Radiation-resistant, anti-static and thermal insulation coated glass and preparation method thereof

A coated glass and antistatic technology, applied in the direction of coating, etc., can solve the problems of vehicle occupant skin burns, increased energy consumption of vehicle air conditioners, and elevated temperature inside the vehicle, to achieve static suppression, strong film adhesion, and improved bonding intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

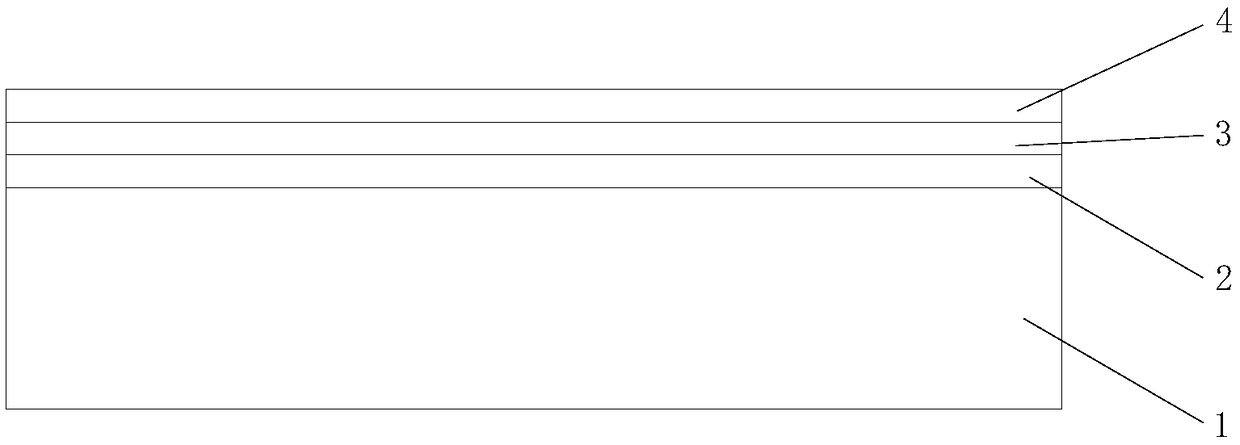

[0023] Embodiment 1: the glass preparation method of the present invention comprises the following steps:

[0024] 1) Select a substrate with a thickness of 3-9mm, and clean the substrate with a cleaning machine;

[0025] 2) Inner layer: Send the substrate into the coating chamber, magnetron sputtering SiO 2 Layer, with DC power supply, Ar gas, O 2 As shielding gas, magnetron sputtering Si target, Si target current 4A, Ar gas flow and O 2 Gas flow 400SCCM: 200SCCM, sputtering on the substrate to form SiO with a thickness of 100-150nm 2 Floor;

[0026] 3) Intermediate layer: Continue magnetron sputtering SiO 2 +ZnO layer, using DC power supply, Ar gas, O2 as protective gas, magnetron sputtering Zn target and Si target, Zn target current 4A, Si target current 4A, Ar gas flow and O 2 Gas flow 400SCCM: 200SCCM, sputtering to form SiO with a thickness of 20nm 2 + ZnO layer;

[0027] 4) Outer layer: Continue magnetron sputtering ZnO layer, use DC power supply, Ar gas, O2 as p...

Embodiment 2

[0028] Embodiment 2: the glass preparation method of the present invention comprises the following steps:

[0029] 1) Select a substrate with a thickness of 3mm, and clean the substrate with a cleaning machine;

[0030] 2) Inner layer: Send the substrate into the coating chamber, magnetron sputtering SiO 2 Layer, with DC power supply, Ar gas, O 2 As shielding gas, magnetron sputtering Si target, Si target current 6A, Ar gas flow and O 2 Gas flow 600SCCM: 300SCCM, sputtering SiO with a thickness of 130nm on the substrate 2 Floor;

[0031] 3) Intermediate layer: Continue magnetron sputtering SiO 2 +ZnO layer, use DC power supply, Ar gas, O2 as protective gas, magnetron sputtering Zn target and Si target, Zn target current 6A, Si target current 6A, Ar gas flow and O 2 Gas flow 600SCCM: 300SCCM, sputtering to form SiO with a thickness of 30nm 2 + ZnO layer;

[0032] 4) Outer layer: Continue magnetron sputtering ZnO layer, use DC power supply, Ar gas, O2 as protective gas, m...

Embodiment 3

[0033] Embodiment 3: the glass preparation method of the present invention comprises the following steps:

[0034] 1) Select a substrate with a thickness of 9mm, and clean the substrate with a cleaning machine;

[0035] 2) Inner layer: Send the substrate into the coating chamber, magnetron sputtering SiO 2 Layer, with DC power supply, Ar gas, O 2 As shielding gas, magnetron sputtering Si target, Si target current 8A, Ar gas flow and O 2 Gas flow 800SCCM: 400SCCM, sputtering SiO with a thickness of 150nm on the substrate 2 Floor;

[0036] 3) Intermediate layer: Continue magnetron sputtering SiO 2 +ZnO layer, using DC power supply, Ar gas, O2 as protective gas, magnetron sputtering Zn target and Si target, Zn target current 8A, Si target current 8A, Ar gas flow and O 2 Gas flow 800SCCM: 400SCCM, sputtering to form SiO with a thickness of 50nm 2 + ZnO layer;

[0037] 4) Outer layer: Continue magnetron sputtering ZnO layer, use DC power supply, Ar gas, O2 as protective gas,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com