Tensile polymethyl methacrylate glass fiber composite base cloth

A technology of polymethyl methacrylate and glass fiber is applied in the field of polymethyl methacrylate glass fiber composite base fabric and glass fiber composite base fabric, which can solve the problems of poor adhesion of the base fabric and improve waterproofness. , good dust peeling, good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

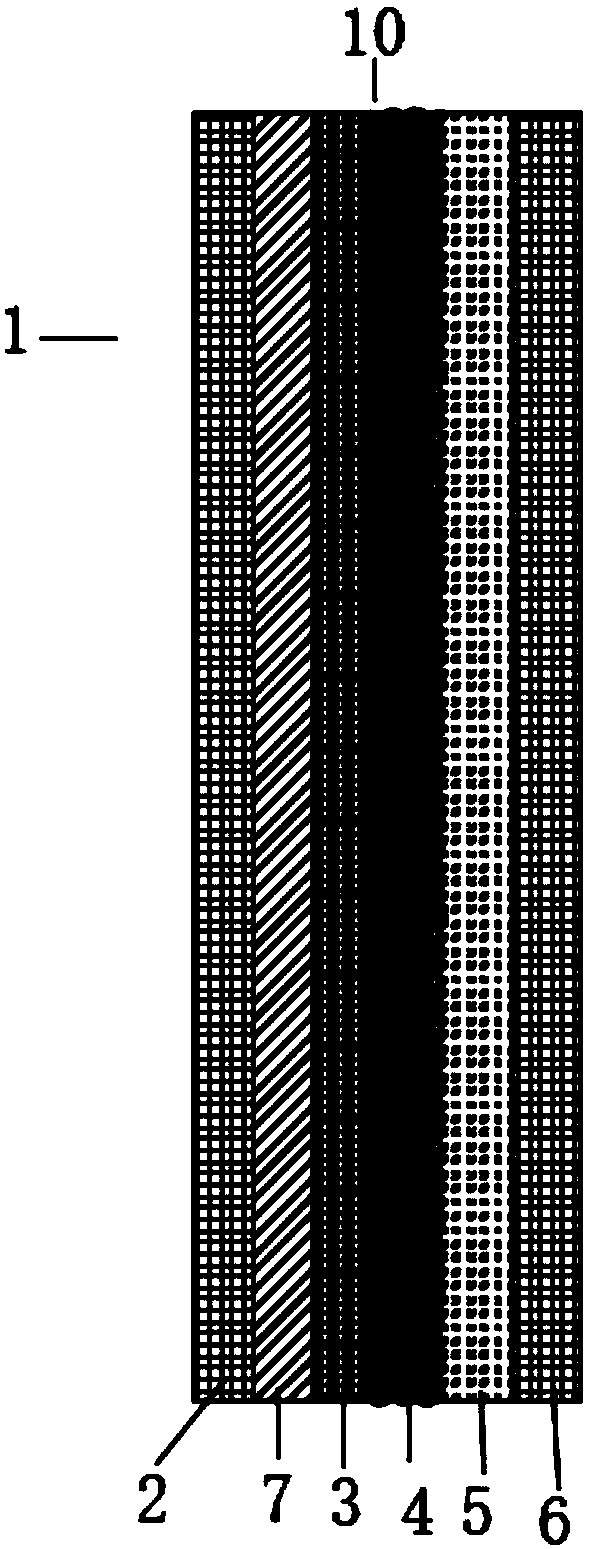

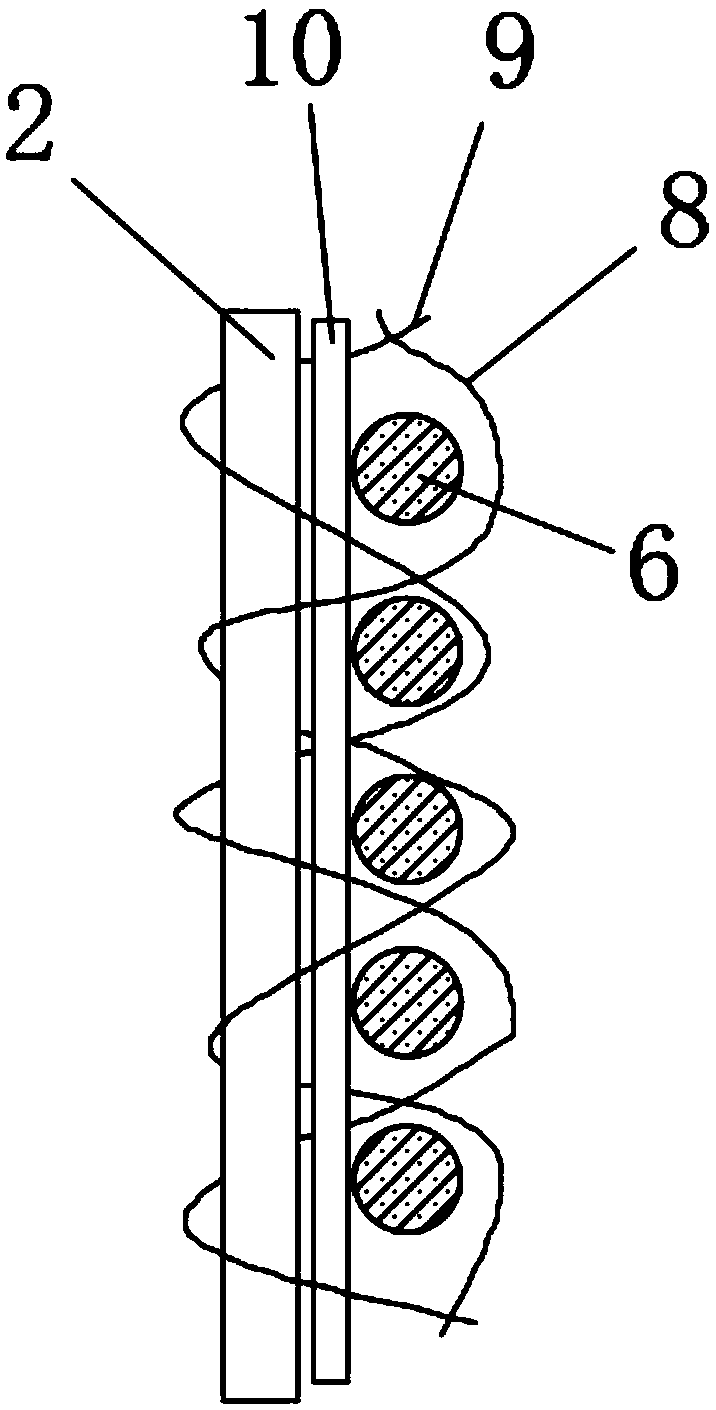

[0019] Example: such as Figure 1-2 As shown, a polymethyl methacrylate glass fiber composite base cloth resistant to pulling comprises a polymethyl methacrylate glass fiber composite cloth 1 and a composite cloth 10, and the composite cloth 10 includes a temperature-resistant layer 3, a waterproof layer 4, The anti-static layer 5 and the anti-corrosion layer 7, by setting the anti-corrosion layer, make it acid-resistant extremely strong, can effectively prevent acid corrosion from causing damage to the base cloth, and one side of the anti-corrosion layer 7 is provided with a temperature-resistant layer 3 to make it Able to withstand high temperatures, one side of the temperature-resistant layer 3 and the side away from the anti-corrosion layer 7 are provided with a waterproof layer 4, and the water resistance is greatly enhanced through the waterproof layer, and one side of the waterproof layer 4 and away from the temperature-resistant layer 3 An antistatic layer 5 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com