Liquid air separation device and method for extracting medium pressure oxygen

An oxygen and liquid technology, applied in the field of air rectification, can solve the problems of multiple expanders, low utilization rate, difficult operation, etc., and achieve the effects of low operating energy consumption, energy saving, and reasonable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be further described in conjunction with the accompanying drawings of the specification, but the present invention is not limited to the following embodiments.

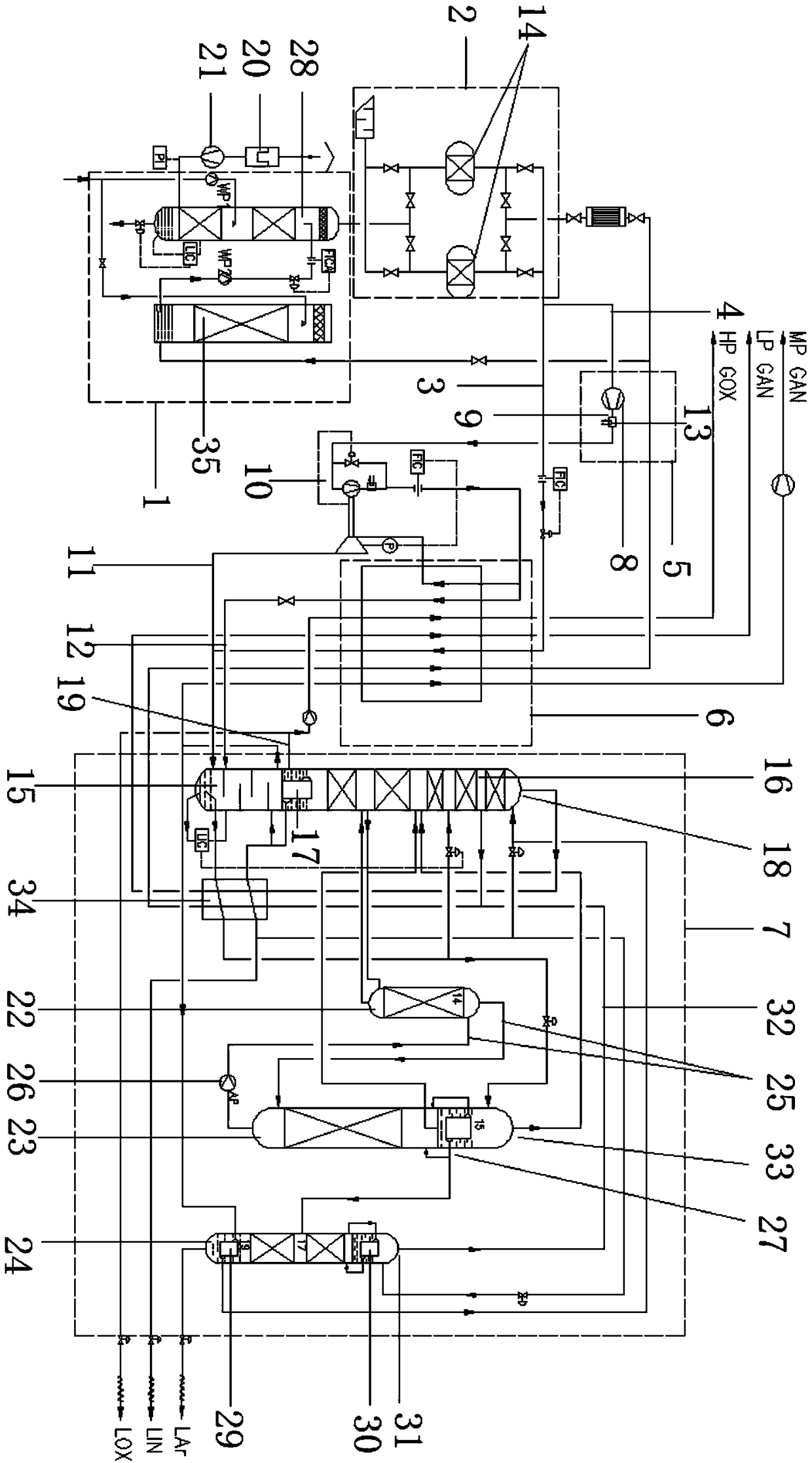

[0025] Such as figure 1 Shown is a specific embodiment of a liquid air separation device for extracting medium-pressure oxygen, including an air compression system, a pre-cooling system 1, and a purification system 2, which are connected to each other with a DC channel 3 and a pressurization channel. 4. The instrument air supply channel, in which the pressurization channel 4 is connected to the pressurization system 5 and the heat exchange system 6 in turn, the DC channel 3 is directly connected to the heat exchange system 6, and the heat exchange system 6 is connected to the rectification system via several pipelines 7. The air in the instrument air supply channel is used as the instrument air source, which improves the utilization rate and saves costs. The raw material air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com