Instrument and method for detecting LED chip

A technology of LED chips and detectors, which is applied in the direction of instrumentation, optical instrument testing, and electrical measurement, and can solve problems such as inaccurate testing, inability to accurately collect optical signals of the tested chip, and mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

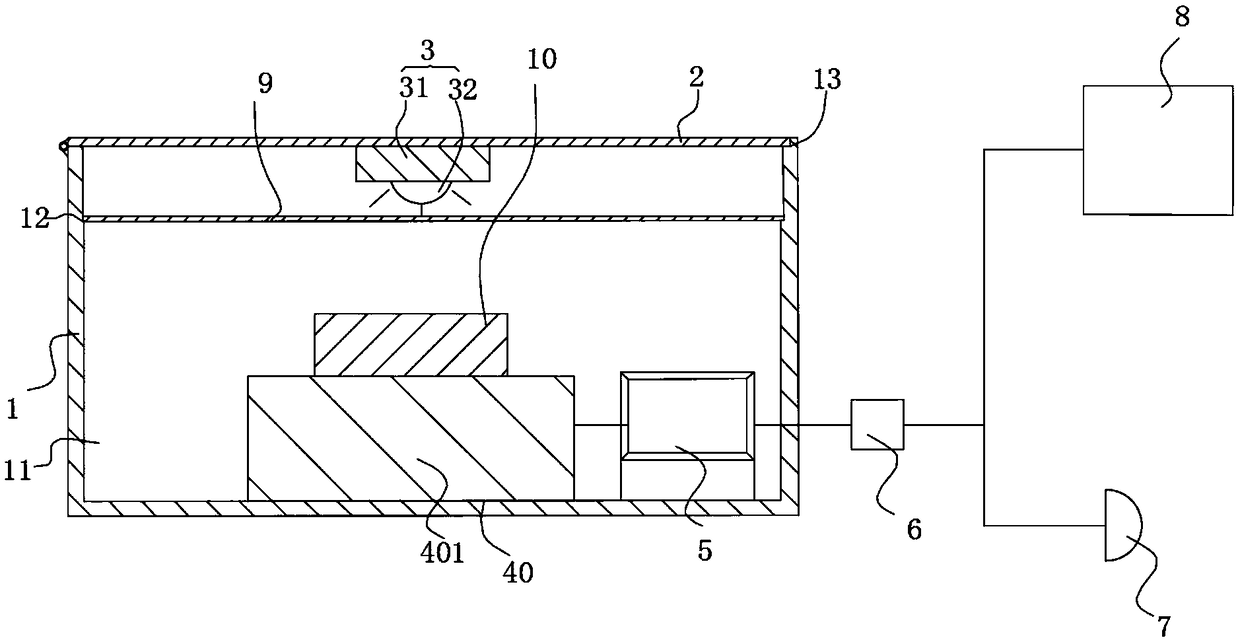

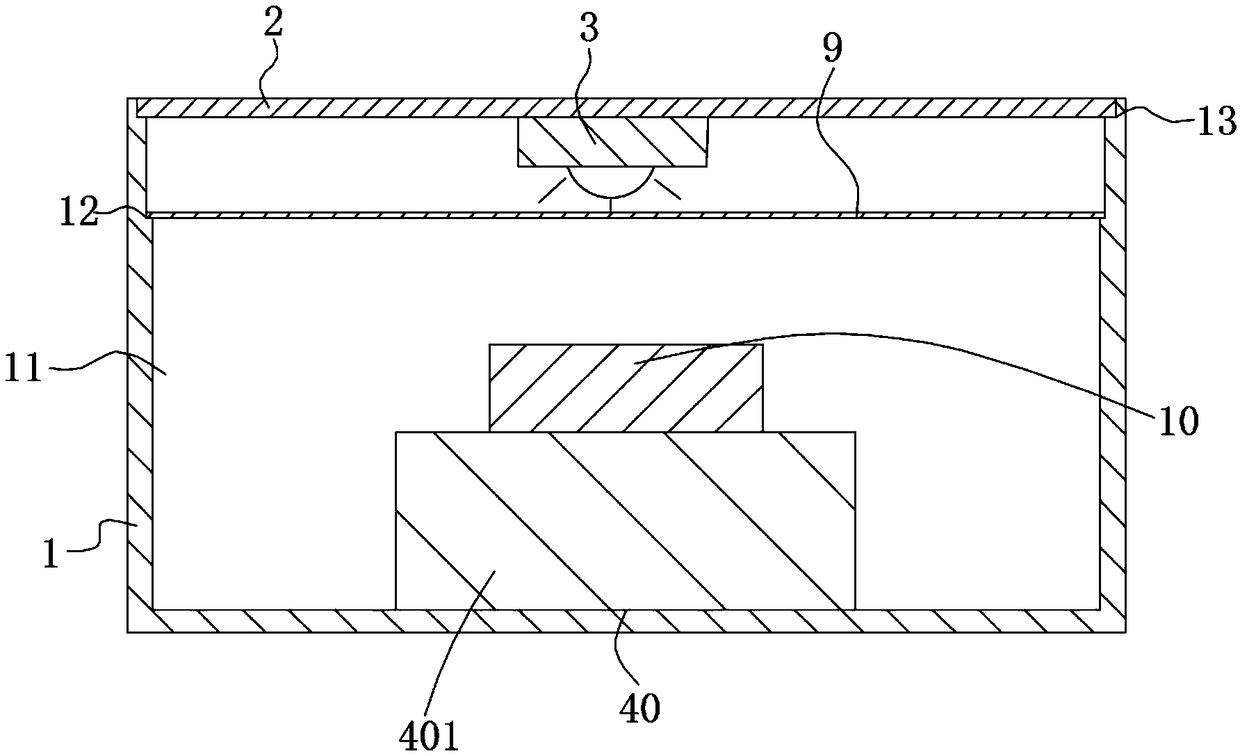

[0030] Such as figure 1 with figure 2 As shown, the instrument for testing LED chips includes a housing 1 , a cover plate 2 , an ultraviolet excitation light source 3 , a test area 40 for an LED chip to be tested, and an electrical characteristic detector 5 . In this embodiment, the electrical characteristic detector 5 is a voltage detector.

[0031] The casing 1 has a cavity 11 , an opening communicating with the cavity 11 is opened at the upper end of the casing 11 , and a step 12 is provided at the upper end of the inner wall of the casing 11 . The cover plate 2 is hinged at one end of the housing 1 and can cover the opening. The cover plate 2 is supported by the stepped surface 13 at the upper end of the housing except for one side of the hinge.

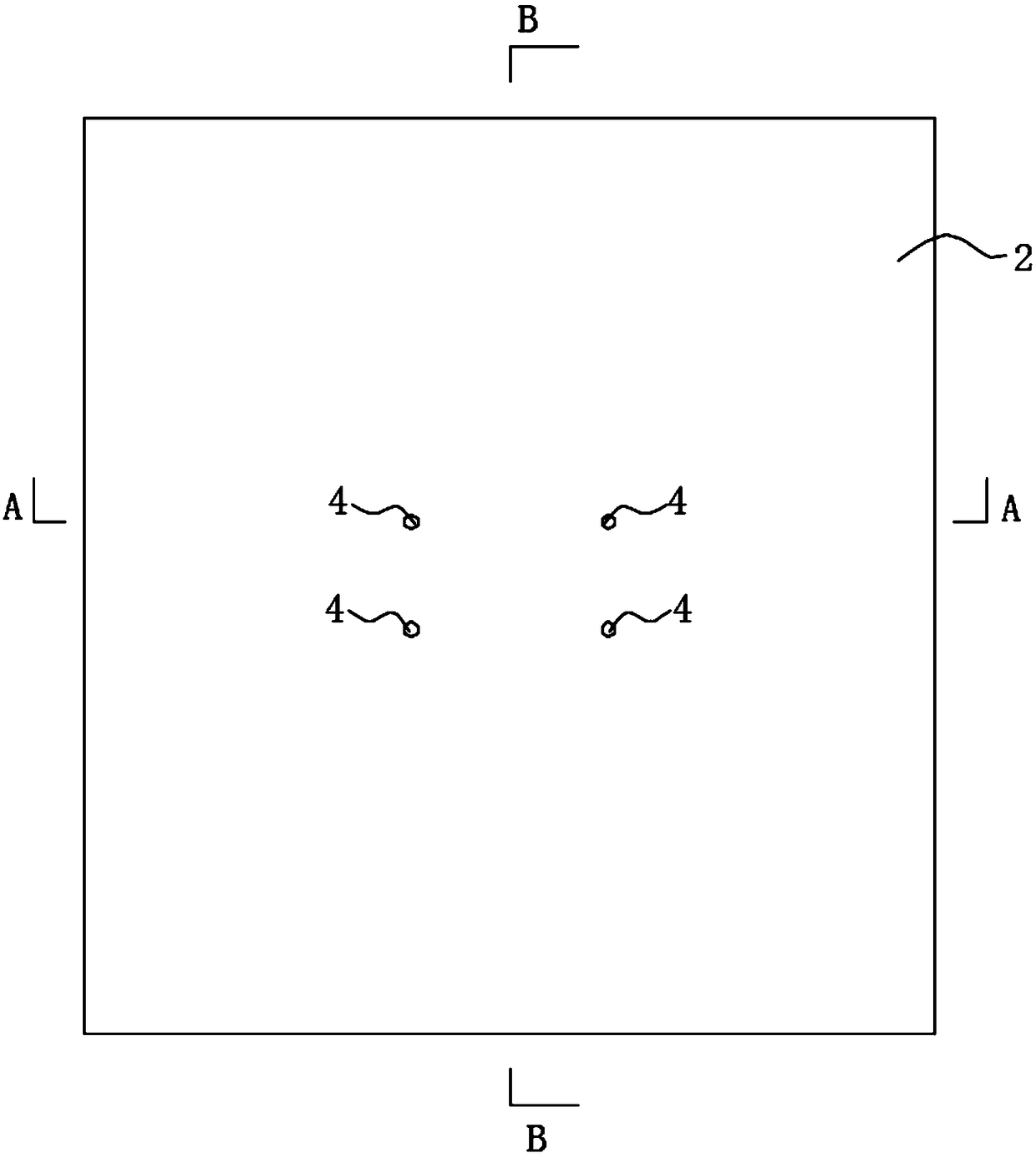

[0032] The ultraviolet excitation light source 3 is installed on the bottom surface of the cover plate 2, in order to better install and disassemble the ultraviolet excitation light source 3, as Figure 3 to Figure 6 As shown...

Embodiment 2

[0045] Such as figure 1 with figure 2 As shown, the instrument for testing LED chips includes a housing 1 , a cover plate 2 , an ultraviolet excitation light source 3 , a test area 40 for an LED chip to be tested, and an electrical characteristic detector 5 . In this embodiment, the electrical characteristic detector 5 is a current detector. Such as Figure 11 The volt-ampere characteristic curve of the LED chip shown shows that when the LED chip reaches the forward voltage VF, the current value of the LED chip is very small, and when the chip is excited by an ultraviolet excitation light source, the current generated inside the chip may not reach the normal value. With forward current, thereby in order to prevent that the electrical characteristic value cannot be detected, an amplifier (not shown in the figure) is also provided between the tested LED chip test area 40 and the electrical characteristic detector 5, and the amplifier is used to amplify the Measure the electr...

Embodiment 3

[0060] The difference between this embodiment and Implementation 1 is that the electrical characteristic detector 5 in the instrument for detecting LED chips is a voltage detector and a current detector, that is, the voltage detector and the current detector put

[0061] placed in the same housing to form an electrical characteristic detector.

[0062] The method for detecting LED chips using the above-mentioned instrument for detecting LED chips includes the following steps.

[0063] 1) Pre-store dead light curves and normal conduction curves corresponding to different LED chip ultraviolet excitation light sources and LED chip current values, and dead light curves and normal conduction curves corresponding to voltage values in the controller. Generally speaking, for the same chip, the dead light curve and normal conduction curve are unique.

[0064] 2) The ultraviolet excitation light source 3 irradiates the LED chip 10 to be tested. The LED chip to be tested is a visible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com