Application of polymer and photoresist containing polymer

A polymer and photoresist technology, applied in the field of environmentally friendly materials, to avoid secondary pollution and easy sublimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: Preparation of PDDA film and complete degradation in natural environment

[0064] (1) Synthesis of polymer PDDA

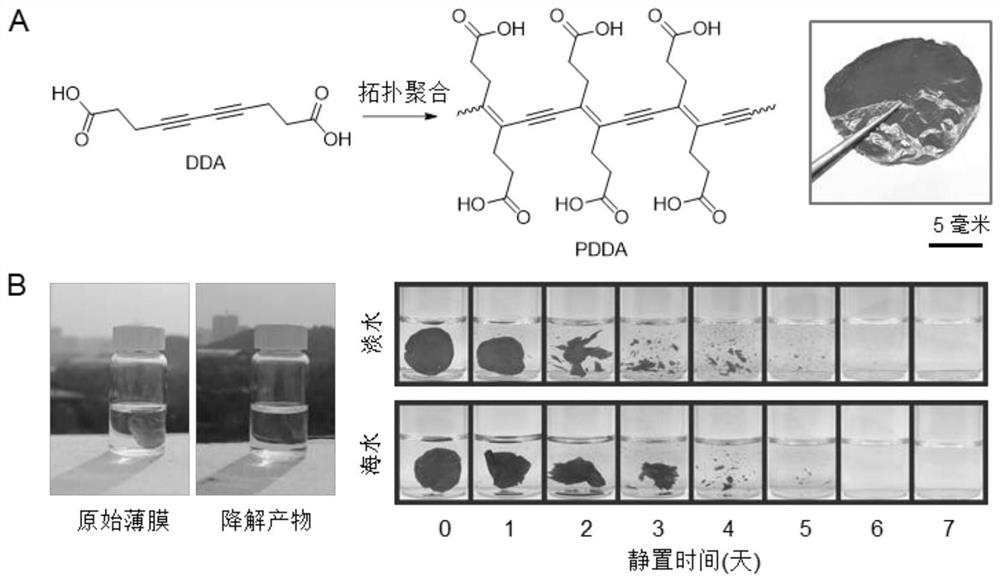

[0065] PDDA is synthesized by host-guest topochemical polymerization using the monomer deca-4,6-diynediic acid (DDA) as the raw material and the guest N,N'-bis(pyridin-4-ylmethyl)ethanediamide as the eutectic scaffold ( figure 1 in A).

[0066] (2) Preparation of PDDA film

[0067] Preparation of PDDA film by solution casting method: PDDA dispersed in deionized water, methanol, ethanol or other commonly used low boiling point solvents is deposited on the nylon membrane, and peeled off from the nylon membrane after drying. The PDDA film is dark red in color and exhibits a highly π-conjugated framework feature ( figure 1 in A). The PDDA thin film remains stable in the dark or under nitrogen conditions, which ensures its good stability as a functional material.

[0068] (3) PDDA is completely degraded in the natural environment

[0069] In t...

Embodiment 2

[0072] Example 2: PDDA microparticles are completely degraded in the natural environment

[0073] (1) The color and Tyndall dispersion effect of PDDA microparticle dispersion completely disappear in natural light

[0074] Of particular concern among plastic pollution are microplastics, which have the potential to enter natural ecosystems from various sources and eventually accumulate in the food chain. In order to ensure that microplastics will not accumulate during the PDDA fragmentation and degradation process, the present invention also detects the degradability of PDDA microparticles (MPs). Such as Figure 4 As shown in A, when the deionized water dispersion of PDDA MPs was exposed to outdoor natural light, the red color of the dispersion and the Tyndall scattering effect disappeared rapidly within 30 minutes; and after the same time in the dark, the dispersion The color and Tyndall effects remain unchanged. The reduction of laser light scattering intensity of PDDA MPs ...

Embodiment 3

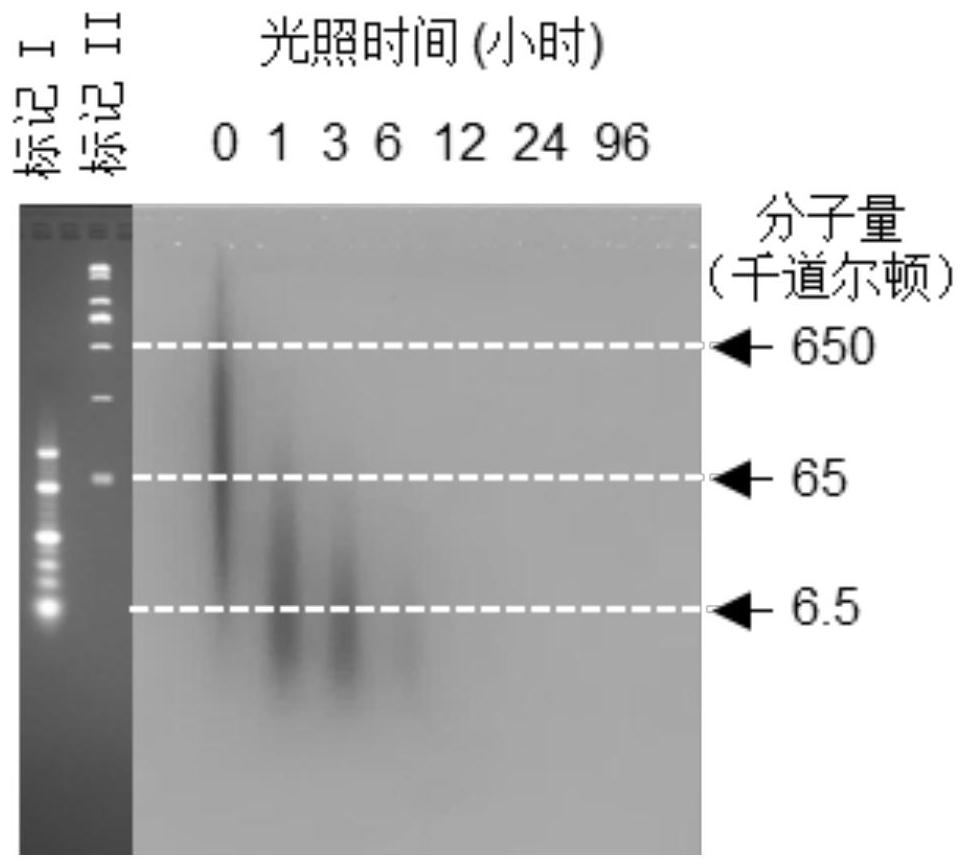

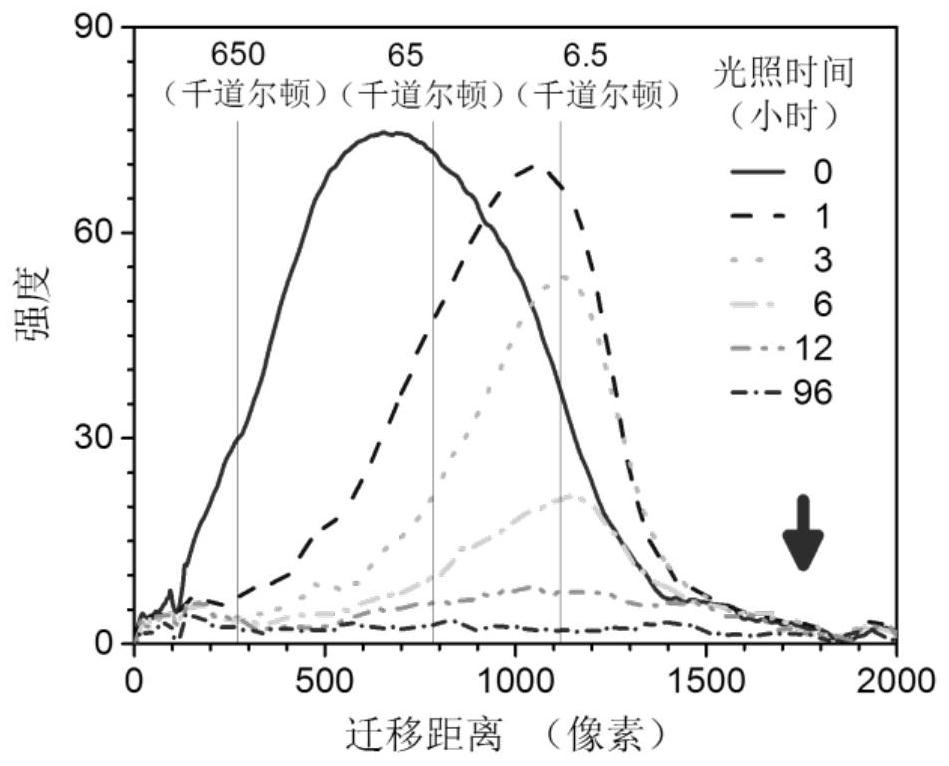

[0077] Embodiment 3: Characterization of PDDA degradation products

[0078] After the PDDA film or solid dispersion was exposed to light in the outdoor natural environment for a week, the degraded mixed crude product was not separated and purified. After lyophilization, it was re-dissolved in deuterated water, and the pH was adjusted to 8 with NaOH. Resonance carbon spectrum, high resolution mass spectrometry, high performance liquid chromatography-mass spectrometry detection. Such as Figure 5As shown in A, there is no residual PDDA signal peak on the H NMR spectrum of the crude product, but a sharp single peak at 2.41ppm appears, which is consistent with the H NMR spectrum of small molecule succinic acid. Such as Figure 5 As shown in B, the carbon NMR spectrum of the crude product is also consistent with the carbon NMR spectrum of succinic acid, and the carbon spectrum peaks associated with the sp and sp2 carbons of PDDA also disappear accordingly, indicating that all C o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com