Manipulator servo control method, system and device based on screw theory

A servo control and robotic arm technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of slow response, large computational load, and slow action of manipulators, achieving good real-time performance, small calculation amount, and avoiding repetitive The effect of solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

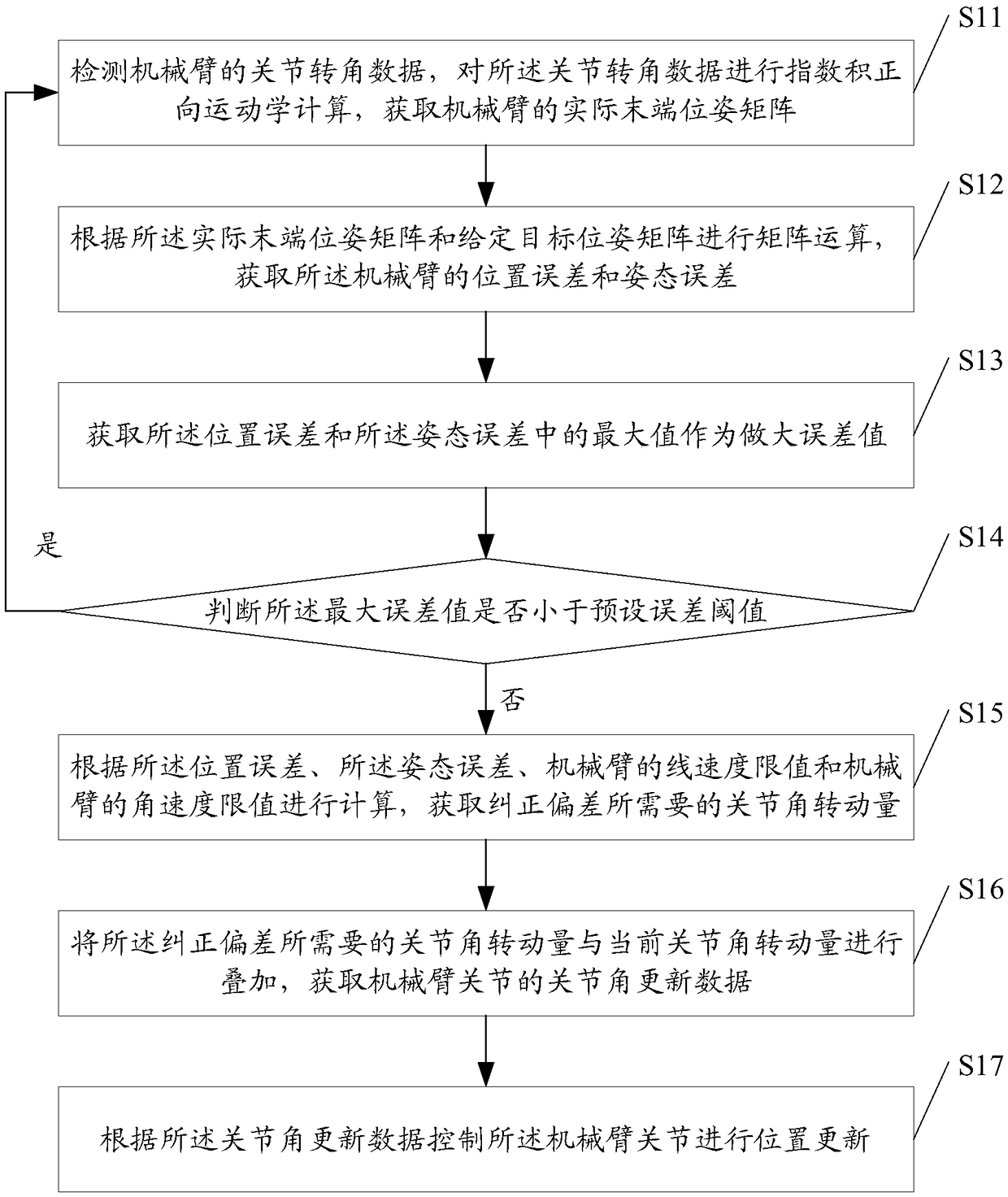

[0064] see figure 1 , figure 1 It is a schematic flow chart of the servo control method of the mechanical arm based on the helix theory in the embodiment of the present invention.

[0065] Such as figure 1 Shown, a kind of mechanical arm servo control method based on spiral theory, described mechanical arm servo control method comprises:

[0066] S11: Detect the joint rotation angle data of the mechanical arm, perform exponential product forward kinematics calculation on the joint rotation angle data, and obtain the actual end pose matrix of the mechanical arm;

[0067] In the specific implementation process of the present invention, the detection of the joint rotation angle data of the mechanical arm, the exponential product forward kinematics calculation is performed on the joint rotation angle data, and the actual terminal pose of the mechanical arm is obtained, including: using the motor shaft installed on the joint The photoelectric encoder on the upper part detects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com