Method for separating and purifying recombinant human ferritin

A technology for separation and purification of ferritin, applied in the field of separation and purification of recombinant human ferritin, can solve the problems of low recovery rate, complicated desalting and dilution operations, unfavorable large-scale production, etc., and achieves increased reliability, high purity, and high recovery rate. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

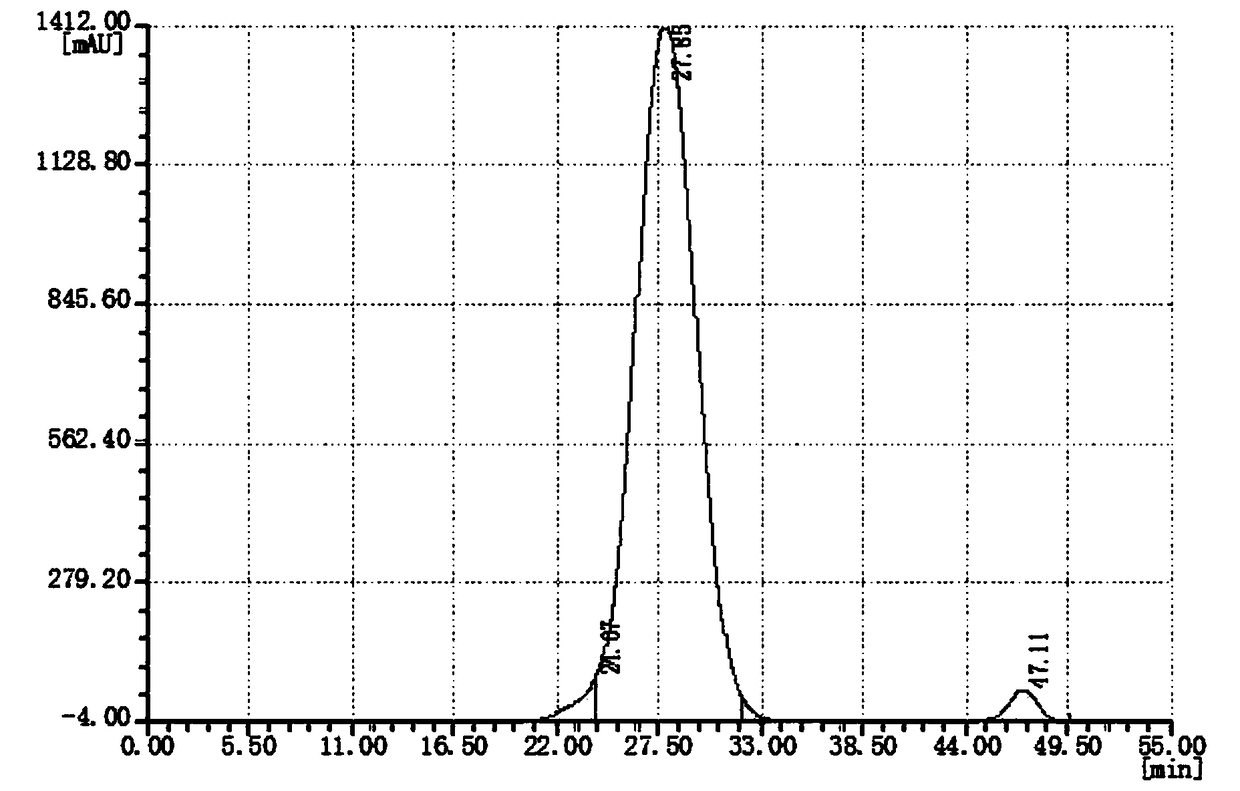

[0031] Embodiment 1, a method for separating and purifying recombinant human ferritin of the present invention, comprising the following steps:

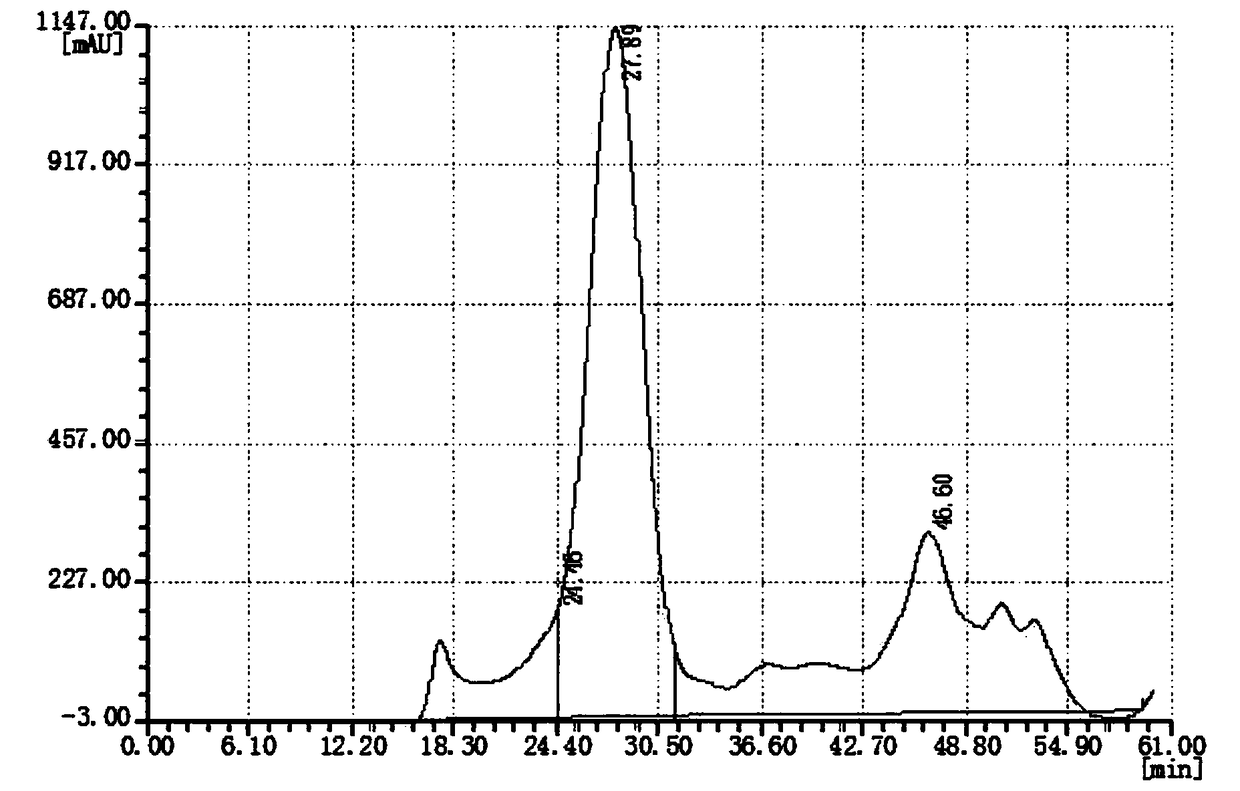

[0032] 1) Centrifuge 10g of Escherichia coli fermentation liquid to obtain the sludge. Add 20mM PBpH7.0 to the sludge according to the mass volume ratio of 1:10. After stirring well, the high-pressure homogenate is crushed twice under the environment of 800bar, heated to 72°C and kept constant. Heating for 5 minutes, centrifuging at 12000g for 10 minutes, then removing the supernatant, filtering with a 0.22um filter membrane to obtain the filtrate, and performing gel filtration detection and ion chromatography detection on the filtrate;

[0033] 2) Anion chromatography treatment: Take 30ml of anion chromatography medium Q Bestarose High Performance and put it into a BXK16 / 20 chromatography column. The following chromatography processes are all carried out on the AKTA protein purification instrument, and the anion chromatography medium...

Embodiment 2

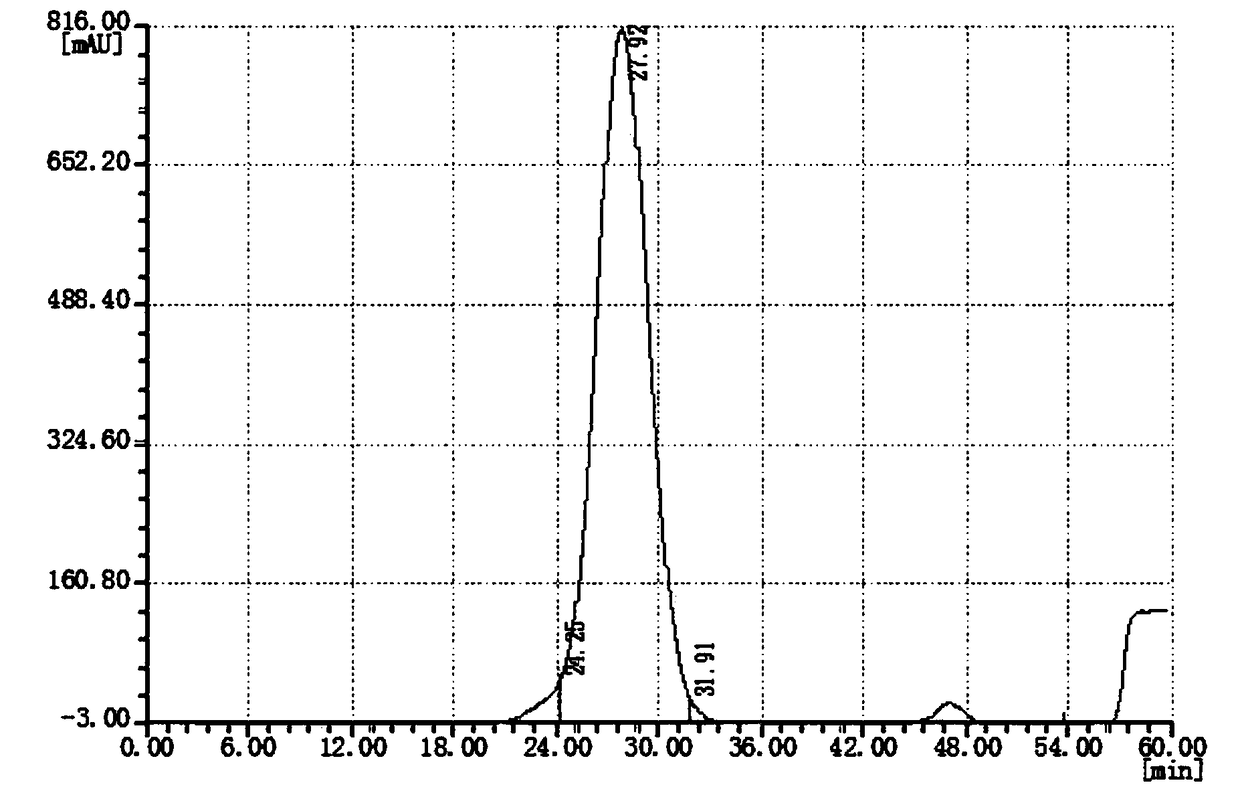

[0040] Embodiment 2, a method for separating and purifying recombinant human ferritin of the present invention, comprising the following steps:

[0041] 1) Centrifuge 10g of Escherichia coli fermentation liquid to obtain the sludge. Add 20mM PBpH7.0 to the sludge according to the mass volume ratio of 1:10. After stirring well, the high-pressure homogenate is crushed twice under the environment of 800bar, heated to 72°C and kept constant. Heating for 5 minutes, centrifuging at 12000g for 10 minutes, then removing the supernatant, filtering with a 0.22um filter membrane to obtain the filtrate, and performing gel filtration detection and ion chromatography detection on the filtrate;

[0042] 2) Anion chromatography treatment: Take 40ml of anion chromatography medium DEAE Bestarose High Performance and put it into a BXK16 / 20 chromatography column. The following chromatography processes are all carried out on the AKTA protein purification instrument, and the anion chromatography med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com