Device and method for detecting dynamic solidification sound field of metal material under vibration condition

A metal material and detection device technology, applied in the field of measurement, to achieve temperature protection, simple method steps, and prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

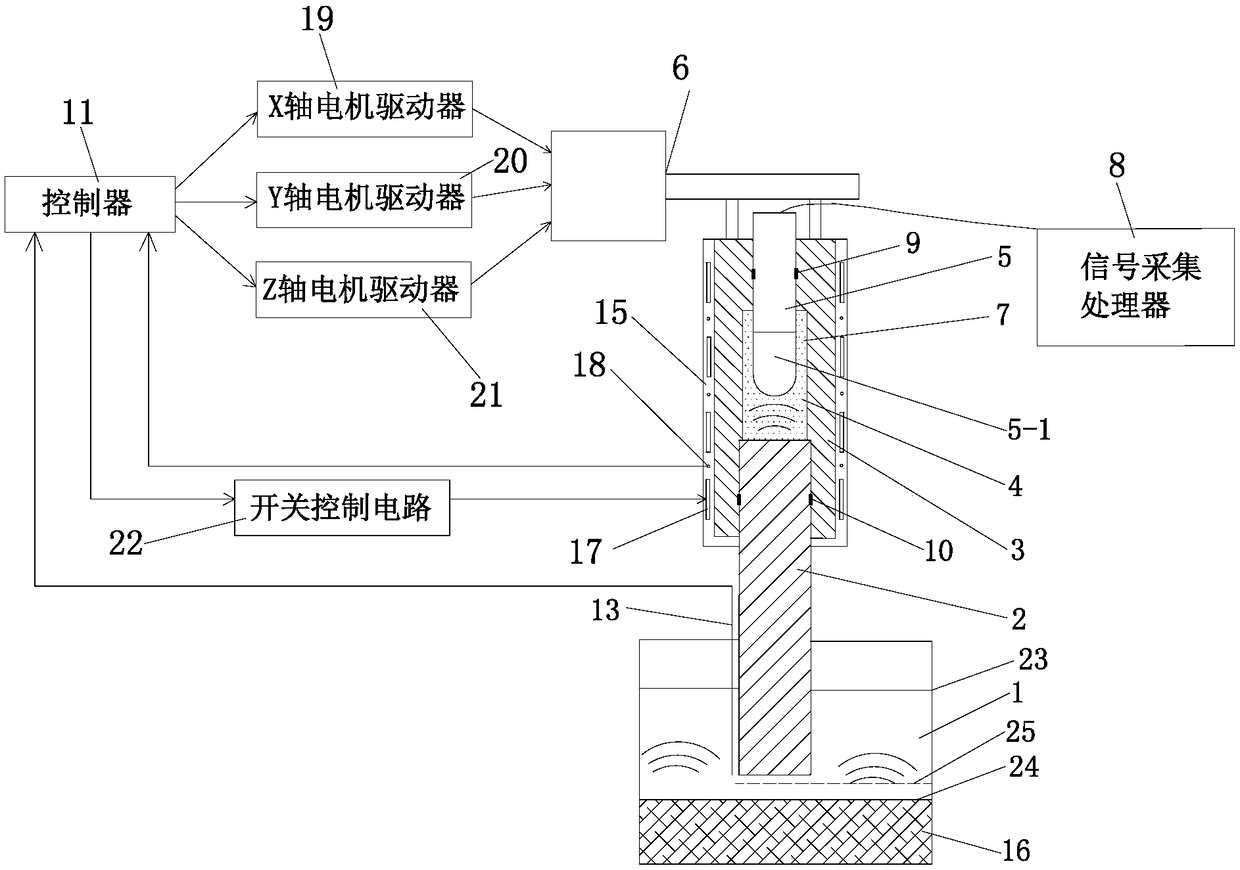

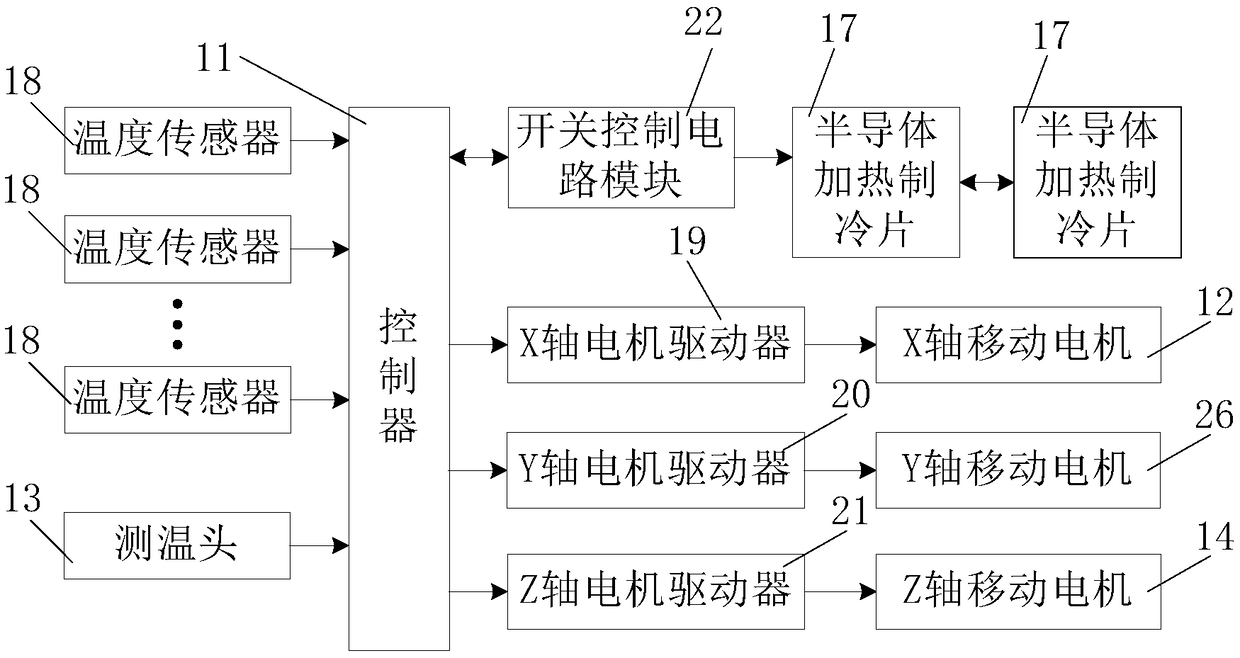

[0042] Such as figure 1 with figure 2 As shown, the metal material dynamic solidification sound field detection device under the vibration condition of the present invention includes a high temperature sound field detection sensor, a three-axis electric displacement platform 6, a controller 11 and a signal acquisition processor 8, and the high temperature sound field detection sensor includes a hydrophone 5 and the waveguide rod 2 used to extend into the high-temperature liquid phase 1 of the metal material, and the couplant sleeve 3 whose upper part is set on the hydrophone 5 and whose lower part is set on the waveguide rod 2, the couplant sleeve 3 The middle space is a couplant cavity 7 filled with an acoustic couplant 4, the inductive element 5-1 of the hydrophone 5 is set in the acoustic couplant 4; the couplant sleeve 3 is hoisted At the bottom of the three-axis electric displacement platform 6, the three-axis electric displacement platform 6 includes an X-axis moving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com