A kind of ultra-high elastic medical PVC pump tube material and its preparation method and application

A PVC resin and pump tube technology, applied in the field of medical equipment, can solve the problems of infusion accuracy attenuation, poor elasticity, poor resilience of PVC hoses that cannot be used as medical pump tubes, etc., achieving high resilience, excellent ultra-high elasticity, The effect of excellent mechanical strength and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Second aspect of the present invention also provides the preparation method of medical PVC pump tubing material, at least comprises the following steps:

[0067] a. Under the condition of 30℃~60℃, first add PVC resin, HIPS, PS, main plasticizer, lubricant, heat stabilizer, antioxidant and light stabilizer into the mixer and fully blend for 20~60 minutes. Add modified PVC and auxiliary plasticizer to the mixer, and continue blending at 60°C to 100°C for 1 to 5 hours to obtain a mixture;

[0068] b. Under the condition of 170°C to 190°C, the mixture is melted and extruded to obtain mixed pellets;

[0069] c. Add the mixed pellets to the extruder, melt and extrude, and cool after pulling to form a pump tube;

[0070] d. The pump tube in c above is irradiated with gamma rays for 0.5-12 hours, and the irradiation dose is 25 kGy.

[0071] In some preferred embodiments, the conditions in the above step a of this application are: 40°C to 55°C, PVC resin, HIPS, PS, main plasti...

Embodiment 1

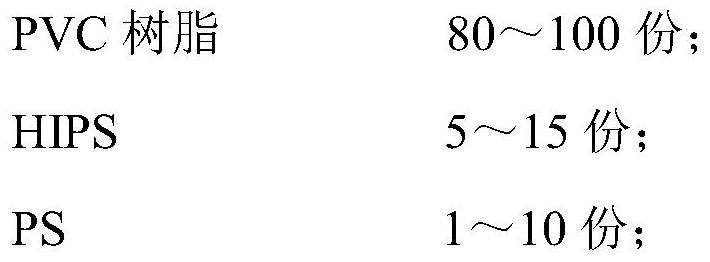

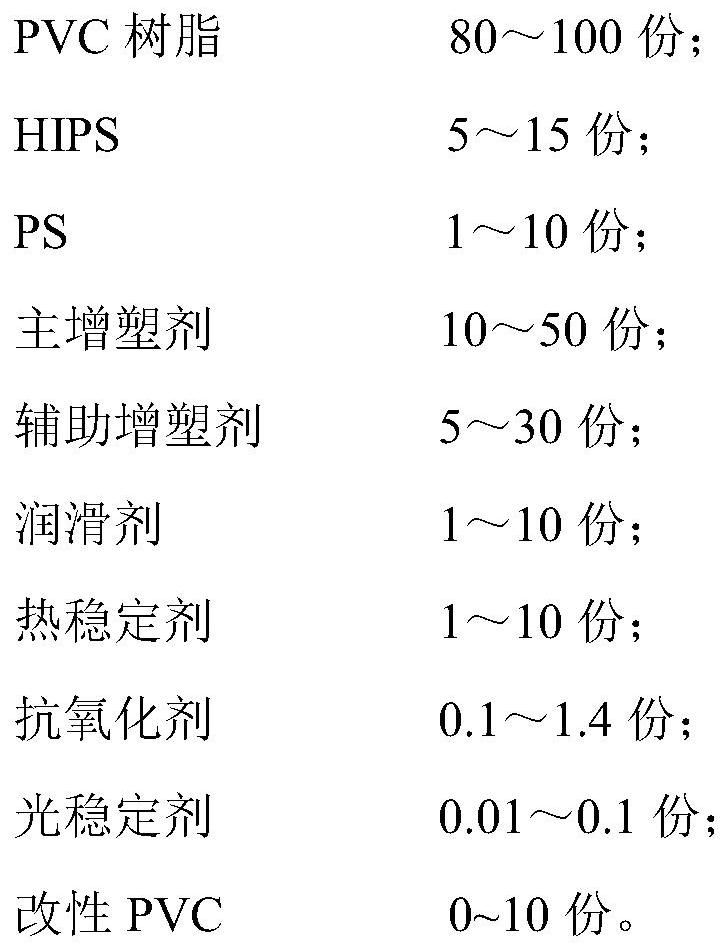

[0081] Embodiment 1 of the present invention provides a super-elastic medical PVC pump tubing material and its preparation method and application. In parts by weight, the components at least include:

[0082]

[0083]

[0084] The above-mentioned main plasticizer is DOP, the auxiliary plasticizer is epoxy soybean oil, the lubricant is zinc stearate, the heat stabilizer is lanthanum stearate, the antioxidant is antioxidant 264, and the light stabilizer is Ciba HALS type 944; when the melt index test condition is 200°C / 5kg, the melt index of the HIPS is 3.6g / 10min, and the melt index of PS is 1.17g / 10min.

[0085] The preparation method of the highly elastic medical PVC pump pipe material comprises the following steps:

[0086] a. At 30°C, first add PVC resin, HIPS, PS, main plasticizer, lubricant, heat stabilizer, antioxidant, and light stabilizer to the mixer and fully blend for 20 minutes, then add modification to the mixer PVC, auxiliary plasticizer, continue blending...

Embodiment 2

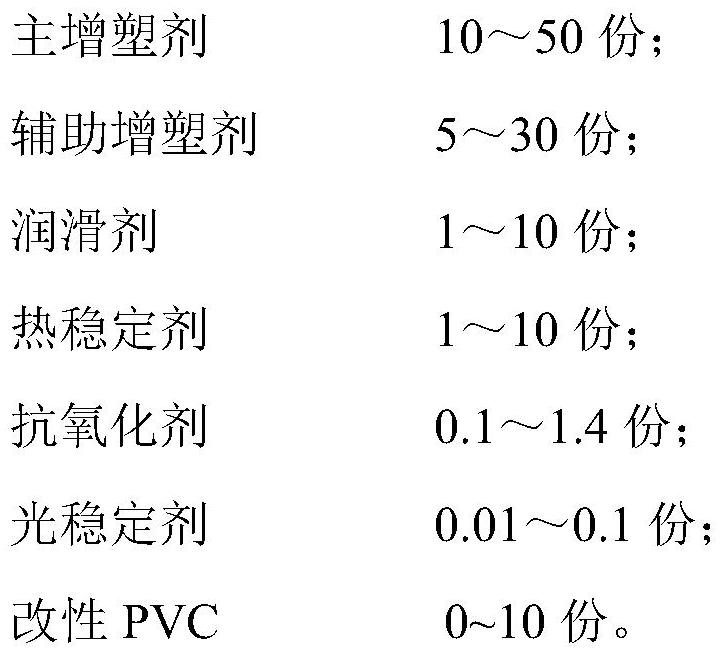

[0092] Embodiment 2 of the present invention provides a super-elastic medical PVC pump tube material and its preparation method and application. In parts by weight, the components at least include:

[0093]

[0094] The above-mentioned main plasticizer is DOP, the auxiliary plasticizer is epoxy linseed oil, the lubricant is zinc stearate, the heat stabilizer is lanthanum stearate, the antioxidant is antioxidant 264, and the light stabilizer is Ciba HALS type 944; when the melt index test condition is 200°C / 5kg, the melt index of the HIPS is 6.5g / 10min, and the melt index of PS is 3.8g / 10min.

[0095] The preparation method of the highly elastic medical PVC pump pipe material comprises the following steps:

[0096] a. At 40°C, first add PVC resin, HIPS, PS, main plasticizer, lubricant, heat stabilizer, antioxidant, and light stabilizer to the mixer and fully blend for 30 minutes, then add modification to the mixer PVC, auxiliary plasticizer, continue blending at 70°C for 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com