Method for preparing magic color reflective film through vacuum evaporation process

A reflective film and vapor deposition technology, applied in the field of reflective film, can solve the problems of poor reflective performance, non-transparency of reflective film, complicated processing technology, etc., and achieve the effect of not easy to deform, reduce contact area, and ensure supporting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing an illusion reflective film by a vacuum evaporation process includes the following steps:

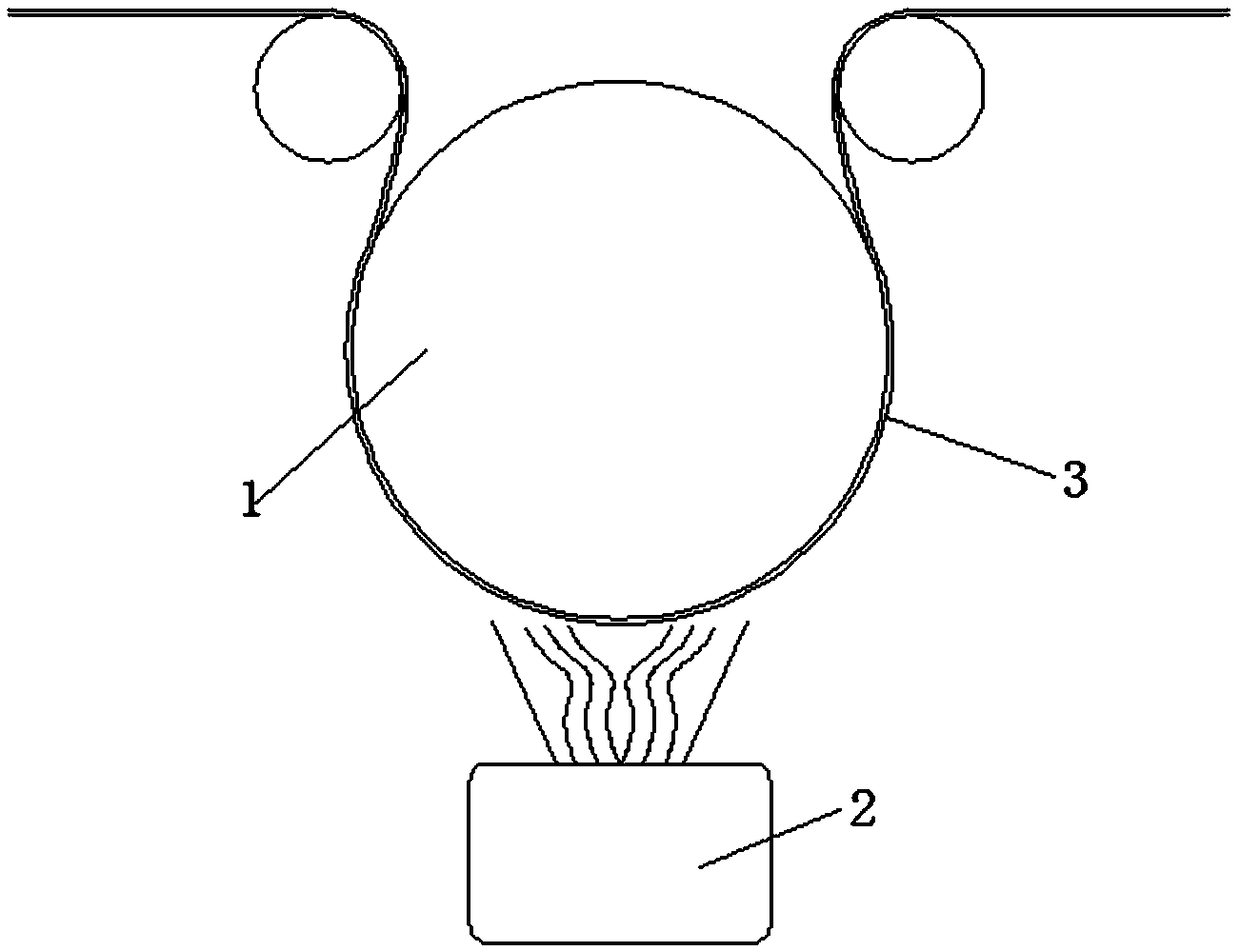

[0044] (1) Load the base film of the plated plant onto the two rewinding and unwinding rollers in the winding chamber of a high vacuum coating equipment, and let the base film of the plated plant pass through the central main drum from one of the rewinding and unwinding rollers. Rewind to another rewinding and unwinding roller, start the forced refrigeration system, connect the air circuit, and cool the main drum to -20℃ for standby;

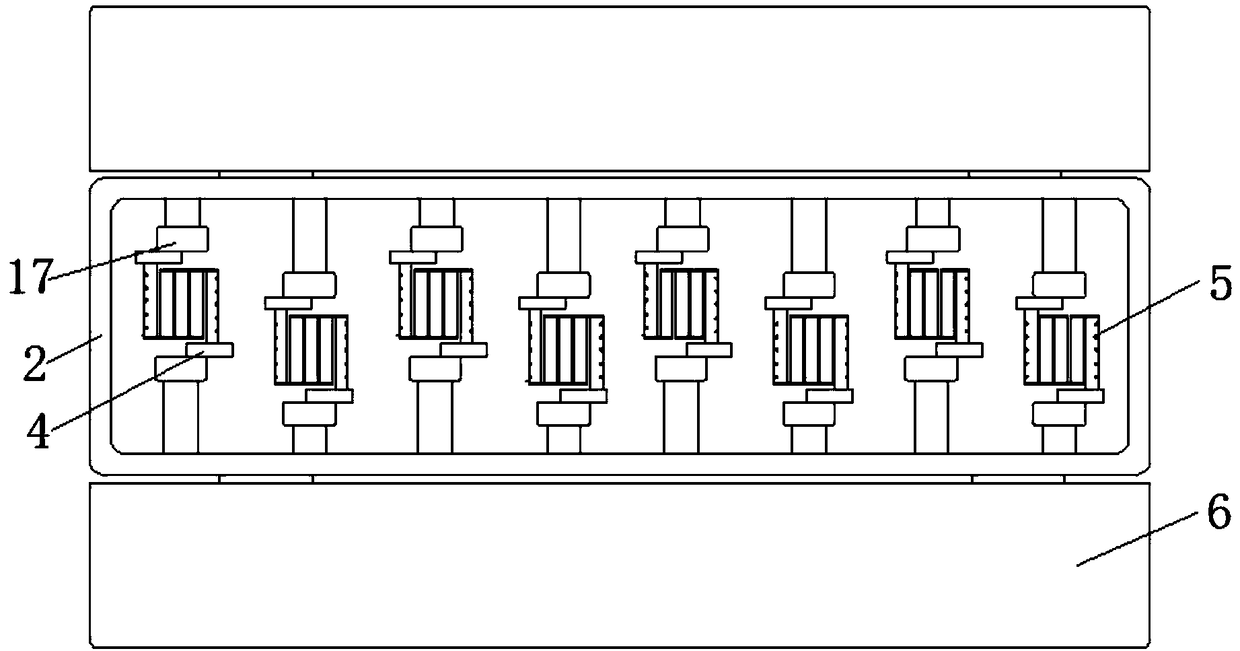

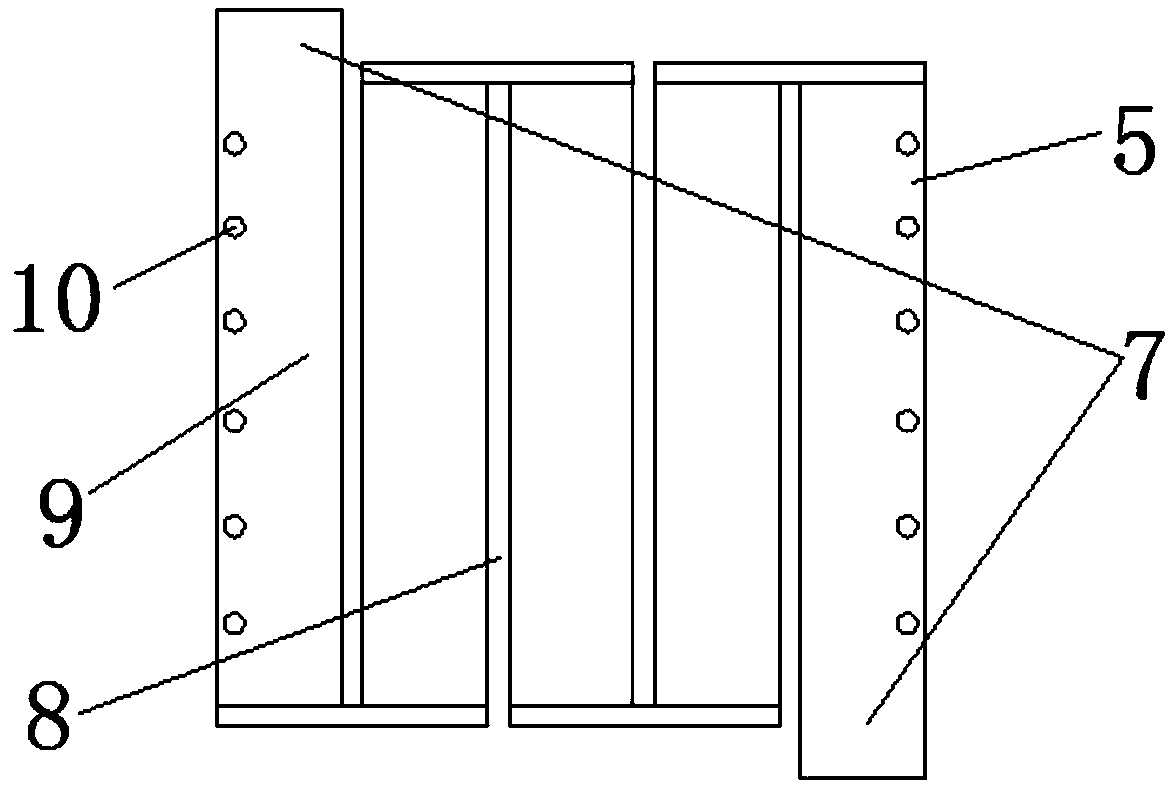

[0045] (2) Put a number of molybdenum boats with zinc sulfide targets closely arranged in the evaporation tank of the high vacuum coating equipment. The zinc sulfide targets have a cylindrical structure, and the targets are closely arranged on the molybdenum boat after being placed upright. The evaporation top surface formed by the placed multiple rows of targets is an arc-shaped evaporation surface with different heights. On the ...

Embodiment 2

[0052] A method for preparing an illusion reflective film by a vacuum evaporation process includes the following steps:

[0053] (1) Load the base film of the plated plant onto the two take-up and unwind rolls in the winding chamber of a high vacuum coating equipment, and let the base film of the plated plant pass through the central main drum from one of the take-up and unwind rolls. Rewind to another rewinding and unwinding roller, start the forced refrigeration system, connect the air circuit, and cool the main drum to -16℃ for standby;

[0054] (2) Put a number of molybdenum boats with zinc sulfide targets closely arranged in the evaporation tank of the high vacuum coating equipment. The zinc sulfide targets have a cylindrical structure, and the targets are closely arranged on the molybdenum boat after being placed upright. The evaporation top surface formed by the placed multiple rows of targets is an arc-shaped evaporation surface with different heights. On the bottom end of ...

Embodiment 3

[0061] A method for preparing a phantom reflective film by a vacuum evaporation process includes the following steps:

[0062] (1) Load the base film of the plated plant onto the two take-up and unwind rolls in the winding chamber of a high vacuum coating equipment, and let the base film of the plated plant pass through the central main drum from one of the take-up and unwind rolls. Rewind to another rewinding and unwinding roller, start the forced refrigeration system, connect the air circuit, and cool the main drum to -13℃ for standby;

[0063] (2) Put a number of molybdenum boats with zinc sulfide targets closely arranged in the evaporation tank of the high vacuum coating equipment. The zinc sulfide targets have a cylindrical structure, and the targets are closely arranged on the molybdenum boat after being placed upright. The evaporation top surface formed by the placed multiple rows of targets is an arc-shaped evaporation surface with different heights. On the bottom end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com