Siphon type cultivation method

A medium and culture medium technology, applied in general culture methods, tissue culture, cell culture supports/coatings, etc., can solve the problems of upper limit of cell density and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

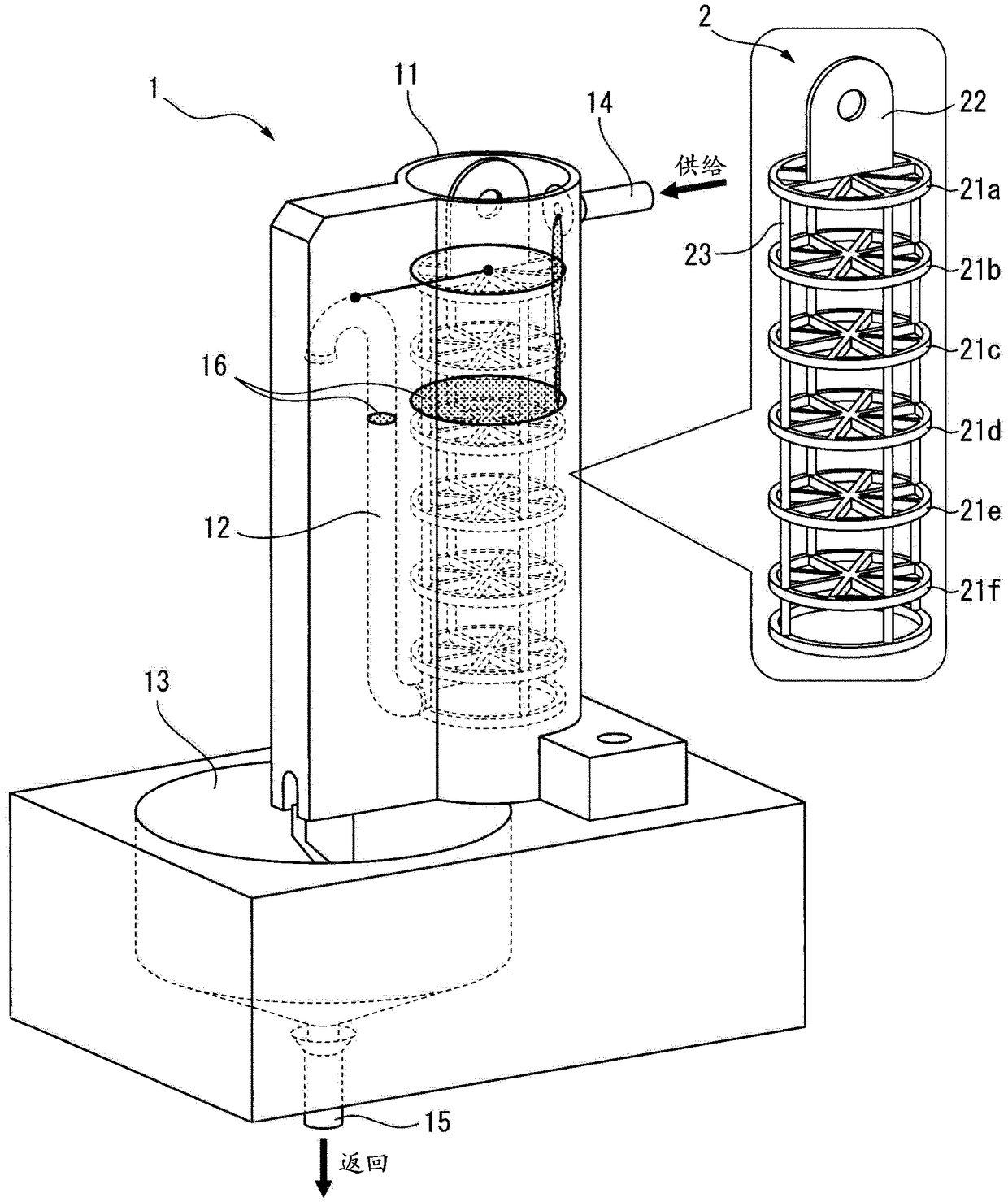

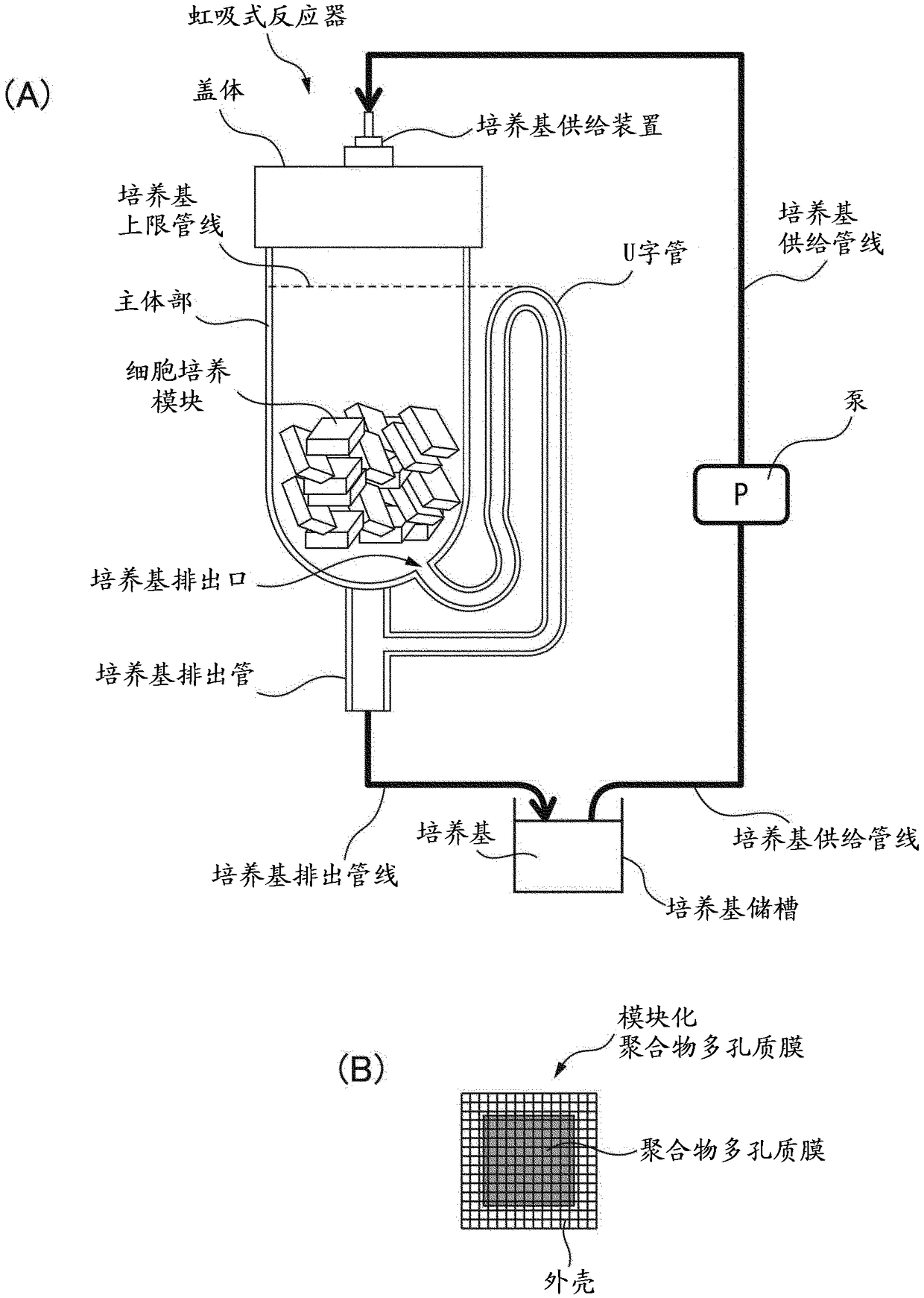

[0227] Cell Culture Method Using Porous Polyimide Membrane Using Siphon Reactor (Part 1)

[0228] The acclimatized and suspended cells of CHO-DP12 cells (ATCC CRL-12445) producing anti-human IL-8 antibody were suspended and cultured in medium (BalanCD (trademark) CHO GROWTH A), and the culture was continued until the number of viable cells per 1 ml was 3.9×10 6 . Inject 12ml of the above-mentioned suspension culture solution into a petri dish with a diameter of 10cm, and then use a nylon mesh (30#, mesh 547μm) to form a coat (shell), and add a certain amount (20cm per module) to the petri dish. 2 12 modules of the sterilized polyimide porous membrane. After wetting the module with the cell suspension, the 2 Let stand overnight in the incubator.

[0229] On day 2, remove the module and place in figure 1 The shown siphon reactor was provided with 10 modules in the step section, and 350 ml of medium (IMDM containing 2% FBS) was stored in the reservoir, and the medium was cir...

Embodiment 2

[0231] Cell Culture Method Using Porous Polyimide Membrane Using Siphon Reactor (Part 2)

[0232] The acclimatized and suspended cells of CHO-DP12 cells (ATCC CRL-12445) producing anti-human IL-8 antibody were suspended and cultured in medium (BalanCD (trademark) CHO GROWTH A), and the culture was continued until the number of viable cells per 1 ml was 9.9×10 6 . Load 10 modules into an oxygen permeable bag for shaking culture in CO 2 Shaking culture was carried out in the incubator overnight. On the second day, the module was taken out from the shaking bag, and under the same conditions as in Example 1, the cells were cultured in a siphon reactor. 350 ml of a culture medium (KBM270 manufactured by Cogent Bio) was stored in the reservoir, and the culture medium was circulated at a rate of 60 ml / min via a tube pump. After 4 days, the culture ended, at which time it was observed that the cell density was 1.0×10 5 cells / cm 2 , the total number of cells is 2.1×10 7 cells. ...

Embodiment 3

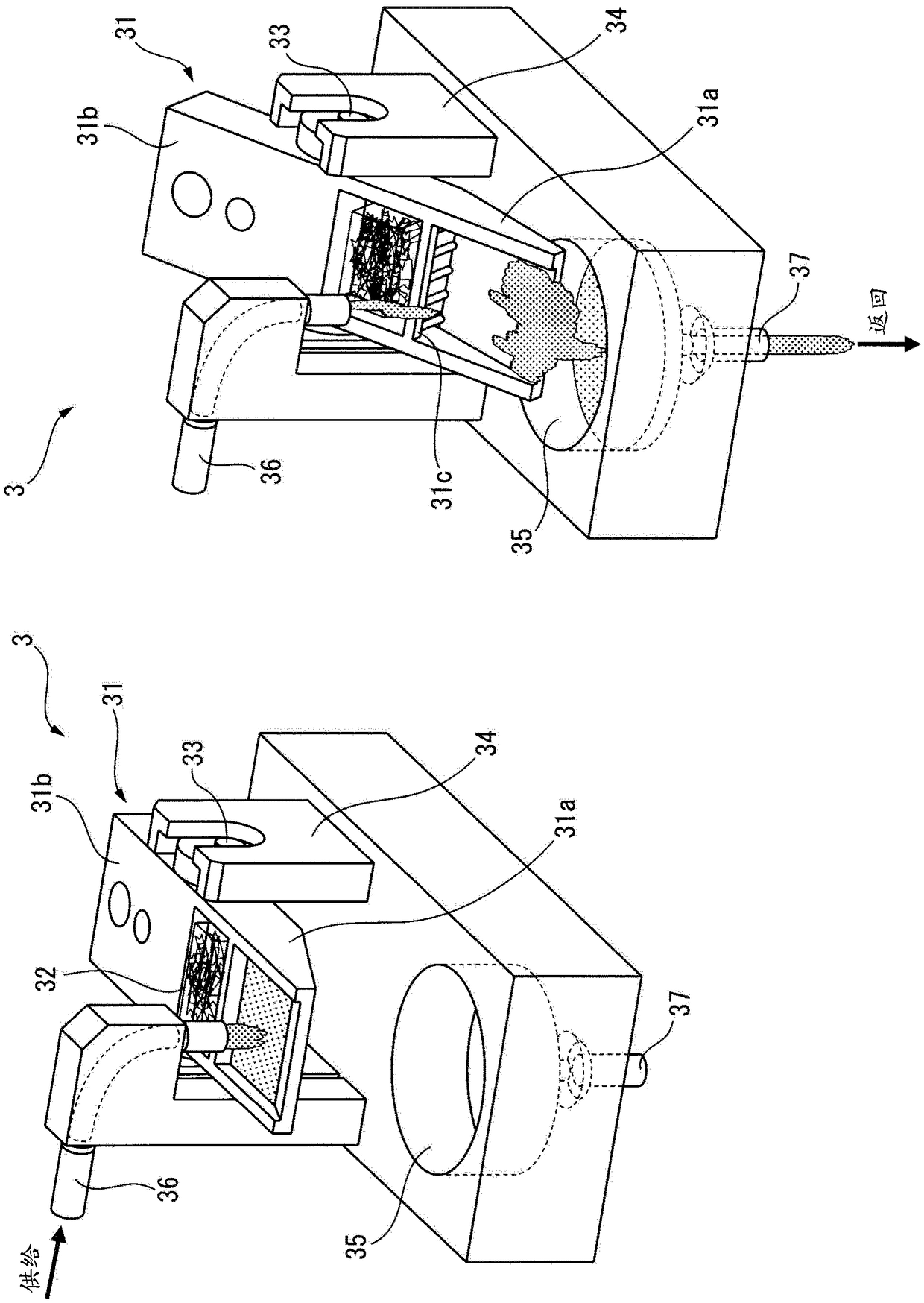

[0234] Metal modules and glass heat-resistant siphon reactors

[0235] The heat resistance of the polyimide porous membrane should be utilized to the maximum, and the sterilization operation should be completed by simple overall dry heat sterilization, and the outer shell, the lining and the polyimide porous membrane made of stainless steel mesh should be produced Consists of metal modules (see image 3 One embodiment of (B)). Specifically, a 1 cm × 1 cm porous polyimide membrane and a stainless steel mesh having the same area as the porous polyimide membrane (called "interlining", not shown) are laminated (according to Porous Polyimide 3 Sheets, 1 sheet of lining, 4 sheets of porous polyimide, 1 sheet of lining, and 3 sheets of porous polyimide were stacked in this order), and the laminated product was sealed with a stainless steel mesh casing to produce a metal module. Work can be performed non-sterile in an open space.

[0236] The heat-resistant siphon reactor made of g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com