Method of Improving Low Temperature Toughness of Materials Based on tscr Dynamic Variation Rules

A low-temperature toughness and variable-schedule technology, applied in temperature control, manufacturing tools, metal rolling, etc., can solve problems such as brittle fracture and high-strength strips that cannot be fully utilized, so as to promote transformation, shorten product production cycle, and promote The effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

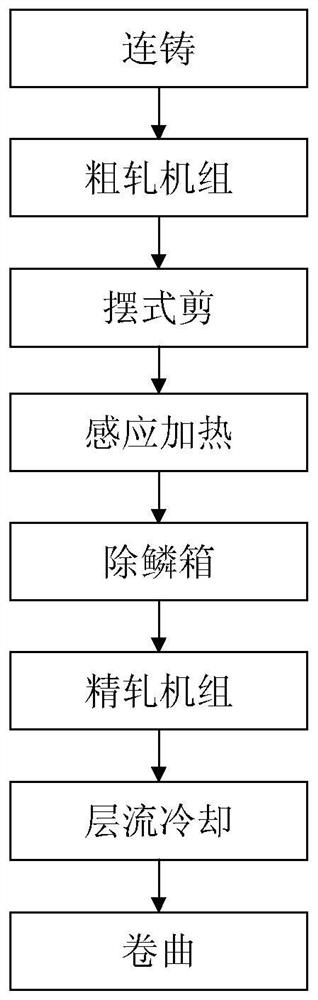

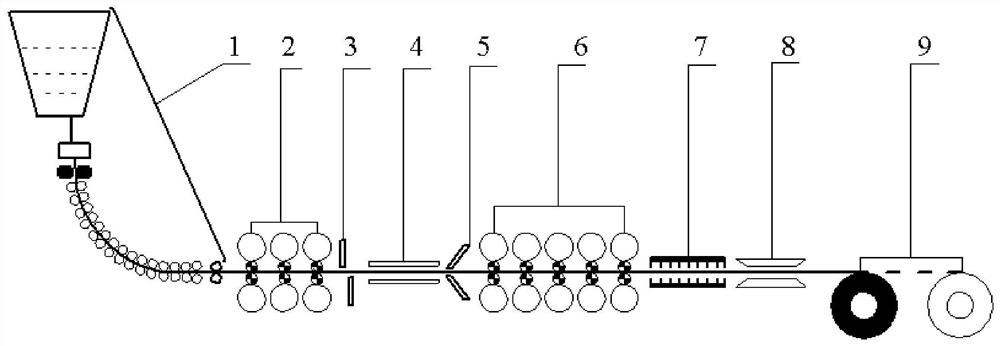

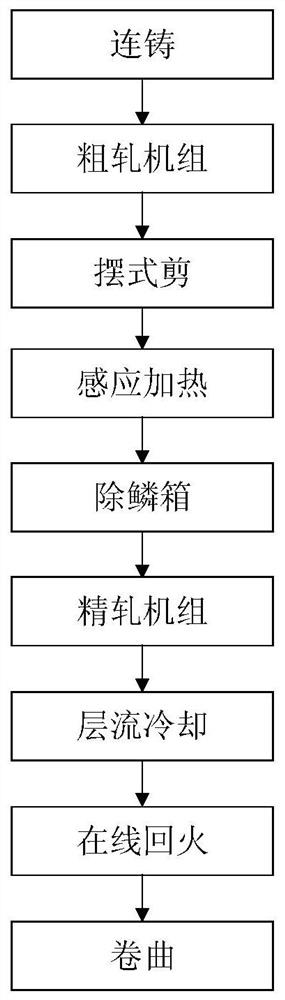

[0032] The temperature process is as Figure 4 shown. The exit temperature of continuous casting is 1500°C, the exit temperature of the strip passing through the third stand of the rough rolling unit is 950°C, the temperature is raised to 1150°C by induction heating, and the strip is rolled by the five-stand finish rolling unit, and finally the strip is passed through the finish rolling unit The temperature of the final stand is 850°C, and the laminar cooling temperature drops to 200°C. When the rolls of a certain stand of the finishing mill are seriously worn and need to be replaced, the finishing mill is in the process of "5-1" dynamic change schedule. After the process, Turn on the online tempering, the roll changing mill will directly exit the rolling and carry out online non-stop roll changing, the finishing rolling unit will change from the original five-stand finishing rolling unit to a four-stand finishing rolling unit, and the online tempering treatment will be carrie...

Embodiment

[0036] A method for improving the low-temperature toughness of materials based on TSCR dynamic variable rules. After continuous casting of strips at 1500°C, the exit temperature of the strips after passing through the third stand of the roughing mill is 950°C. The final stand temperature of the finishing mill is 850°C, and the laminar cooling temperature drops to 200°C. When a roll of a stand of the finishing mill is severely worn and needs to be replaced, the finishing mill will carry out During the "5-1" dynamic schedule change process, after the process, the online tempering is turned on, the roll changing mill directly exits rolling and performs online non-stop roll changing, and the finishing rolling unit is changed from the original five-stand finishing rolling unit to four. The rack finishing unit is subjected to on-line tempering treatment, the on-line tempering temperature is raised to 620°C, kept for 40s, and then air-cooled for crimping.

[0037] The exit temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com