Preparation method of probiotic ass milk powder

A technology of probiotics and donkey milk powder, which is applied in the direction of dairy products, milk preparations, applications, etc., can solve the problems of poor product phase and solubility, and destroy active ingredients, etc., and achieve the effect of retaining activity and good product phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

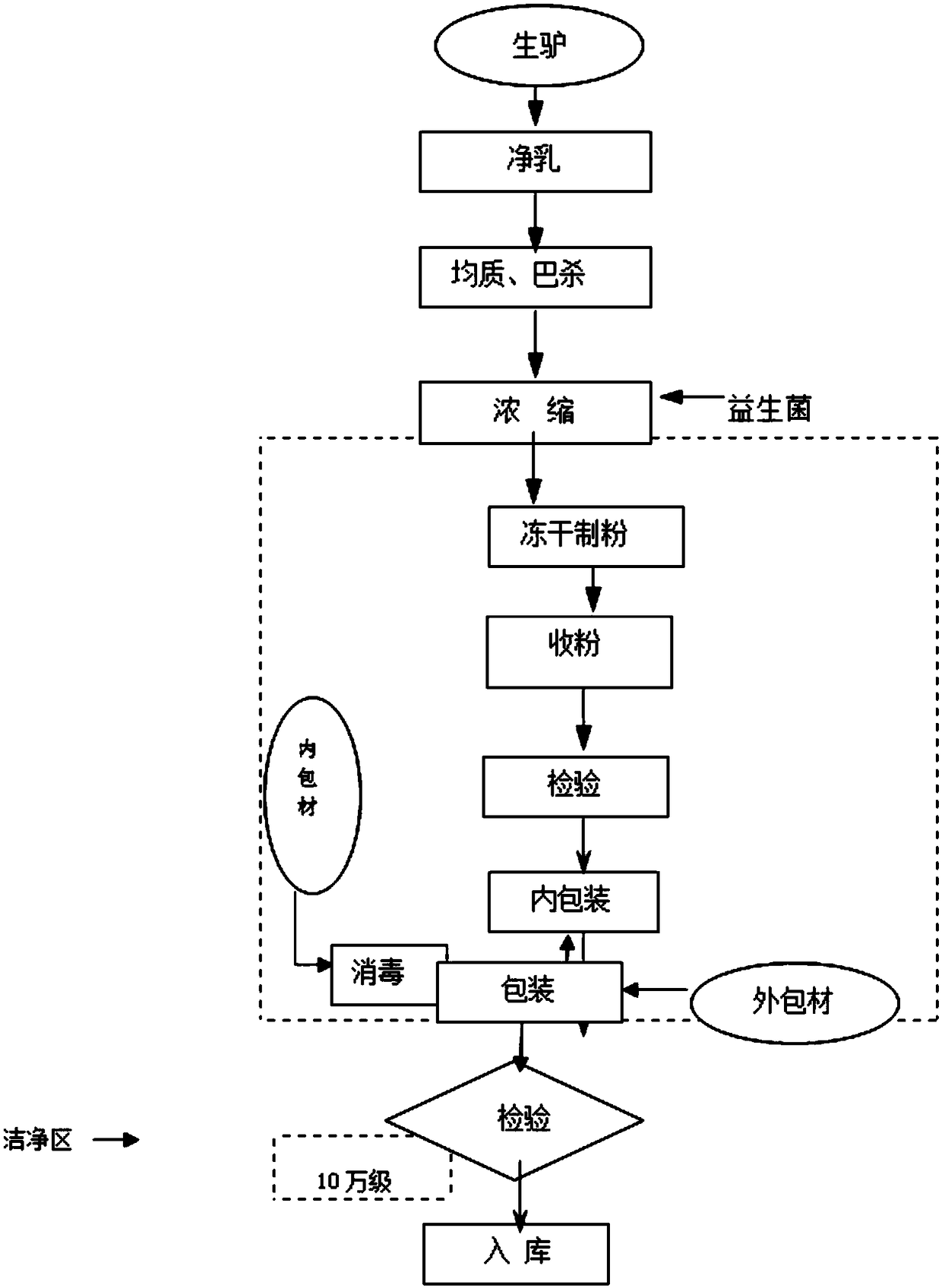

[0029] Such as figure 1 As shown, this implementation provides a production method of probiotic donkey milk powder, which involves low-temperature vacuum concentration of raw donkey milk after heat treatment of the raw material milk. Specific steps are as follows:

[0030] (1) Raw material donkey milk inspection and storage: fresh donkey milk will be inspected according to the acceptance standards of donkey milk, and after passing the inspection, it will be put into storage for production;

[0031] (2) Centrifugal milk cleaning: Use a milk cleaning machine to separate raw donkey milk at a high speed at 0.20 MPa to remove dust, hair and other impurities in donkey milk.

[0032] (3) Homogenization: put the donkey milk heated to 50°C into the homogenization system, and perform homogenization treatment under the condition of 25-30MPa;

[0033] (4) Heat treatment: suck the homogenized donkey milk into a vacuum tank, and put it into a heat treatment system for low-temperature past...

Embodiment 2

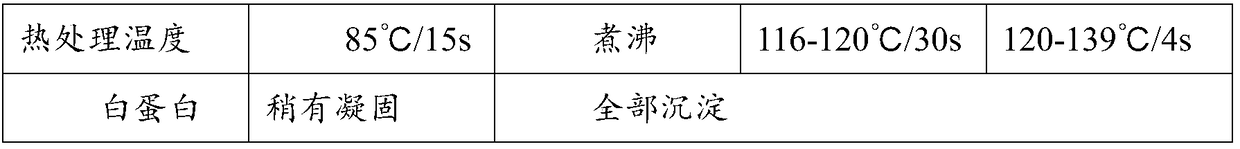

[0046] Sterilization of fresh donkey milk at different temperatures found that boiling and above temperatures seriously damage indicators such as albumin, vitamins and minerals in donkey milk, and cause fat to float up, seriously affecting product quality. Under the condition of 85℃ / 15s, it can not only meet the sterilization conditions but also keep the nutrients in the milk.

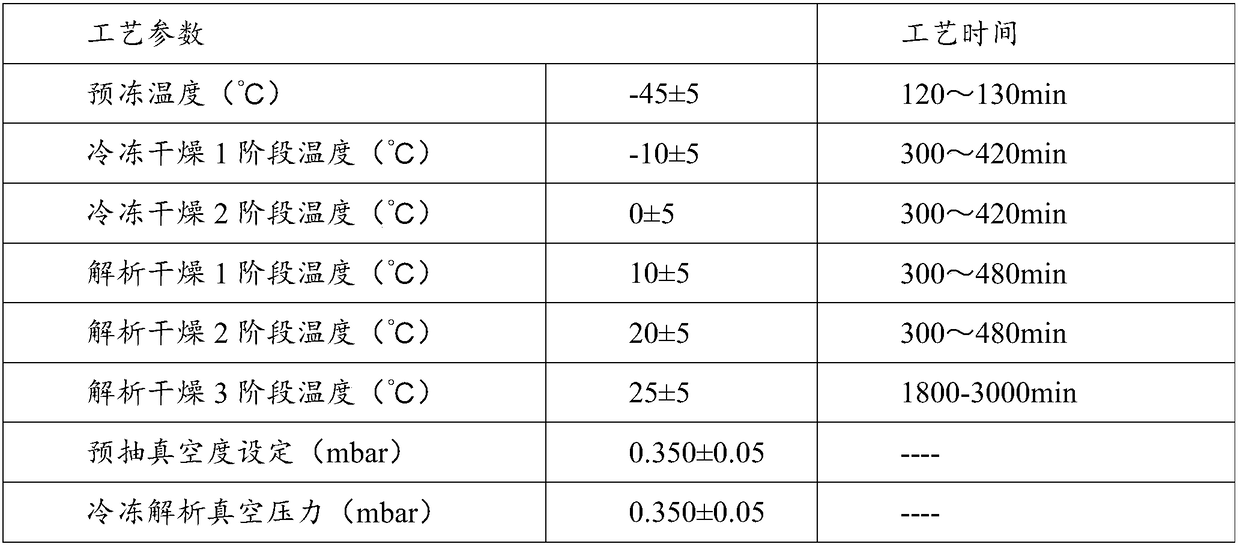

[0047] Table 2: Production Process Screening

[0048]

[0049]

[0050] Table 3: Comparison of common milk powder production processes

[0051]

[0052] Table 3 compares different milling processes and finds that the vacuum freeze-drying milling technology adopted in the present invention can retain the nutritional active ingredients in donkey milk to the greatest extent.

Embodiment 3

[0054] A probiotic donkey milk powder is obtained by removing impurities, homogenizing and sterilizing the donkey milk, then concentrating in a low-temperature vacuum, adding probiotics after concentration, and using the probiotic donkey milk powder obtained by freeze-drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com