Automatically-monitoring temperature returning box for solder paste, and use method thereof

An automatic monitoring, solder paste technology, applied in auxiliary devices, printed circuits, manufacturing tools, etc., can solve the problems of short solder paste rewarming time, abnormal rewarming time, hidden quality problems, etc. The effect of cream waste and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

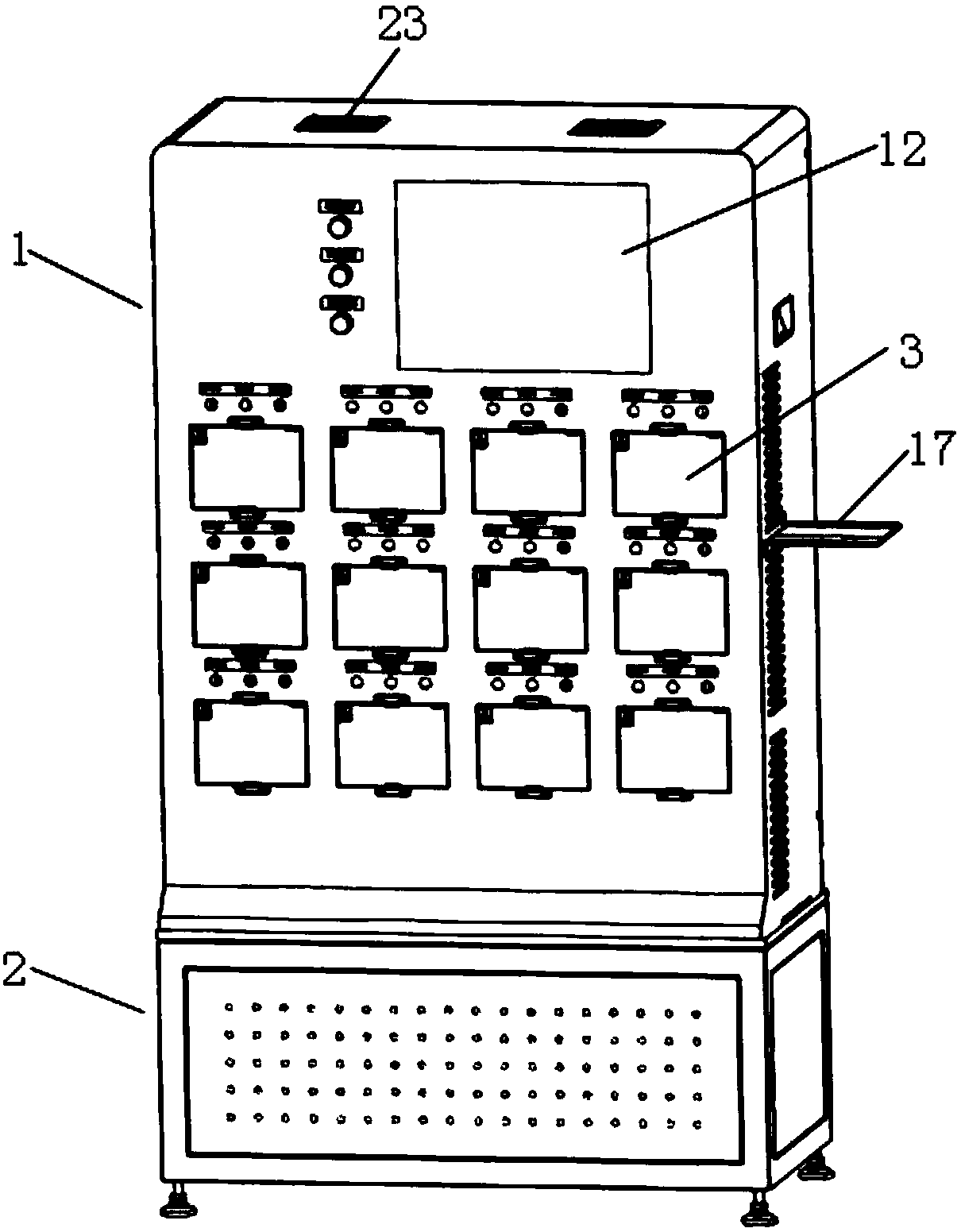

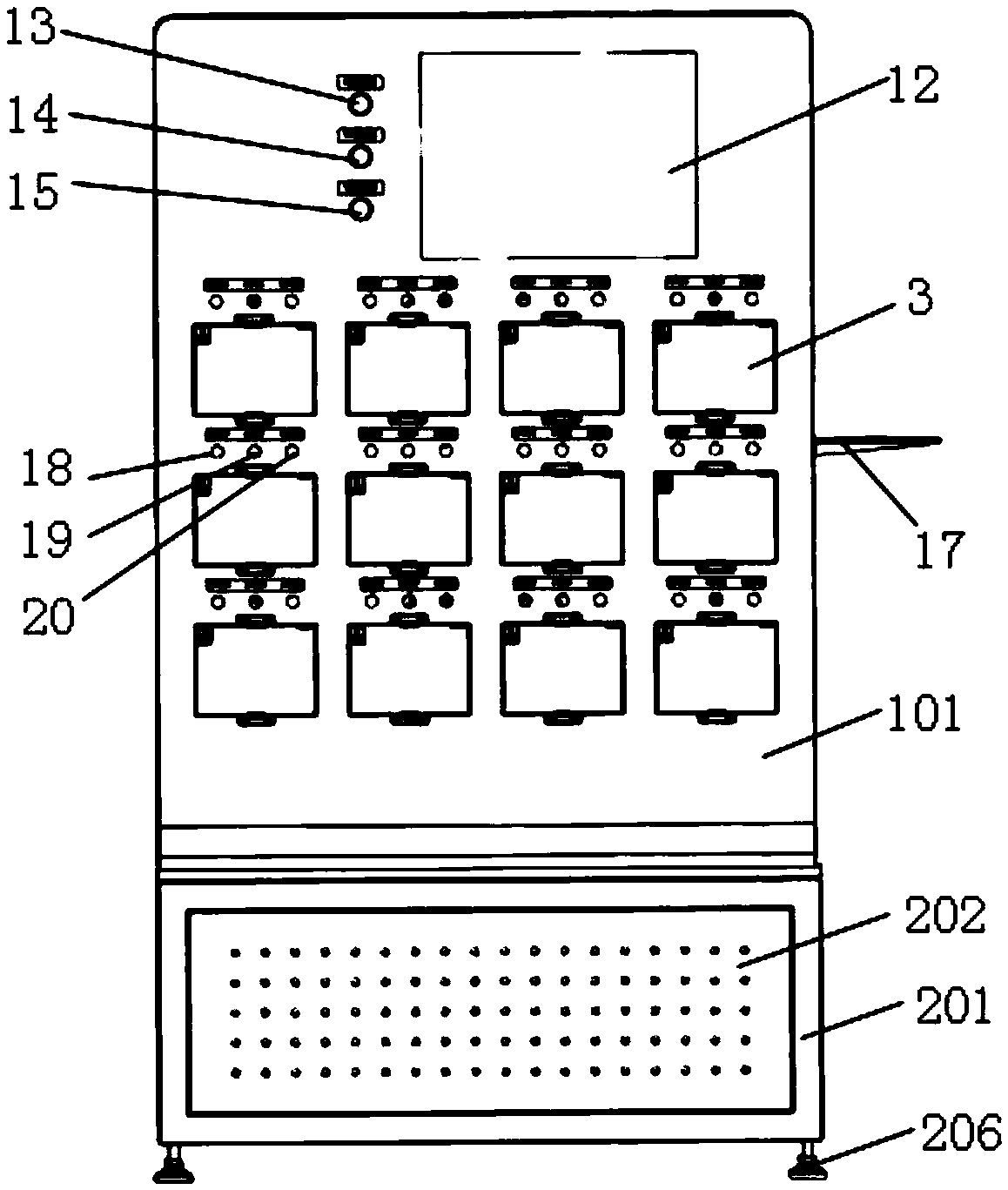

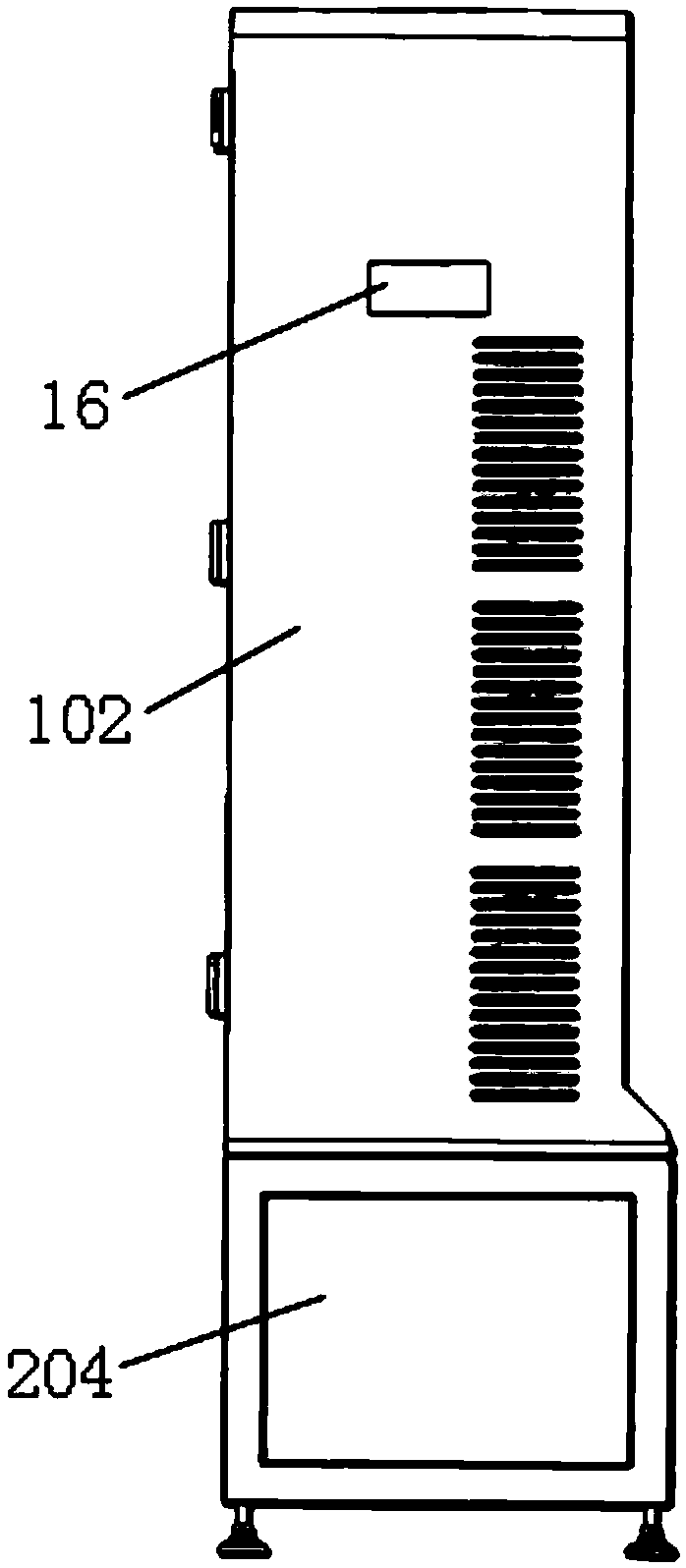

[0049] An automatic monitoring type solder paste reheating box, as attached Figure 1-5 As shown, it includes a box body 1 and a base 2, the base 2 is provided with a tray, the box body 1 is installed on the base 2 through the tray, and a foot pad is provided between the tray and the base 2; the box body 1 includes a stretched front panel 101, Left side plate 102, right side plate 103 and back plate, stretch front panel 101 covers top, front end and bottom end of box body 1, and left side plate 102 and right side plate 103 connect with stretch front panel 101 from left and right sides respectively. Fixedly connected, the left side plate 102 and the right side plate 103 are provided with a hand grip groove 16, and the hand grip groove 16 is used to move and carry the reheating box; one side of the box body 1 is provided with a mouse board 17, and the mouse board 17 is used For placing the scanner.

[0050] Rear panel comprises left door 104 and right door 105, and left door 10...

Embodiment 2

[0070] Based on the above embodiments, a method of using an automatic monitoring type solder paste reheating box includes a method of using unopened solder paste and a method of using solder paste after opening; wherein,

[0071] The method for using the unopened solder paste comprises the following steps:

[0072] 101. After the solder paste leaves the warehouse, the operator scans the barcode on the solder paste bottle and the QR code on the empty return warming cabinet 3 respectively;

[0073] 102. Open the revolving door 4 of the warming cabinet 3, put the solder paste into the warming cabinet 3, close the revolving door 4, and after the sensor 10 senses the solder paste, send a signal to the programmable logic controller, and the revolving door 4 is automatically locked ;

[0074] 103. The programmable logic controller records the solder paste information and the information of the corresponding temperature recovery cabinet 3, monitors the temperature recovery time, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com