Organic electrophosphorescent material, preparation method and applications thereof, and OLED device containing organic electrophosphorescent material

A technology of electrophosphorescence and phosphorescent materials, which is applied in the field of OLED light-emitting materials, and can solve problems such as difficult purification, strong intermolecular force of conjugated light-emitting second ligands, and insoluble problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

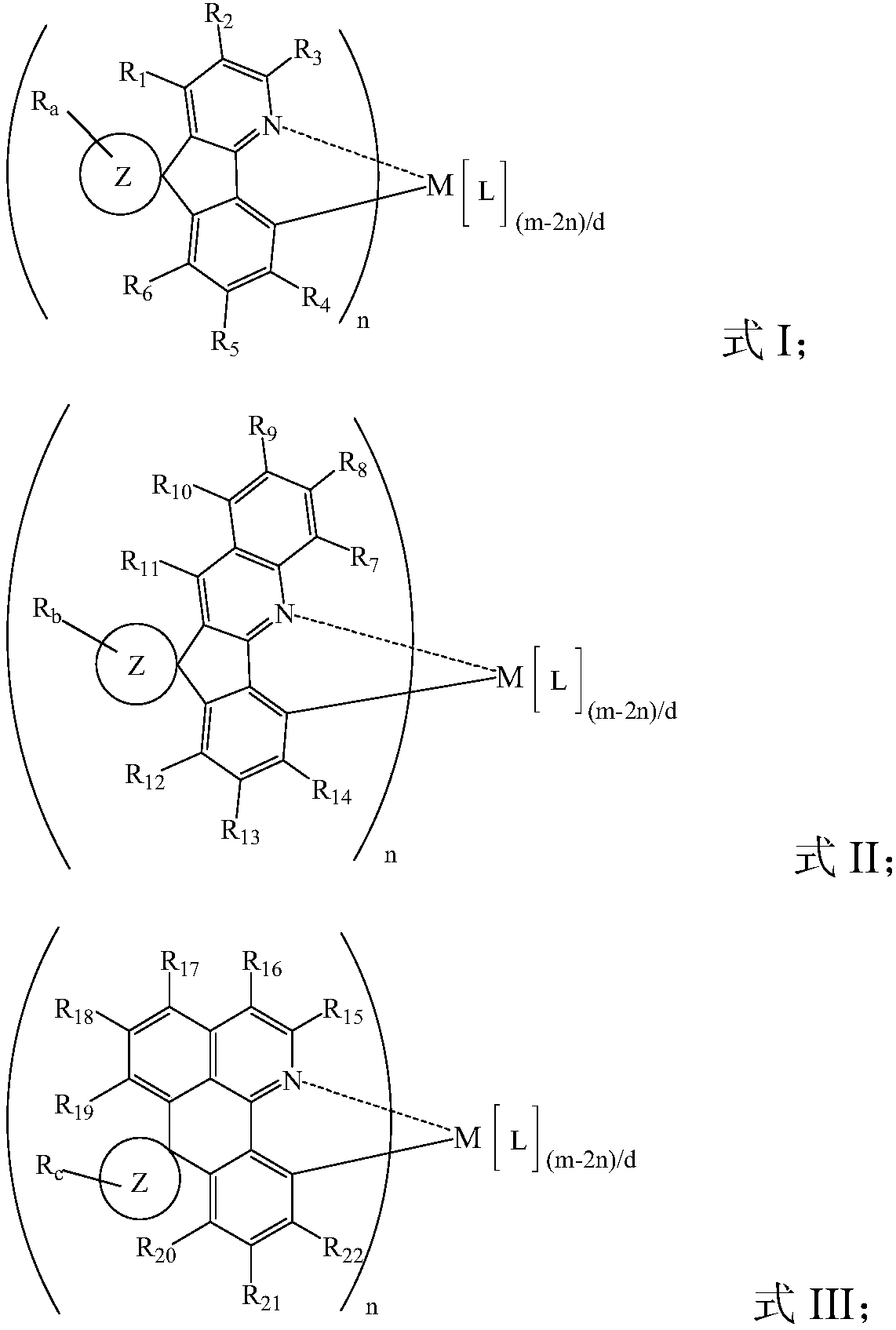

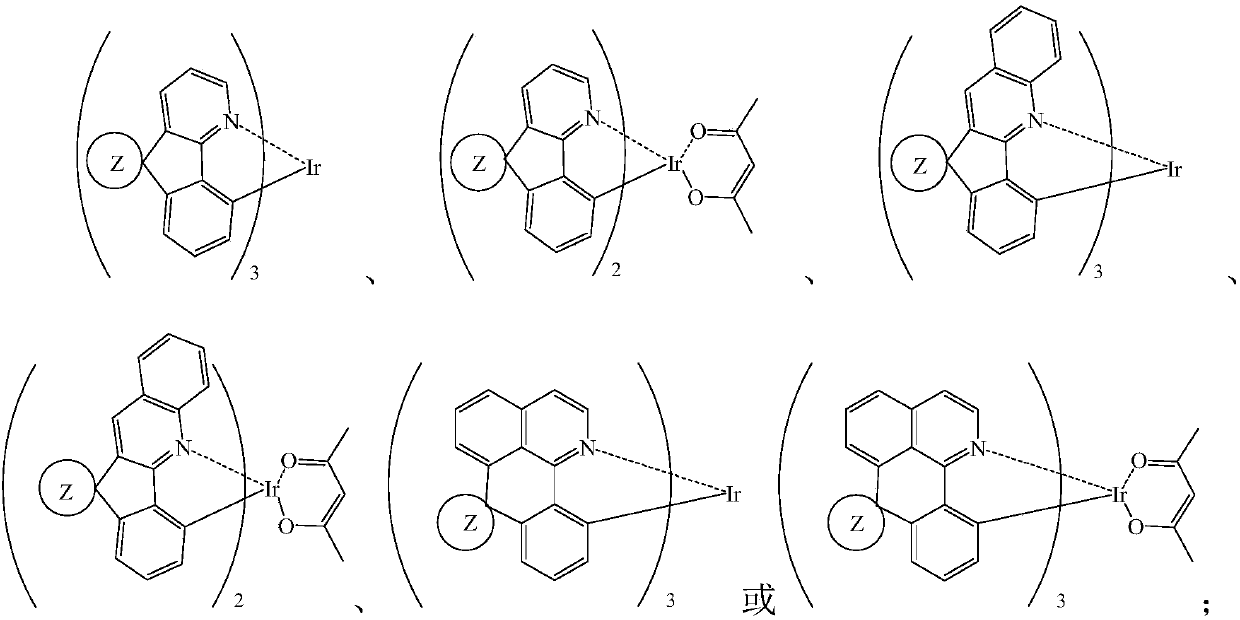

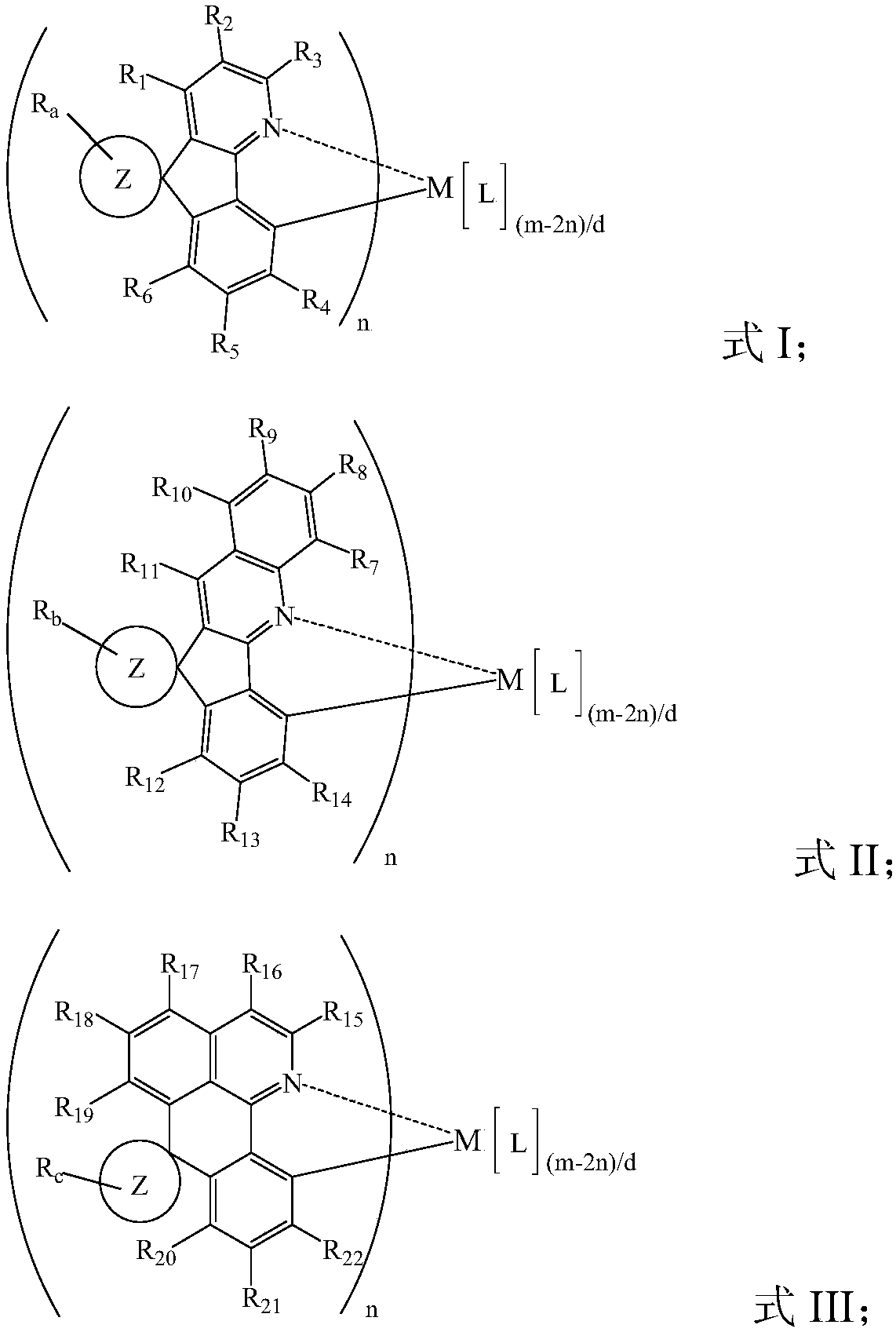

[0065] Embodiments 1-5 provide iridium-based organic electrophosphorescent materials (referred to as Ir-1 to Ir-5 in sequence) with the structure of formula I, and their structural formulas are as follows:

[0066]

[0067] Taking Ir-3 as an example, its preparation method is as follows:

[0068] (1) compound (2.02g, 10mmol), phenylboronic acid (1.8g, 15mmol), potassium carbonate (5g, 50mmol), triphenylphosphine (15g, 50mmol), palladium acetate (0.15g, 0.62mmol), water (20mL) and di Oxyhexane (50mL) was mixed, under the protection of nitrogen, reflux reaction at 25°C for 24h, cooled after the reaction, adjusted the pH to 2-3 with 3% acetic acid, extracted with ethyl acetate (3×20mL), evaporated solvent, to obtain the compound 3g of the crude product; mix the above crude product with 50mL polyphosphoric acid, react at 210°C for 5h, cool after the reaction, add 50mL of ice water, adjust the pH>7 with NaOH solution (1mol / L), and use ethyl acetate Extraction (3 × 20mL), ev...

Embodiment 6-10

[0081] Embodiments 6-10 provide iridium-based organic electrophosphorescent materials (referred to as Ir-6 to Ir-10 in sequence) with the structure of formula I, and their structural formulas are as follows:

[0082]

[0083] Taking Ir-8 as an example, its preparation method is as follows:

[0084] (1) Compounds are prepared according to the preparation method of Ir-3

[0085] (2) Compound (6.62g, 30.0mmol), IrCl 3 ·H 2 O (3.7g, 10mmol), water (30mL) and 2-ethoxyethanol (90mL) were mixed, under the protection of nitrogen, reflux reaction at 120°C for 12h, the reaction formula is as follows:

[0086]

[0087] After the reaction was completed, it was filtered, washed with methanol (3×20 mL), and dried in vacuo to obtain a dimer compound;

[0088] (3) Dimer compound (9g, 10mmol) that acetylacetone (10g, 100mmol), step (2) obtains, sodium carbonate (10.6g, 100mmol) and 2-ethoxyethanol (200mL) are mixed, in 25 Reaction at ℃ for 24h, the reaction formula is as follows:...

Embodiment 11-16

[0094] Embodiments 11-16 provide iridium-based organic electrophosphorescent materials (referred to as Ir-11 to Ir-16 in sequence) having the structure of formula II, and their structural formulas are as follows:

[0095]

[0096] Taking Ir-16 as an example, its preparation method is as follows:

[0097] (1) compound (2.5g, 10mmol), phenylboronic acid (1.8g, 15mmol), potassium carbonate (5g, 50mmol), triphenylphosphine (15g, 50mmol), palladium acetate (0.15g, 0.62mmol), water (20mL) and di Oxyhexane (50mL) was mixed, under the protection of nitrogen, reflux reaction at 25°C for 24h, cooled after the reaction, adjusted the pH to 2-3 with 3% acetic acid, extracted with ethyl acetate (3×20mL), evaporated solvent, to obtain the compound 3g of the crude product; mix the above crude product with 50mL polyphosphoric acid, react at 210°C for 5h, cool after the reaction, add 50mL of ice water, adjust the pH>7 with NaOH solution (1mol / L), and use ethyl acetate Extraction (3 × ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com