A preparation method of a monolithic catalyst containing potassium and zinc oxide nanorods and the resulting product and application

A technology of zinc oxide nanorods and monolithic catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, mechanical equipment, etc., can solve the problems of unreported and inaccessible catalysts, and achieve high back pressure and easy implementation , high combustion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a method for preparing a monolithic catalyst containing potassium and zinc oxide nanorods. The monolithic catalyst can be used as a diesel vehicle particulate filter (i.e. DPF). The preparation method comprises the following steps:

[0030] (1) Pretreatment of DPF carrier:

[0031] Put the DPF carrier into an appropriate amount of deionized water for ultrasonic cleaning, and then put it into an appropriate amount of absolute ethanol for ultrasonic washing. After cleaning, put the DPF carrier into an oven to dry.

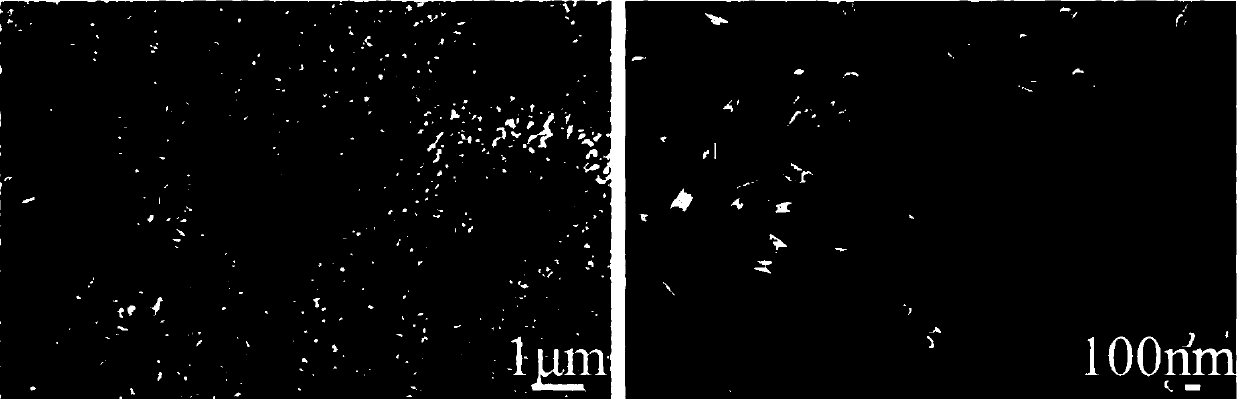

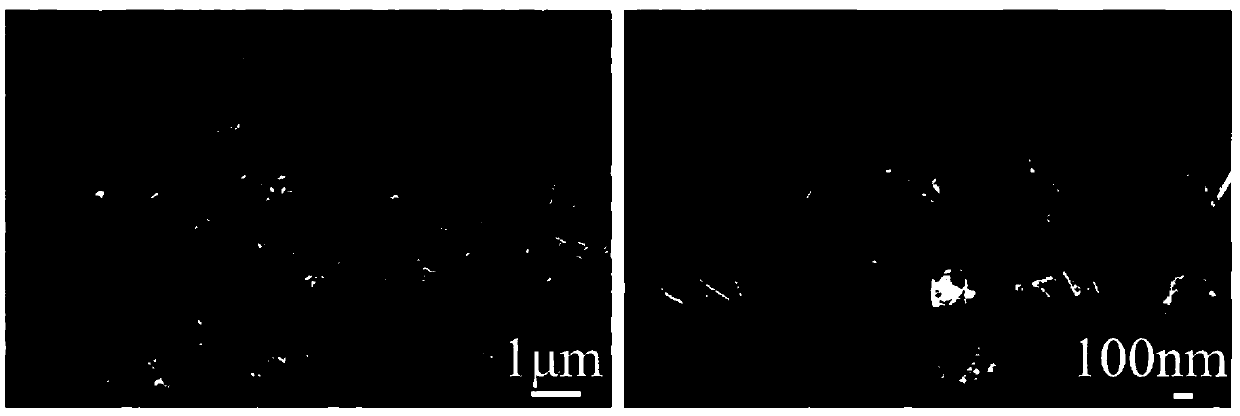

[0032] (2) Growth of ZnO nanorods:

[0033] ①Preparation of seed solution: Prepare zinc acetate ethanol solution, stir until completely dissolved, and set aside;

[0034] ②Seed growth: put the dried DPF carrier into the zinc acetate seed solution prepared in ① and put it into an ultrasonic machine for ultrasonication, then take out the DPF carrier from the seed solution with tweezers and put it in an oven for drying . Then imm...

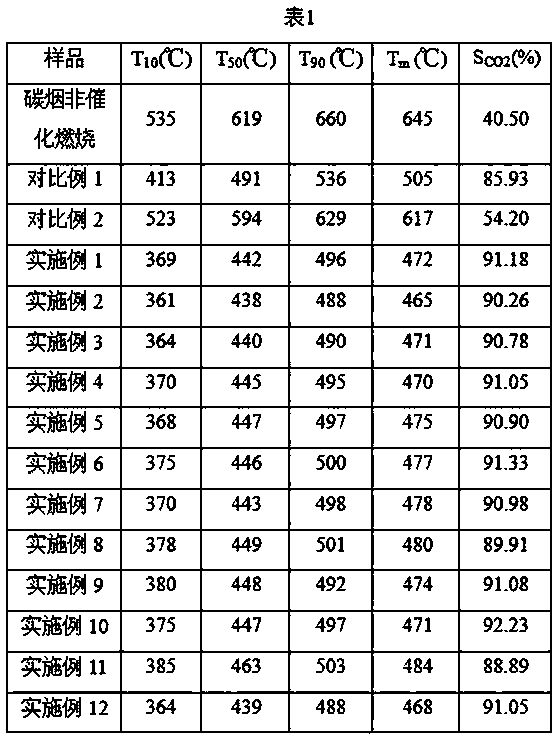

Embodiment 1

[0052] (1) Pretreatment of aluminum titanate carrier:

[0053] Put the aluminum titanate carrier into an appropriate amount of deionized water and ultrasonically wash it for 10 minutes, then put it into an appropriate amount of absolute ethanol and ultrasonically wash it for 10 minutes. After cleaning, put the aluminum titanate carrier into an oven and dry it at 80°C 2h.

[0054] (2) Growth of ZnO nanorods:

[0055] Prepare a zinc acetate ethanol solution with a concentration of 20 mmol / L and 100 mL (weigh 0.4390 g of zinc acetate and add it to a beaker containing 100 mL of ethanol solution, stir until completely dissolved);

[0056] Put the dry aluminum titanate carrier in (1) into The prepared zinc acetate seed solution was placed in an ultrasonic machine for ultrasonication for 1 min, and then the aluminum titanate carrier was taken out from the seed solution with tweezers and dried in an oven at 150°C for 5 min. Repeat the above-mentioned ultrasonic and drying proc...

Embodiment 2

[0062] A monolithic catalyst containing potassium and zinc oxide nanorods was prepared according to the method of Example 1, except that aluminum titanate was replaced by cordierite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com