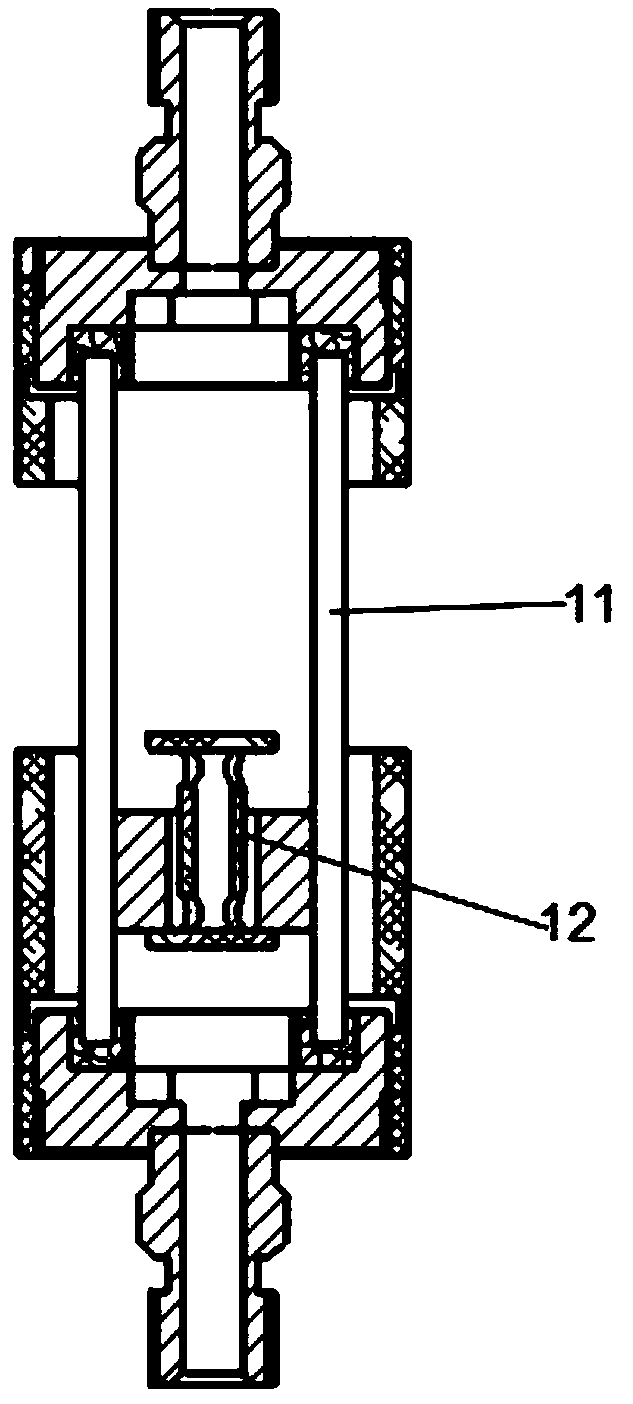

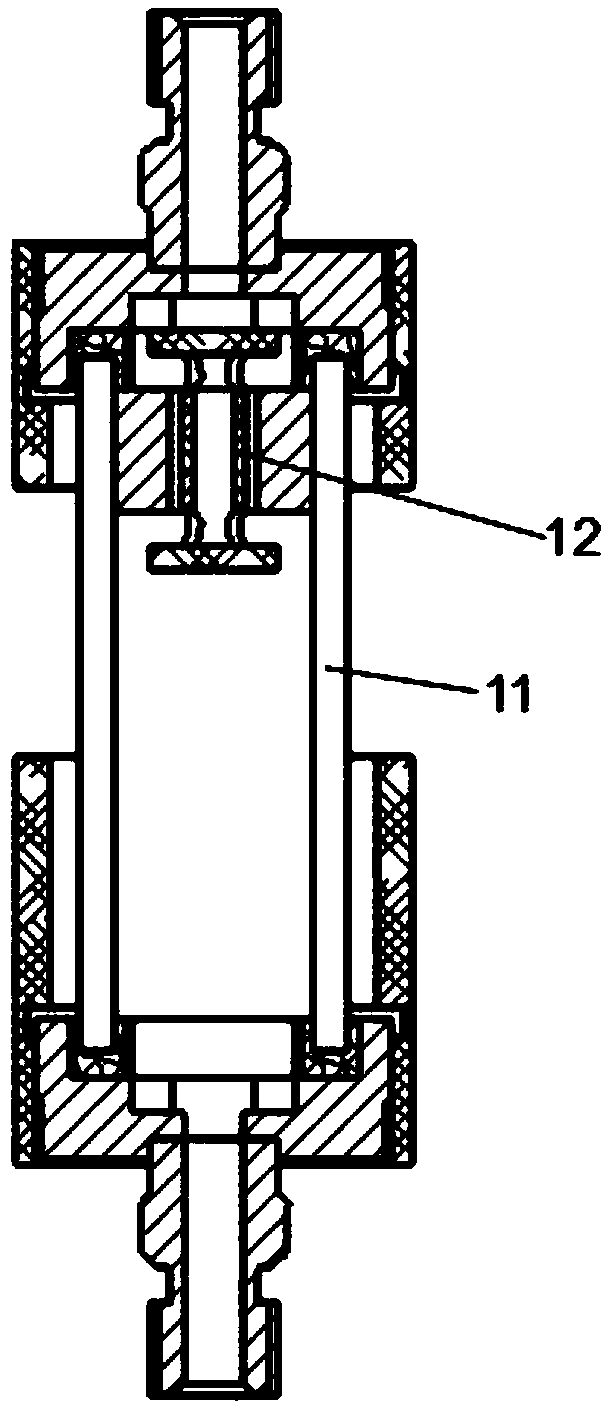

[0020] Embodiment: an automatic cleaning optical flow cell.

[0021] refer to Figure 1 to Figure 7As shown, an automatic cleaning optical flow cell includes a flow cell body 1, a first three-way solenoid valve 2, a second three-way solenoid valve 3, a controller 4, an optical sensor 5 and a light source 6, wherein the light source 6 and the optical sensor 5 are symmetrically installed on the left and right sides of the flow cell body 1, the first three-way solenoid valve 2 and the second three-way solenoid valve 3 are respectively connected to the flow cell body 1 through pipelines, the first three-way solenoid valve 2, the second three-way solenoid valve The three-way solenoid valve 3, the optical sensor 5 and the light source 6 are all electrically connected to the controller 4. In the actual detection process, the function of the light source is to provide the required light for optical detection, and input the detected data through the optical sensor 5. Store and output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com