Silicon carbide MOSFET device and preparation method thereof

A silicon carbide, N-JFET technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as current limiting capability, sudden change in electric field, and hidden reliability problems, and improve resistance to voltage shocks. , the effect of improving the current conduction capability and optimizing the current transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

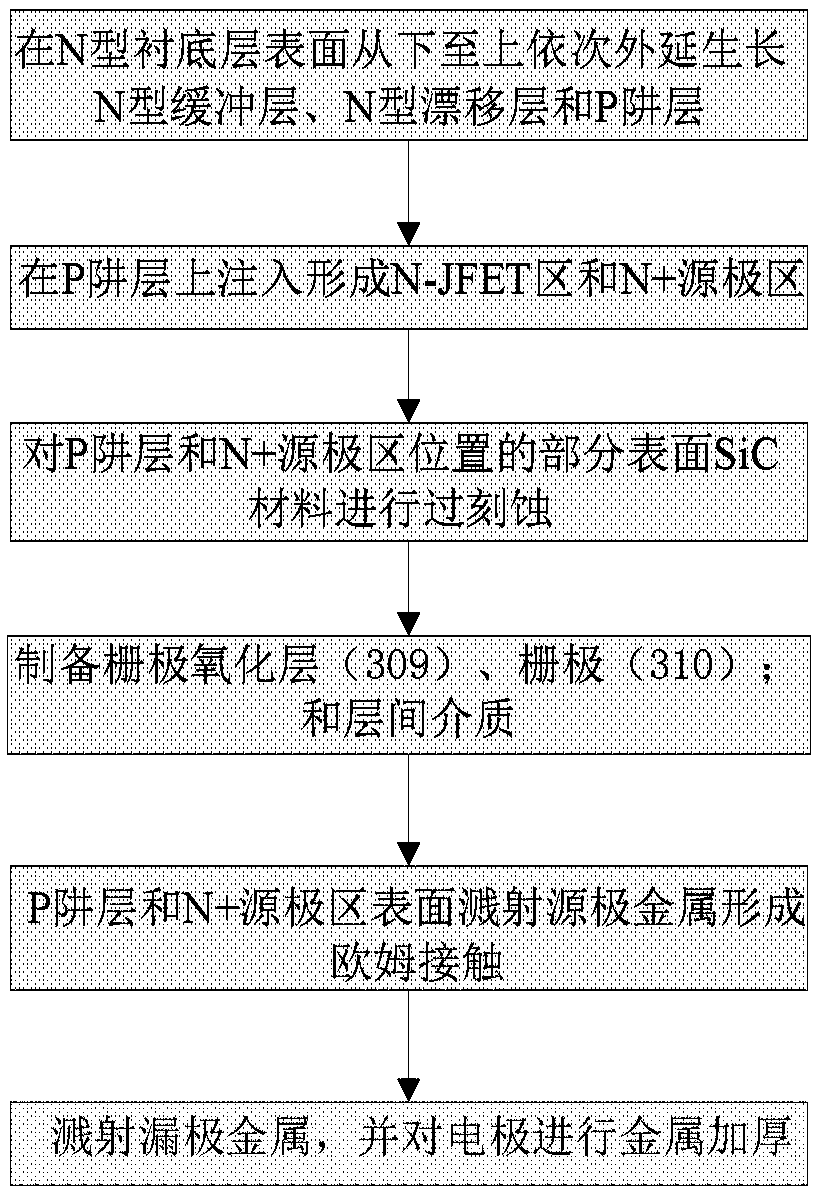

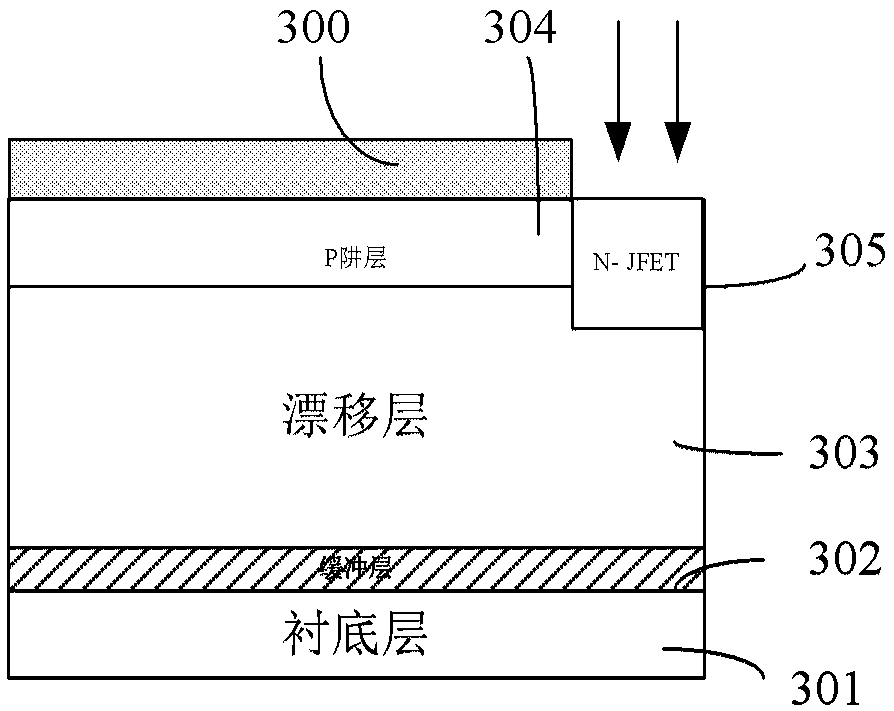

[0039] According to an embodiment of the present invention, a method for preparing a silicon carbide MOSFET is provided, such as figure 2 shown, including:

[0040] Over-etching the SiC material on the part of the surface of the P well layer 304 and the N+ source region 306;

[0041] The source contact window is etched, and the source metal 312 is sputtered on the surface of the P well layer 304 and the N+ source region 306 to form an ohmic contact.

[0042] Wherein, in the P well layer 304, the middle area of the P well concentration is the highest, and gradually decreases toward both sides. If it is not etched away, the concentration of the P well surface area is not enough to form an ohmic contact. Concentrated P+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com