Experimental facility capable of implementing visualization of condensation of inside and outside of steam tube

An experimental device and steam tube technology, which is applied in the field of condensation heat transfer experiments, can solve the problems of inability to conduct condensation experiments in the tube and inability to conduct condensation experiments outside the tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

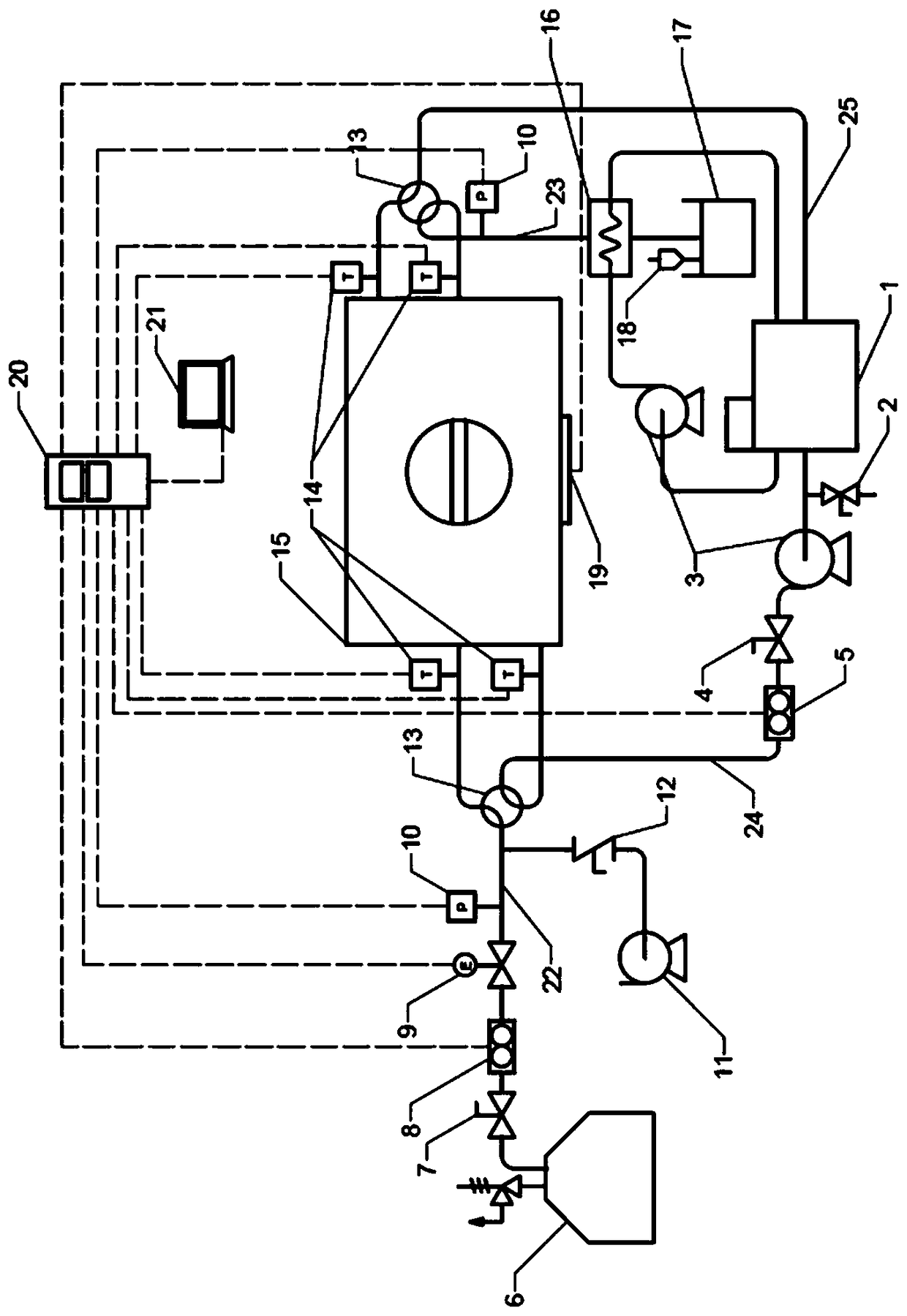

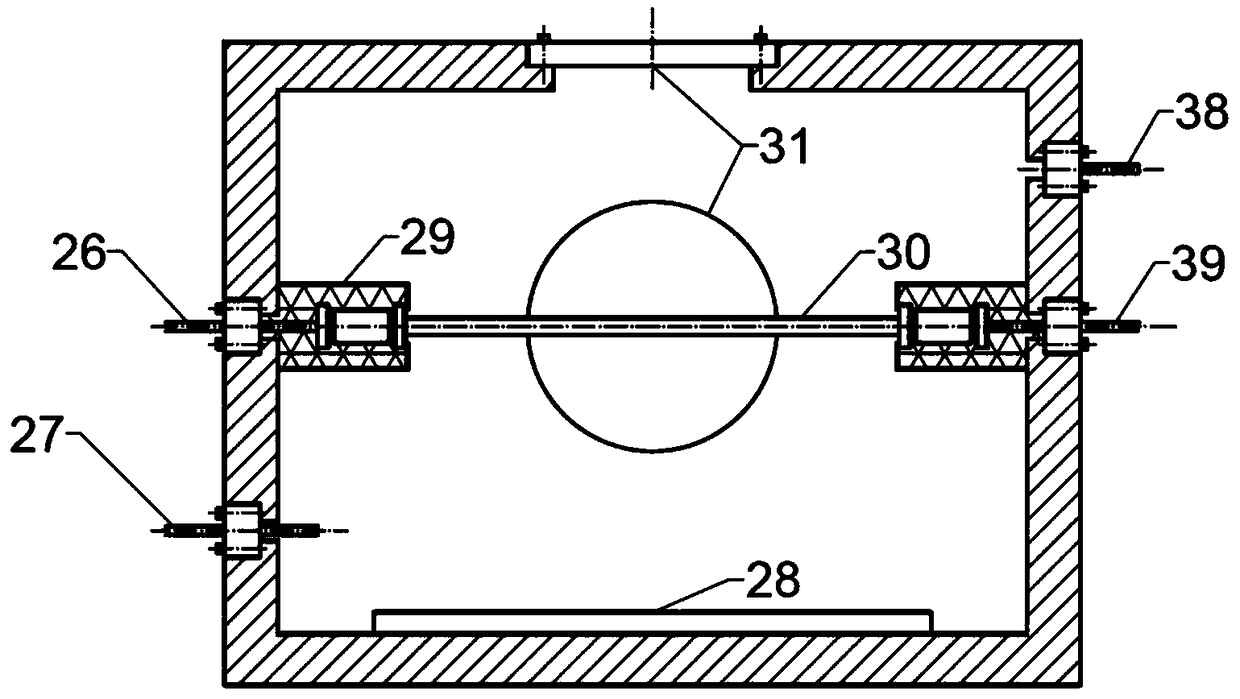

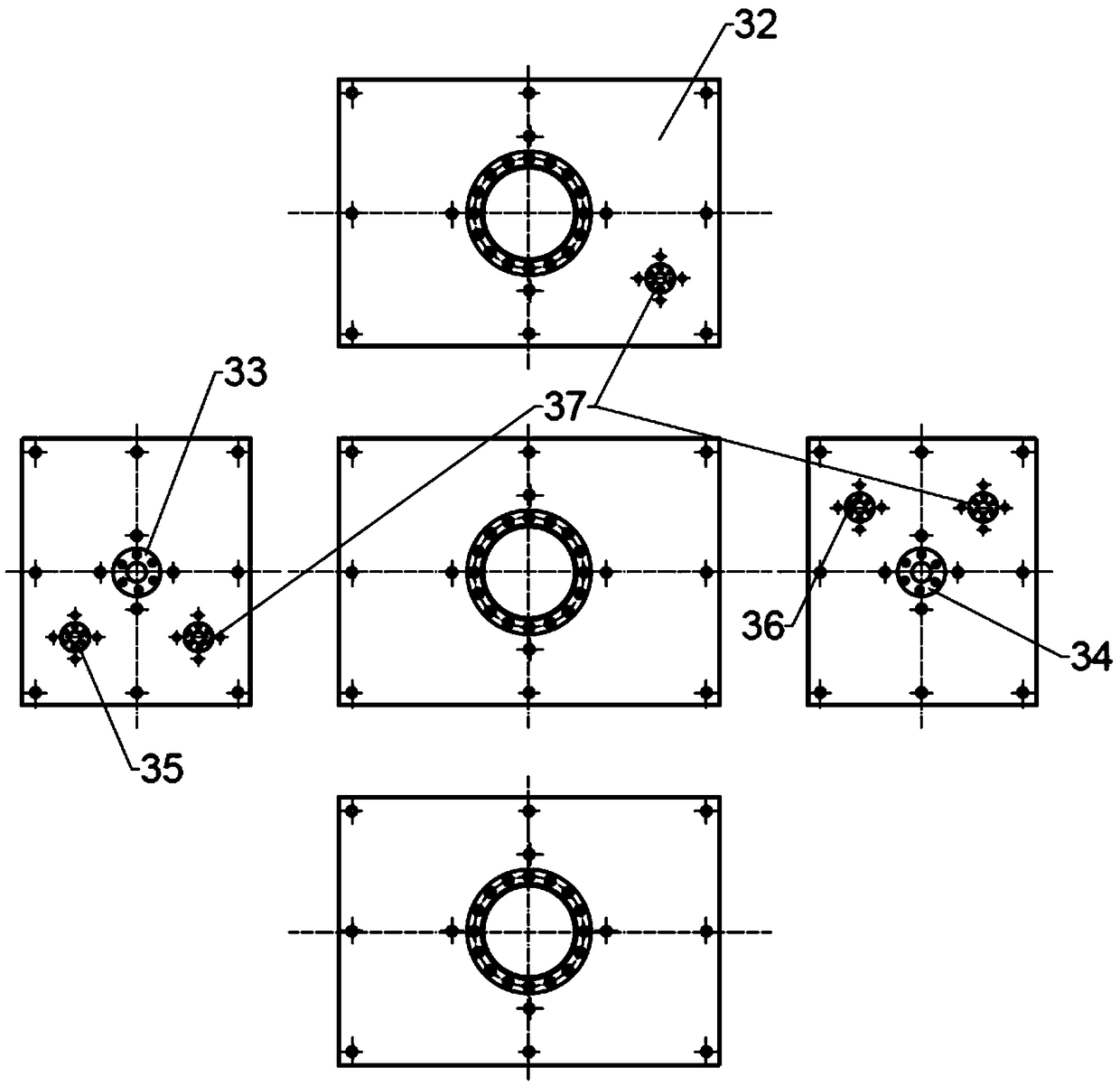

[0025] It mainly includes steam supply system, cooling water system, vacuum system, visual experiment body and data acquisition system.

[0026] In the steam supply system, the steam generator 6 generates steam, the initial steam flow is controlled by the steam flow regulating valve 7, and the vortex flowmeter 8 records the cumulative flow and the instantaneous flow. An electric valve 9 is installed on the gas supply main pipe, which can adjust its opening according to the negative feedback of the set condensing pressure to control the steam flow. When carrying out the in-pipe condensation experiment, switch the two four-way valves 13 so that the main air supply pipe 22 and the main exhaust pipe 23 are connected to the experimental pipe section 30 , and the main water supply pipe 24 and the main return water pipe 25 are connected to the vacuum cavity 15 . When carryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com