Non-preheating plasma arc welding method for brass sheet

A plasma arc and welding method technology, applied in the field of plasma arc welding, can solve the problems of high welding cost, high output energy, pores, deformation, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

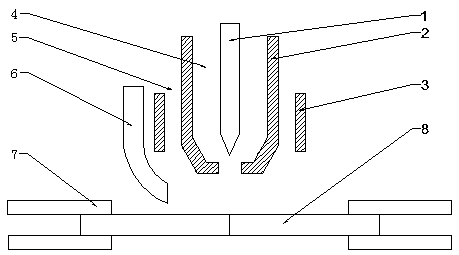

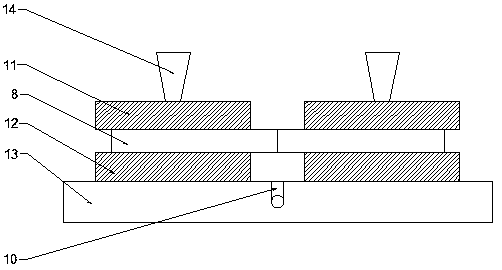

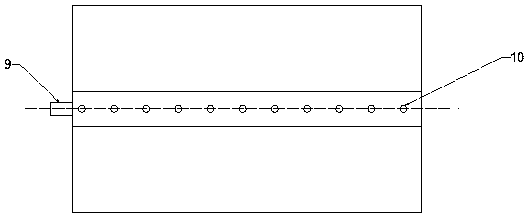

[0049] Embodiment: refer to attached Figure 1-6 Shown, a kind of non-preheating plasma arc welding method of thin plate brass, comprises the following steps:

[0050] (1) Pre-welding treatment of the plate: first use alcohol to remove the oil stain on the surface of the plate 8, then polish the surface of the plate 8 with 400# sandpaper to remove the oxide film, then clean the surface with acetone to remove the oil stain and impurities on the surface of the weldment, and finally bake Keep it dry for later use, do not overheat during the grinding process, and the temperature does not exceed 100°C. The thickness of the thin plate 8 used is 2mm; the chemical composition of the material is shown in the table below

[0051]

[0052](2) Assembling the plate: fix the 8 workpieces of the plate on the fixture 7, use I-shaped grooves to control the assembly accuracy, and do not use a backing plate on the back; the fixture 7 includes a bottom plate 13, a left pressing piece, and a ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com