Investment casting process for super duplex stainless steel pump housing

A technology of duplex stainless steel and investment casting, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of repairing welding zone cracks, technical requirements for argon welding of cracks, and difficult to stabilize metallographic structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

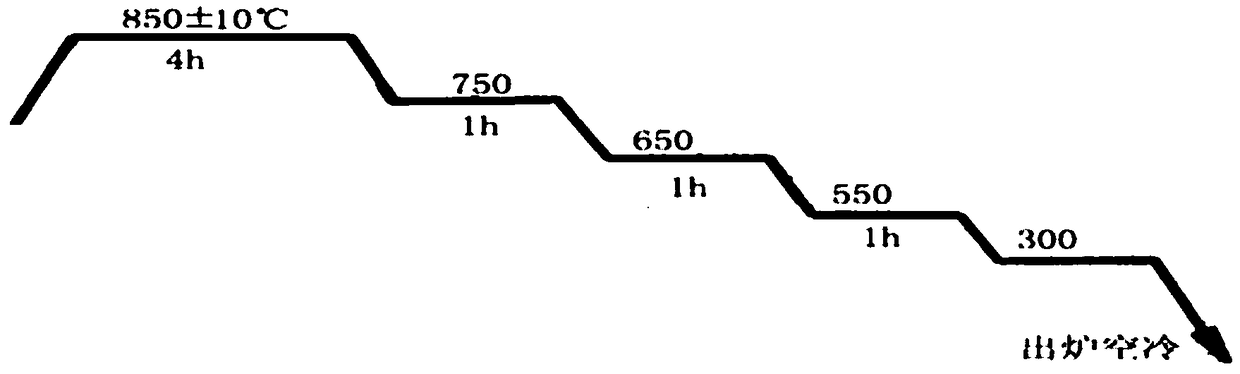

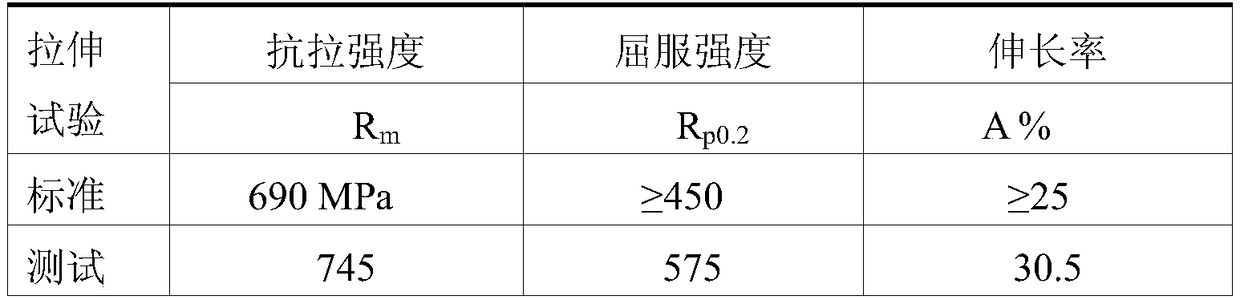

[0090] The preparation process of the invention includes wax mold making, pouring system design, tree formation, shell making, dewaxing, mold shell, mold shell cleaning, mold shell roasting, molten steel melting, pouring, shelling, cutting and post-treatment.

[0091] 1. Chemical composition control

[0092] (1) Raw material preparation: C ≤ 0.01% industrial pure iron, Ni-0 or Ni-1 electrolytic nickel plate, electrolytic manganese C ≤ 0.02%, ferrosilicon C ≤ 0.03%, pure molybdenum, ferrochromium nitride C≤0.03%, ultra-low carbon duplex stainless steel 2205 finished packaging material and 6A pouring riser return material, etc., in order to ensure that the final chemical composition of super duplex stainless steel carbon content is in the middle and lower line of standard specifications, all raw materials should be First, use a spectrometer to detect the composition, and control the carbon content to not exceed the default technical requirements.

[0093] (2) Preheating of raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com