Preparation method of polylactic acid/polyadipic acid-butylene terephthalate blend

A technology of butylene terephthalate and polyadipic acid, which is applied in the field of preparation of polylactic acid/polyadipate-butylene terephthalate blends, can solve the poor compatibilization effect of ADR reaction to achieve excellent compatibilization and toughening effects, strong molecular entrainment ability, and fine interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The PLA and PBAT blends were heated to 50°C in a vacuum drying oven and vacuumed to ensure sufficient drying of the materials during the experiment and to inhibit thermal degradation during the heating and blending process. A total of 63g of PLA and PBAT resins were added to the mixing chamber, which can not only ensure that the samples are fully mixed, but also ensure that enough supercritical fluid is injected, and the airtightness of the internal mixer is good. The internal mixing chamber of the conventional internal mixer is strengthened and sealed, and the single plunger pump is connected with the internal mixing chamber to form a supercritical carbon dioxide assisted blending internal mixing mixing device.

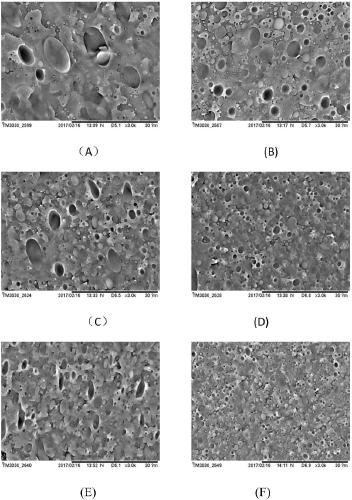

[0021]The preparation method of polylactic acid / polyadipate-butylene terephthalate (PLA / PBAT) blend, PLA and PBAT are blended according to mass fraction 70:30, add mass fraction on this basis 0, 0.3, 0.5, 1.0 parts of ADR compatibilizer, see Examples 1 to 4 in...

Embodiment 2

[0029] The PLA and PBAT blends were heated to 50°C in a vacuum drying oven and vacuumed to ensure sufficient drying of the materials during the experiment and to inhibit thermal degradation during the heating and blending process. According to the conclusion obtained from the preliminary test, adding 63g of PLA and PBAT resin to the mixing chamber can ensure that the samples are fully mixed, and enough supercritical fluid can be injected, and the airtightness of the internal mixer is good.

[0030] The mixer of the conventional internal mixer is strengthened and sealed, and the single plunger pump is connected with the internal mixing chamber to form a supercritical carbon dioxide assisted blending internal mixing device.

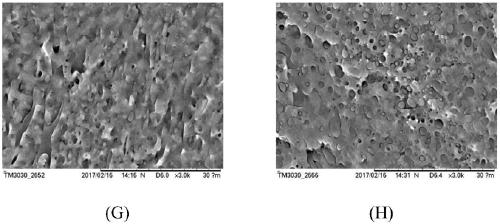

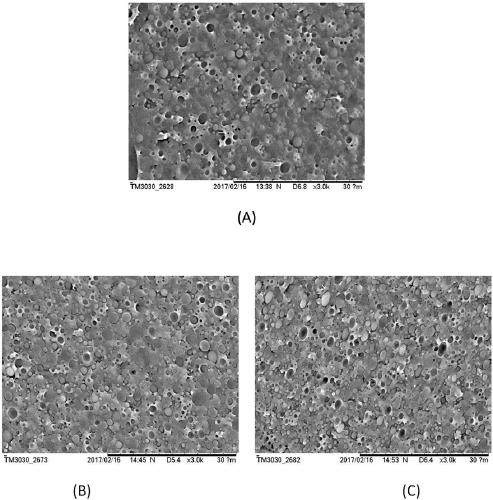

[0031] In order to ensure a better refinement effect of OMMT on PBAT, PBAT and OMMT were conventionally melt blended first, and the mass ratios of PBAT and OMMT were 30:0.3, 30:0.6 and 30:1.0, respectively. Then PBAT-OMMT, PLA and ADR are added to the mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com