Liquid surface conditioning agent and preparation method thereof

A liquid surface and adjusting agent technology, applied in the direction of metal material coating process, etc., can solve the problems of easy coagulation of suspension, short storage period, low concentration of effective colloidal titanium salt, etc. The effect of adhesion and coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

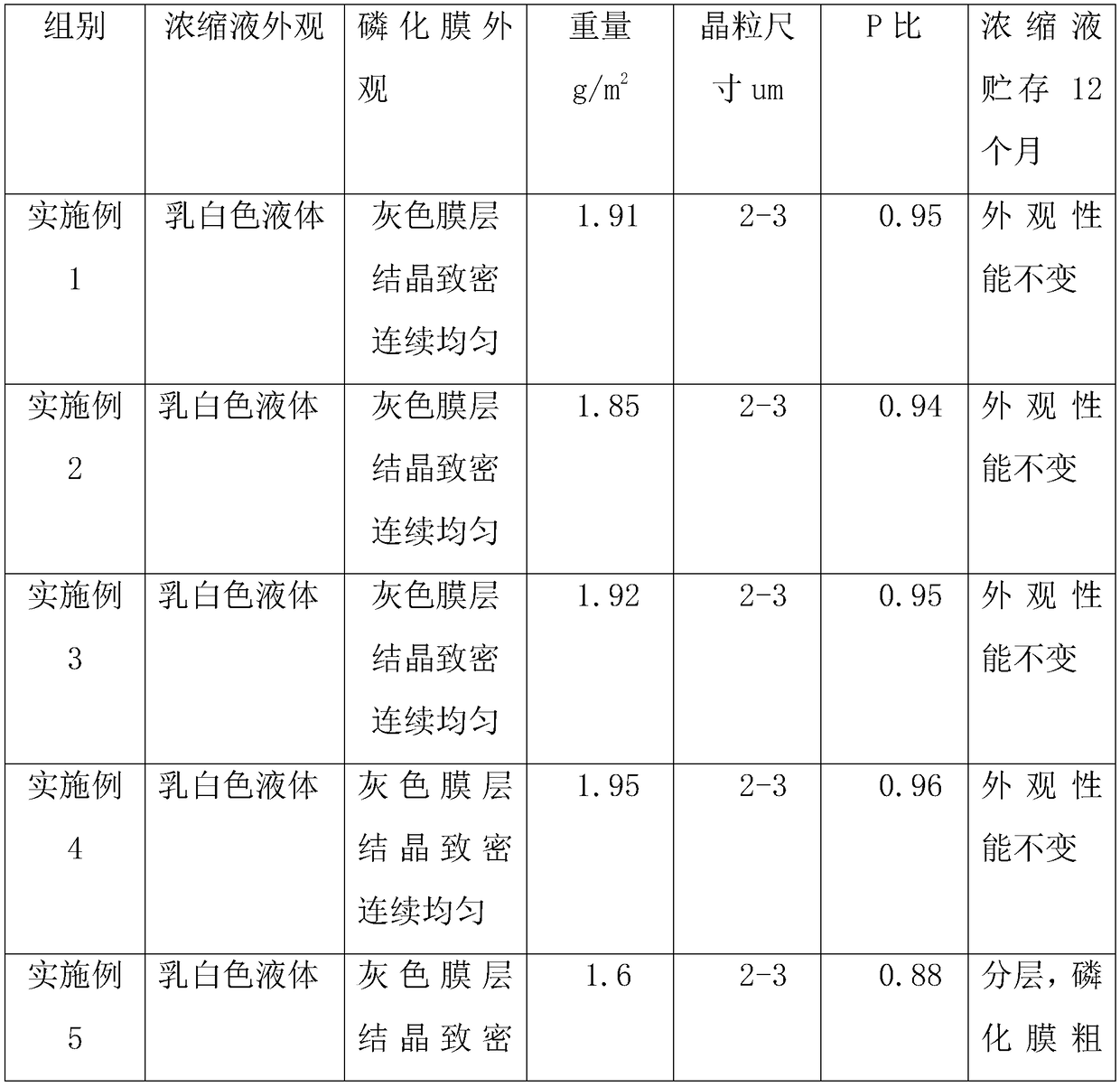

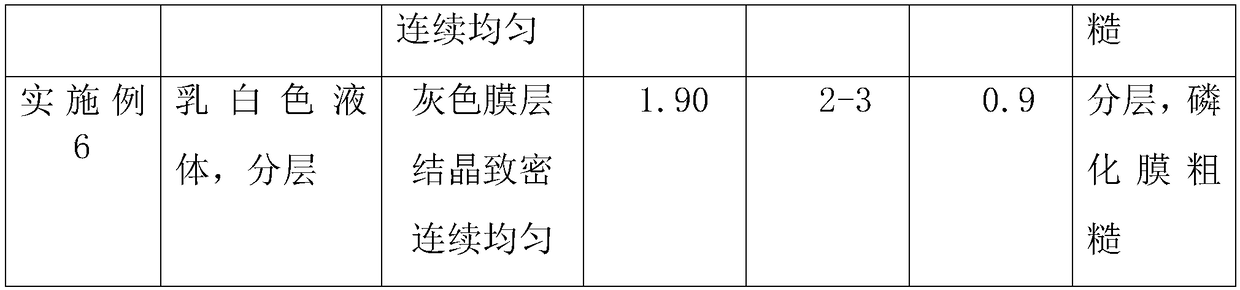

Examples

Embodiment 1

[0021] A preparation method of a liquid surface conditioner, each component of the liquid surface conditioner is calculated by mass percentage, comprising the following steps:

[0022] Step 1, the 10% phosphopeptide compound, 5% sodium tripolyphosphate, 5% sodium pyrophosphate, 25% potassium phosphate, 1% polyoxyethylene ether, 1% N-lauroyl sarcosine were added to 47 % of purified water, then add 1% sodium hydroxide and 5% potassium hydroxide to adjust the pH value of the mixed solution to 8.0;

[0023] Step 2, at room temperature, disperse and stir at high speed for 30 minutes to obtain the concentrated solution of the liquid surface modifier;

[0024] Step 3, take 3-5 g of the concentrated solution of the liquid surface regulator described in step 2, and dissolve it in 1000 mL of purified water to obtain the liquid surface regulator;

[0025] The use method of the present invention includes the following steps: after the liquid surface conditioner is diluted, the concentrat...

Embodiment 2

[0027] A preparation method of a liquid surface conditioner, each component of the liquid surface conditioner is calculated by mass percentage, comprising the following steps:

[0028] Step 1, the 15% phosphopeptide compound, 5% sodium tripolyphosphate, 5% sodium pyrophosphate, 30% potassium phosphate, 1% polyoxyethylene ether, 1% N-lauroyl-N-hydroxyethylglycine Sequentially add to 47% purified water, then add 1% sodium hydroxide and 5% potassium hydroxide to adjust the pH value of the mixed solution to 9.0;

[0029] Step 2, at room temperature, disperse and stir at high speed for 30 minutes to obtain the concentrated solution of the liquid surface modifier;

[0030] Step 3, take 3-5 g of the concentrated solution of the liquid surface regulator described in step 2, and dissolve it in 1000 mL of purified water to obtain the liquid surface regulator;

[0031] The use method of the present invention includes the following steps: after the liquid surface conditioner is diluted, ...

Embodiment 3

[0033] A preparation method of a liquid surface conditioner, each component of the liquid surface conditioner is calculated by mass percentage, comprising the following steps:

[0034] Step 1, the 10% phosphopeptide compound, 5% sodium tripolyphosphate, 5% sodium pyrophosphate, 25% potassium phosphate, 1% polyoxyethylene ether, 1% N-alkylsulfonic acid acylglycine were added to 47% purified water, then add 1% sodium hydroxide and 5% potassium hydroxide to adjust the pH value of the mixed solution to 10.0;

[0035] Step 2, at room temperature, disperse and stir at high speed for 30 minutes to obtain the concentrated solution of the liquid surface modifier;

[0036] Step 3, take 3-5 g of the concentrated solution of the liquid surface regulator described in step 2, and dissolve it in 1000 mL of purified water to obtain the liquid surface regulator;

[0037] The use method of the present invention includes the following steps: after the liquid surface conditioner is diluted, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com