Patents

Literature

30results about How to "Low yield rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

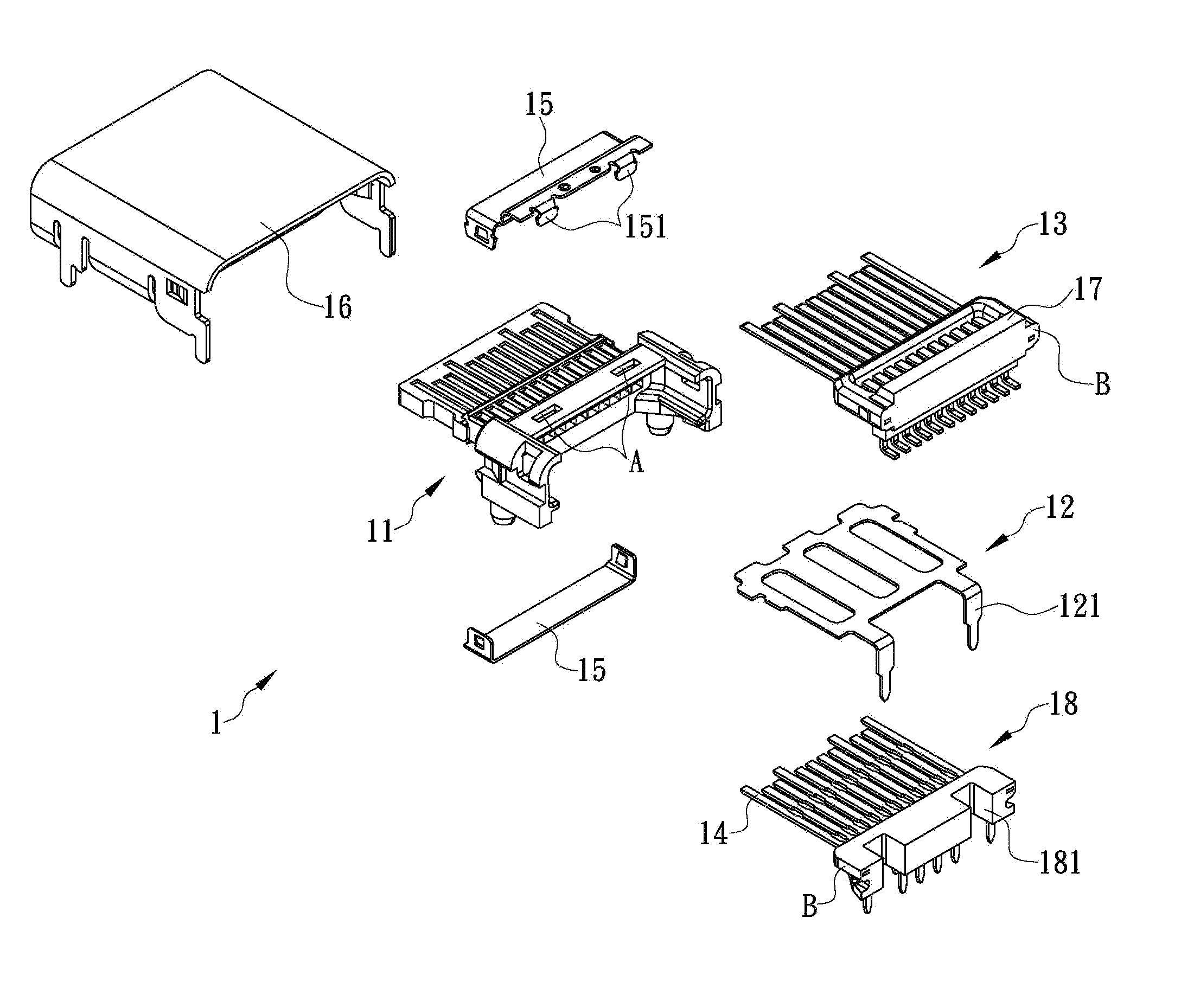

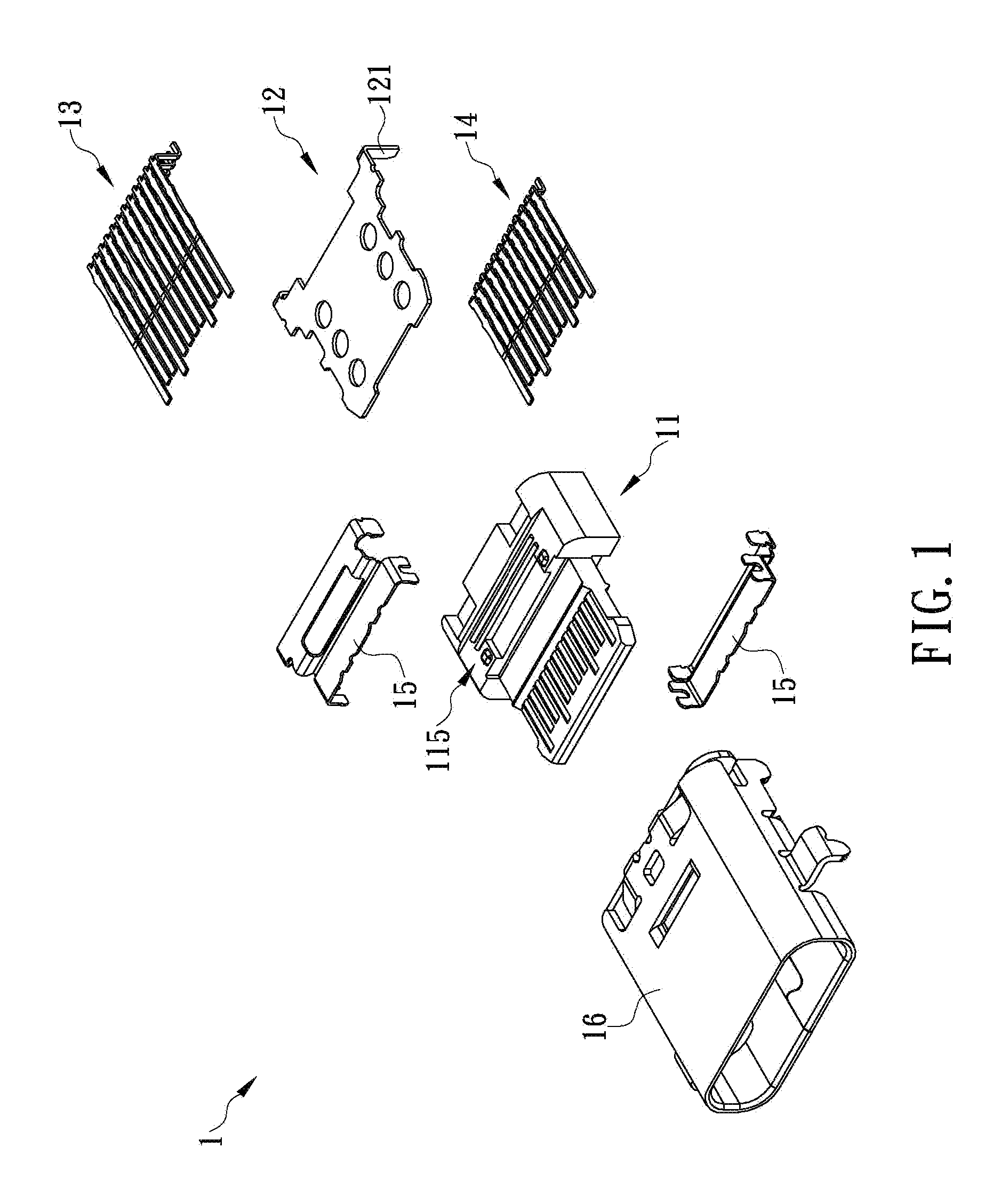

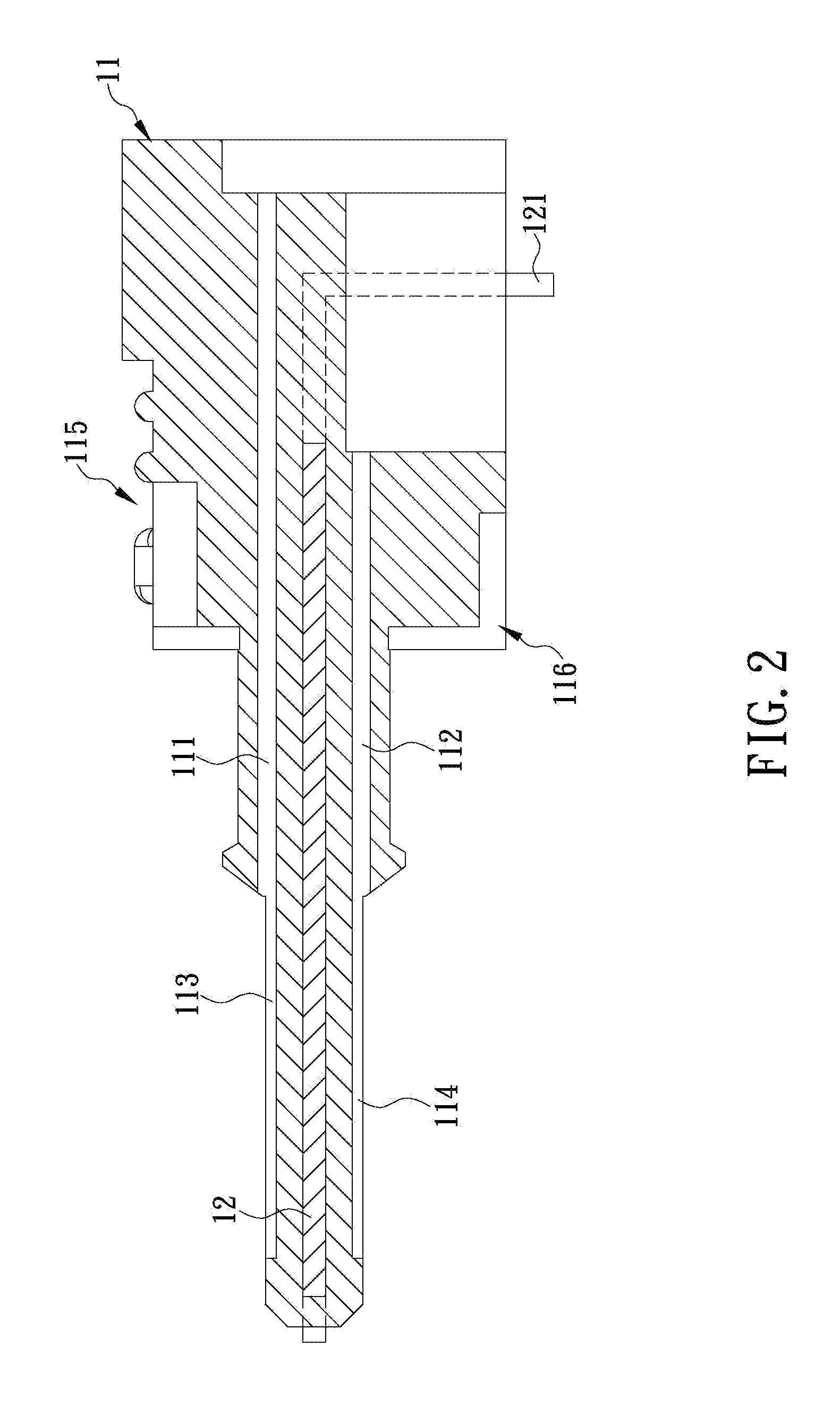

Connector having metal separating plate being fastened by tongue plate in integral formation

ActiveUS9281643B1Increase manufacturing costLow production yield rateTwo-part coupling devicesCoupling protective earth/shielding arrangementsMetallic enclosureEngineering

The present invention is to provide a connector having a metal separating plate being fastened by a tongue plate in integral formation, which is compatible to USB Type-C standard and includes a tongue plate made of plastic integrally and provided with a metal separating plate fixedly disposed therein; a plurality of first connection terminals respectively inserted into first connection slots formed in the tongue plate near a top surface of the metal separating plate; a plurality of second connection terminals respectively inserted into second connection slots formed in the tongue plate near a bottom surface of the metal separating plate; grounding boards having structures respectively matched with the tongue plate, so as to enclose an outer edge of the tongue plate; and a metal casing having a structure matching with the tongue plate, so as to allow the tongue plate and grounding boards to be assembled into the metal casing.

Owner:GUIMA SCI & TECH

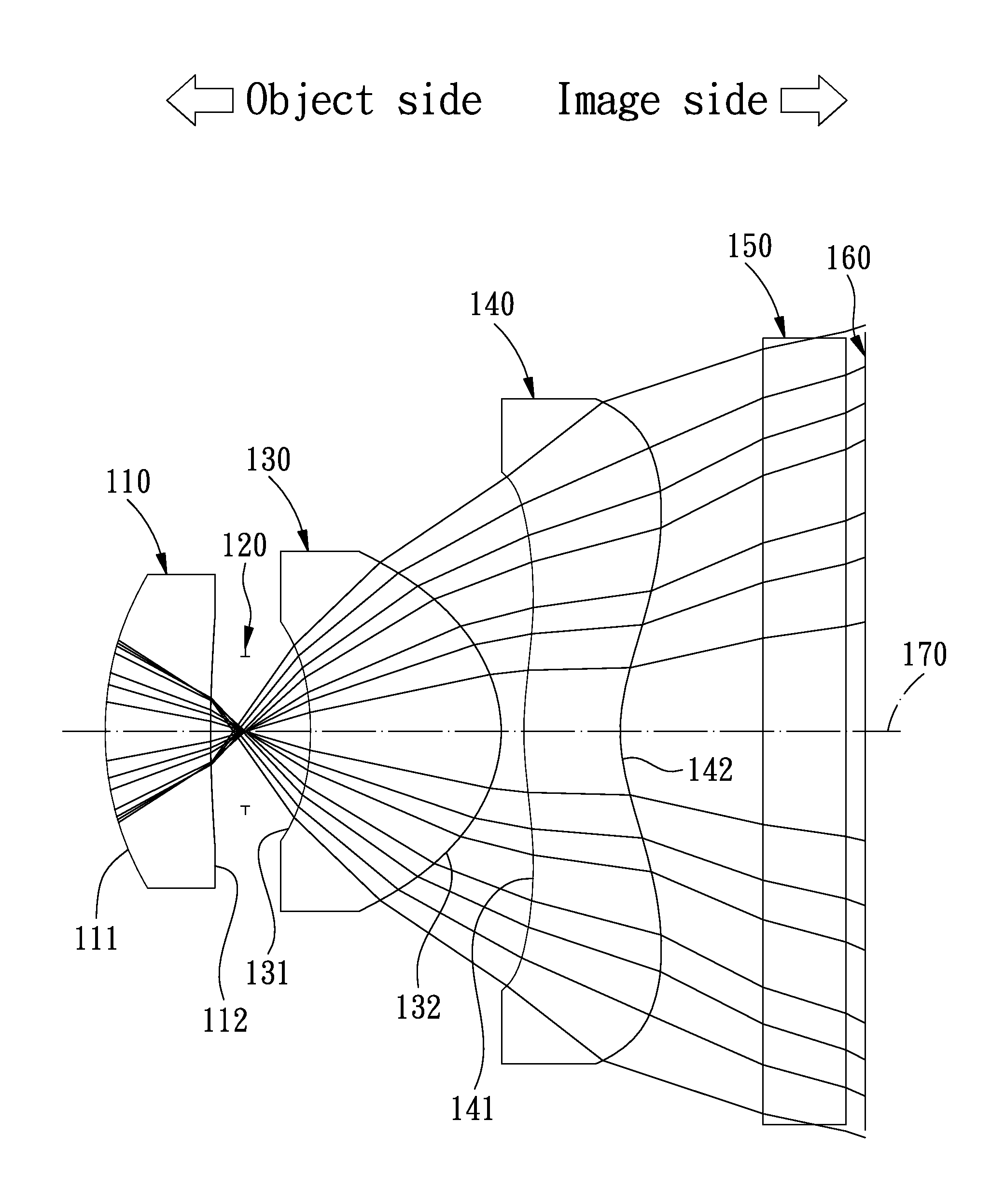

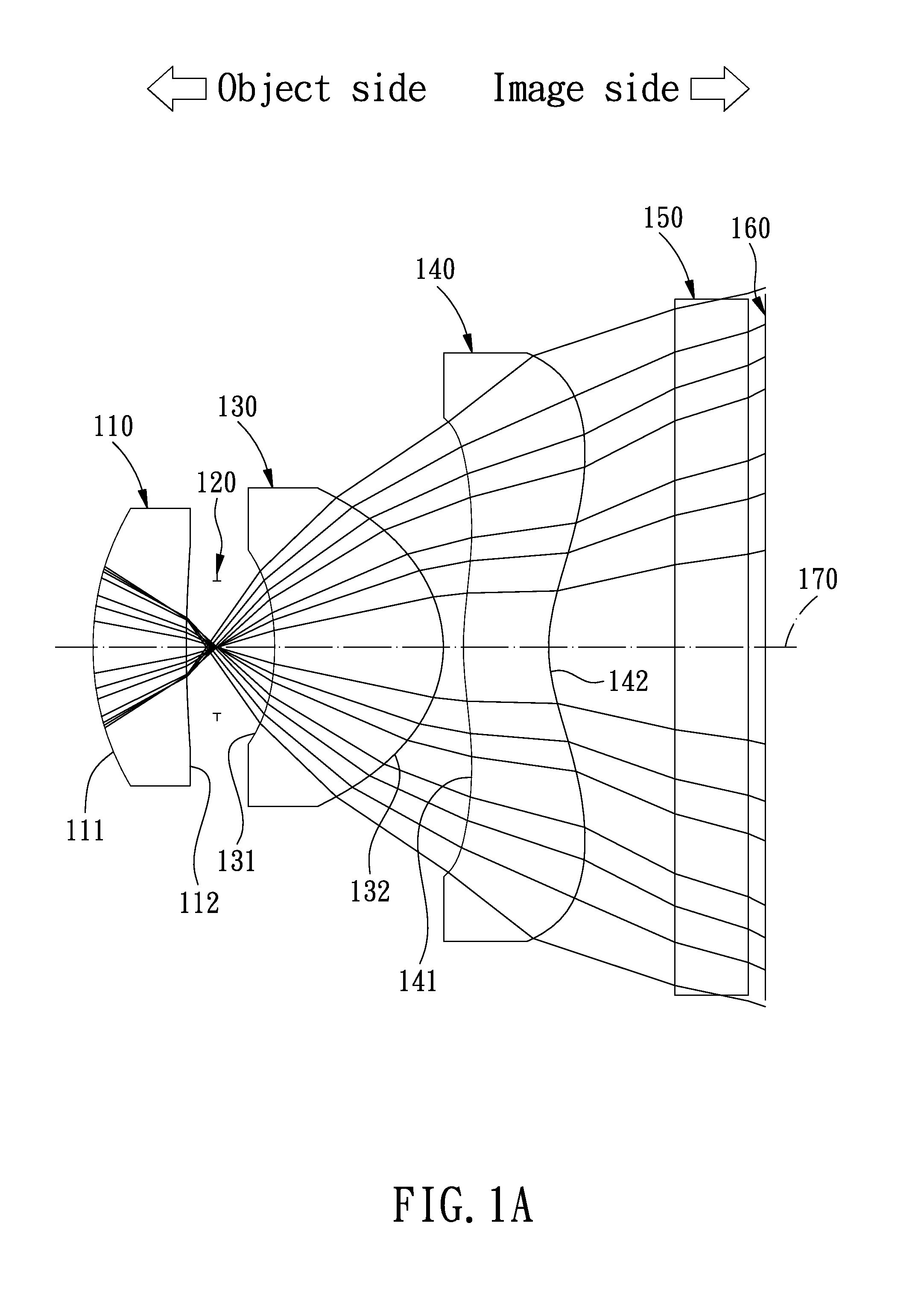

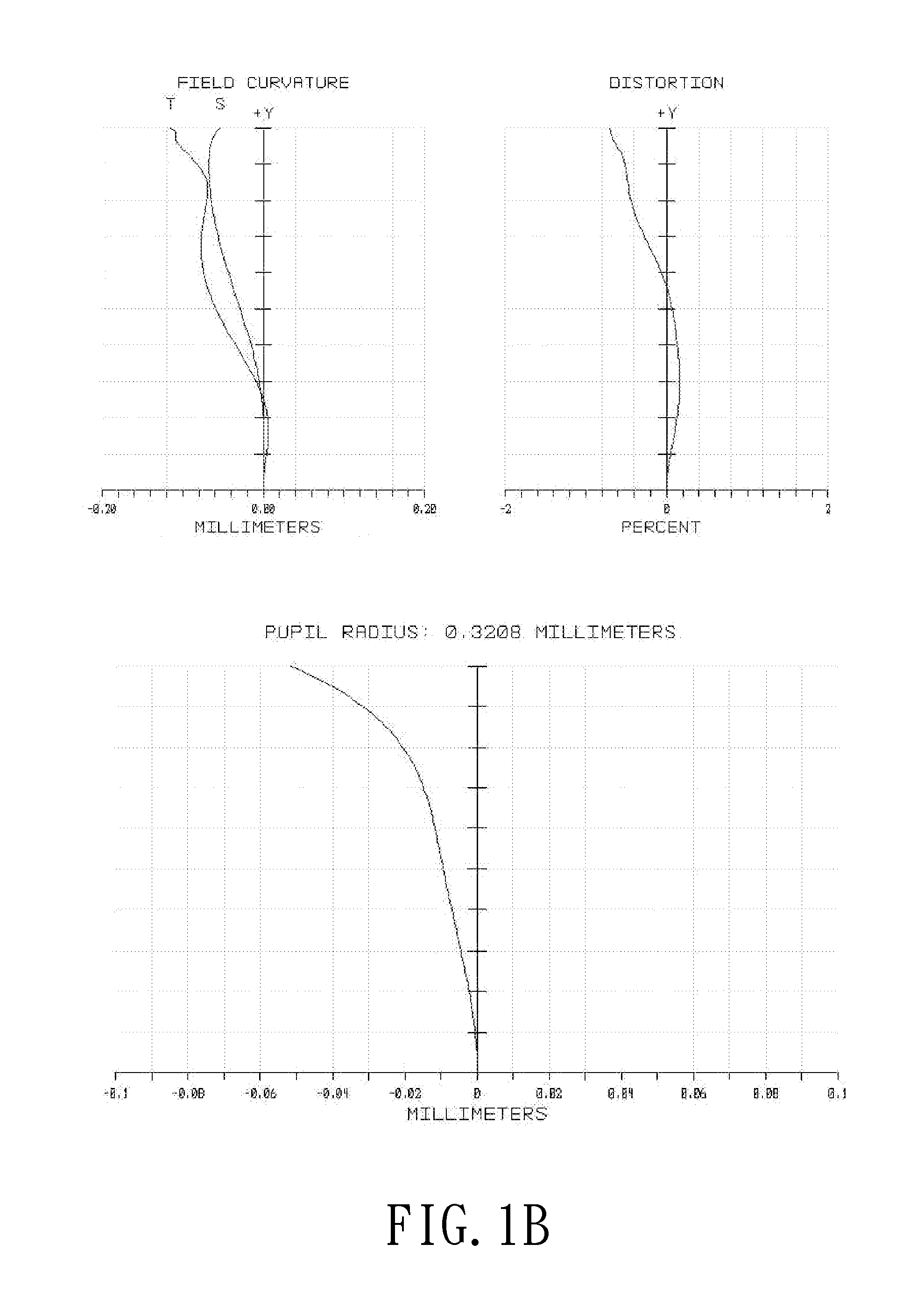

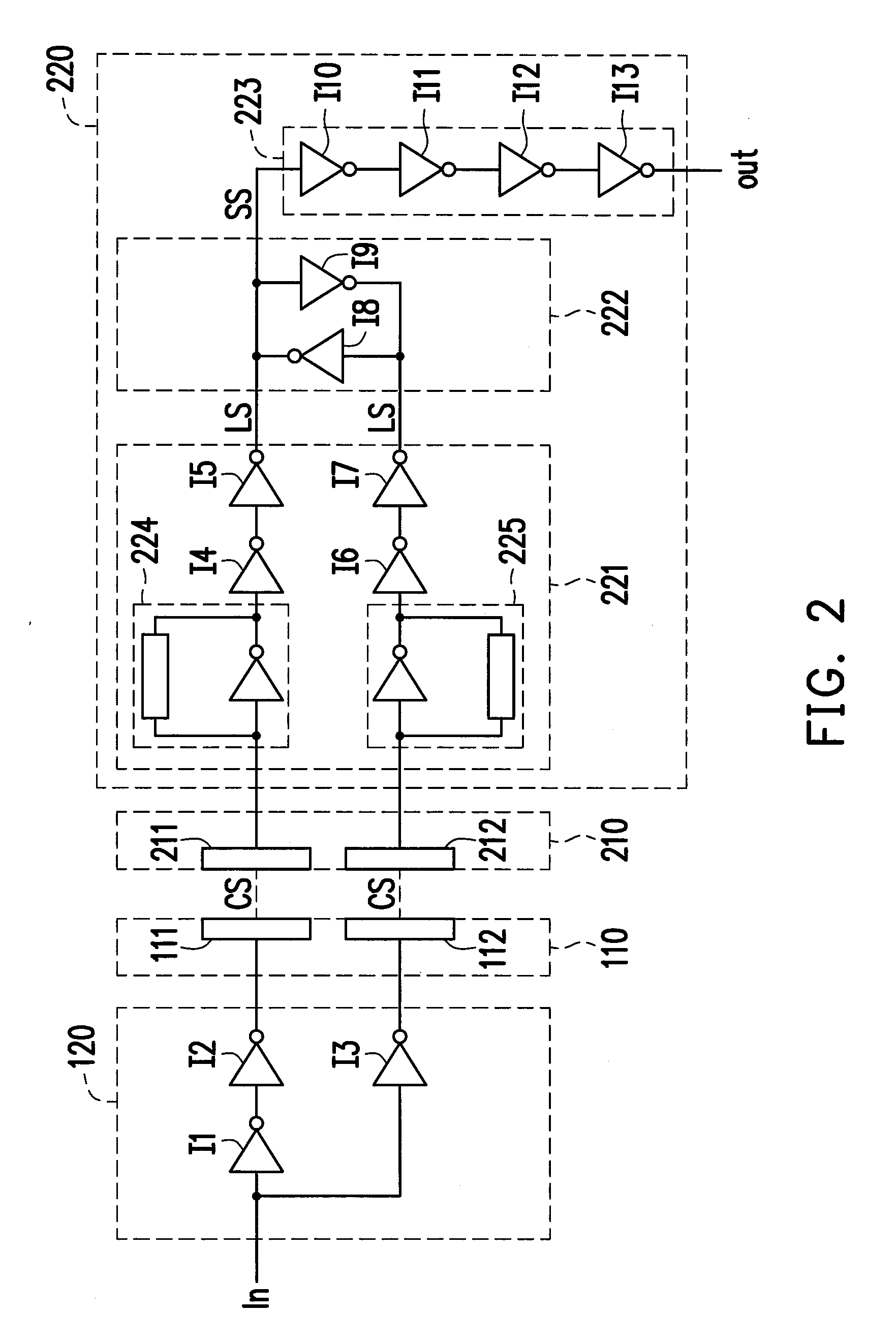

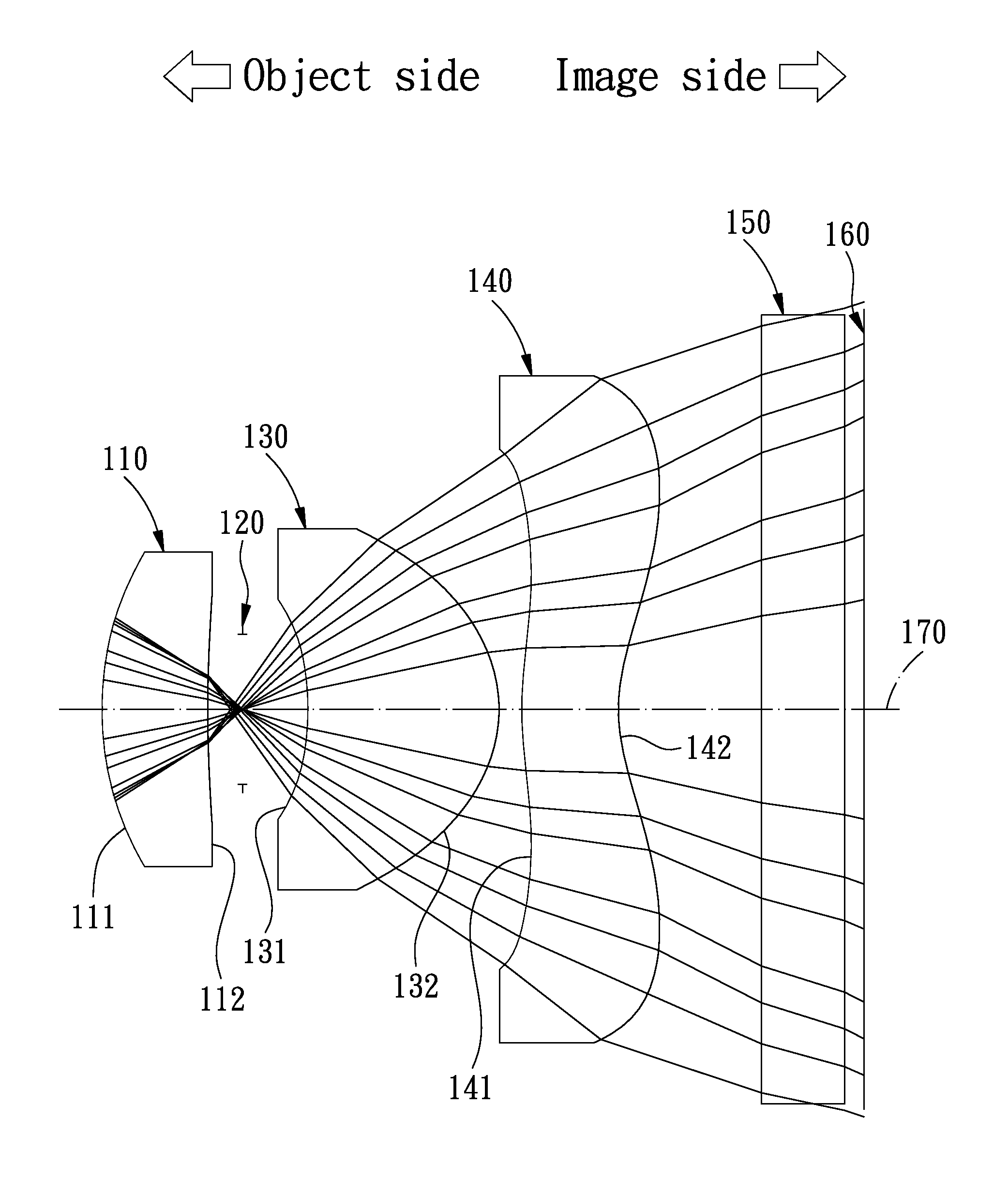

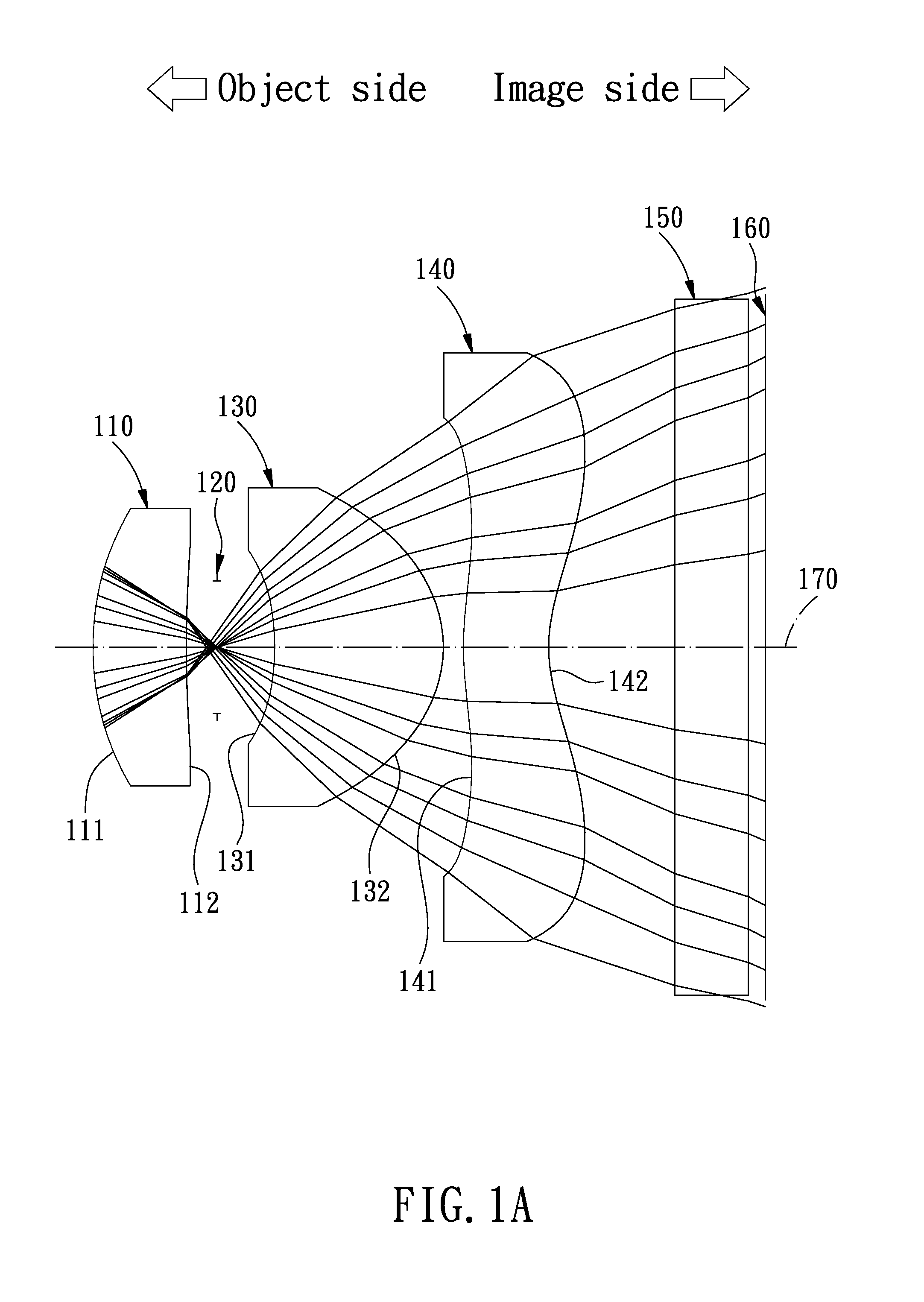

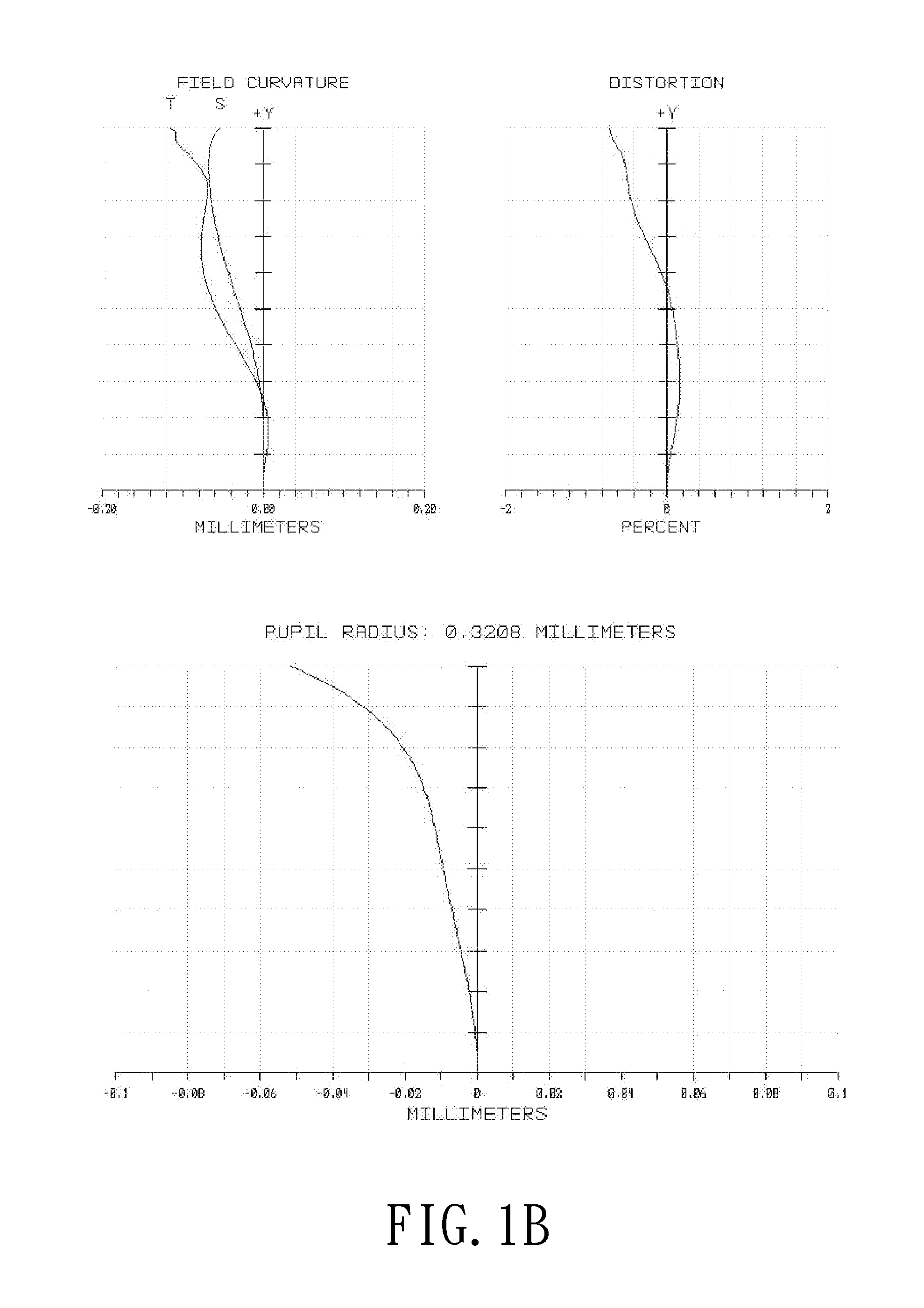

Three-piece optical lens system

A three-piece optical lens system comprises, in order from the object side to the image side: a first lens element with a positive refractive power having a convex object-side surface, one of the object-side surface and an image-side surface being aspheric; a stop, a second lens element with a positive refractive power having a concave object-side surface, one of the object-side surface and an image-side surface being aspheric; a third lens element with a negative refractive power having a concave image-side surface, one of an object-side surface and the image-side surface being aspheric. A refractive index of the third lens element is N3, an Abbe number of the third lens element is V3, and they satisfy the relations: N3>1.57; V3<40. Such arrangements can reduce the volume of the three-piece optical lens system and improve the image quality of the periphery of the image.

Owner:NEWMAX TECH

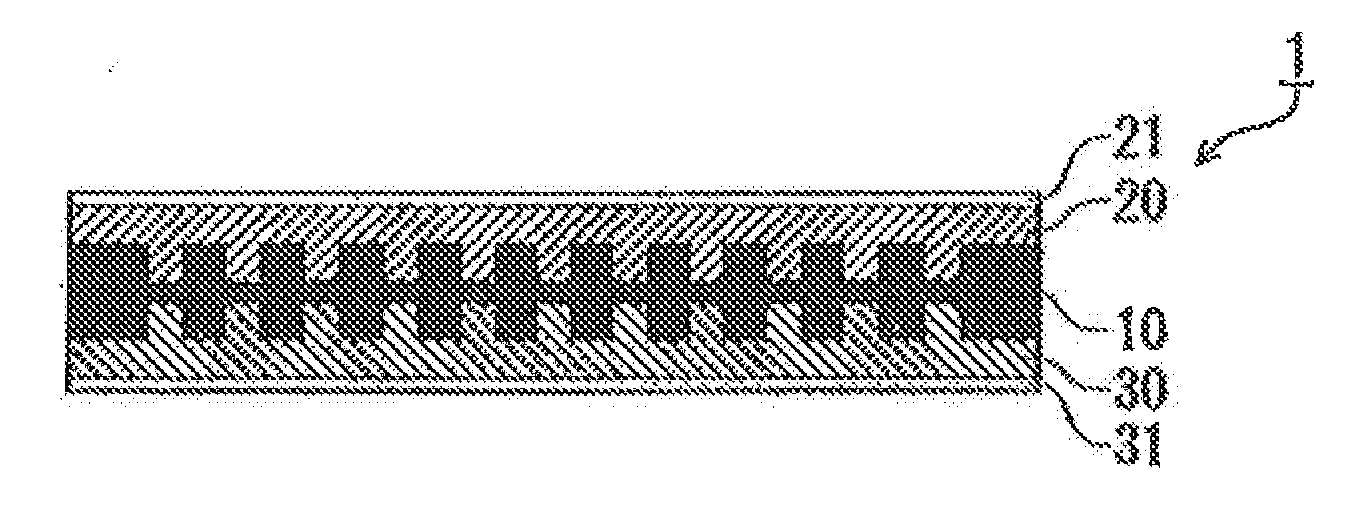

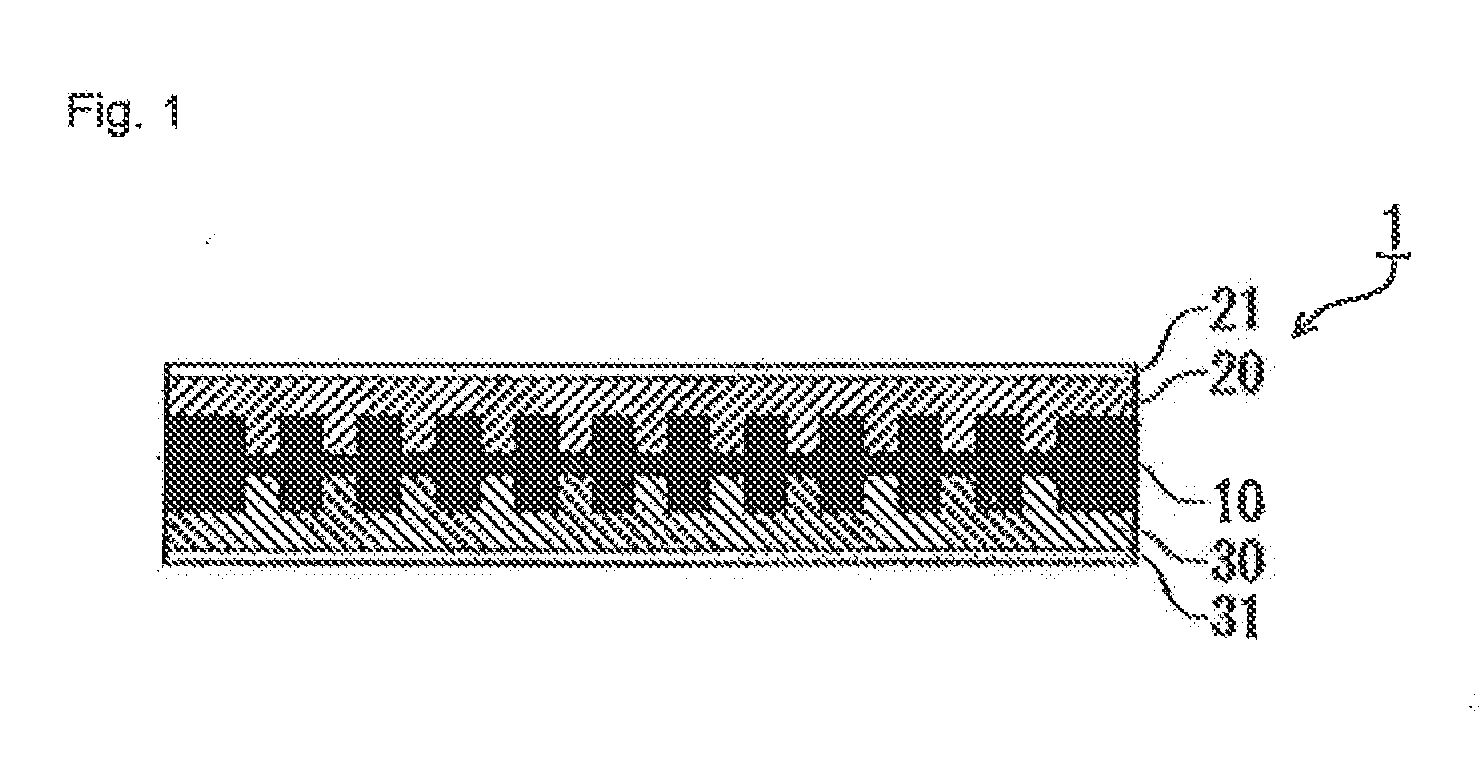

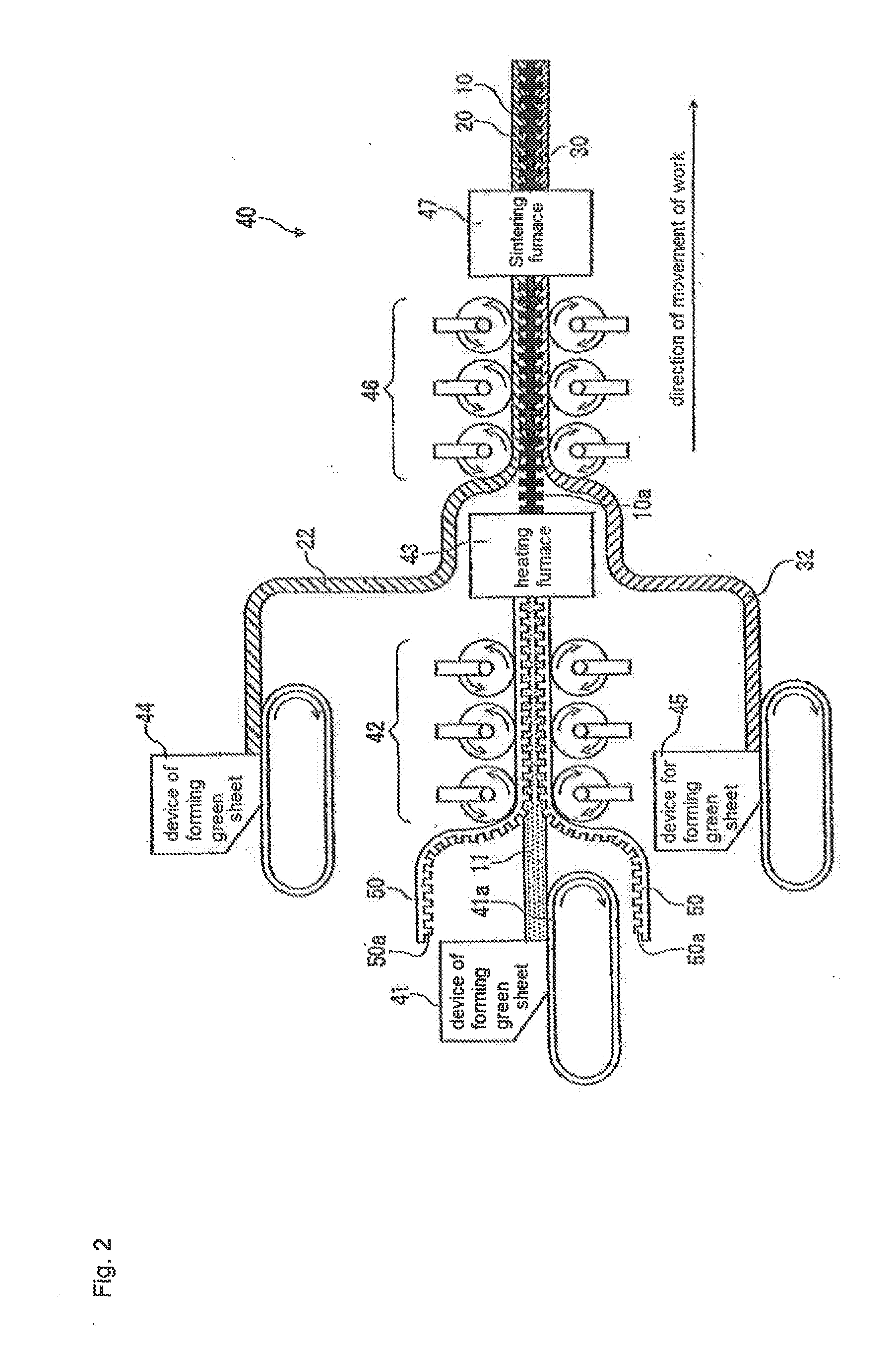

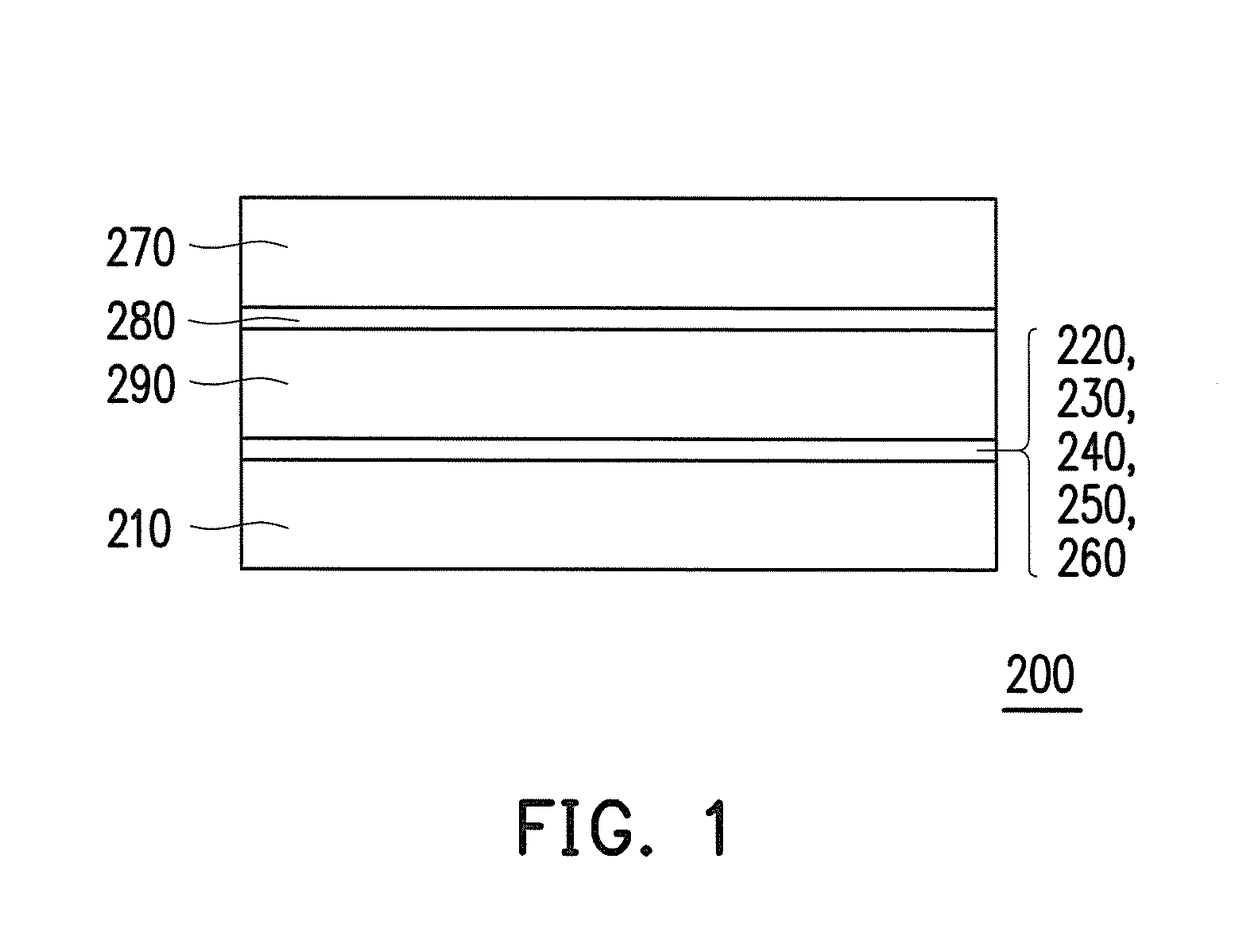

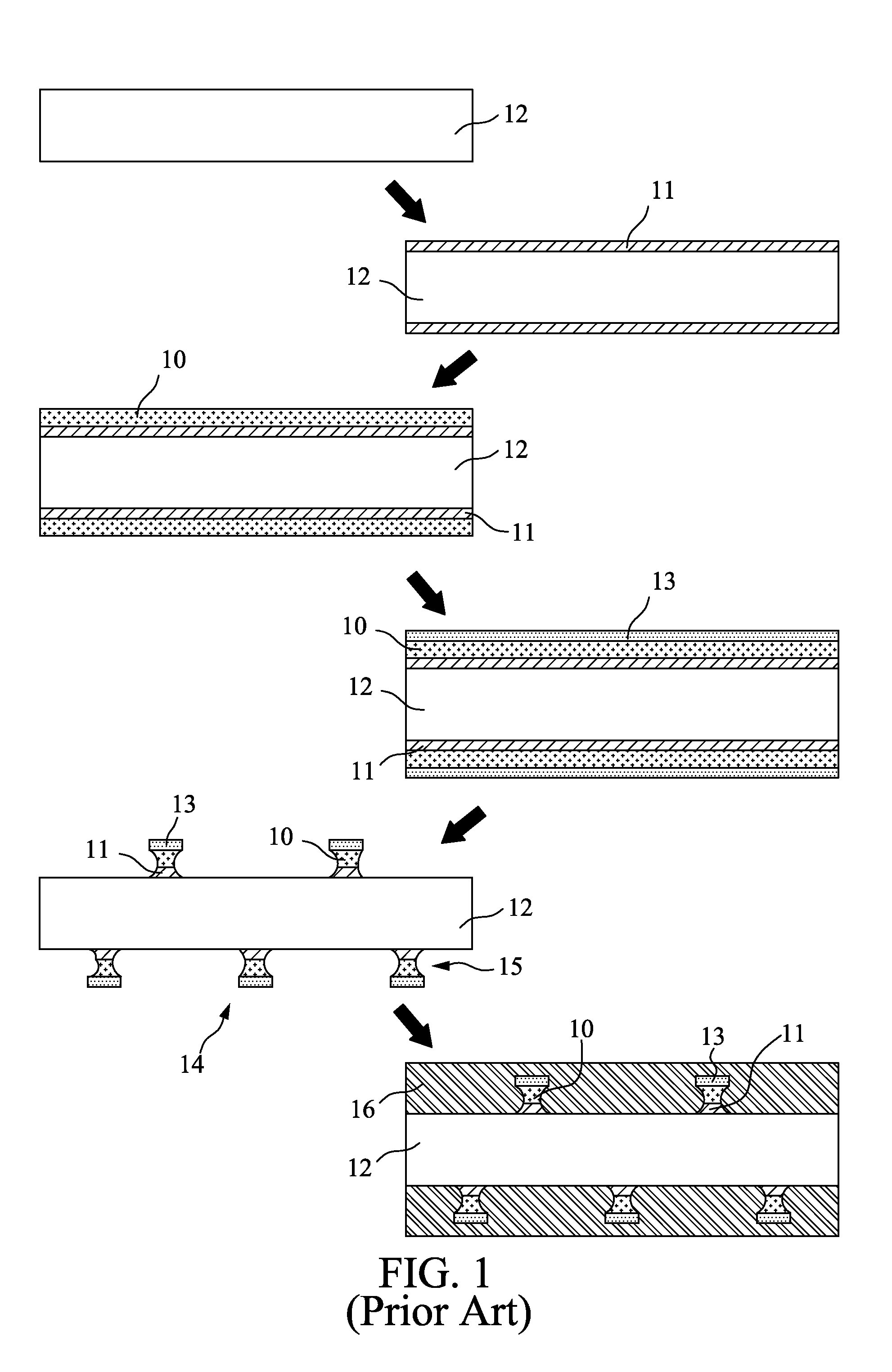

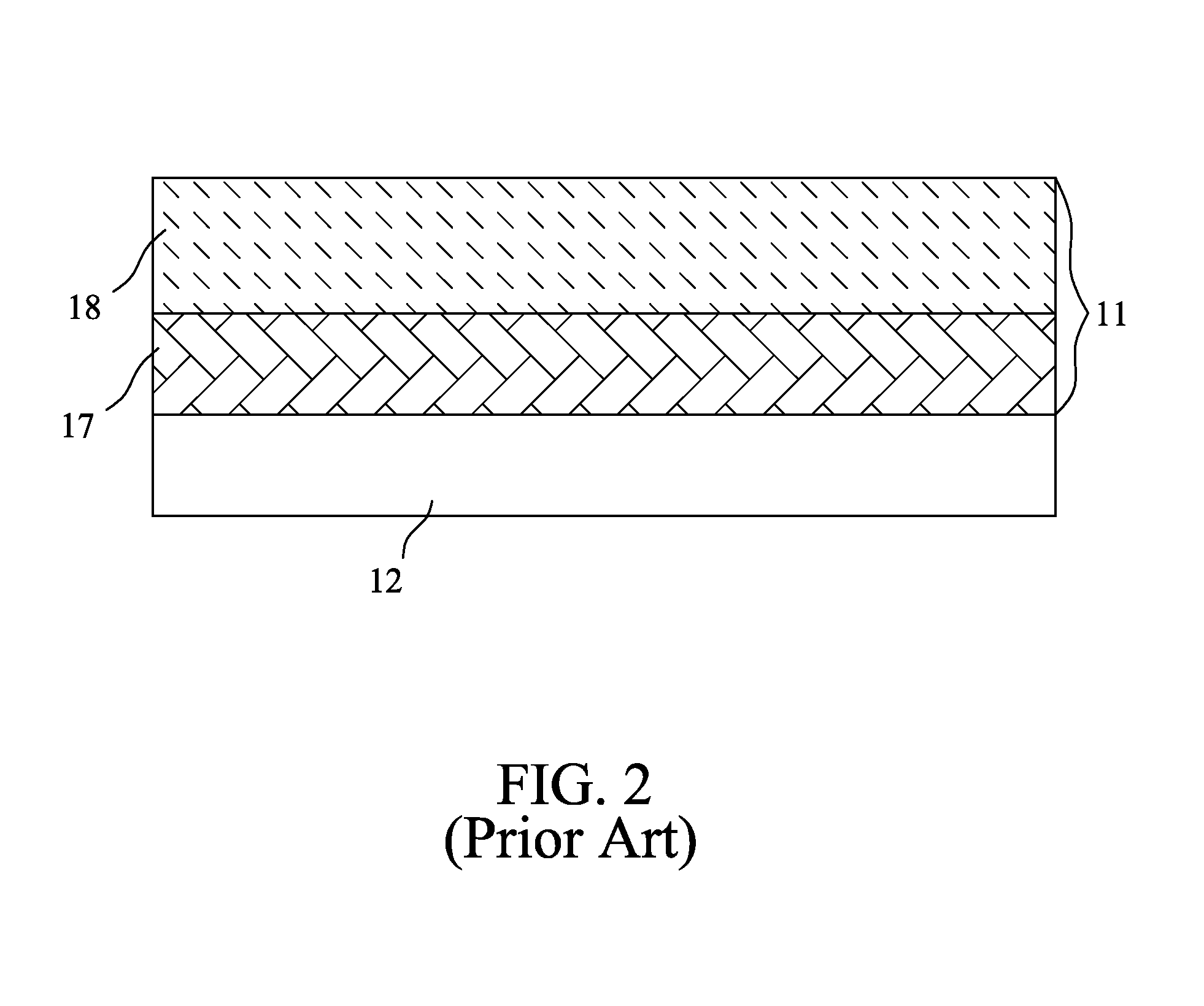

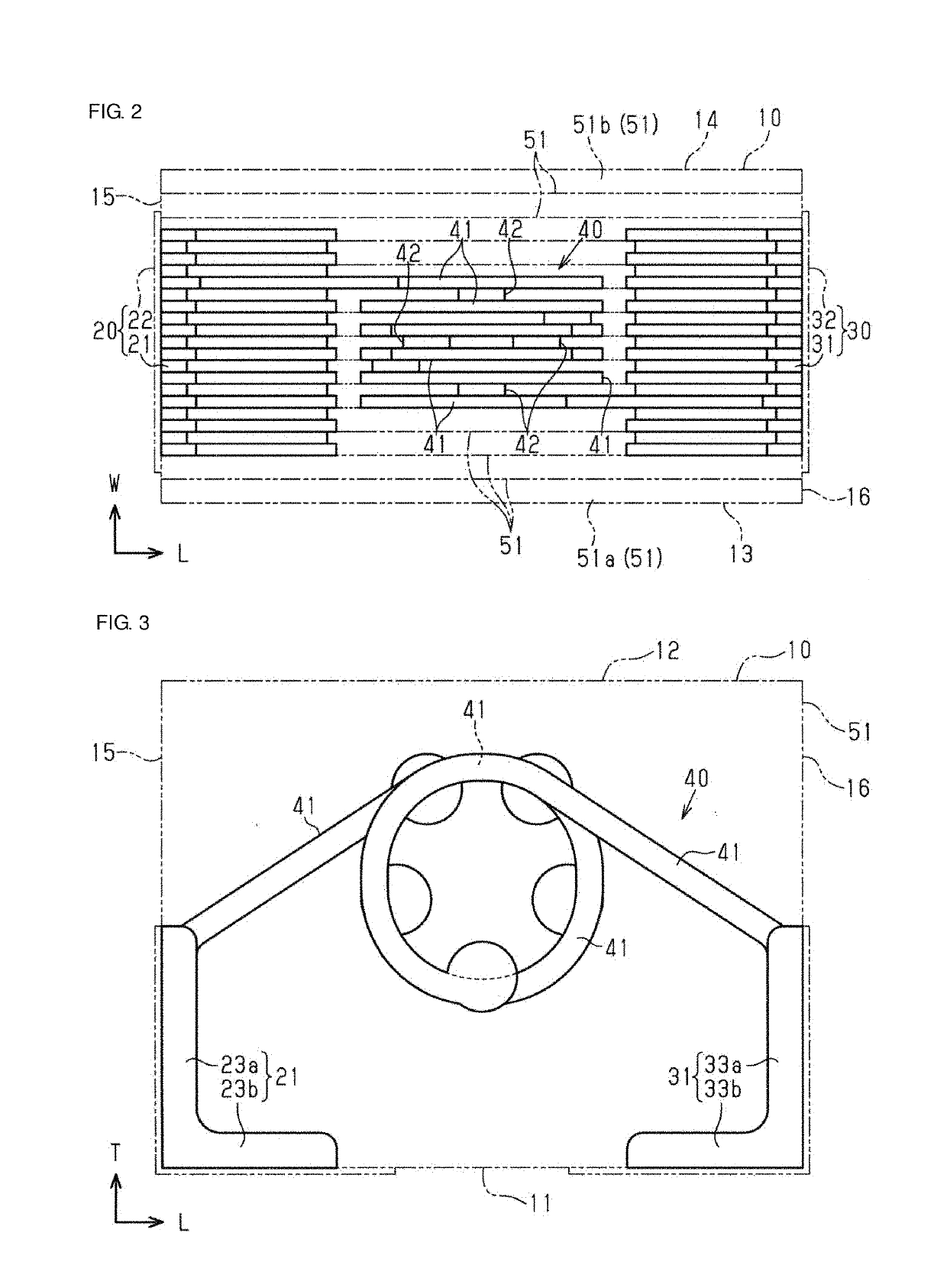

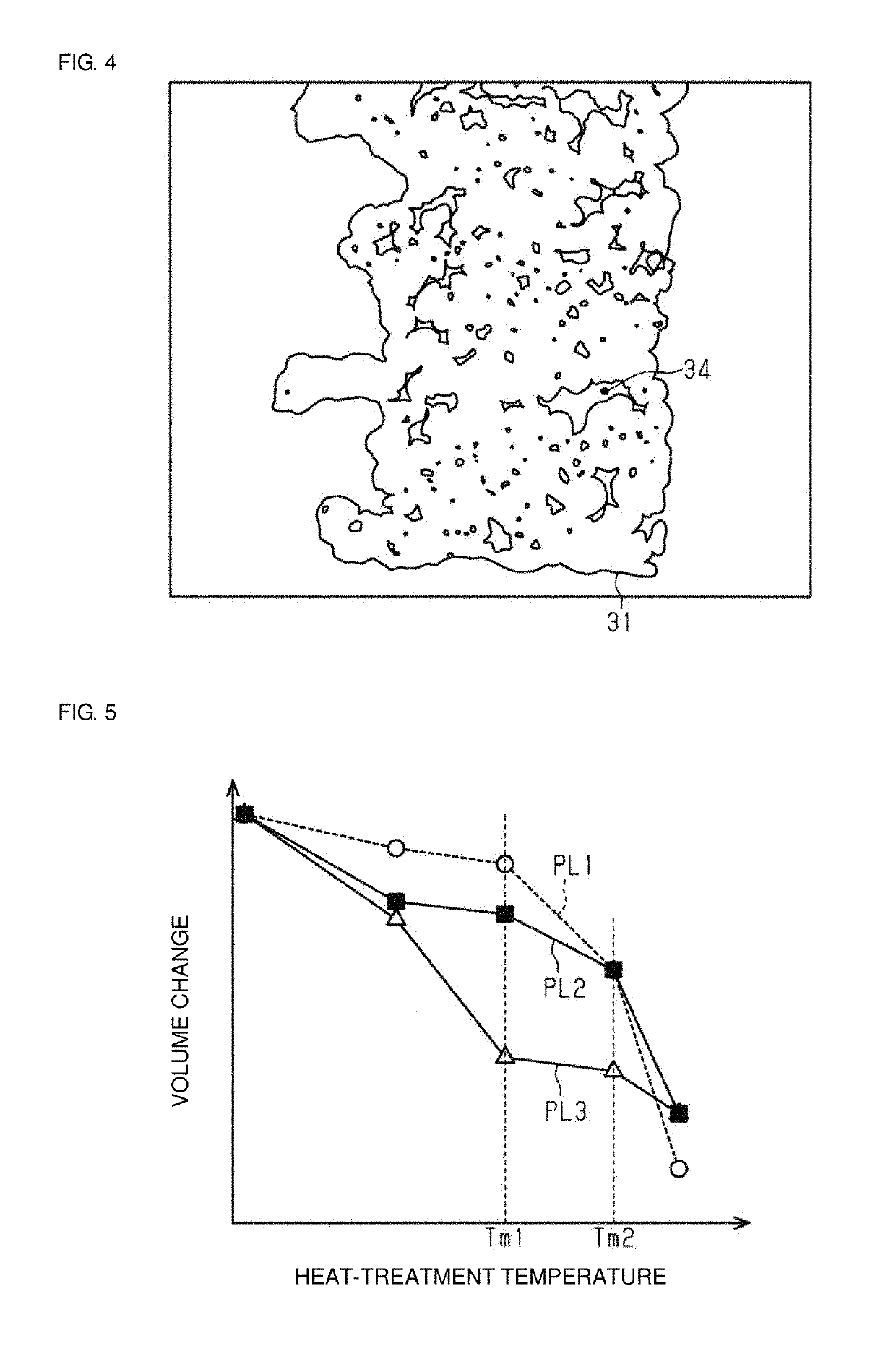

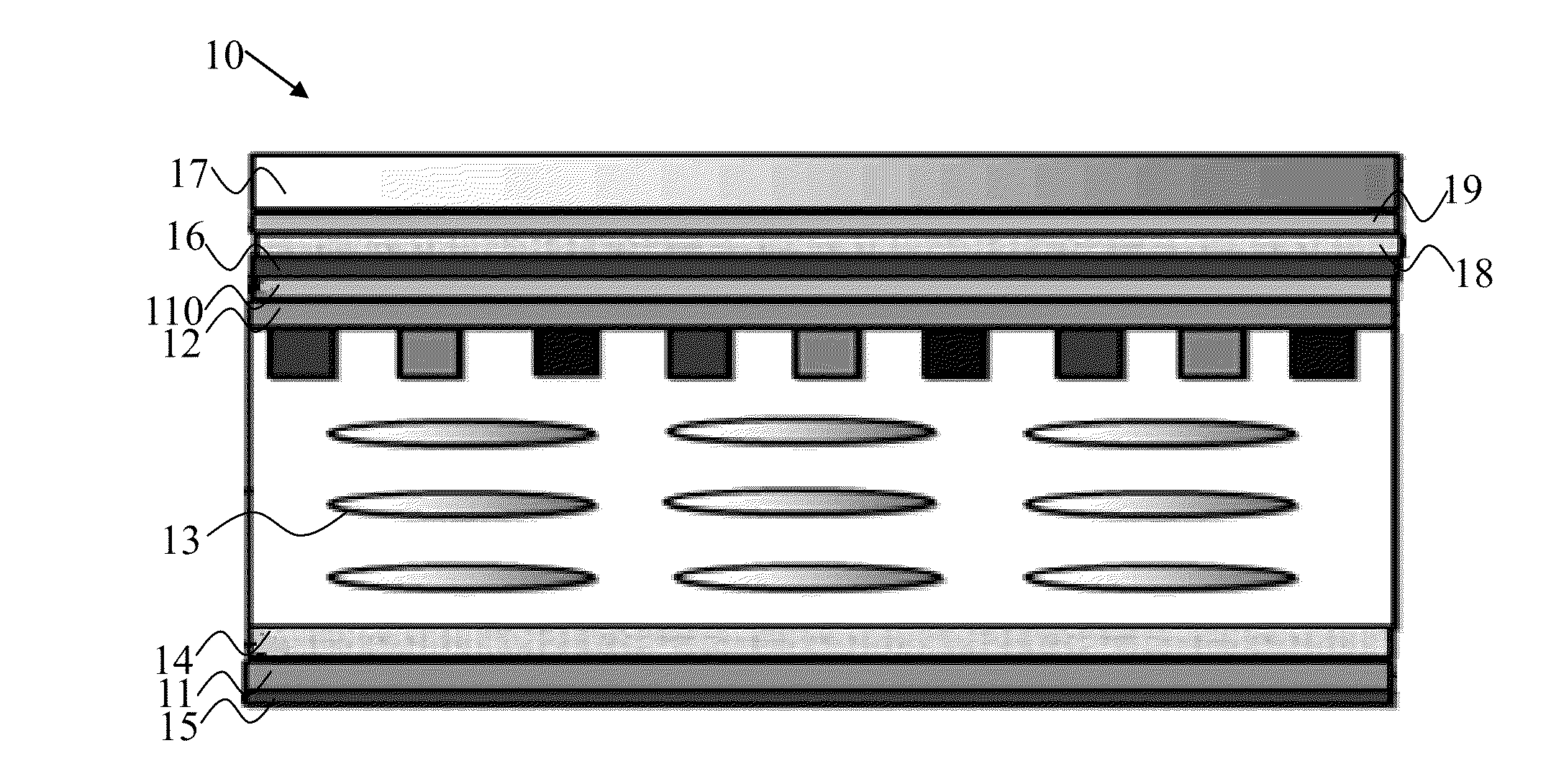

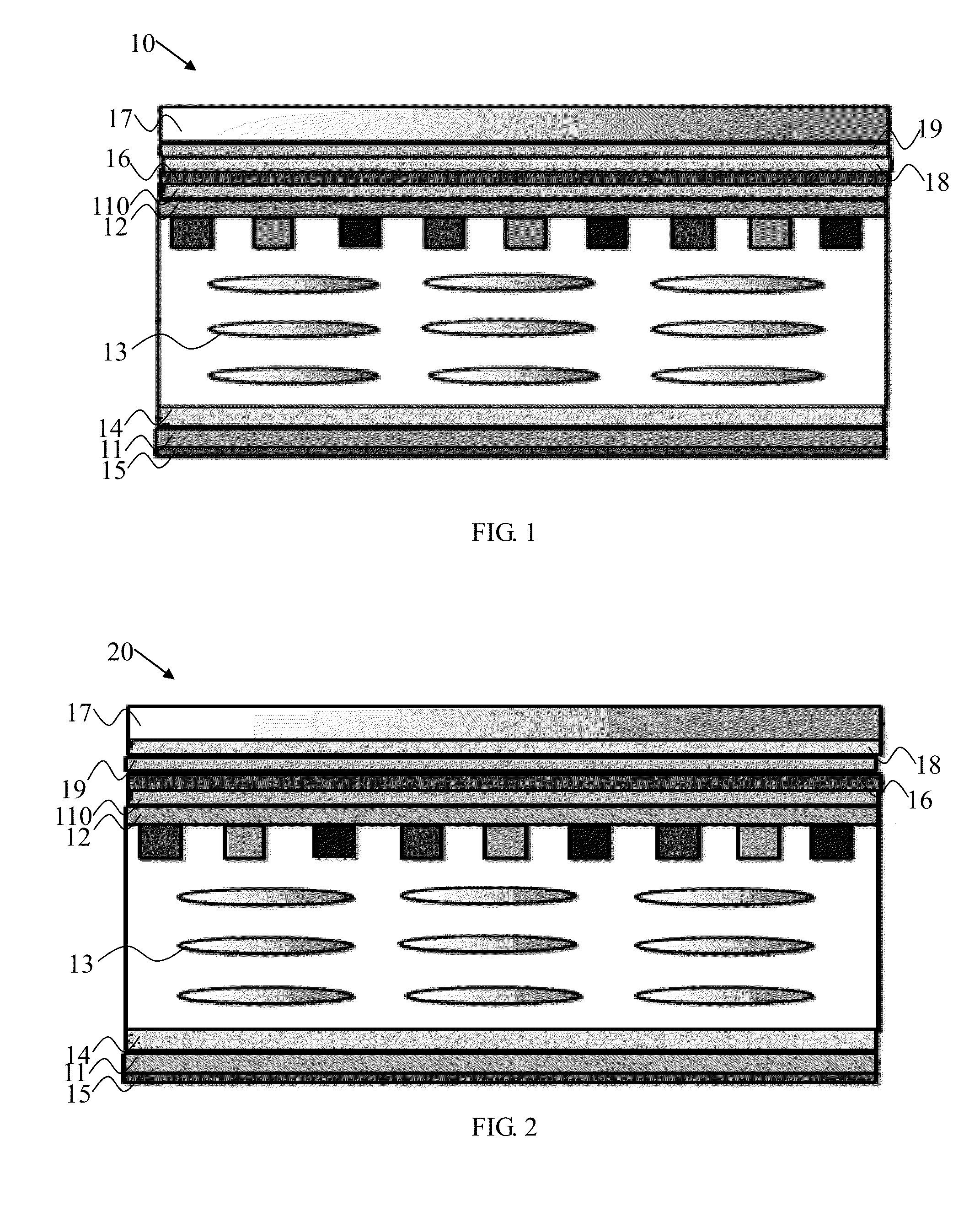

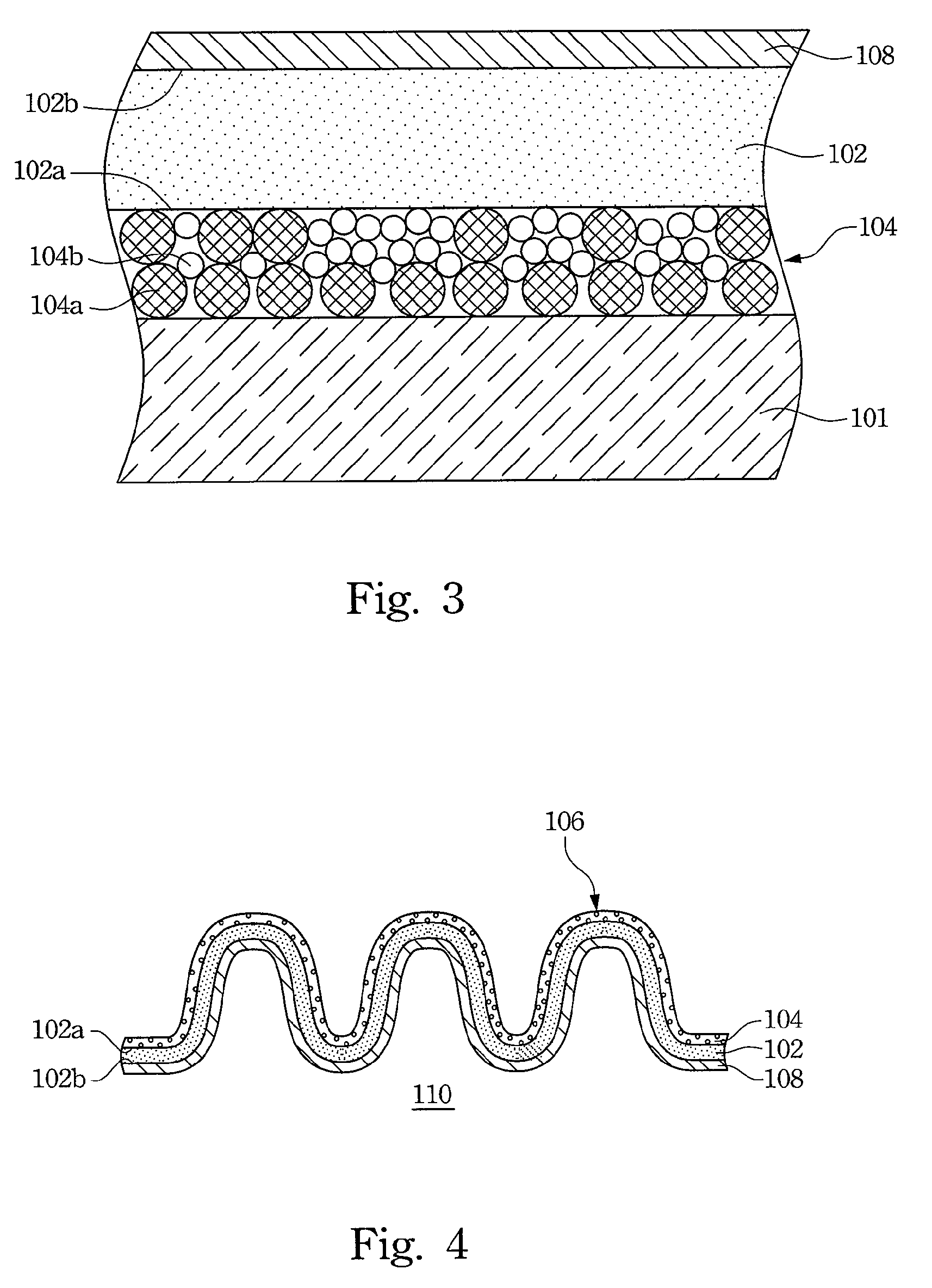

Method of manufacturing layered structure constituting all-solid-state battery, apparatus for manufacturing the same, and all-solid-state battery provided with layered structure

ActiveUS20130209873A1Lower yield rateInterfacial resistance be lowerElectrode thermal treatmentAssembling battery machinesLayered structureSolid-state battery

The present invention provides a method of manufacturing a layered structure and an apparatus for manufacturing a layered structure where the layered structure comprises a solid electrolyte layer, a positive electrode active material layer, and a negative electrode active material layer, which together constitute an all-solid-state battery, enables the interfacial resistance to be lowered, enables the interfacial strength to be increased, enables an improved yield rate, and enables a low manufacturing cost.The layered structure that has concavities and convexities formed on the surface is manufactured by the method comprising steps of:forming a green sheet S111, where the green sheet for a solid electrolyte layer 11 is formed; forming concavities and convexities S112, where (1) the green sheet for a solid electrolyte layer 11 and (2) the sheet member 50 that is made from material that is caused to disappear when heated, and that has concavities and convexities, are formed in one piece, and the concavities and convexities are formed on the surface of the green sheet for a solid electrolyte layer 11; heating S113, where the sheet member 50 is caused to disappear by heating the green sheet for a solid electrolyte layer 11 and the sheet member 50 that are formed in one piece, and where the green sheet for a solid electrolyte layer 11 is sintered.

Owner:SINTOKOGIO LTD

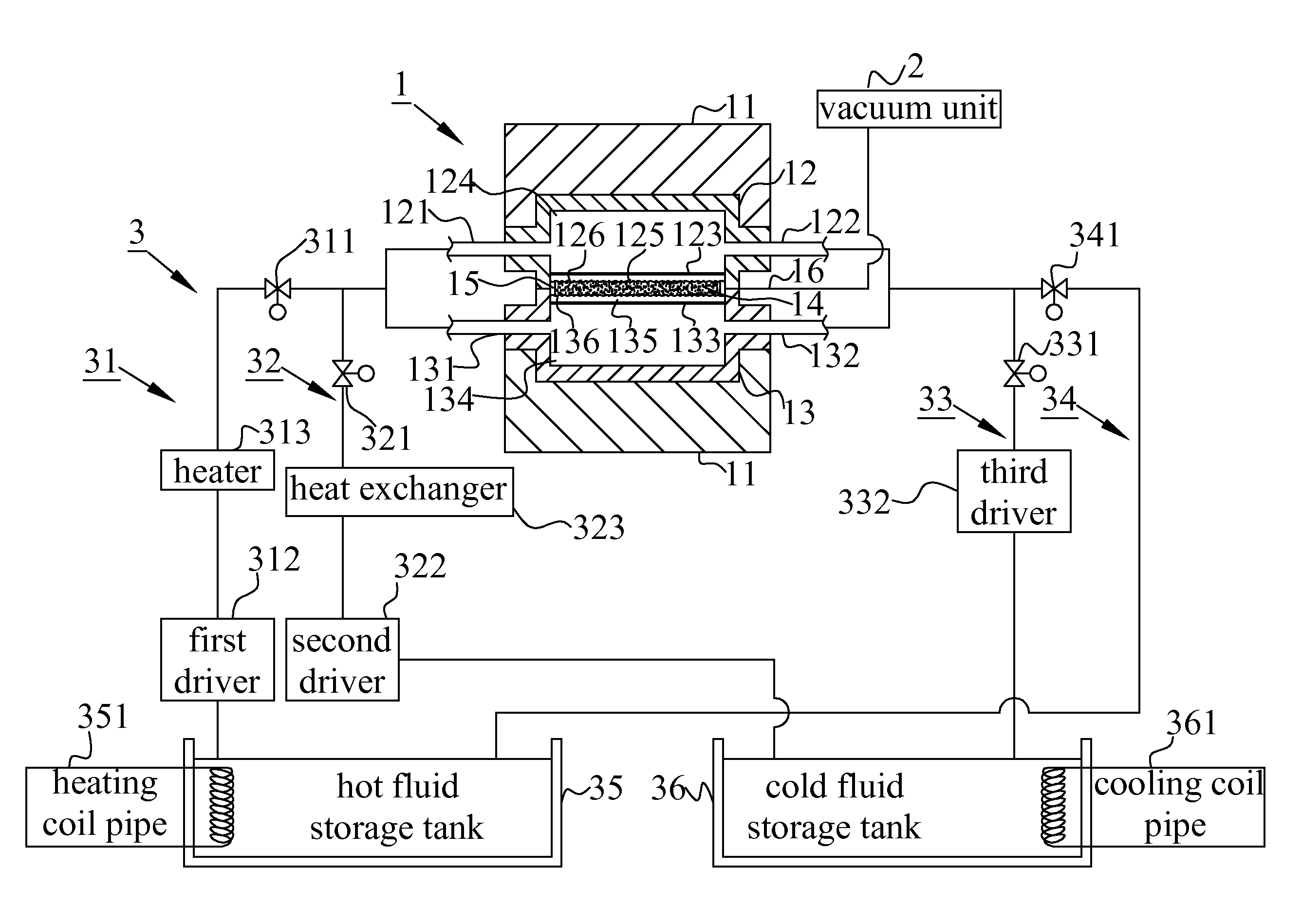

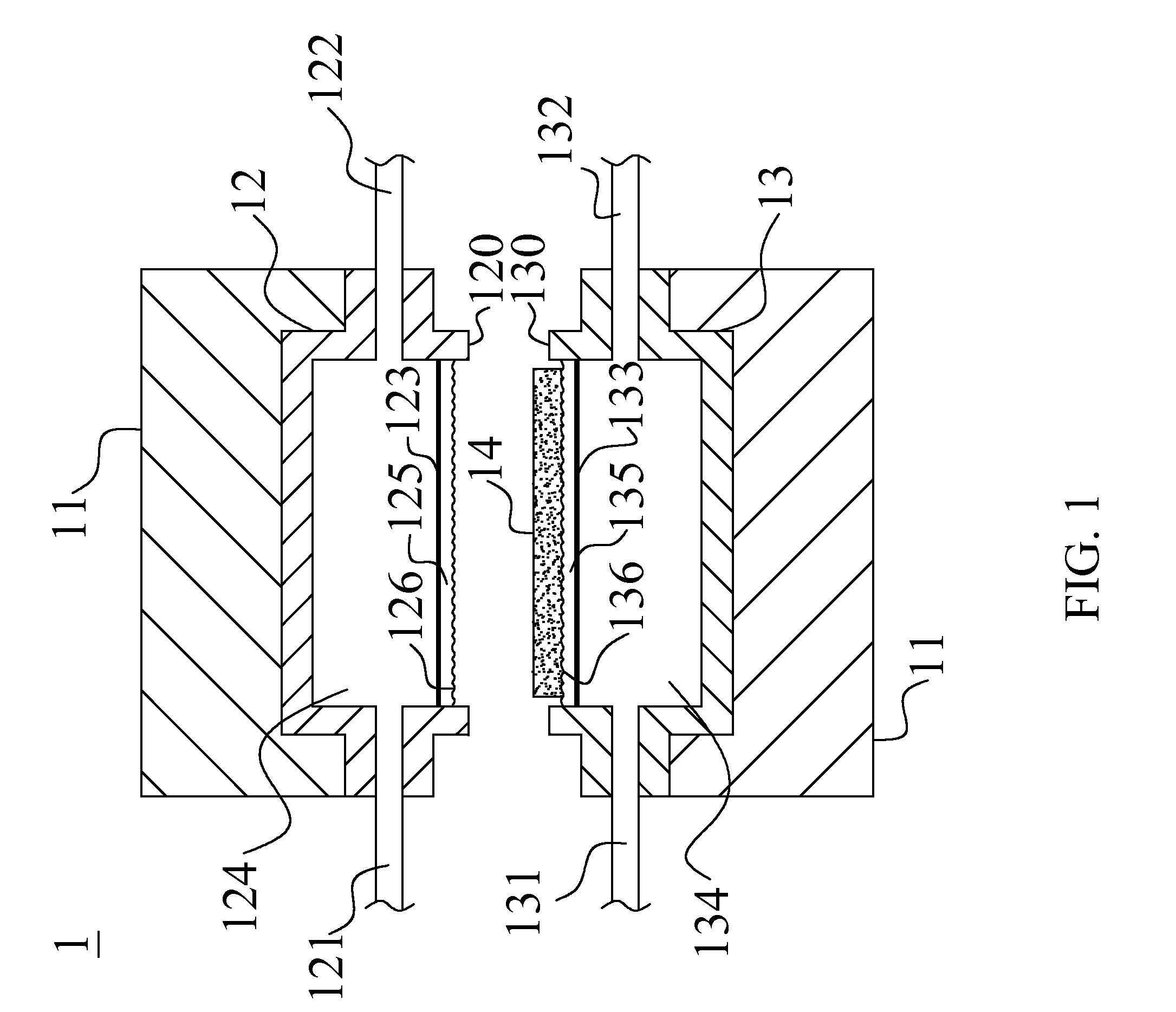

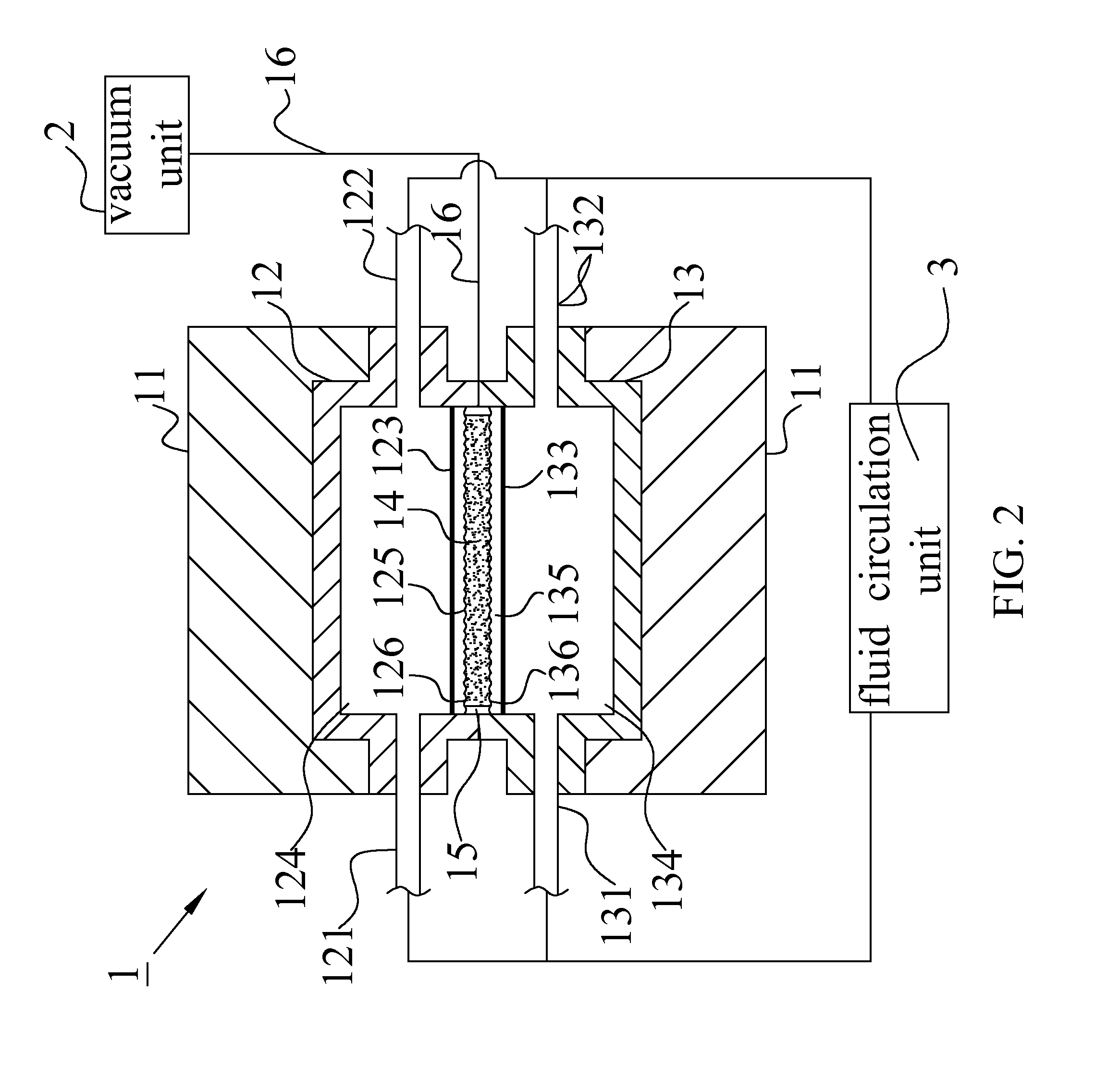

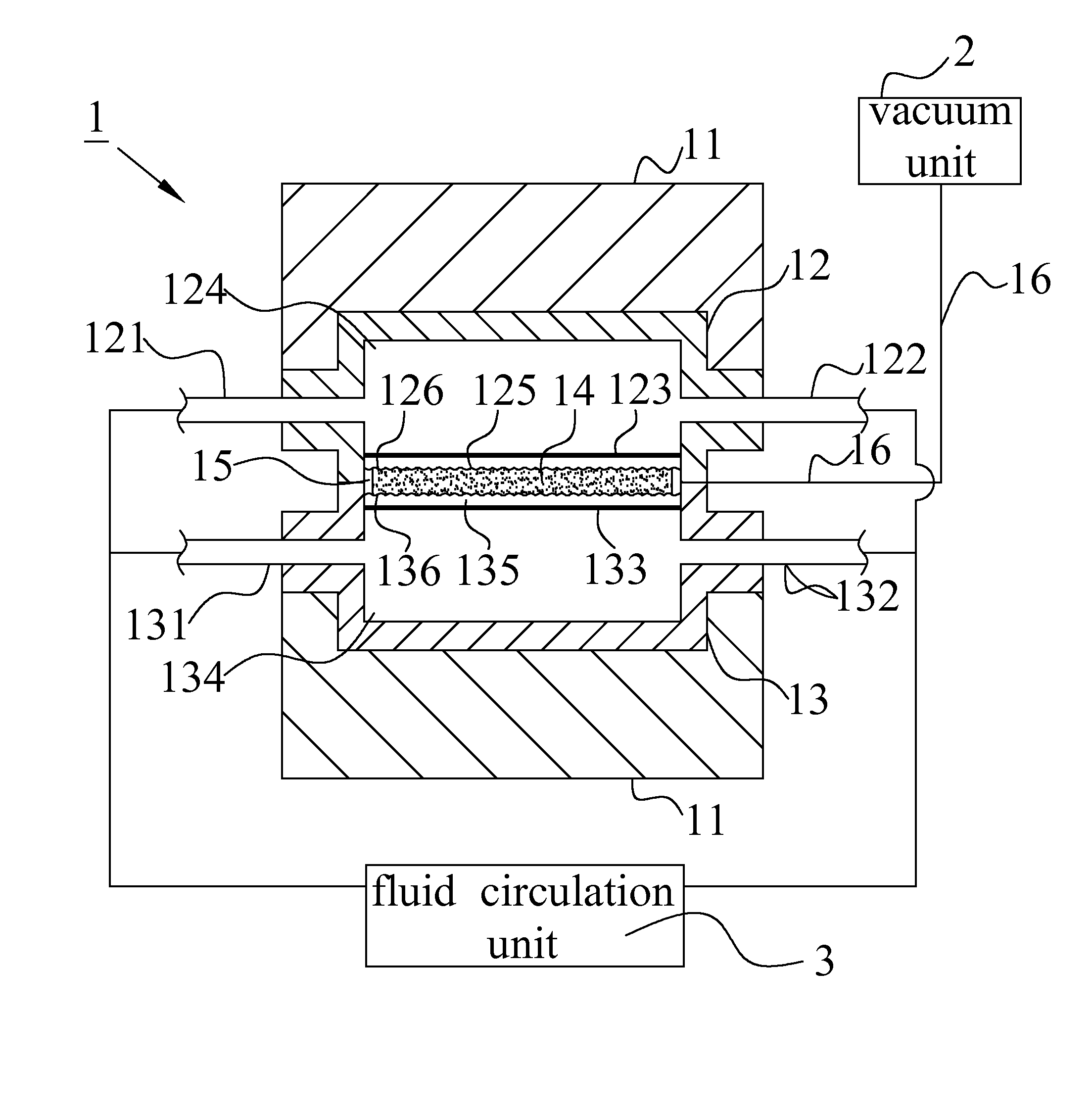

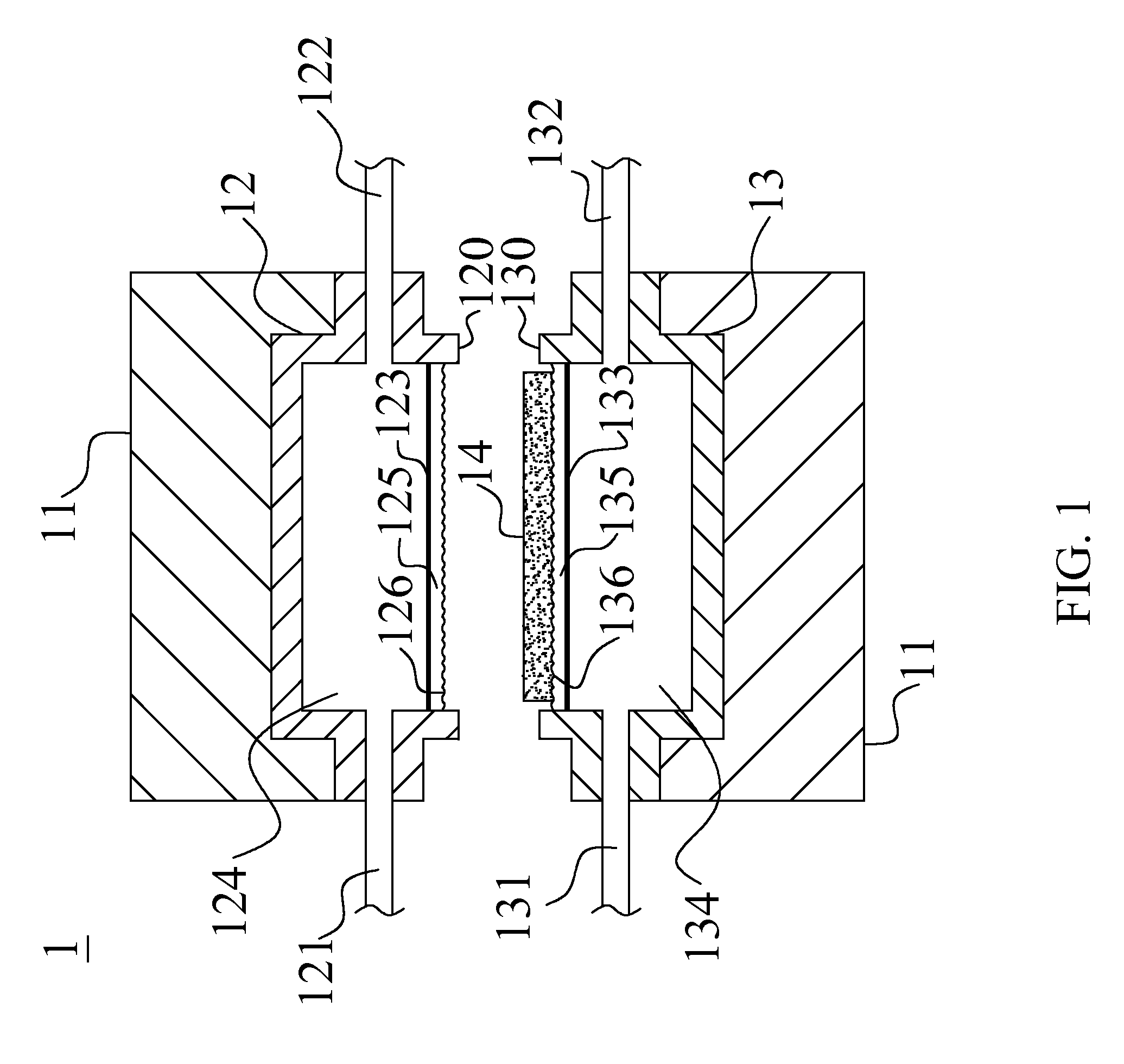

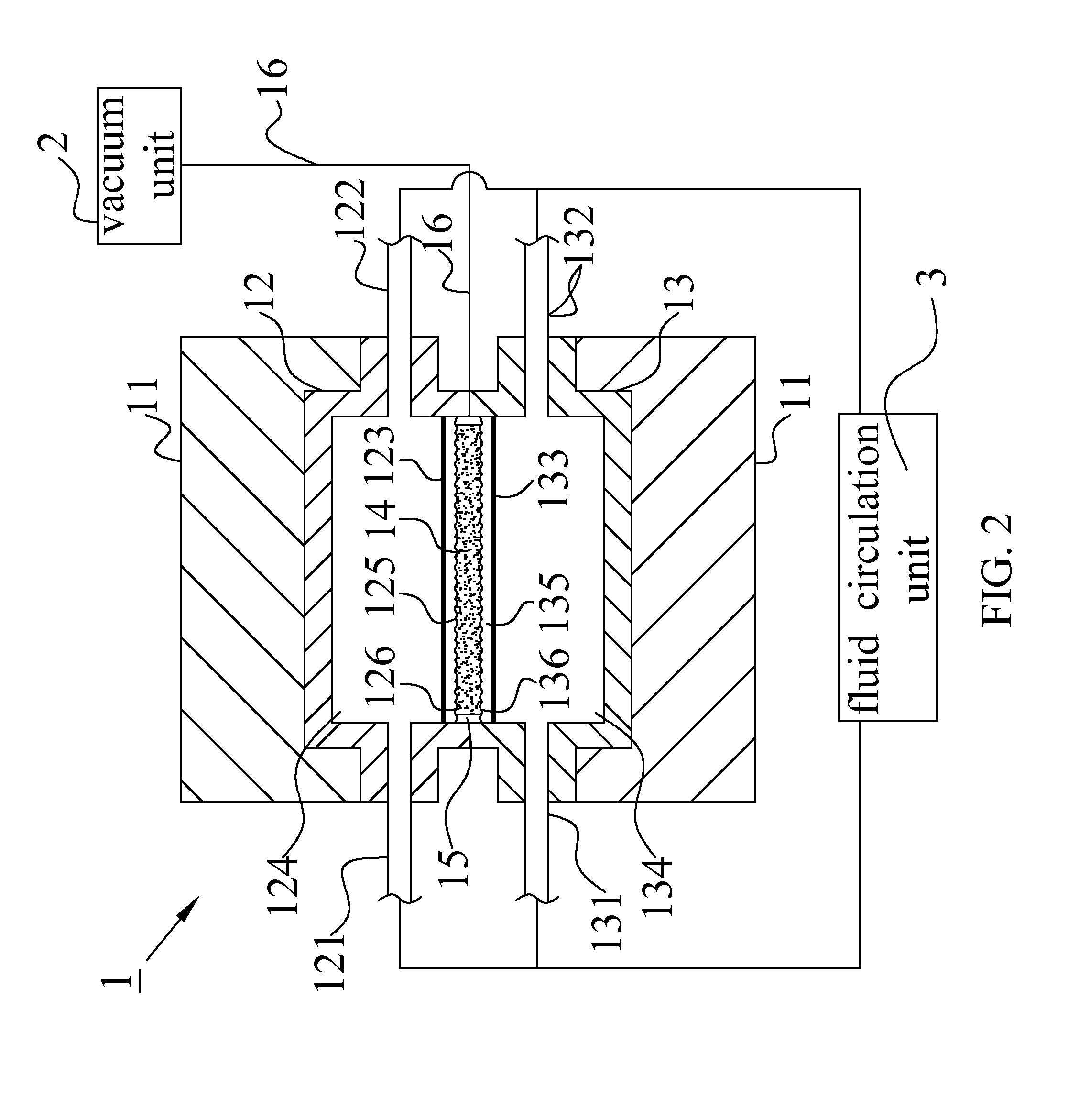

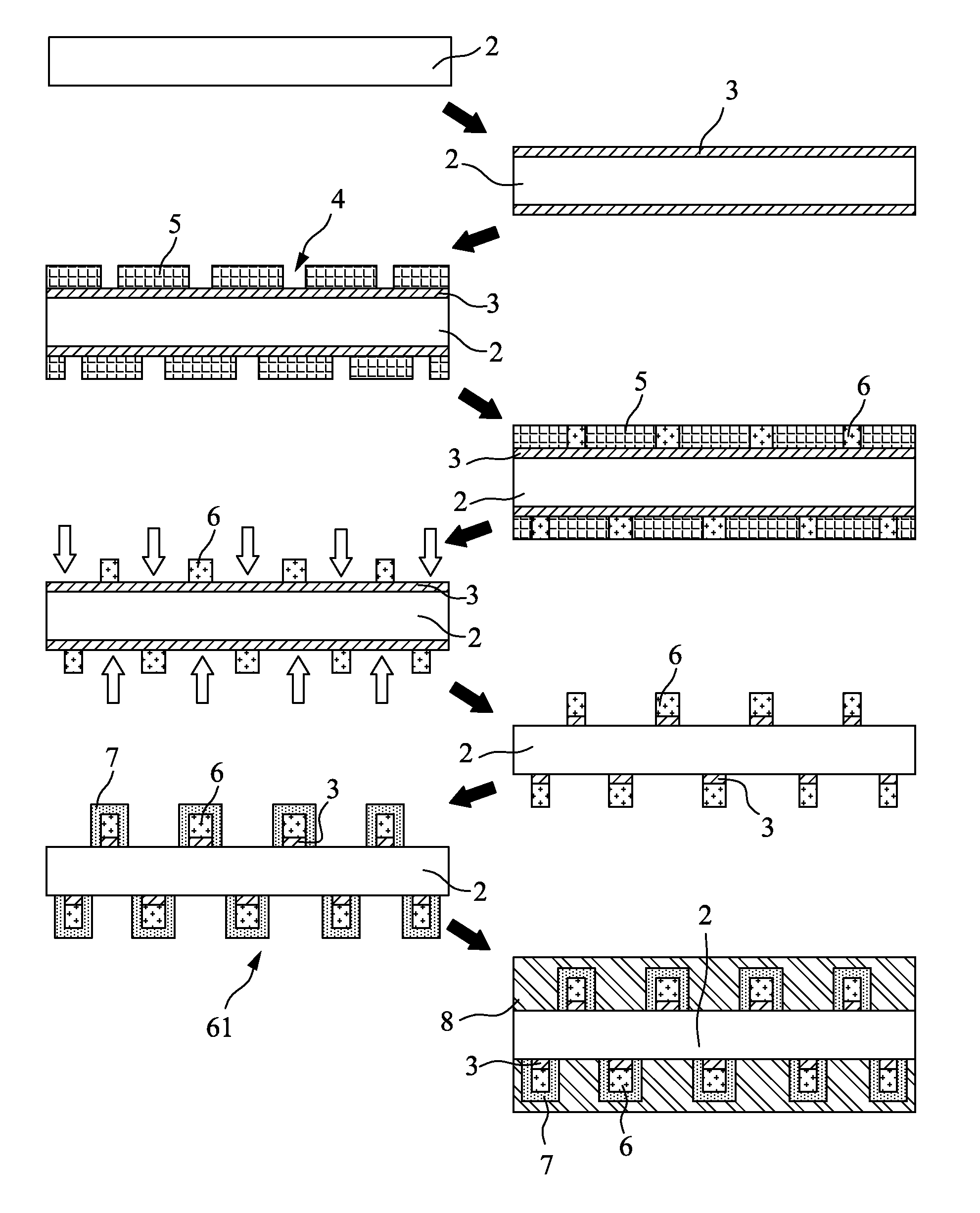

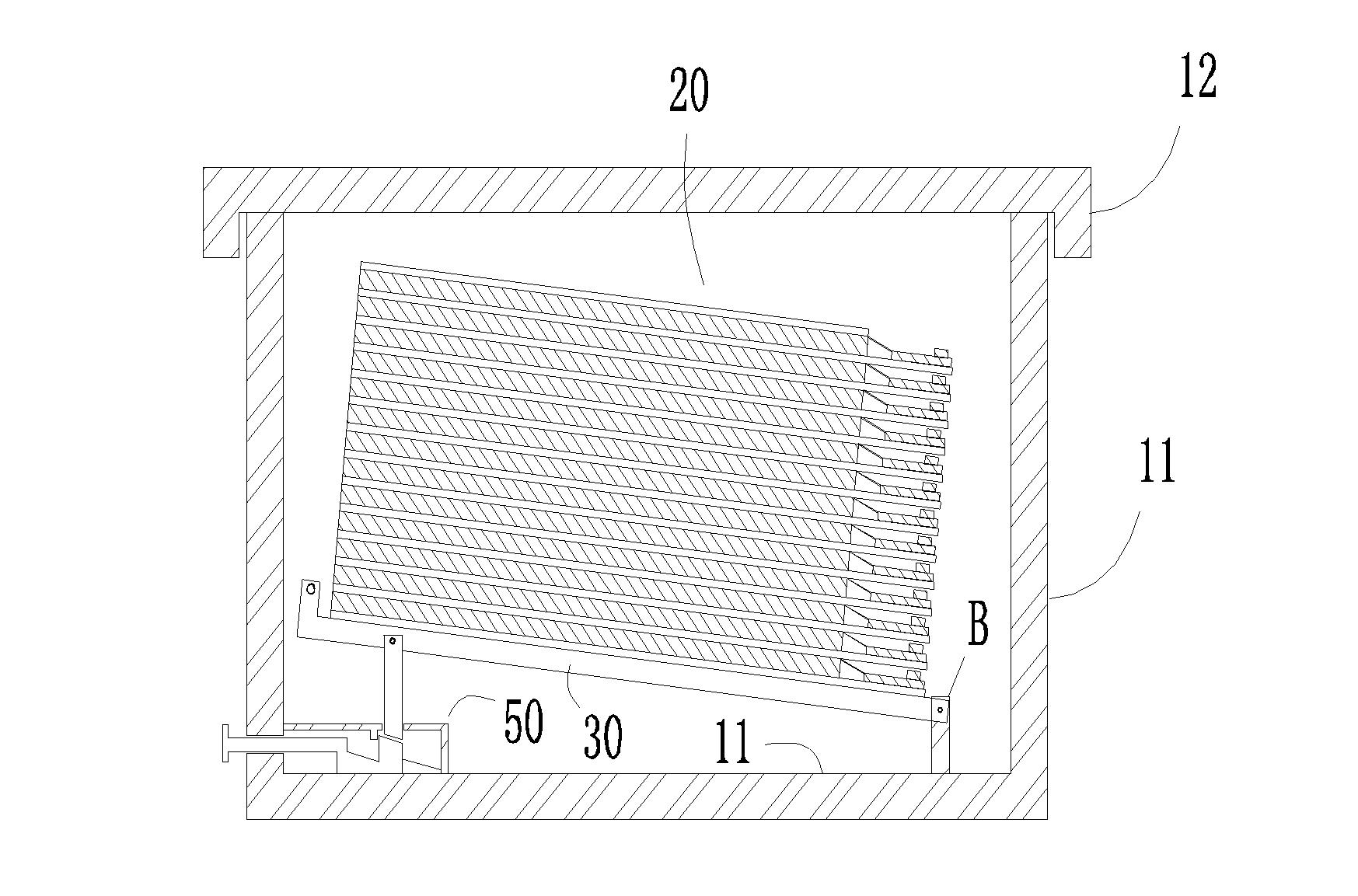

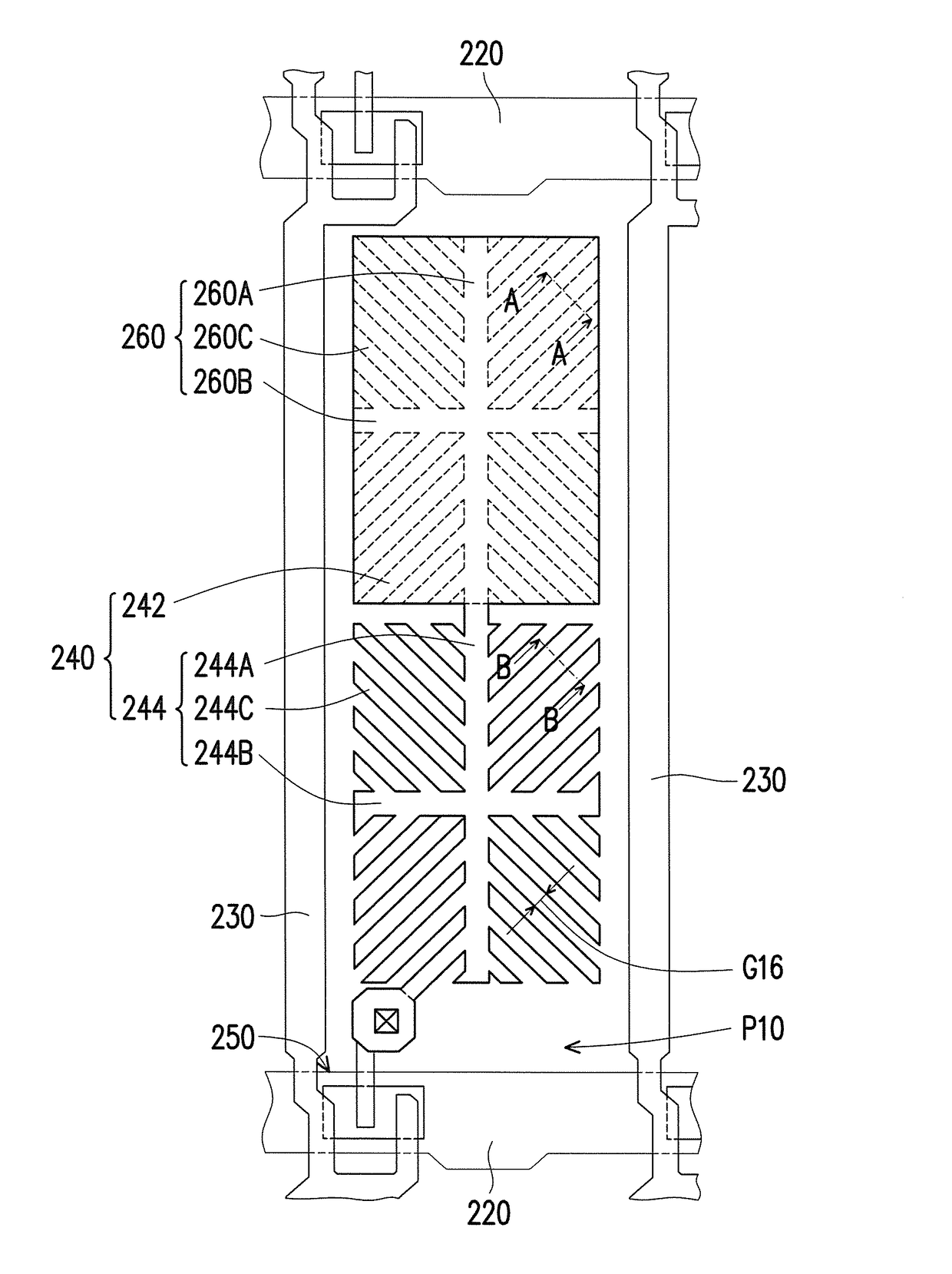

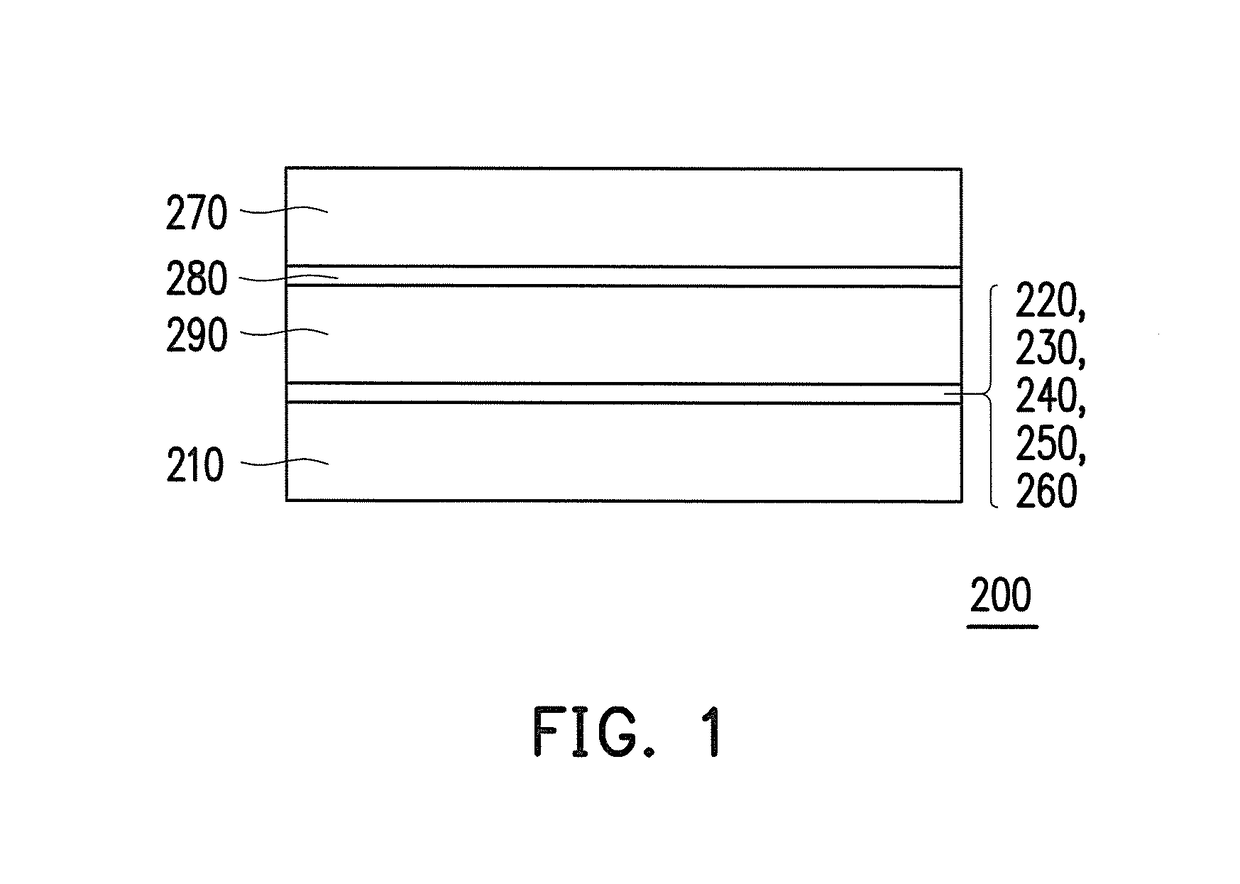

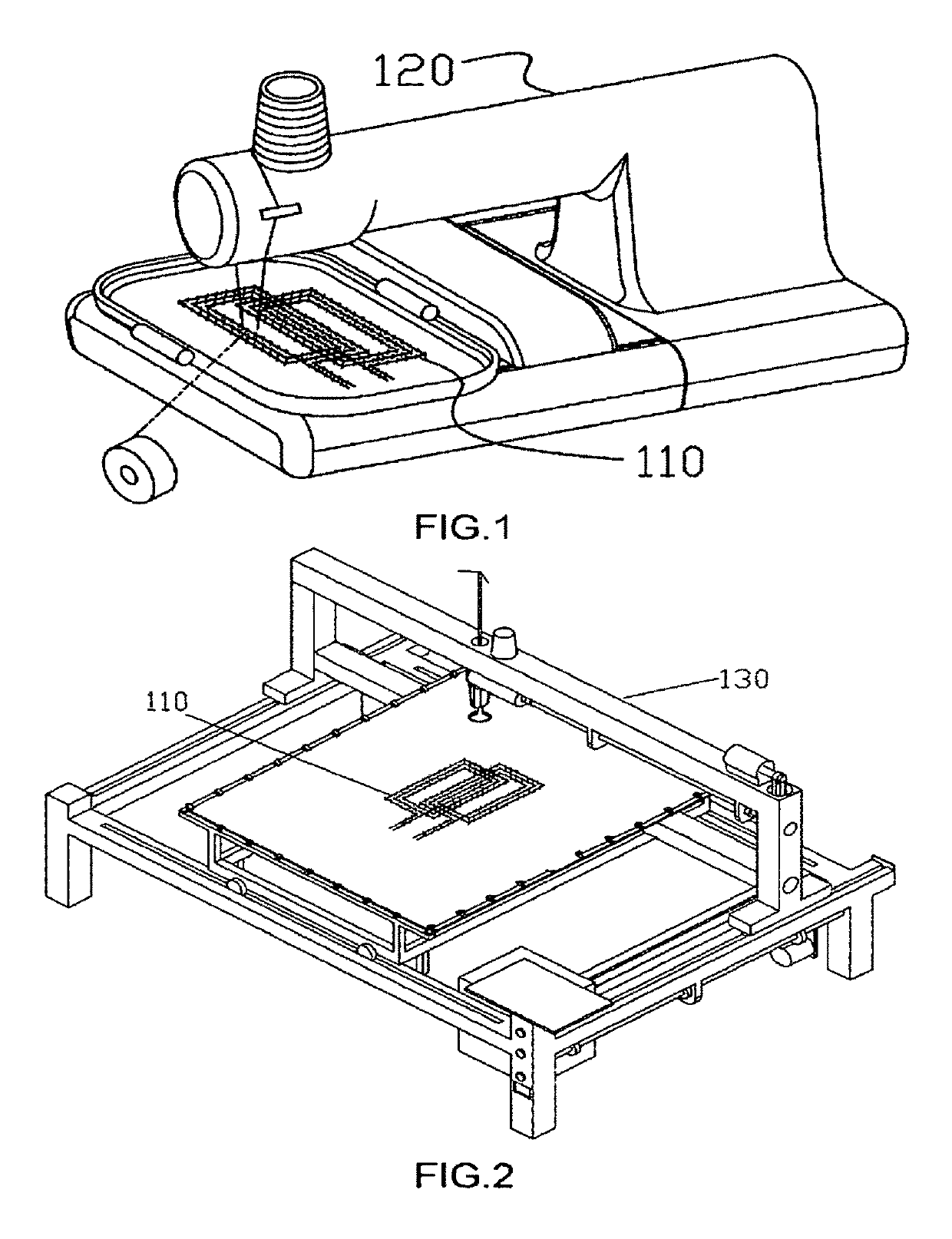

Uniform-pressure shaping apparatus and system

InactiveUS20110287124A1Low yield rateConfectioneryCeramic shaping apparatusEngineeringFluid circulation

In a uniform-pressure shaping apparatus and system, the system comprises a uniform-pressure shaping apparatus, a vacuum unit and a fluid circulation unit, and the apparatus comprises a first cavity and a second cavity, each including a sealed pressure chamber, a heat conduction film and a template. An object to be imprinted is put on a pattern-imprinting surface of the template. When the first and second cavities get close to each other, the vacuum unit vacuums the space between the pattern-imprinting surfaces of the two templates. Meanwhile, the fluid circulation unit drives a hot fluid to pass through the two sealed pressure chambers. With the iso-pressure characteristic of the hot fluid, the object to be imprinted is heated and pressed uniformly until a desired shape is formed, and then a cold fluid is driven to pass through the two sealed pressure chambers to cool the object to be imprinted.

Owner:CHENMING MOLD IND CORP

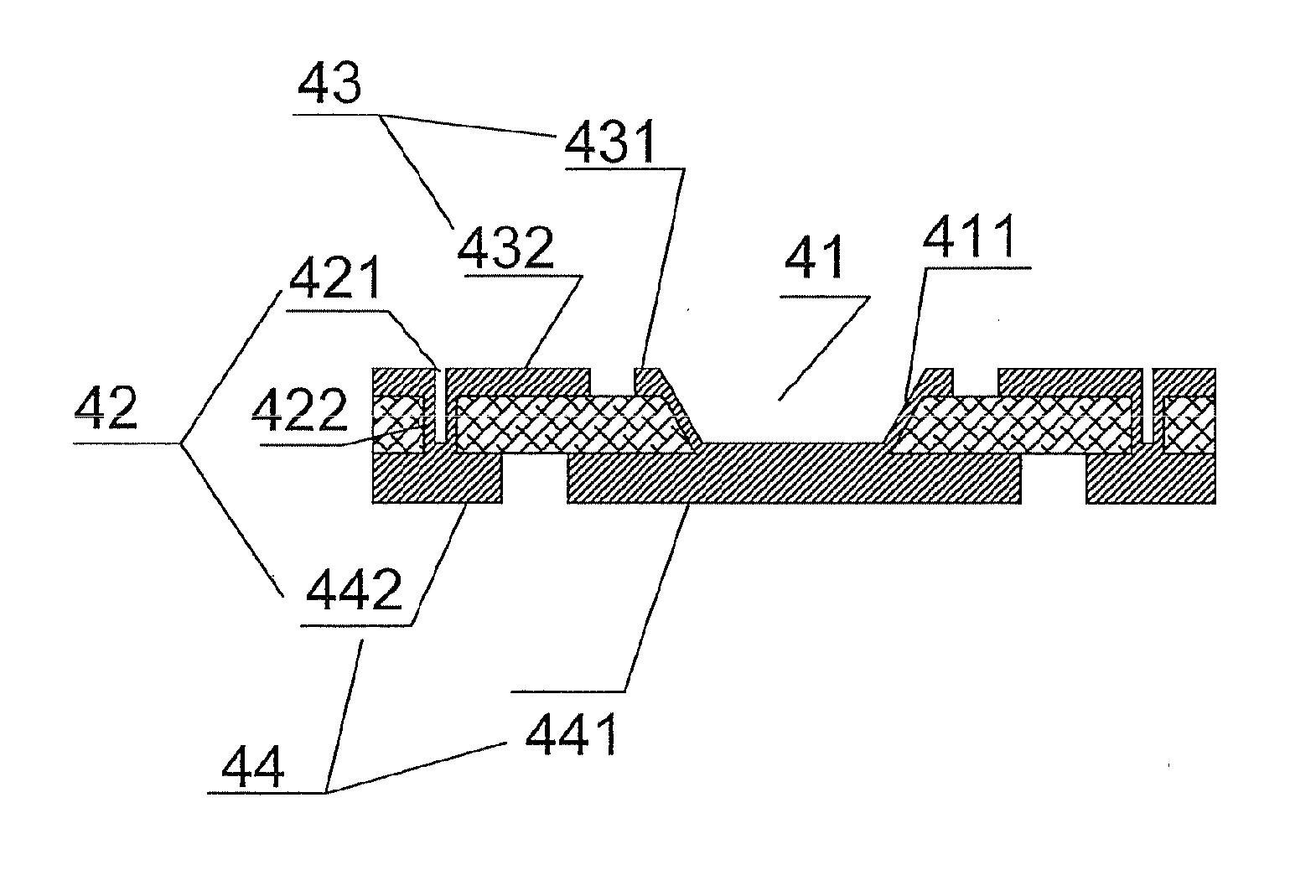

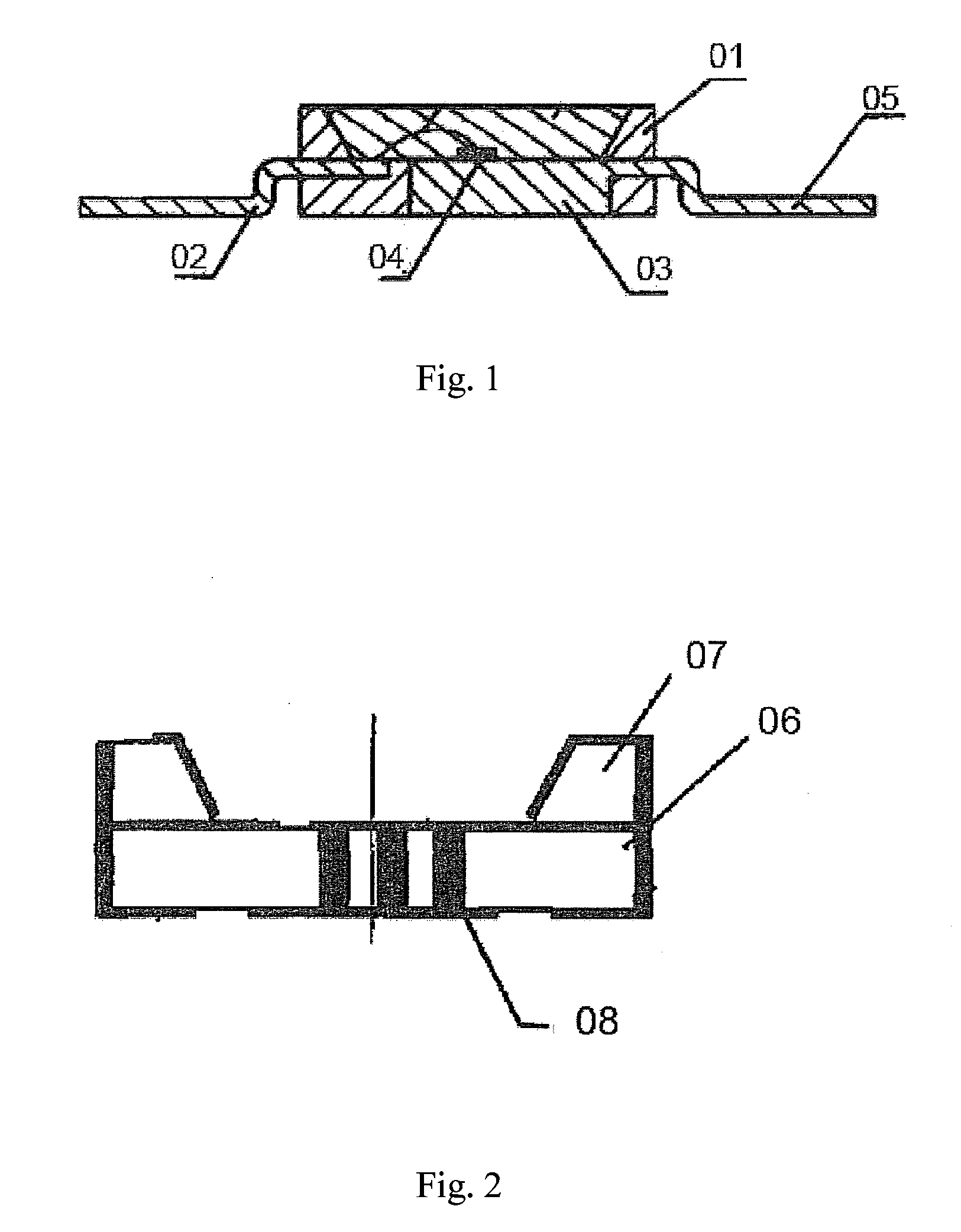

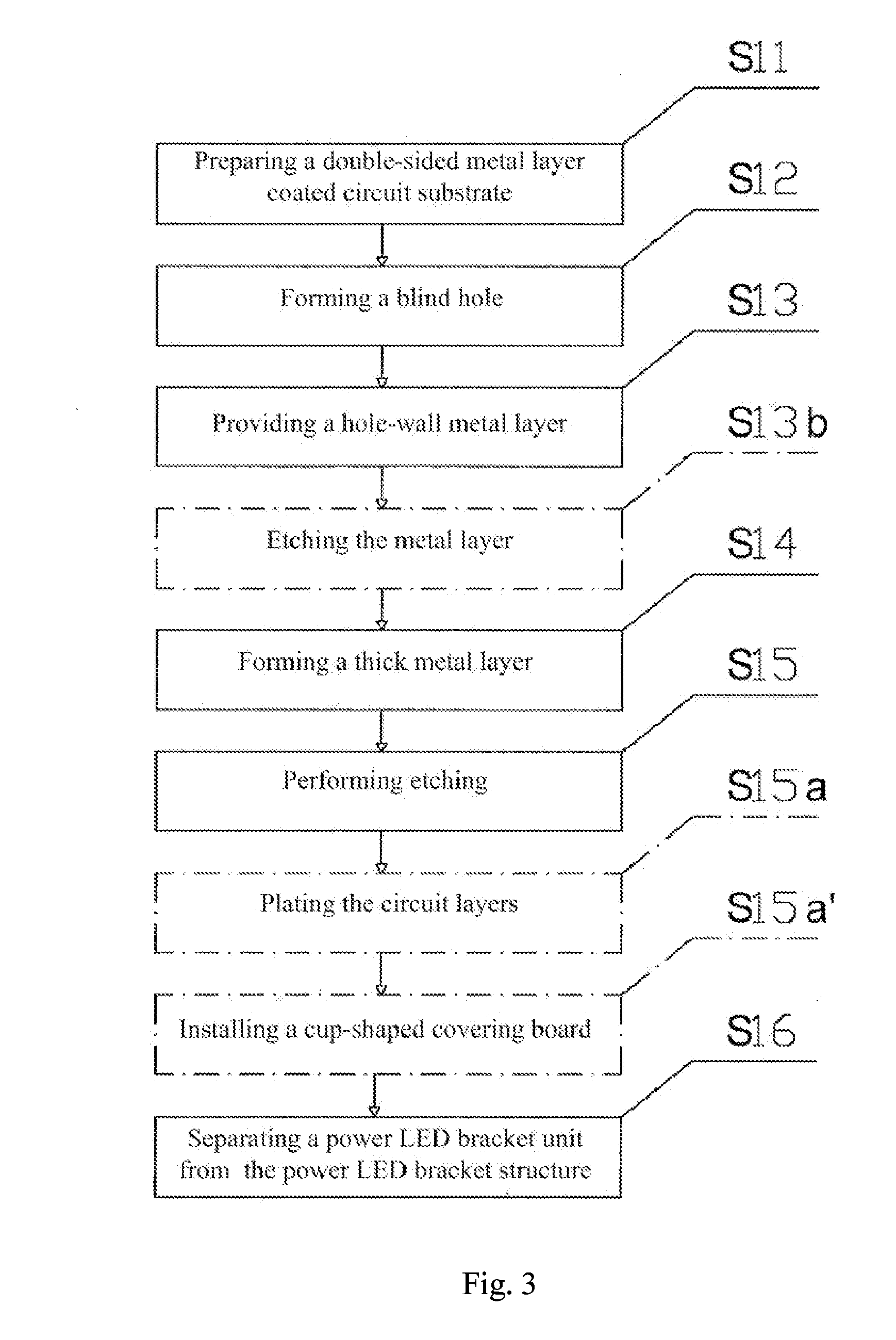

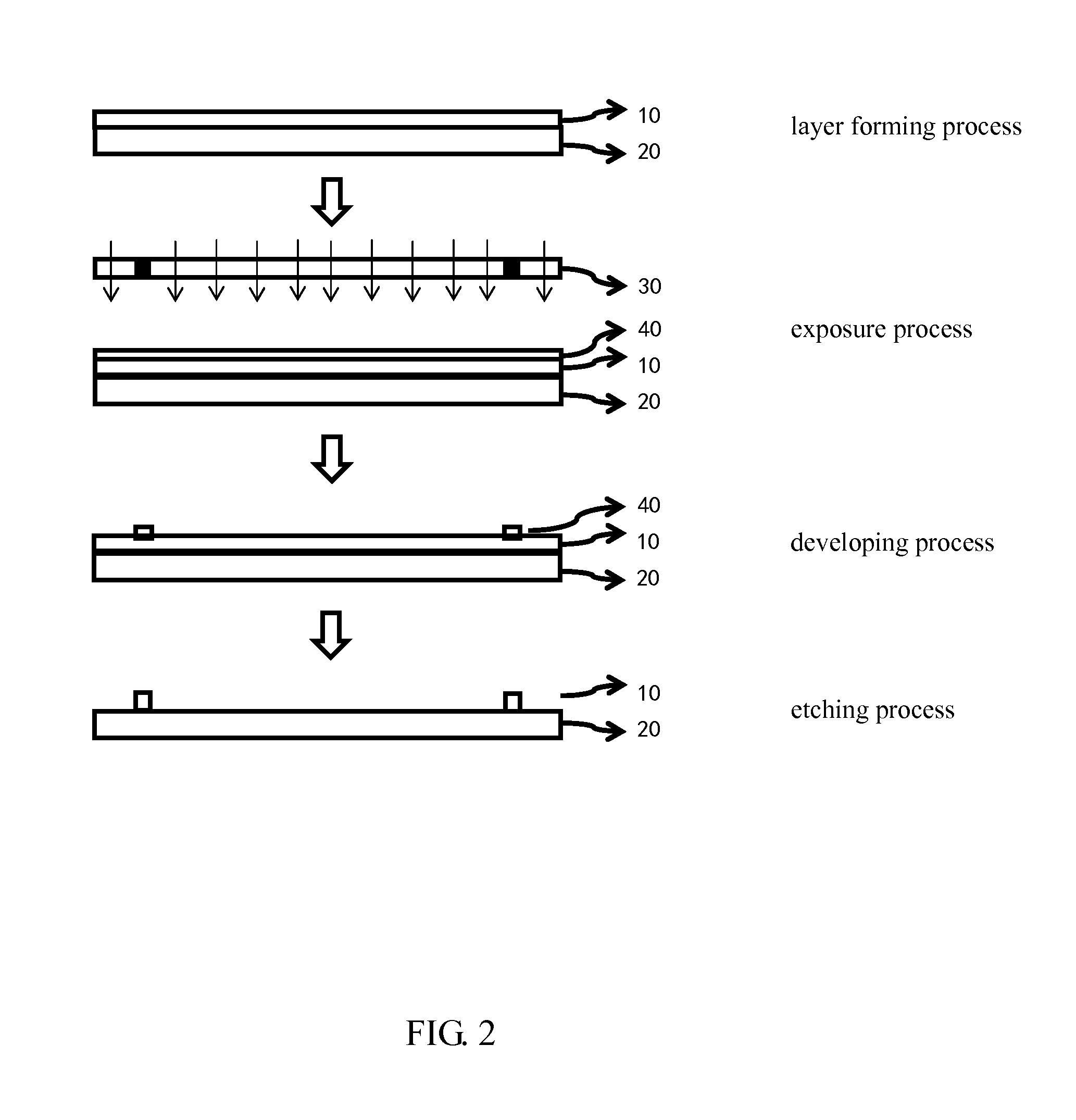

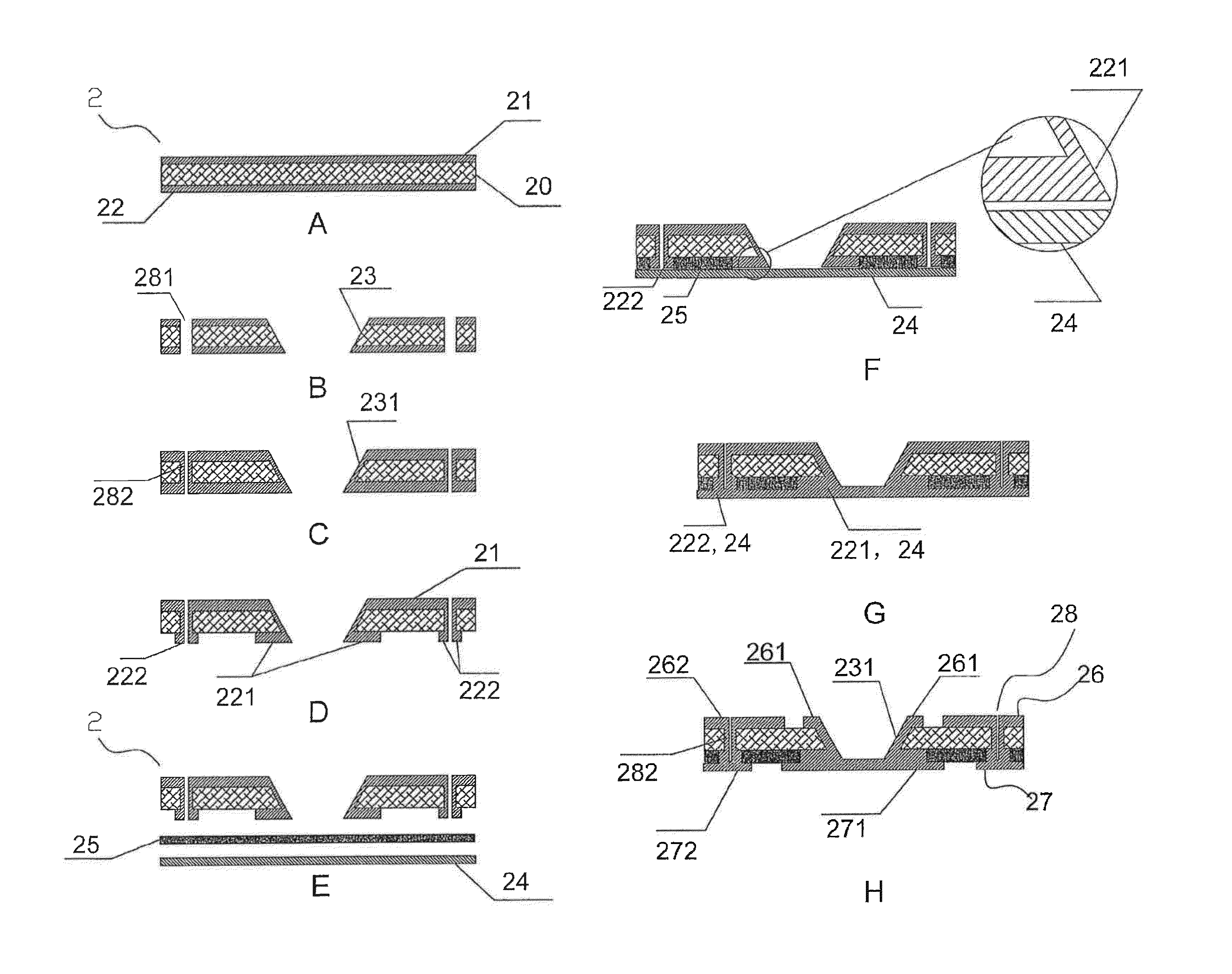

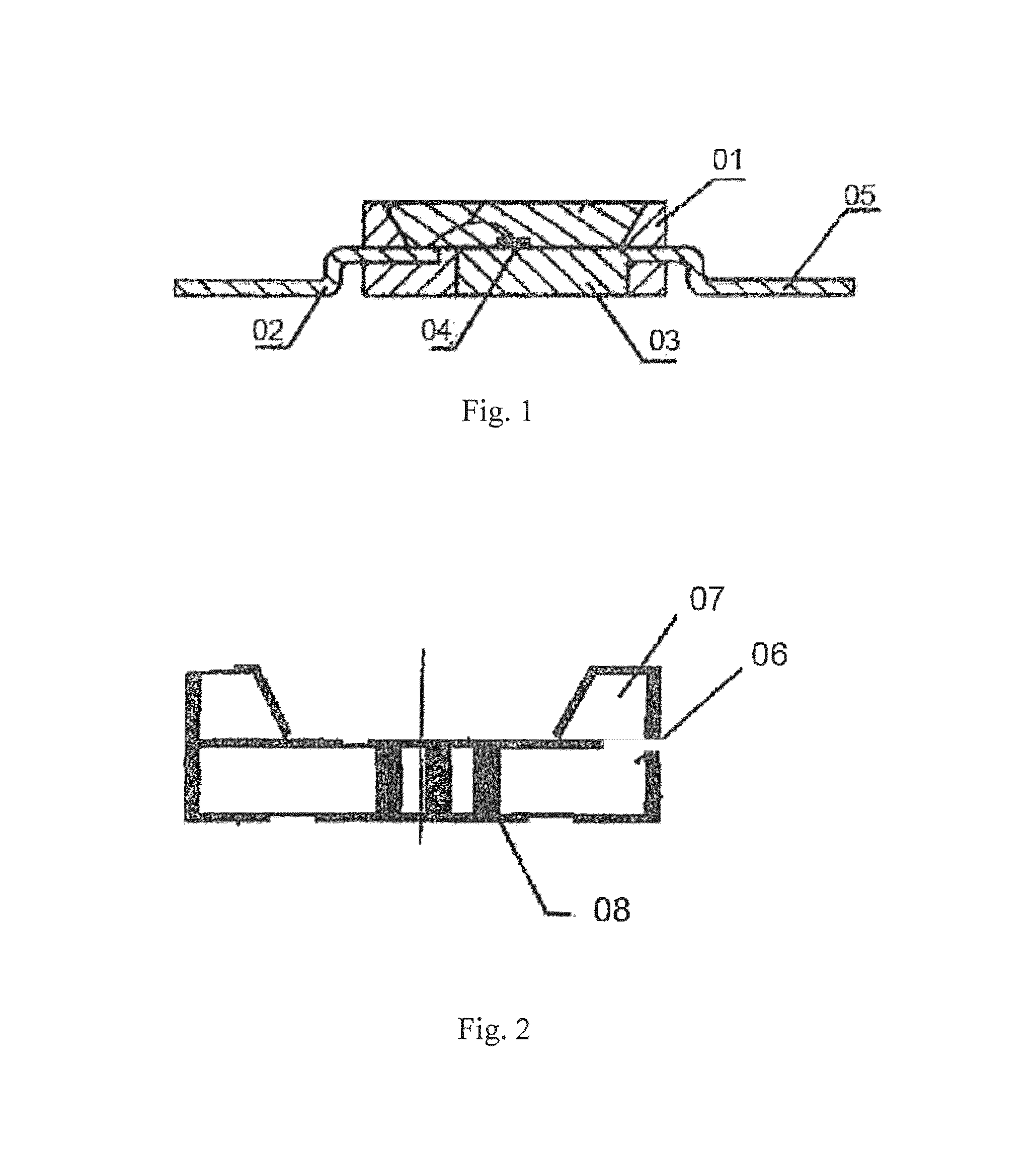

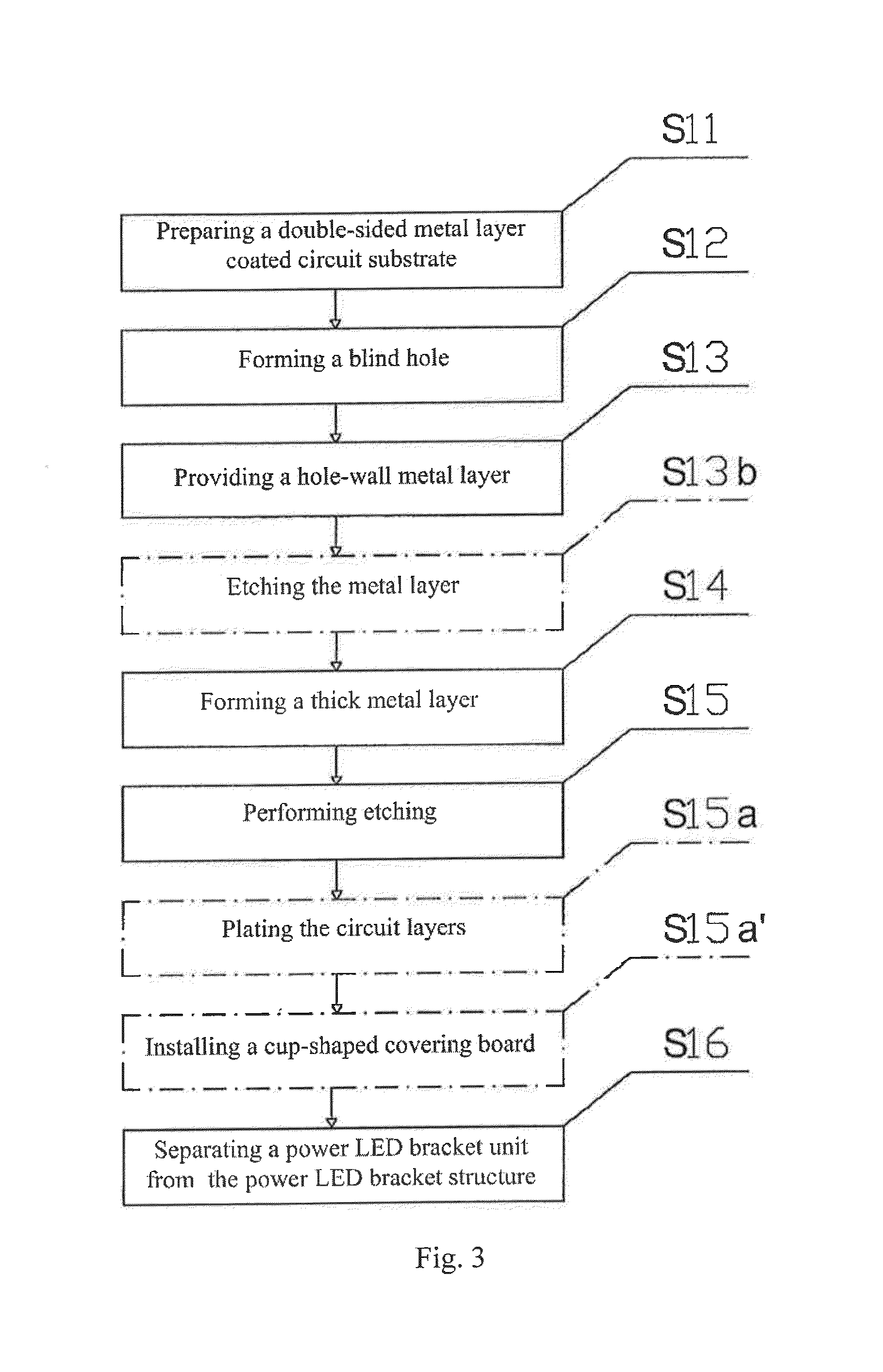

Manufacture Method for a Surface Mounted Power LED Support and its Product

ActiveUS20130121007A1Low costEasy to manufactureLighting support devicesPrinted circuit aspectsSurface mountingPhysics

A manufacture method for a surface mounted power LED support comprises providing a wiring board having both sided metal layers. In addition, the method comprises forming a hole. Further, the method comprises setting a metal layer in the surface of the hole. Still further, the method comprises thickening the metal layer of the wiring board. The method also comprises etching the metal layer of the wiring board. Moreover, the method comprises cutting the wiring board to form single support unit. A surface mounted power LED support comprises a both sided wiring board, a hole formed in the wiring board and wiring layers set on the surface of the wiring board.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD +1

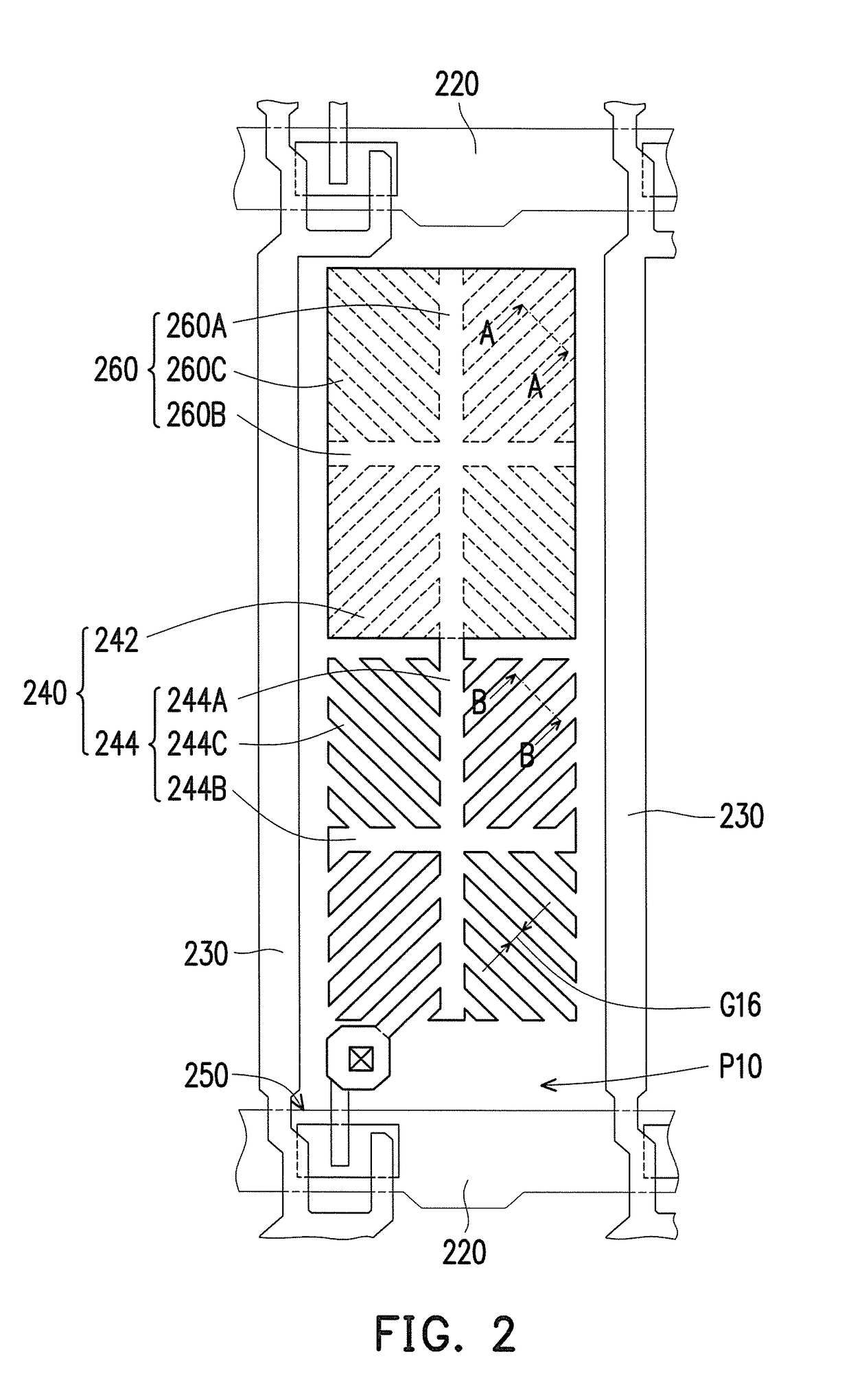

Display device

The disclosure provides a display device. The pixel electrode of the display device includes a first pixel electrode and a second pixel electrode having the same electric potential. The first interlayer is formed between the first substrate and the first pixel electrode. Adjacent two of the first strip-shaped branches of the first interlayer form a first gap to expose part of the first substrate. The common electrode layer is disposed over the second substrate. The pixel electrode is positioned between the first substrate and the display medium layer. The first pixel electrode extends to cover the first gap. A difference between a maximum distance between the first pixel electrode and the common electrode layer and a maximum distance between the second pixel electrode and the common electrode layer is 0.1 μm to 0.4 μm.

Owner:INNOLUX CORP

Uniform-pressure shaping apparatus and system

In a uniform-pressure shaping apparatus and system, the system comprises a uniform-pressure shaping apparatus, a vacuum unit and a fluid circulation unit, and the apparatus comprises a first cavity and a second cavity, each including a sealed pressure chamber, a heat conduction film and a template. An object to be imprinted is put on a pattern-imprinting surface of the template. When the first and second cavities get close to each other, the vacuum unit vacuums the space between the pattern-imprinting surfaces of the two templates. Meanwhile, the fluid circulation unit drives a hot fluid to pass through the two sealed pressure chambers. With the iso-pressure characteristic of the hot fluid, the object to be imprinted is heated and pressed uniformly until a desired shape is formed, and then a cold fluid is driven to pass through the two sealed pressure chambers to cool the object to be imprinted.

Owner:CHENMING MOLD IND CORP

Touch sensing electrode structure and method of manufacturing same

ActiveUS9128663B1Extended service lifeLow yield rateCircuit optical detailsDigital data processing detailsTouch SensesOptoelectronics

A method of manufacturing touch sensing electrode structure includes the steps of selecting a predetermined substrate material to form a substrate layer; forming at least one adhesion layer on the substrate layer; forming a masking layer with recessed lines on the adhesion layer; forming metal conductive electrodes in the recessed lines on the masking layer; removing the masking layer for the metal conductive electrodes to present a circuit pattern and etching off portions of the adhesion layer located between the metal conductive electrodes; and forming at least one weatherproof layer on peripheral surfaces of the metal conductive electrodes. The touch sensing electrode structure manufactured according to the above method has high yield rate and is weatherproof, and the metal conductive electrodes thereof have precisely controlled small width.

Owner:APLUS SEMICON TECH CO LTD

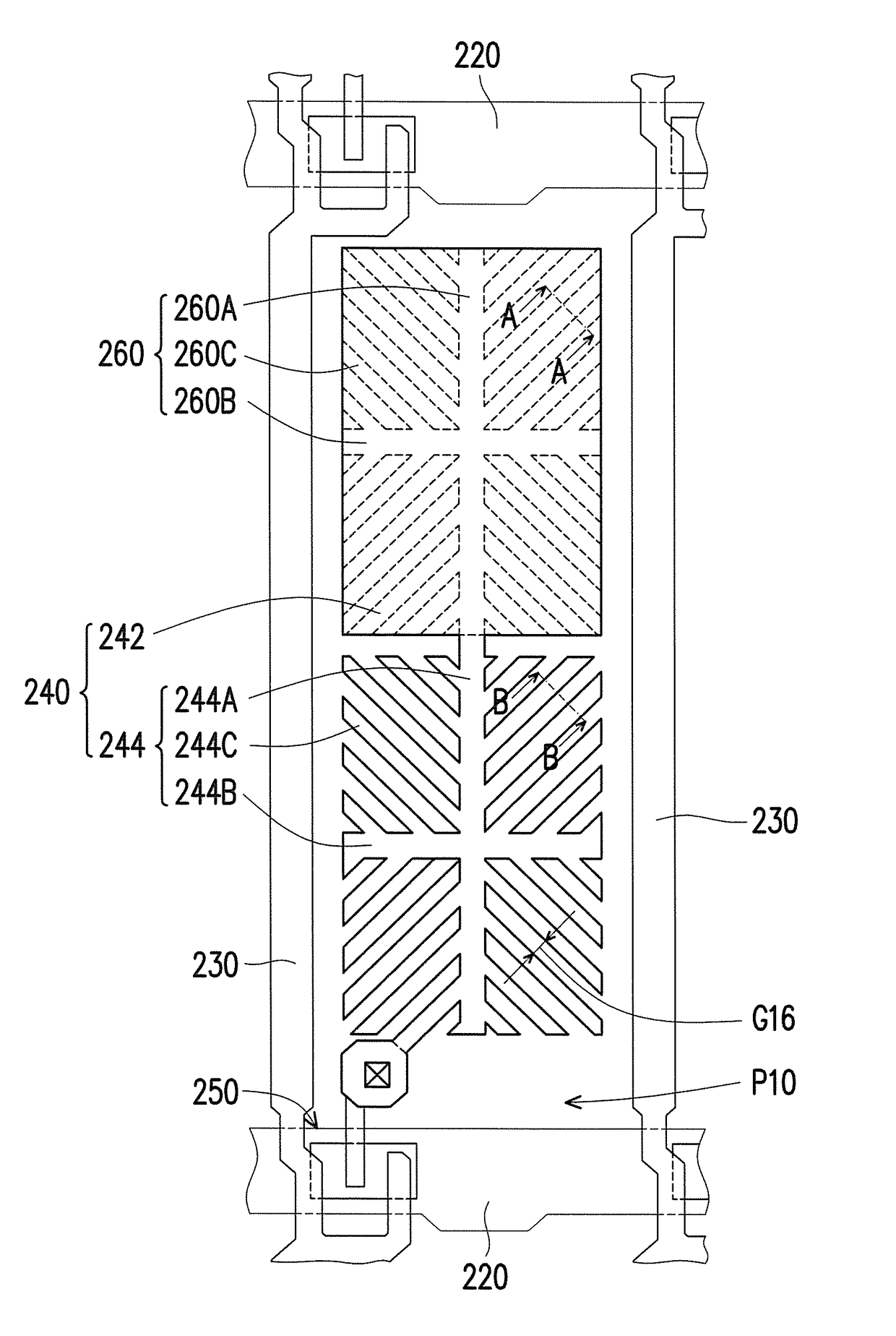

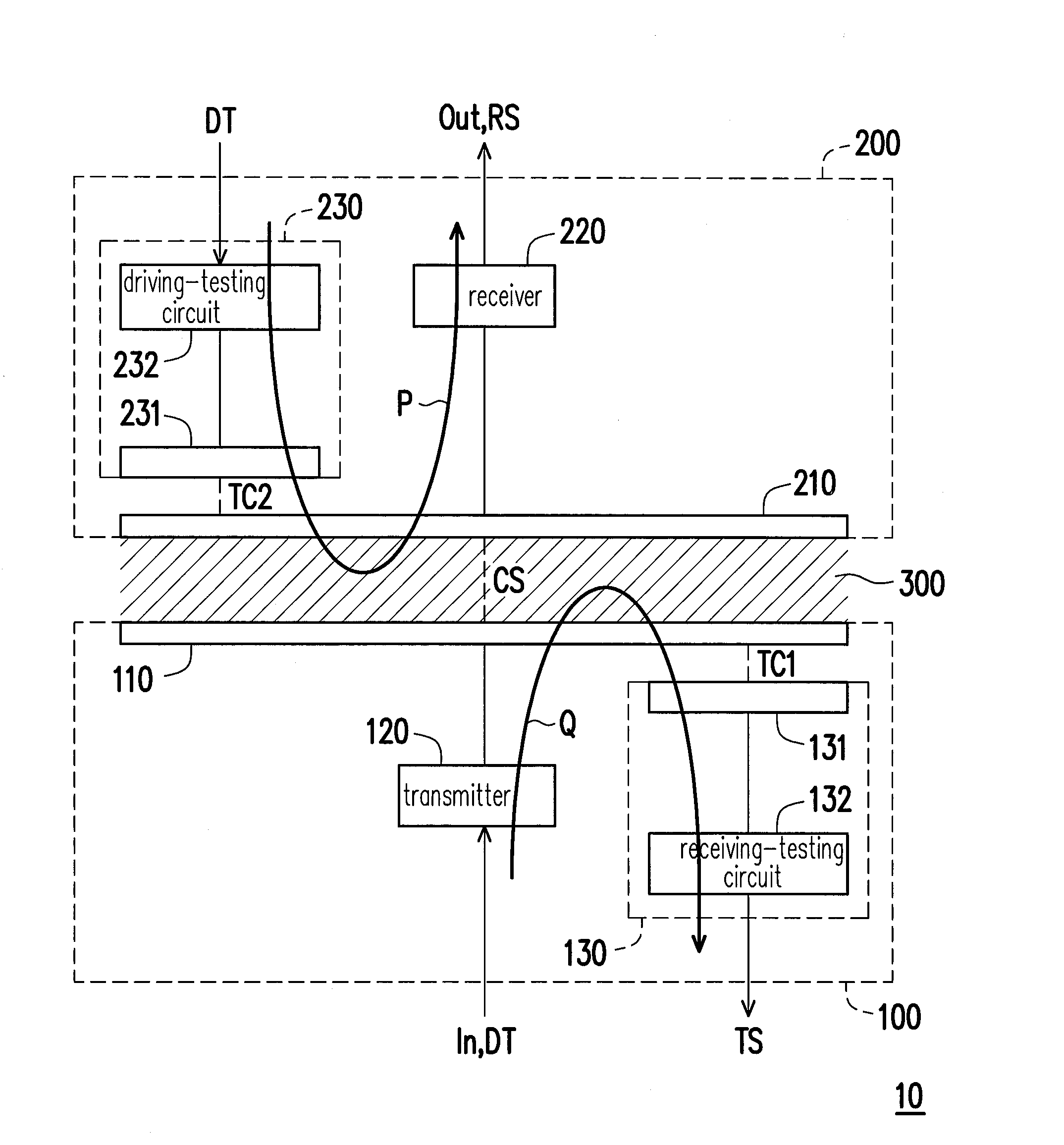

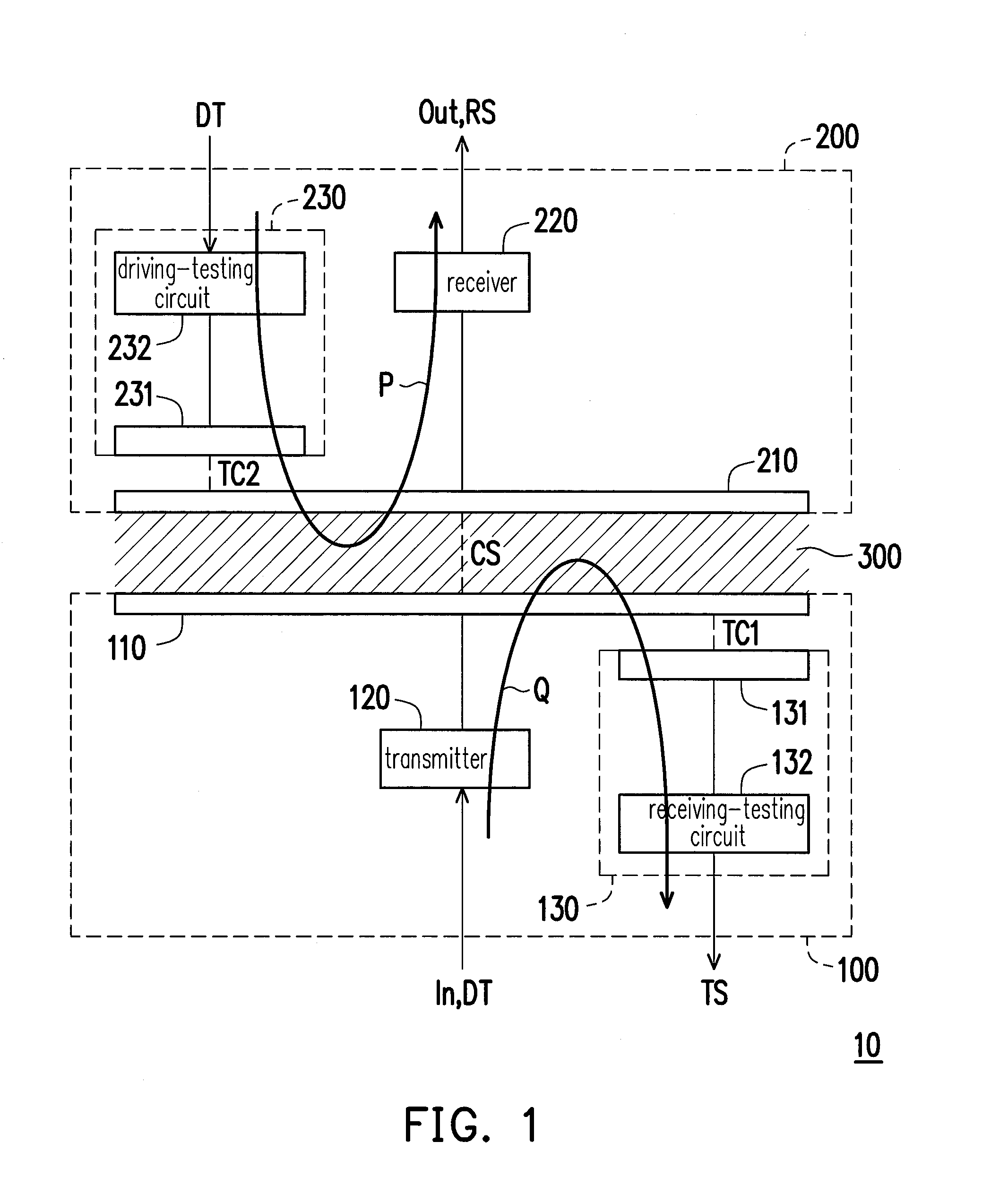

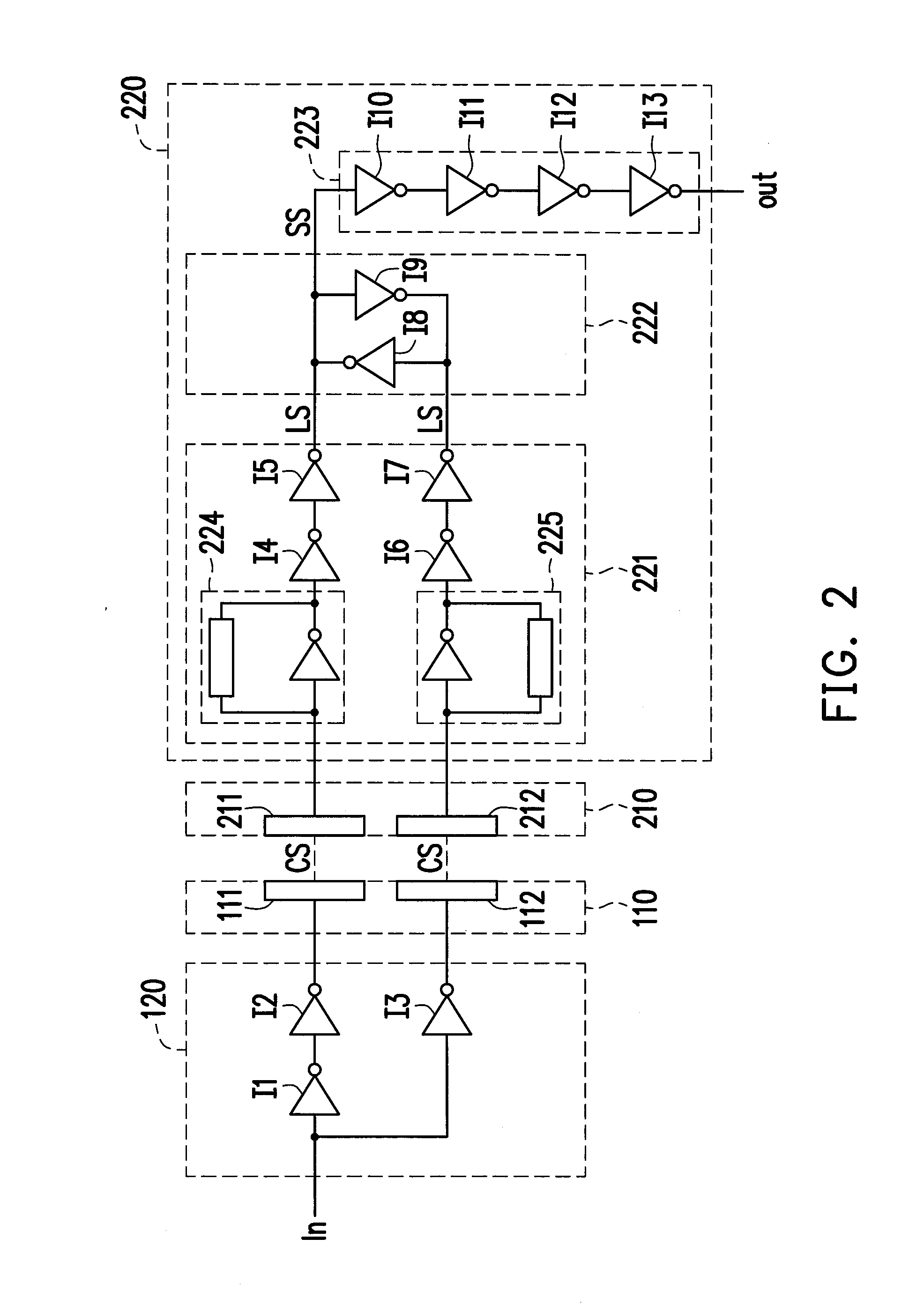

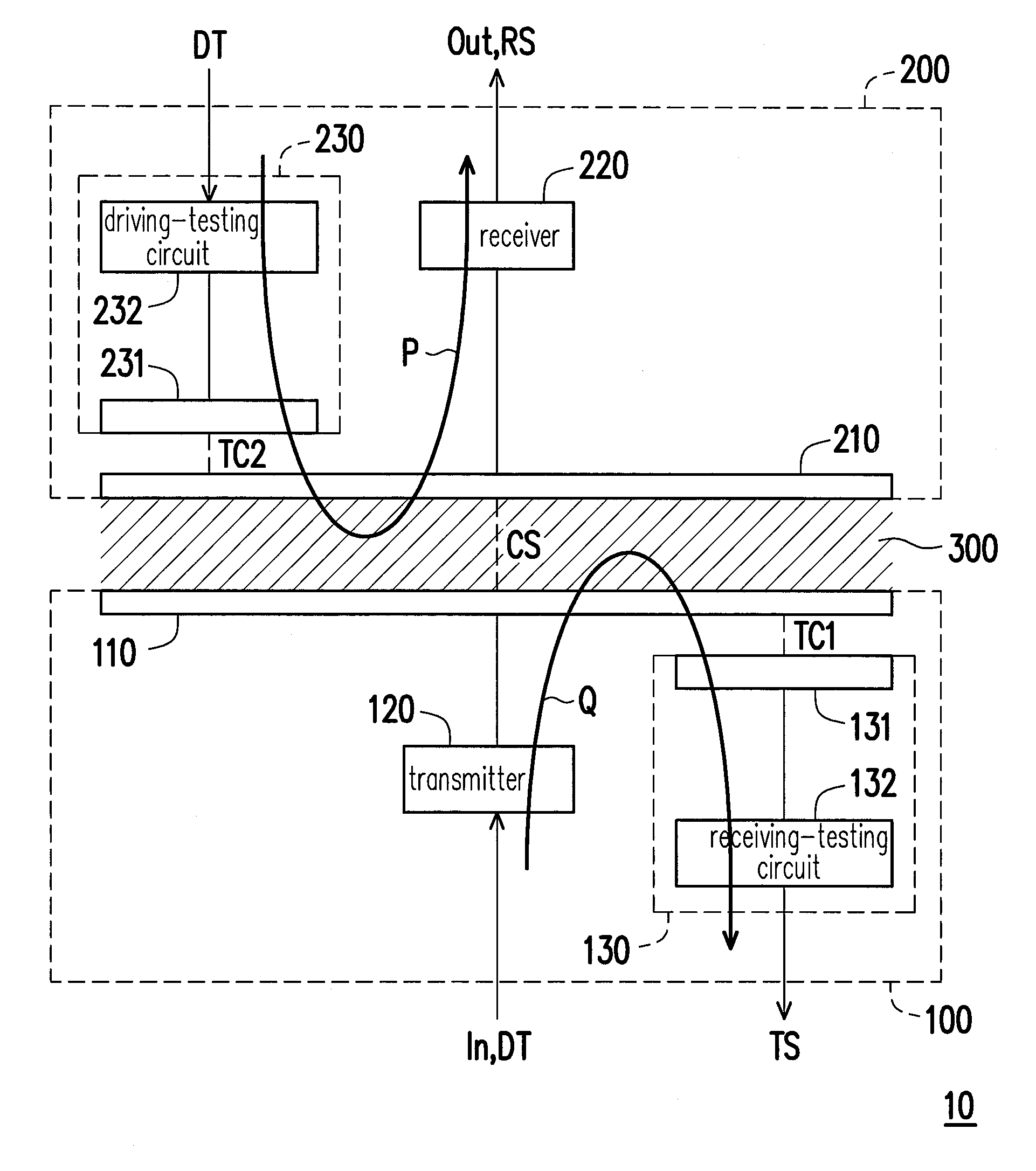

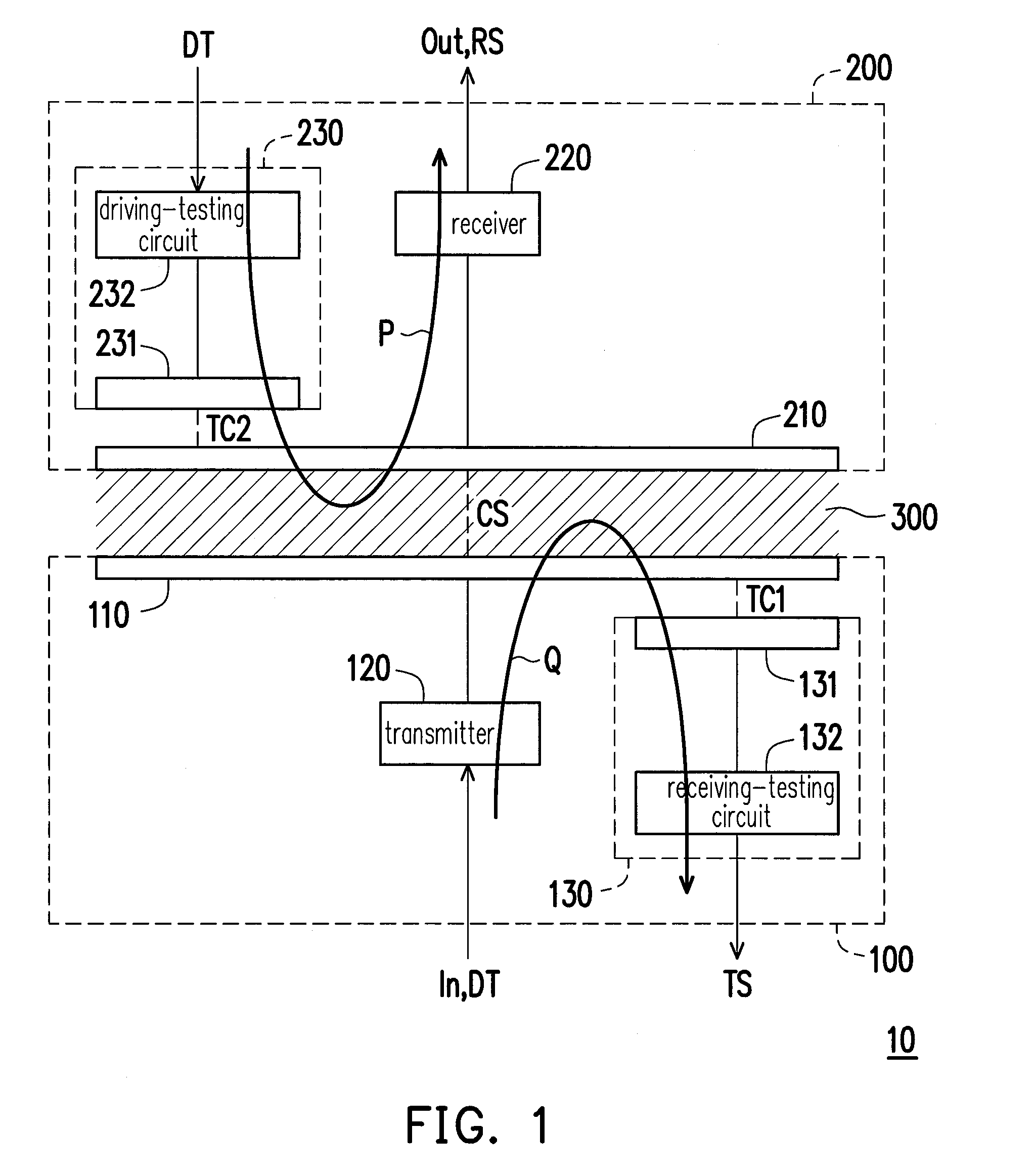

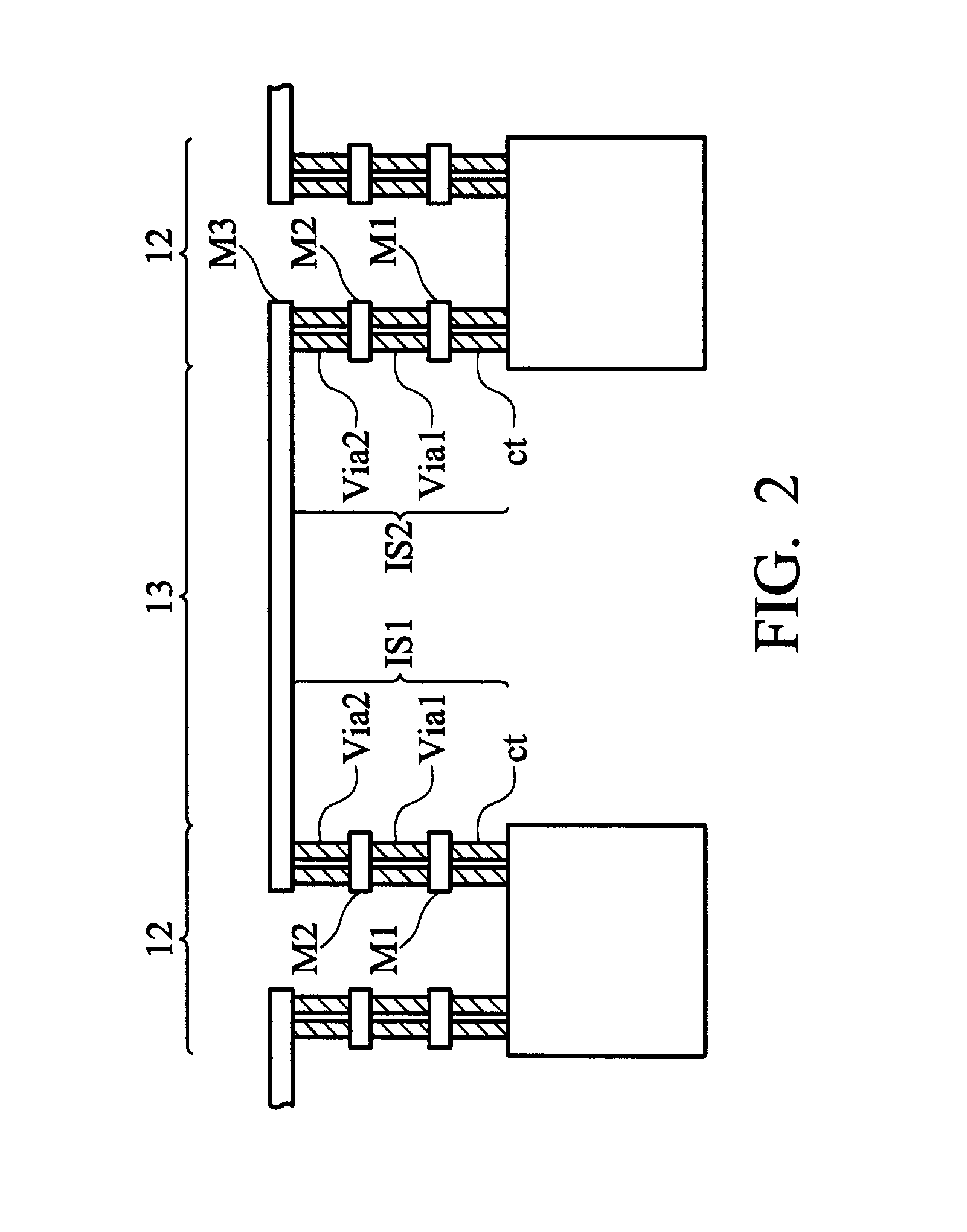

Chip-to-chip signal transmission system and chip-to-chip capacitive coupling transmission circuit

ActiveUS20140210496A1Improve communication qualityImprove enforceabilityTransmitters monitoringNear-field systems with capacitive couplingCapacitanceCapacitive coupling

A chip-to-chip signal transmission system is provided, which includes a first chip, a second chip, and a dielectric layer. A signal transmission is performed between a transmitter of the first chip and a receiver of the second chip through a transmission-metal-pad unit and a receiving-metal-pad unit. The transmitter transmits a transmission-testing-coupling signal through the transmission-metal-pad unit according to a driving-testing signal when the transmitter receives the driving-testing signal. A first testing unit receives the transmission-testing-coupling signal and outputs a transmission-testing signal according to the transmission-testing-coupling signal. A second testing unit transmits a receiving-testing-coupling signal through the receiving-metal-pad unit according to the driving-testing signal when the second testing unit receives the driving-testing signal. The receiver receives the receiving-testing-coupling signal and outputs a receiving-testing signal according to the receiving-testing-coupling signal.

Owner:I-SHOU UNIVERSITY

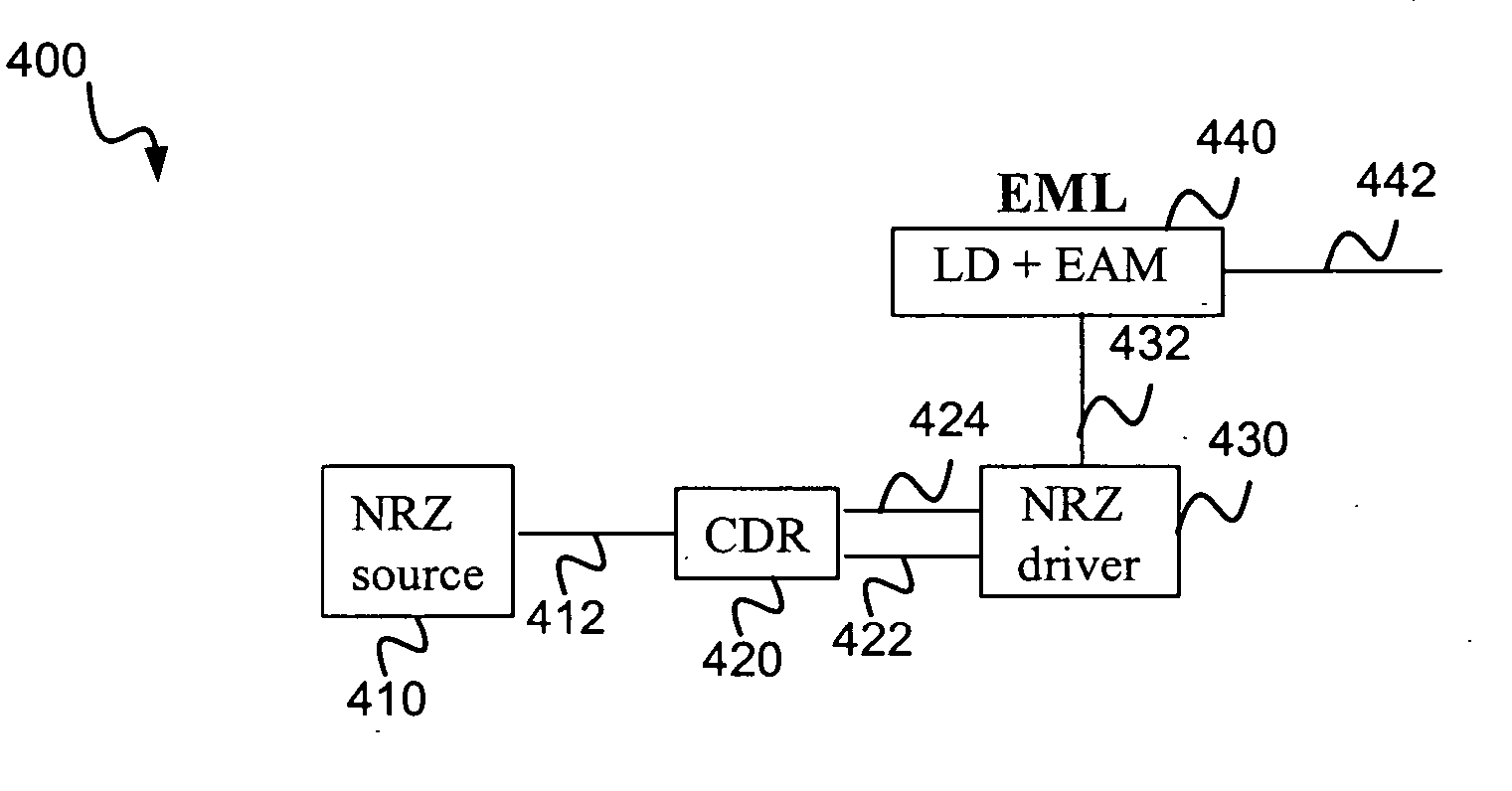

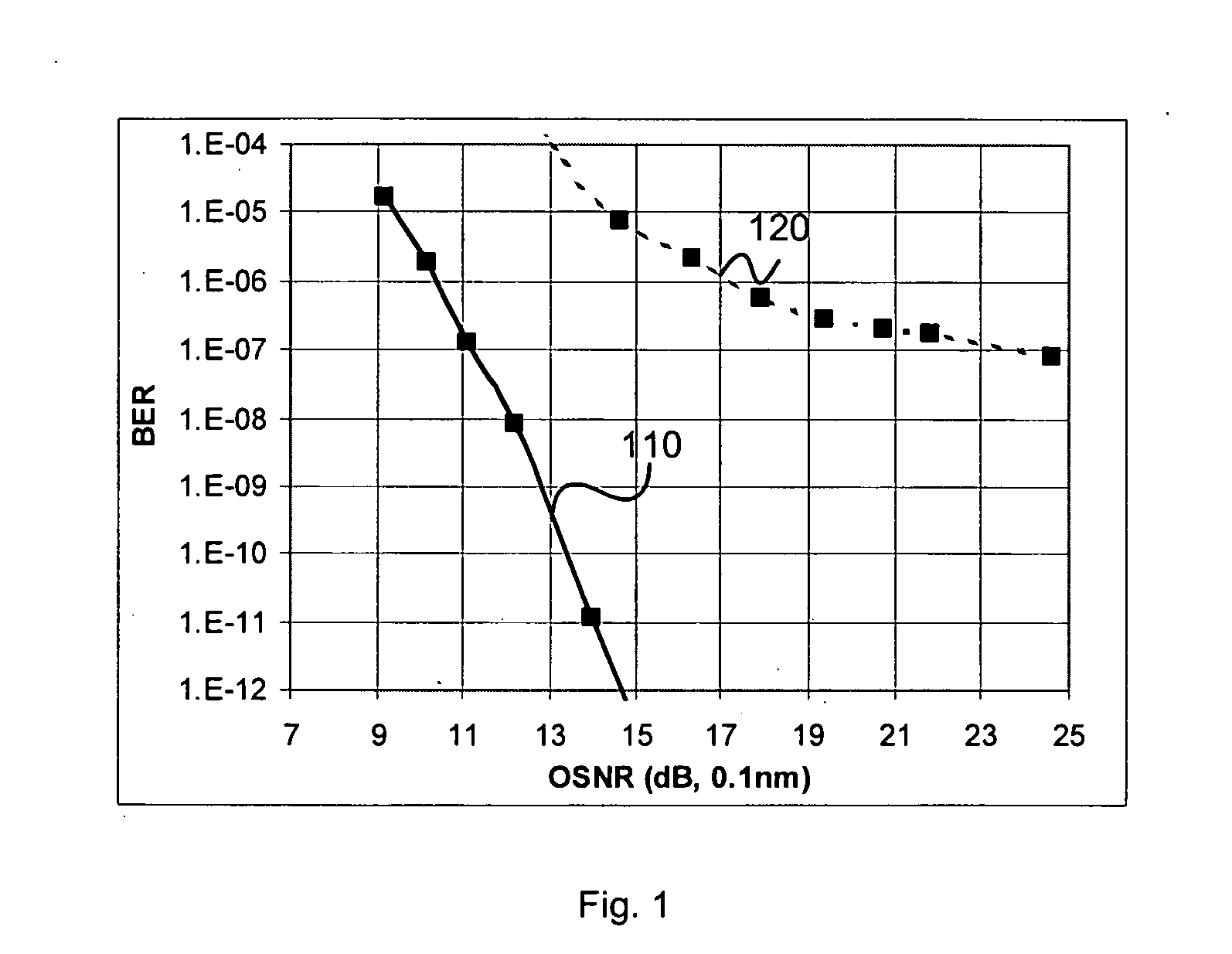

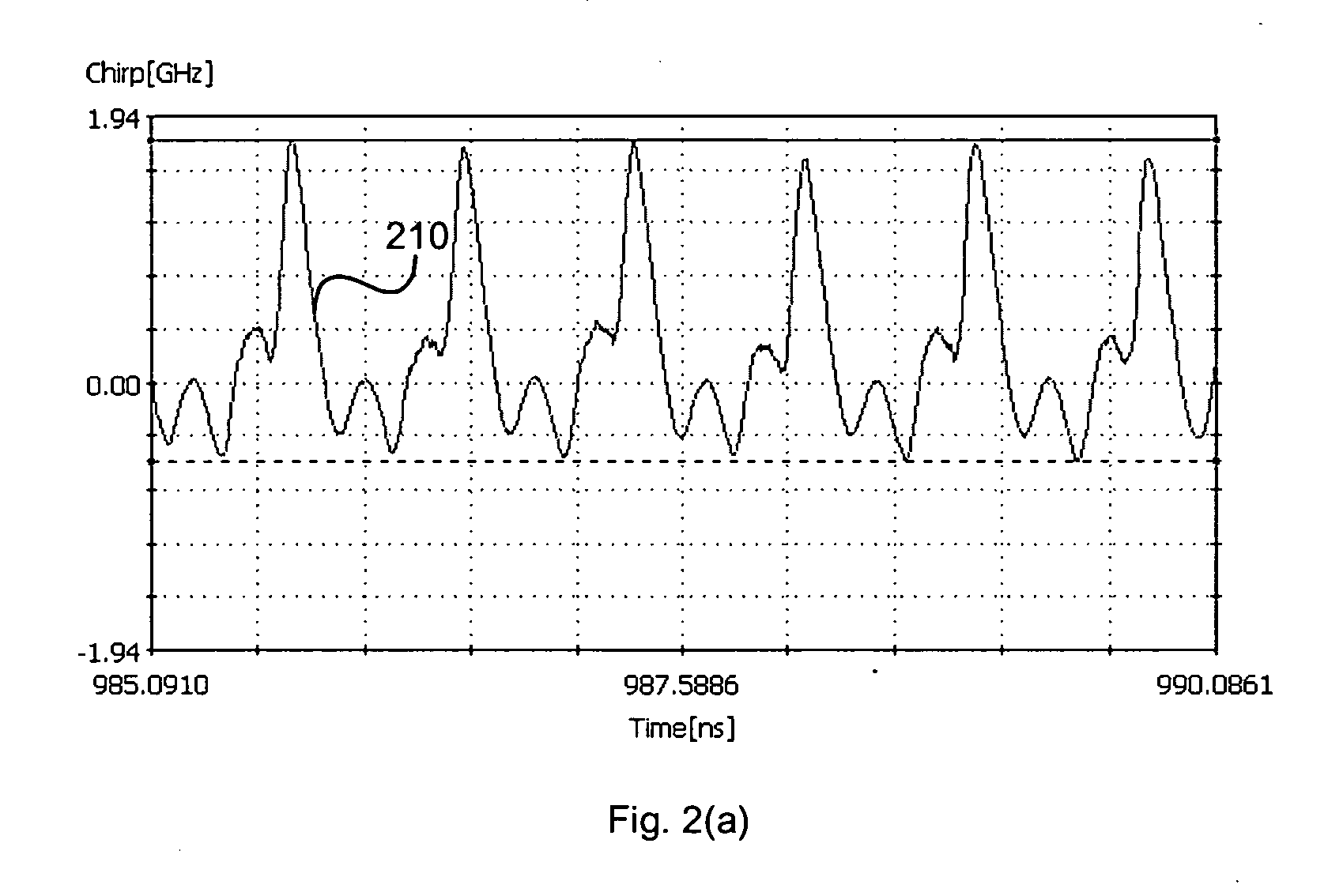

Transmission system and method employing electrical return-to-zero modulation

InactiveUS20060120729A1Improve performanceWide range of usesElectromagnetic transmittersReturn-to-zeroElectro-absorption modulator

A system and method for transmitting a signal for optical network applications. The system includes an optical transmitter configured to output an optical signal. The optical signal is associated with a return-to-zero modulation. Additionally, the system includes an optical fiber transmission system coupled to the optical transmitter and configured to transmit the optical signal and output the transmitted optical signal. The optical transmitter includes a return-to-zero driver configured to receive at least a first data signal and generate a drive signal, a light source configured to generate a laser, and an electroabsorption modulator configured to receive the laser and the drive signal and generate the optical signal. Each of the first data signal and the drive signal is an electrical signal. The optical signal includes data associated with the return-to-zero modulation. The optical fiber transmission system is free from any dispersion compensation device.

Owner:FUTUREWEI TECH INC

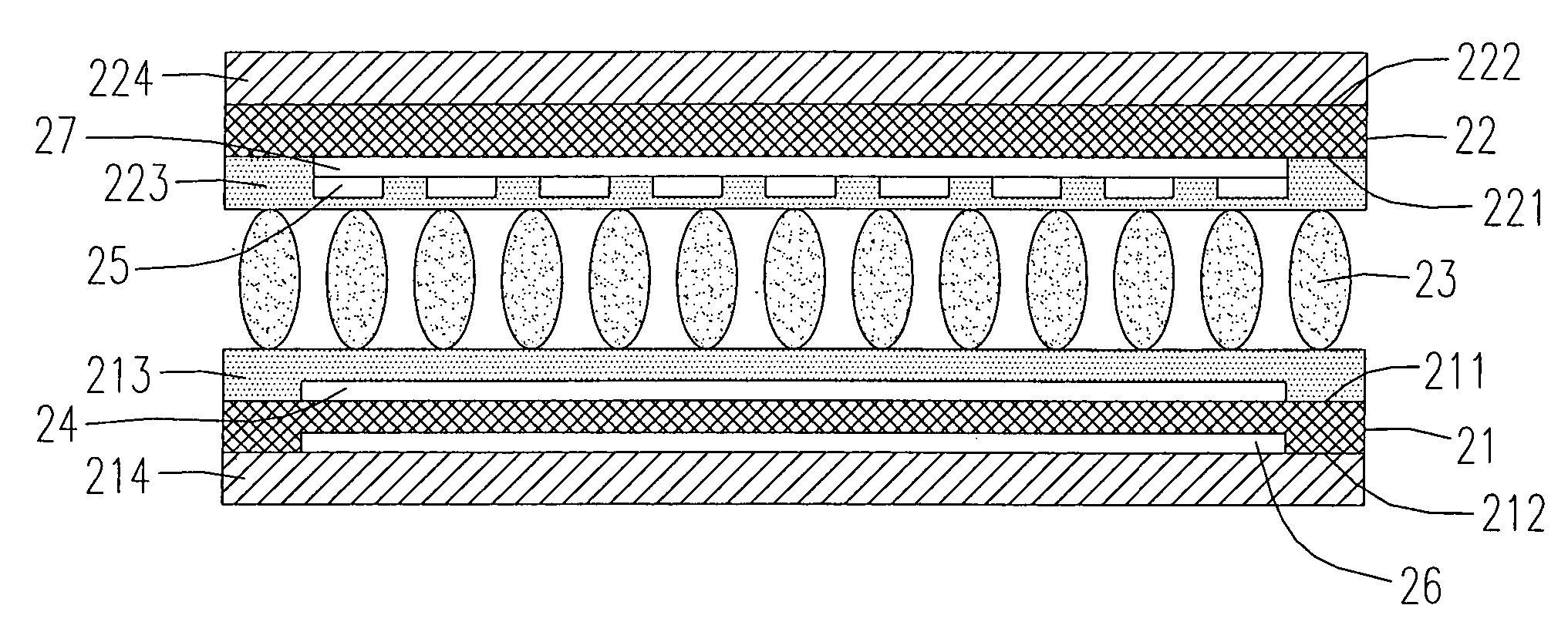

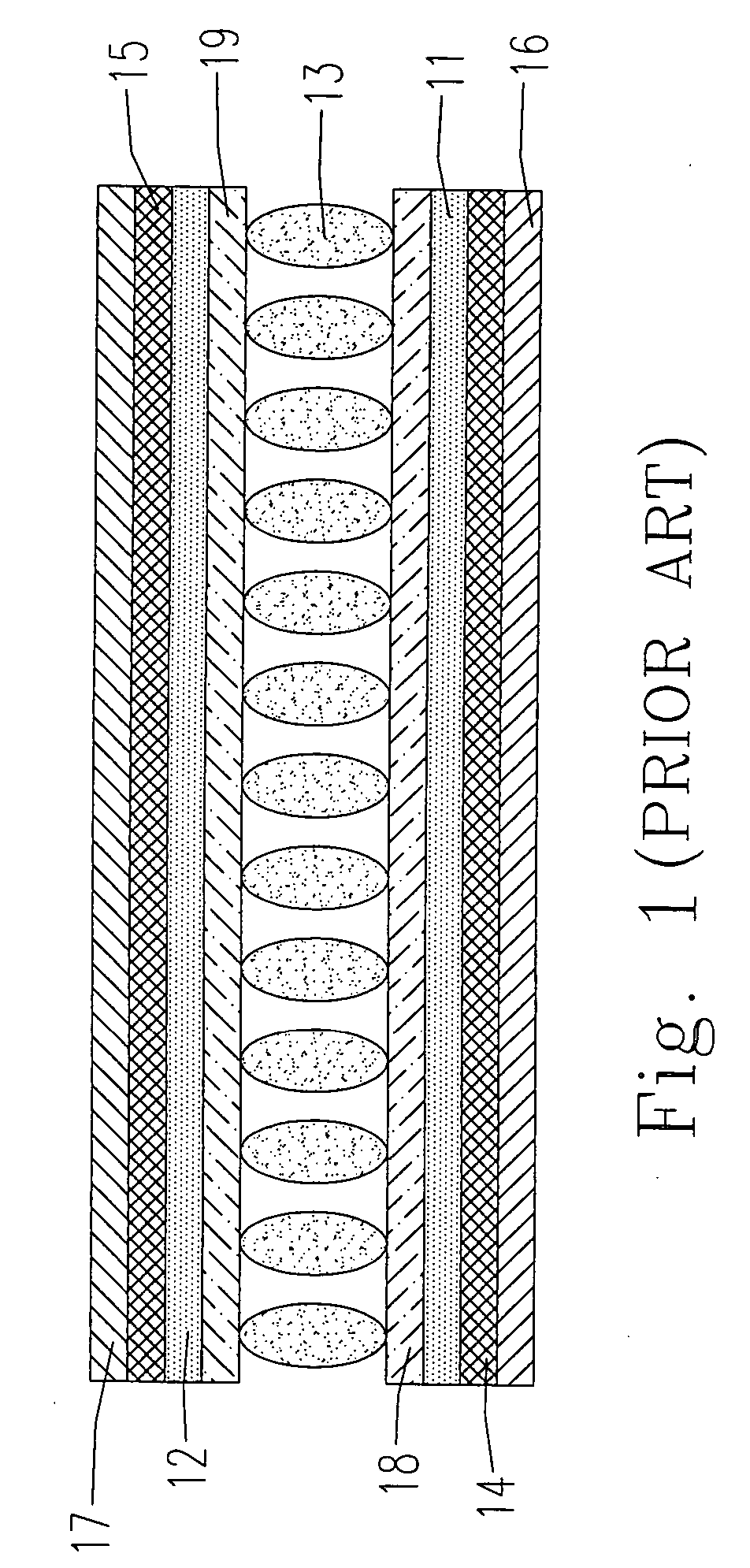

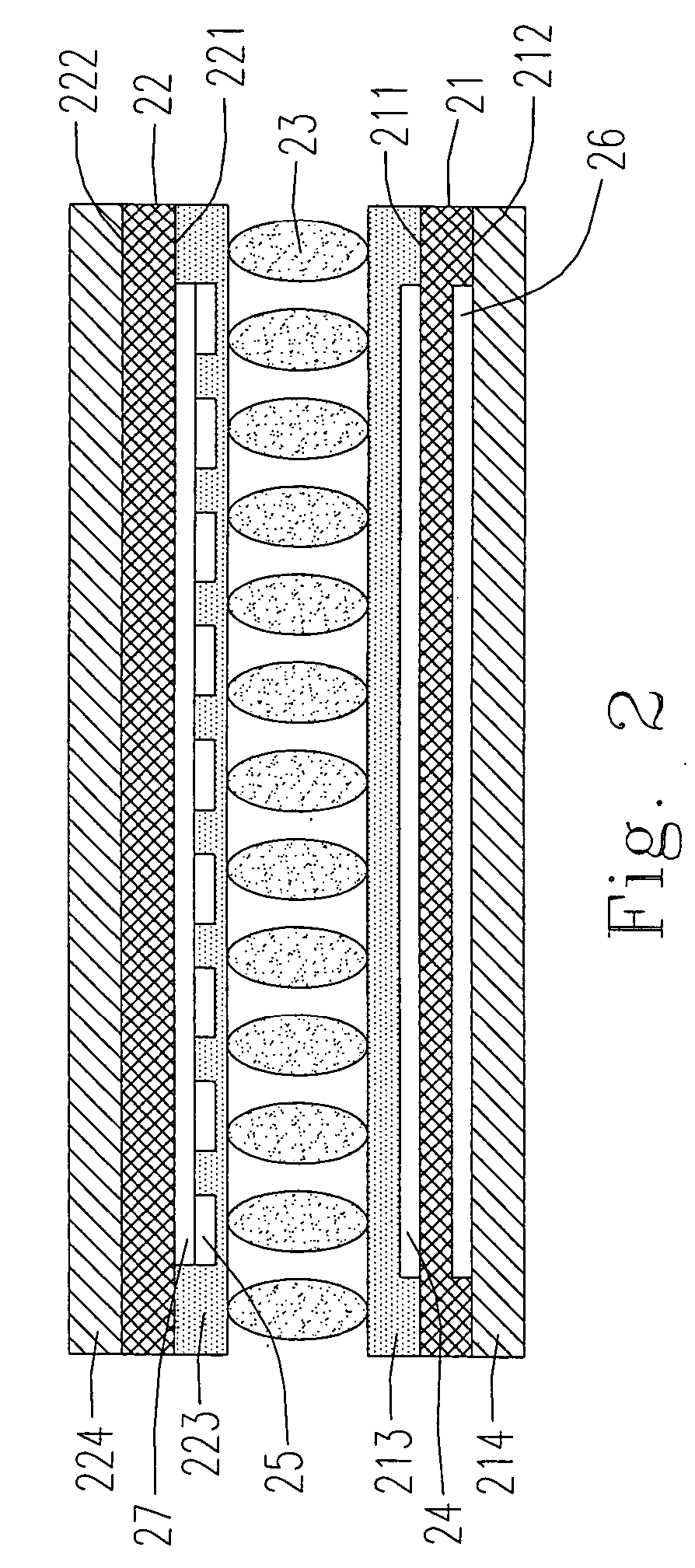

Liquid crystal dispaly panel

InactiveUS20050110938A1Lowering thickness and weight and costReduce thicknessNon-linear opticsLiquid-crystal displayEngineering

A wide-viewing-angle liquid crystal display panel is provided. The wide-viewing-angle liquid crystal display panel includes a first wide-viewing-angle substrate having a first surface and a second surface, a first alignment film mounted on the first surface, a first polarizer mounted on the second surface, a second wide-viewing-angle substrate having a third surface and a fourth surface, a second alignment film mounted on the third surface, a second polarizer mounted on the fourth surface, and a liquid crystal layer, wherein the first wide-viewing-angle substrate and the second wide-viewing-angle substrate are so positioned that the first surface is near the third surface than the second surface, and the liquid crystal layer is placed therebetween.

Owner:OPTIMAX TECHNOLOGY CORPORATION

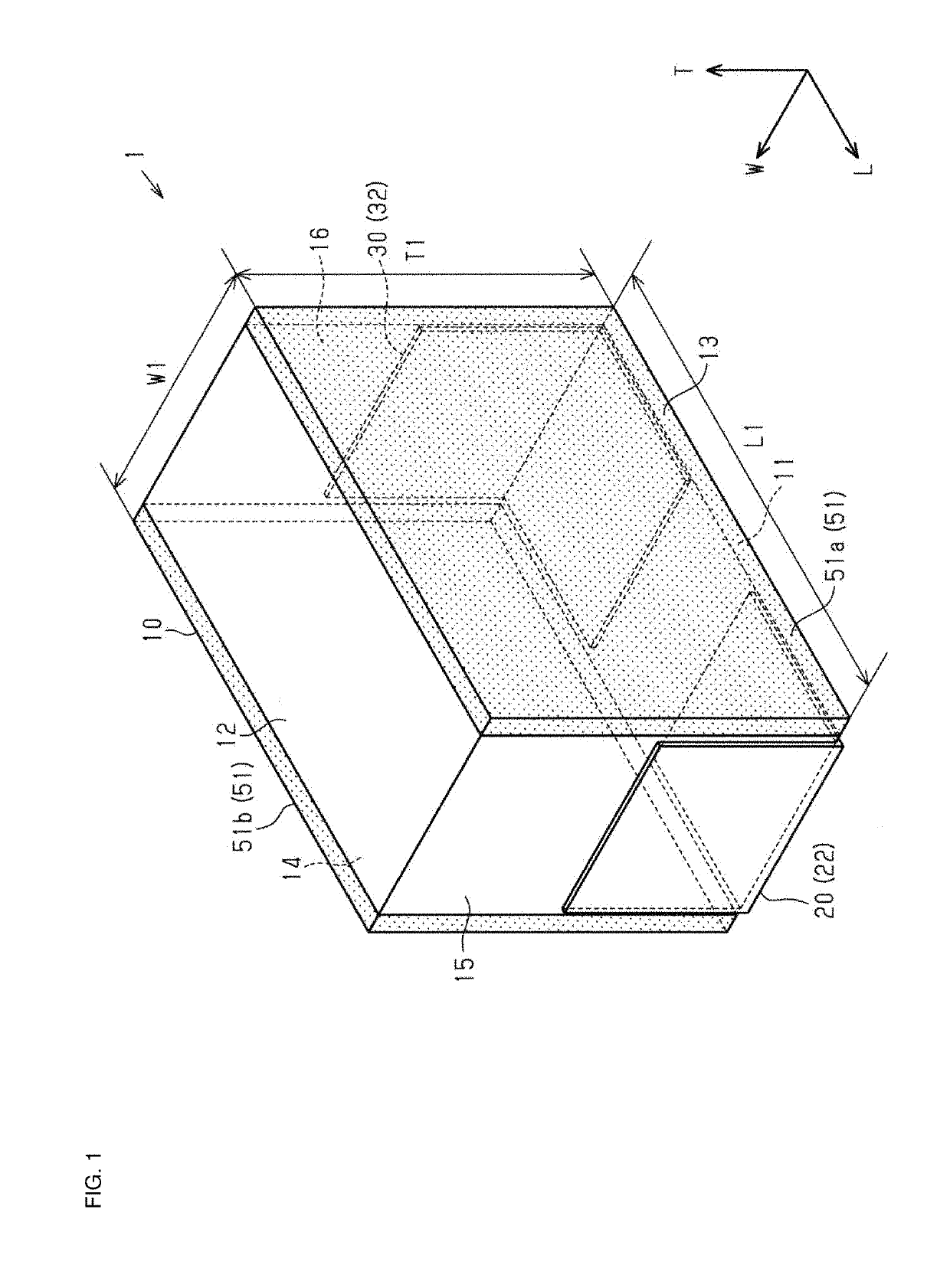

Inductor component

PendingUS20190198225A1Low yield rateReduce internal defectsTransformers/inductances coils/windings/connectionsCoils manufactureElectrical and Electronics engineeringElectrical conductor

Owner:MURATA MFG CO LTD

Chip-to-chip signal transmission system and chip-to-chip capacitive coupling transmission circuit

ActiveUS9274167B2Improve communication qualityImprove enforceabilityTransmitters monitoringNear-field systems with capacitive couplingCapacitanceCapacitive coupling

Owner:I-SHOU UNIVERSITY

Three-piece optical lens system

A three-piece optical lens system comprises, in order from the object side to the image side: a first lens element with a positive refractive power having a convex object-side surface, one of the object-side surface and an image-side surface being aspheric; a stop, a second lens element with a positive refractive power having a concave object-side surface, one of the object-side surface and an image-side surface being aspheric; a third lens element with a negative refractive power having a concave image-side surface, one of an object-side surface and the image-side surface being aspheric. A refractive index of the third lens element is N3, an Abbe number of the third lens element is V3, and they satisfy the relations: N3>1.57; V3<40. Such arrangements can reduce the volume of the three-piece optical lens system and improve the image quality of the periphery of the image.

Owner:NEWMAX TECH

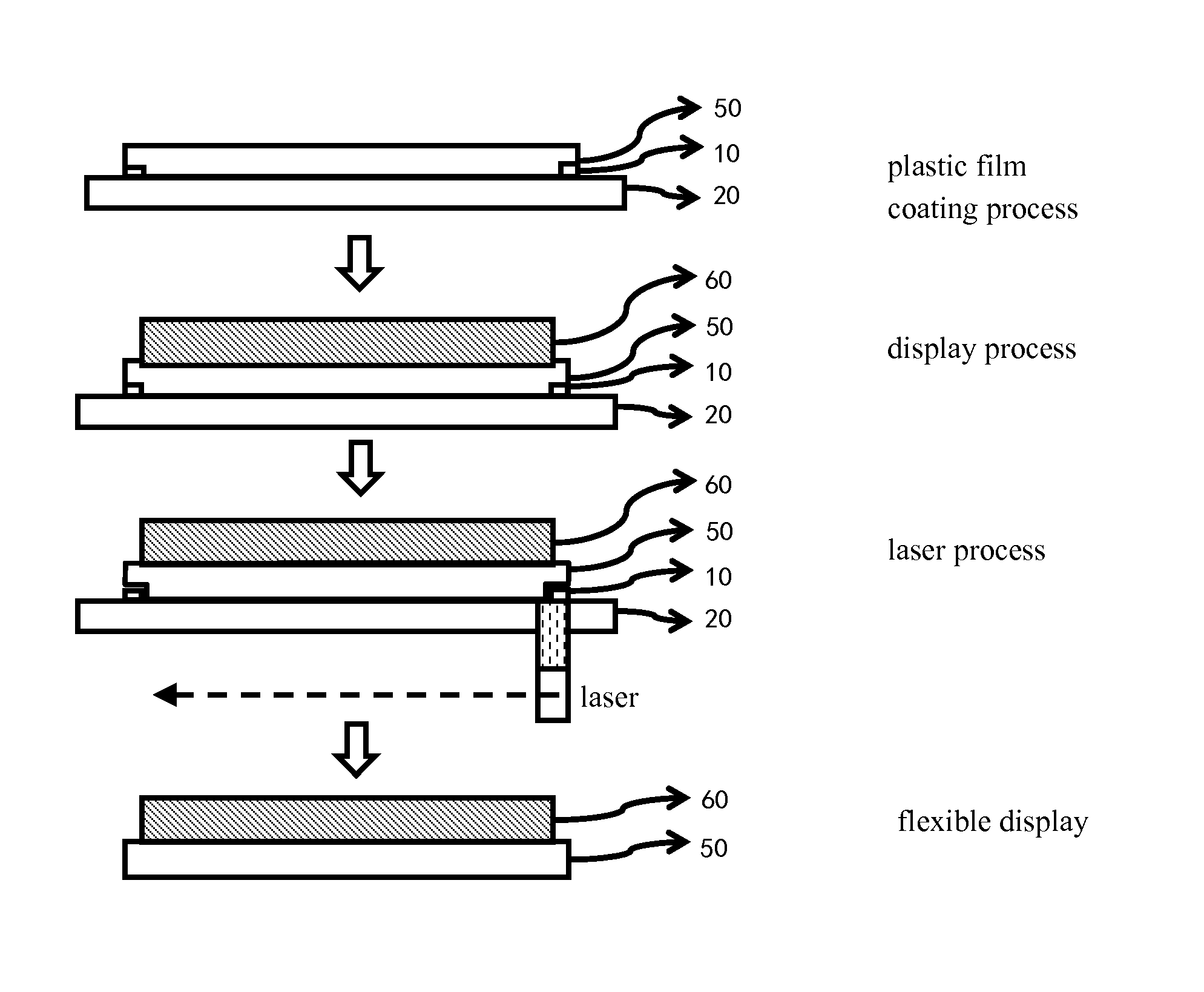

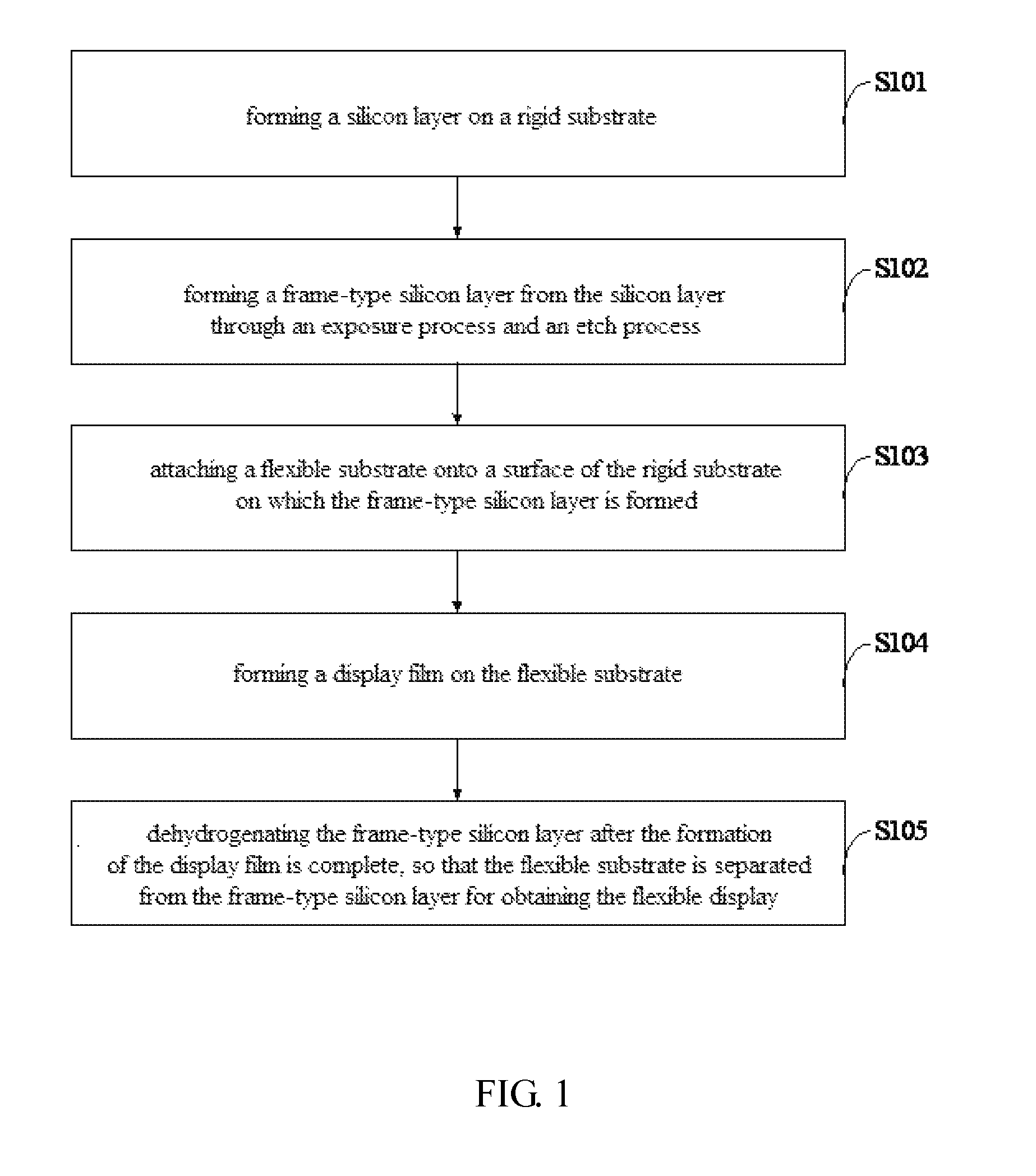

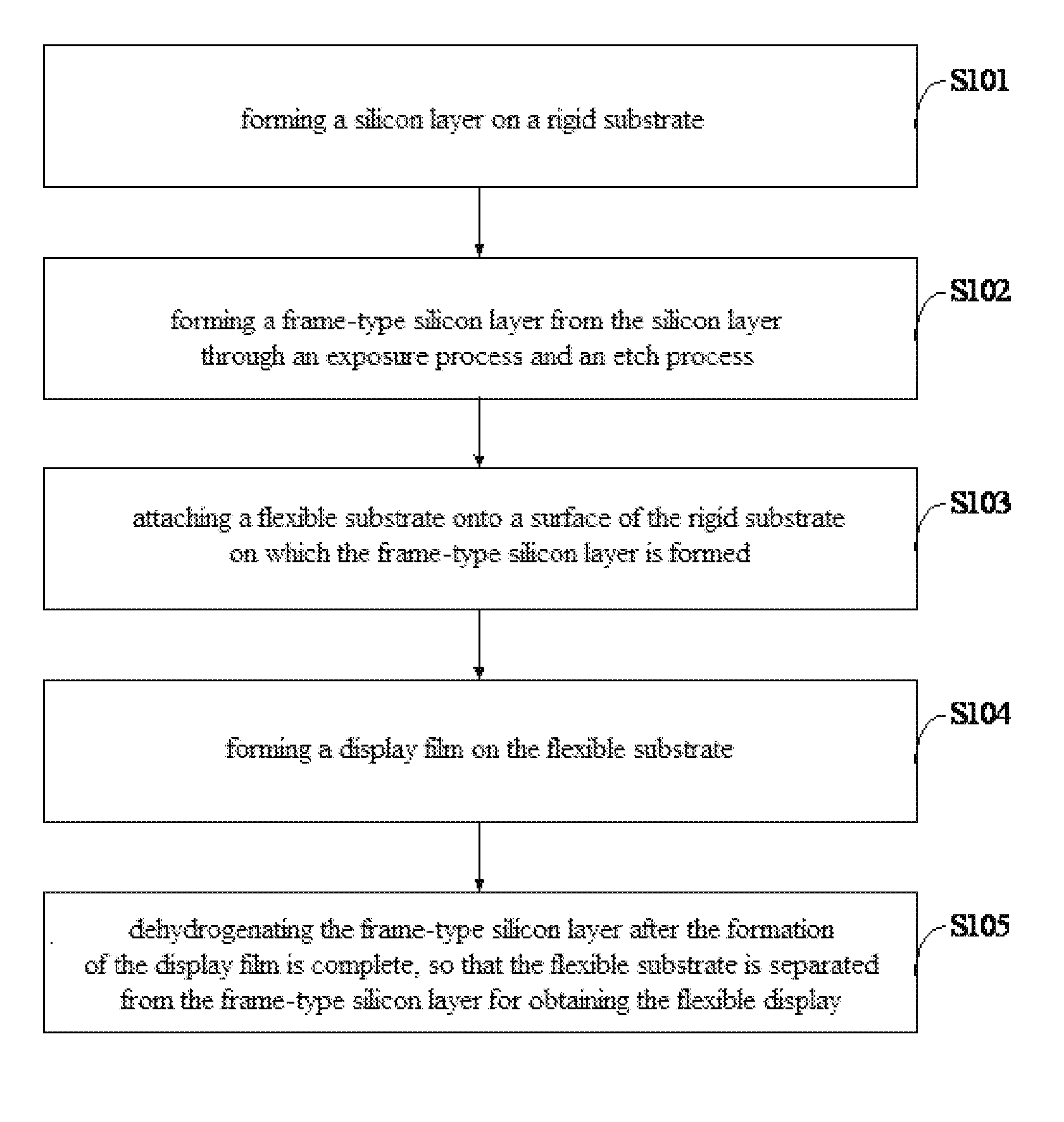

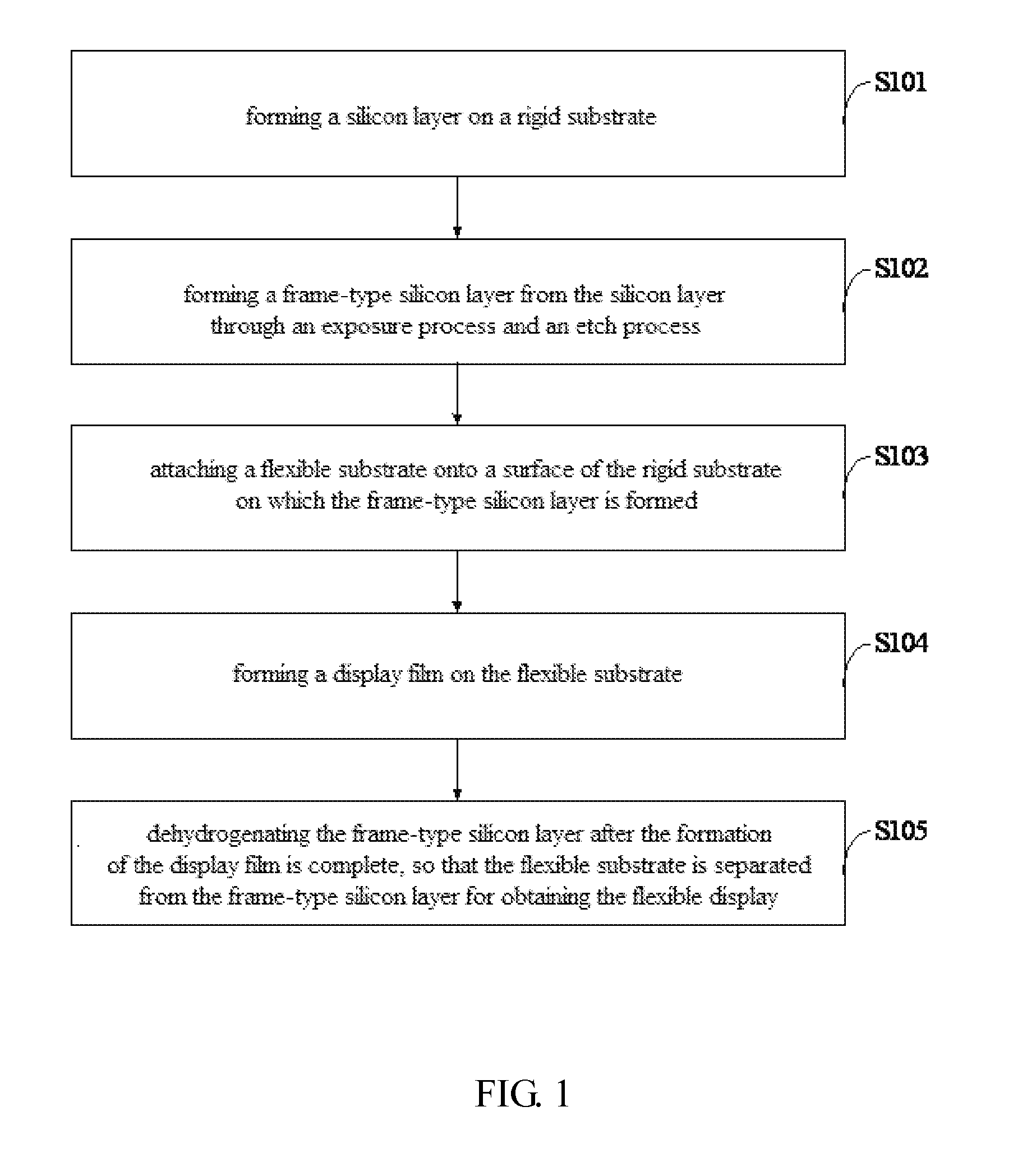

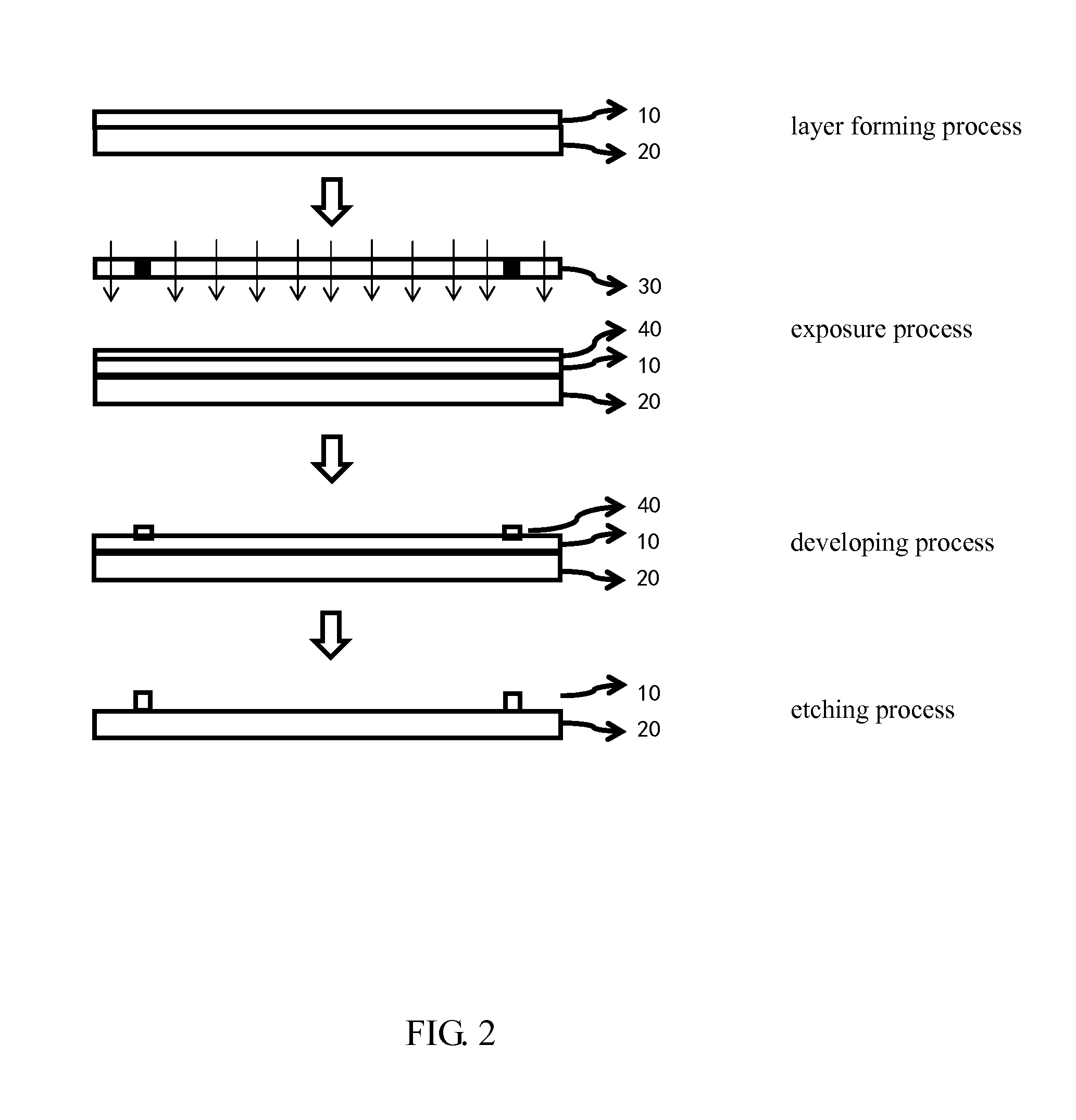

Manufacturing method of a flexible display

ActiveUS9287077B2Low yield rateImprove bindingTube/lamp screens manufactureSolid-state devicesAmorphous siliconDisplay device

A manufacturing method of a flexible display is provided, which comprises steps of forming an silicon layer on a rigid substrate, forming a frame-type silicon layer from the silicon layer, attaching a flexible substrate onto the surface of the rigid substrate on which the frame-type amorphous silicon layer is formed, forming a display film on the flexible substrate, and dehydrogenating the frame-type silicon layer after the formation of the display film is complete, so that the flexible substrate is separated from the frame-type silicon layer for obtaining the flexible display. The manufacturing method of the flexible display prevents the problem of low yield rate caused by the damage to the plastic substrate in the separation process.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

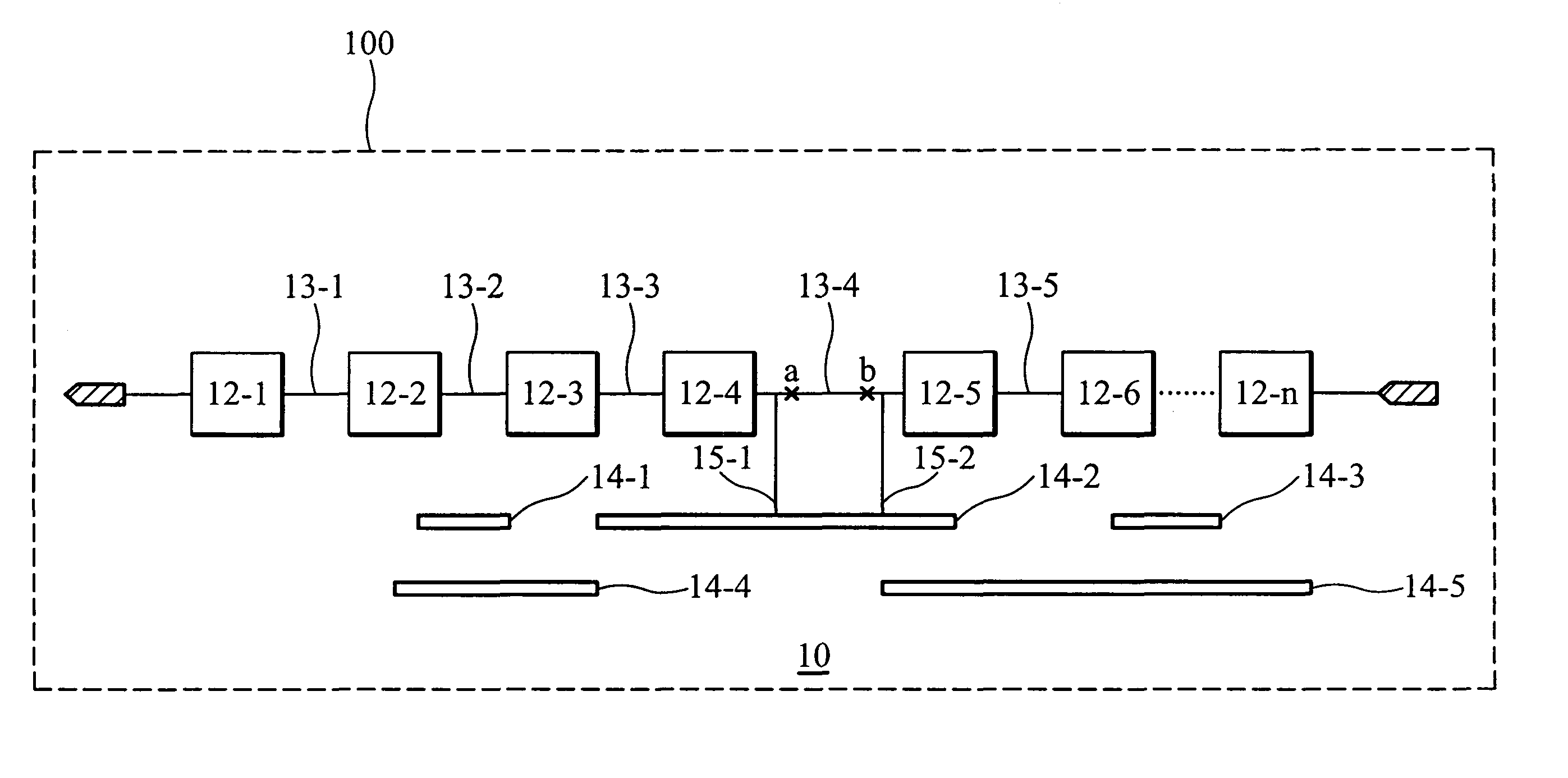

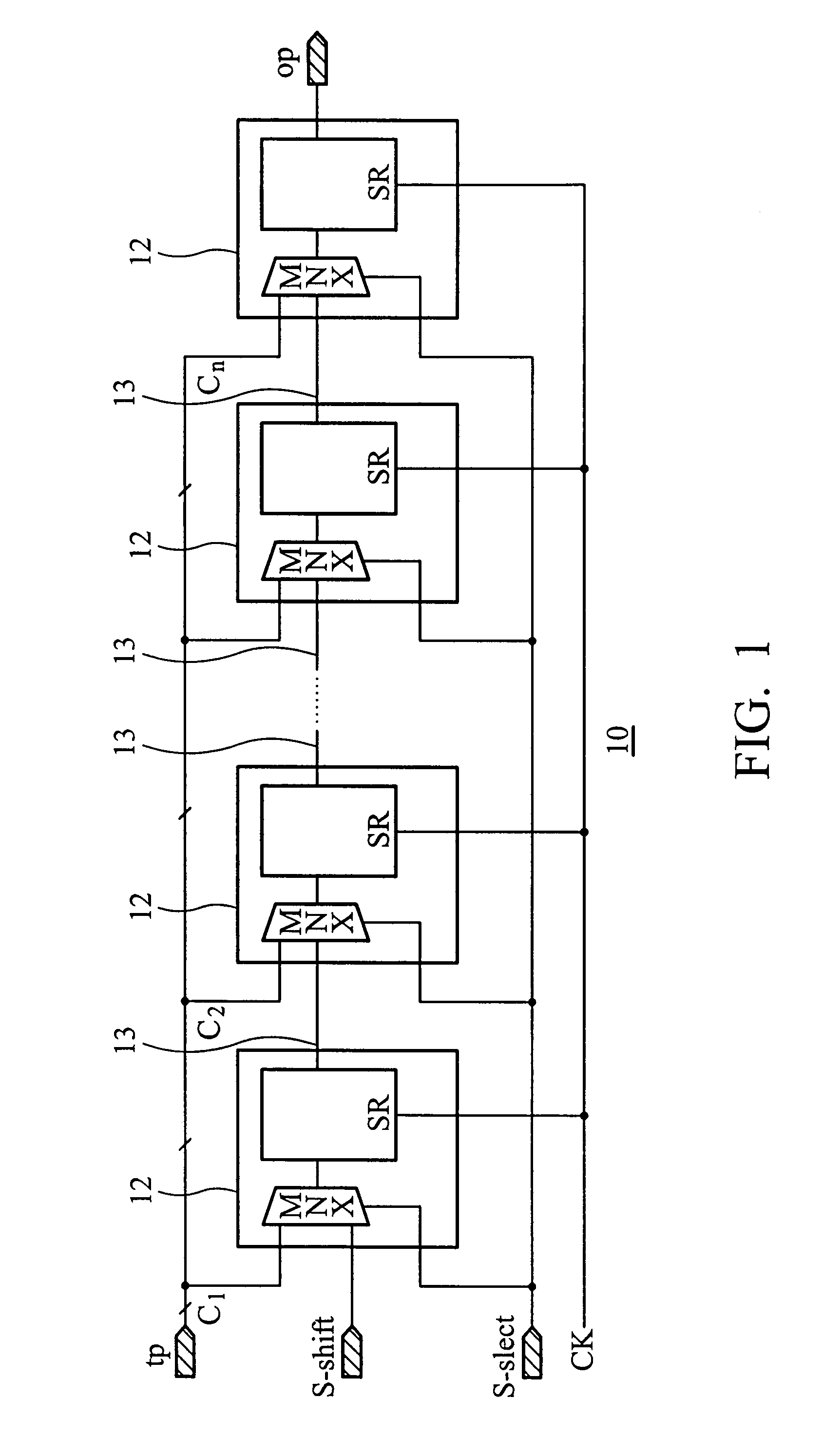

Integrated circuit capable of locating failure process layers

InactiveUS7036099B2Easy to findLow yield rateElectrical testingSpecial data processing applicationsLower yieldScan chain

An integrated circuit for locating failure process layers. The circuit has a substrate with a scan chain disposed therein, having scan cells connected to form a series chain. Each connection is formed according to a layout constraint of a minimum dimension provided by design rules for an assigned routing layer. Since the connection in the assigned routing layer is constrained to a minimum, the scan chain is vulnerable to variations in processes relevant to the assigned routing layer. The scan chain makes it easier to locate processes causing low yield rate of the scan chain.

Owner:FARADAY TECH CORP

Manufacturing method of a flexible display

ActiveUS20150332885A1Low yield rateImprove bindingTube/lamp screens manufactureSolid-state devicesAmorphous siliconDisplay device

A manufacturing method of a flexible display is provided, which comprises steps of forming an silicon layer on a rigid substrate, forming a frame-type silicon layer from the silicon layer, attaching a flexible substrate onto the surface of the rigid substrate on which the frame-type amorphous silicon layer is formed, forming a display film on the flexible substrate, and dehydrogenating the frame-type silicon layer after the formation of the display film is complete, so that the flexible substrate is separated from the frame-type silicon layer for obtaining the flexible display. The manufacturing method of the flexible display prevents the problem of low yield rate caused by the damage to the plastic substrate in the separation process.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

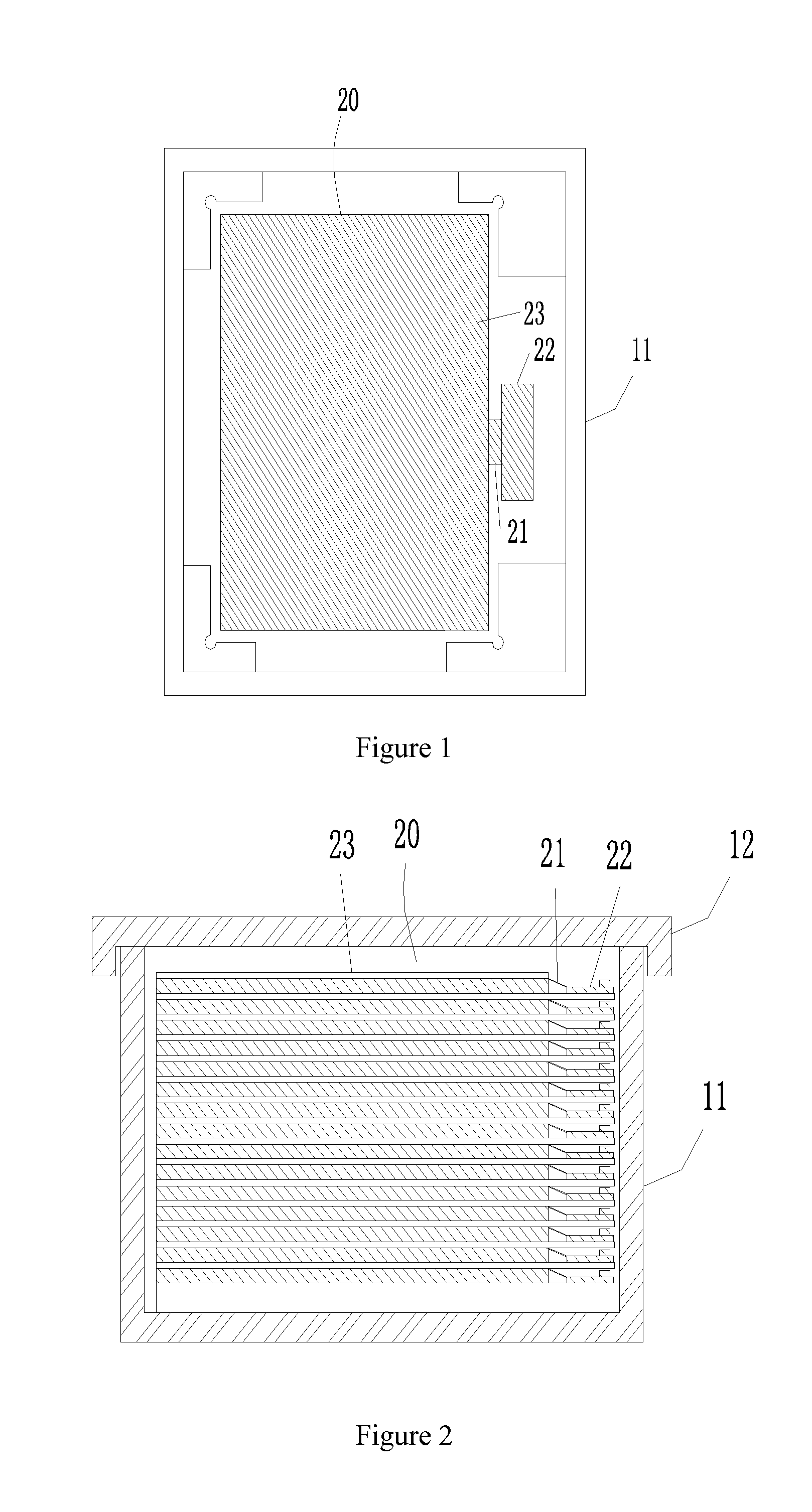

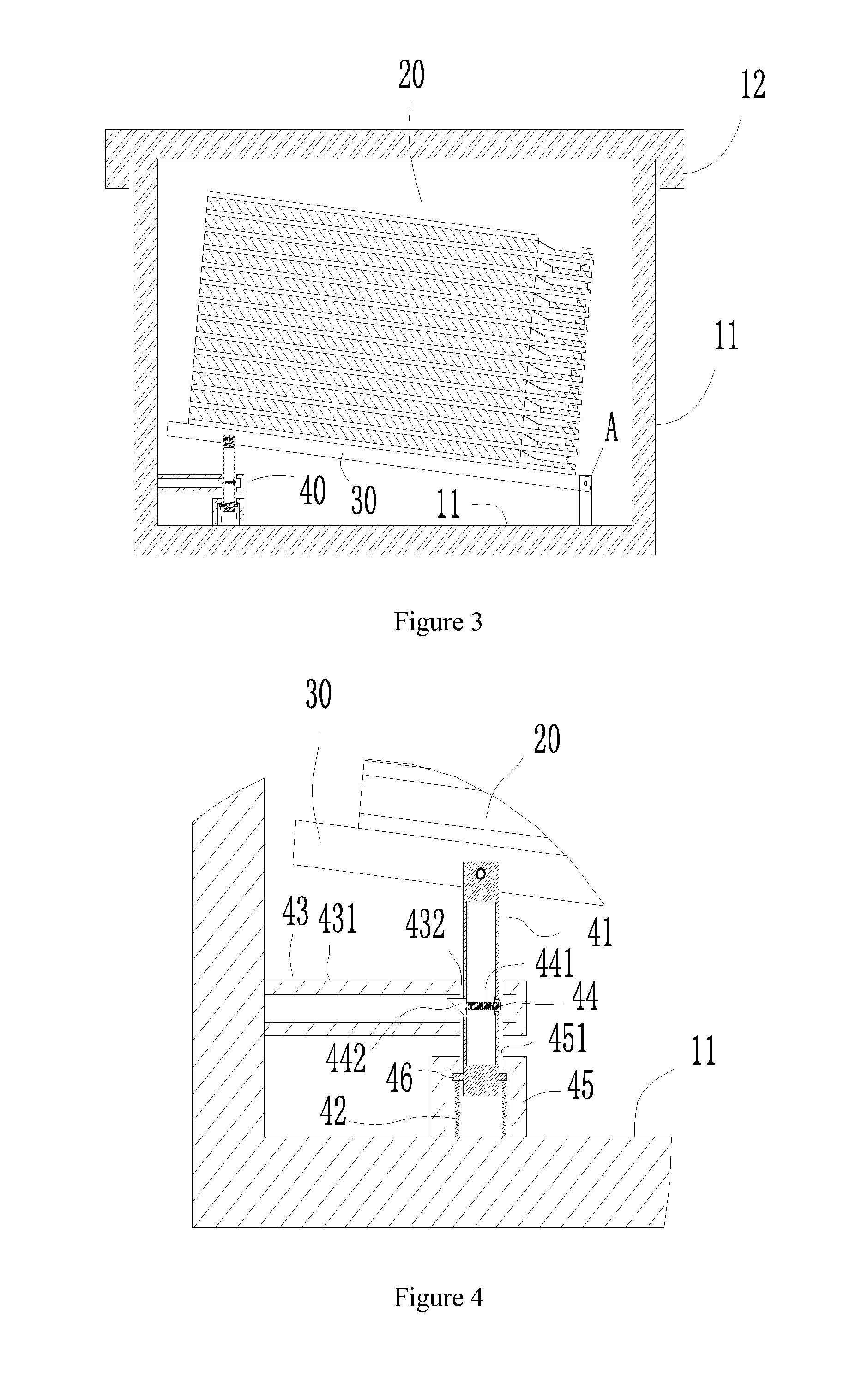

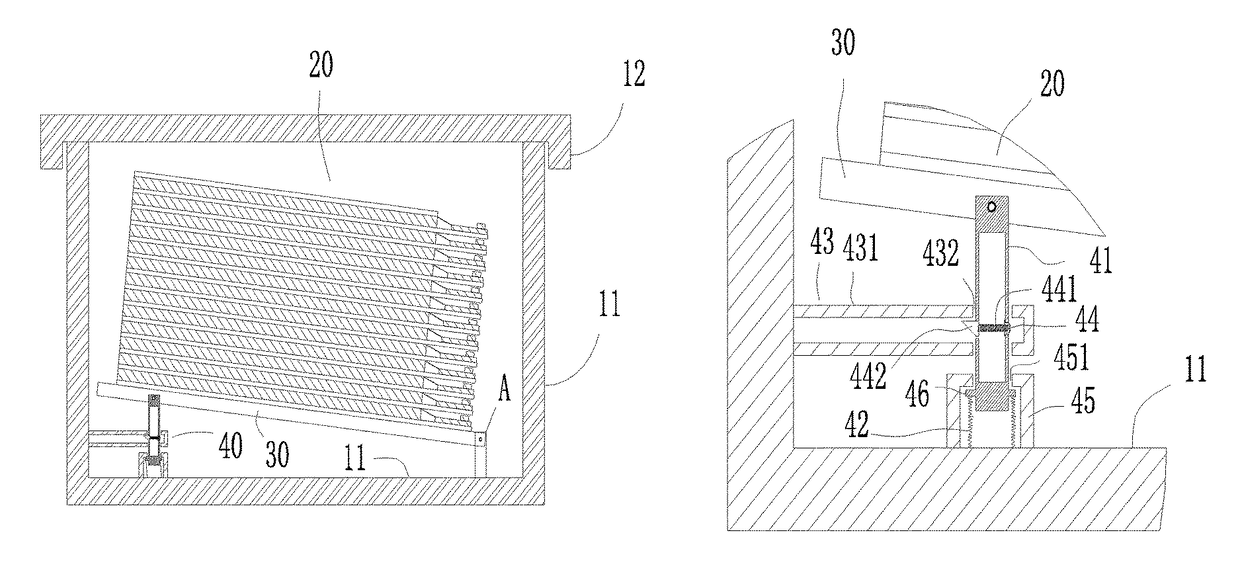

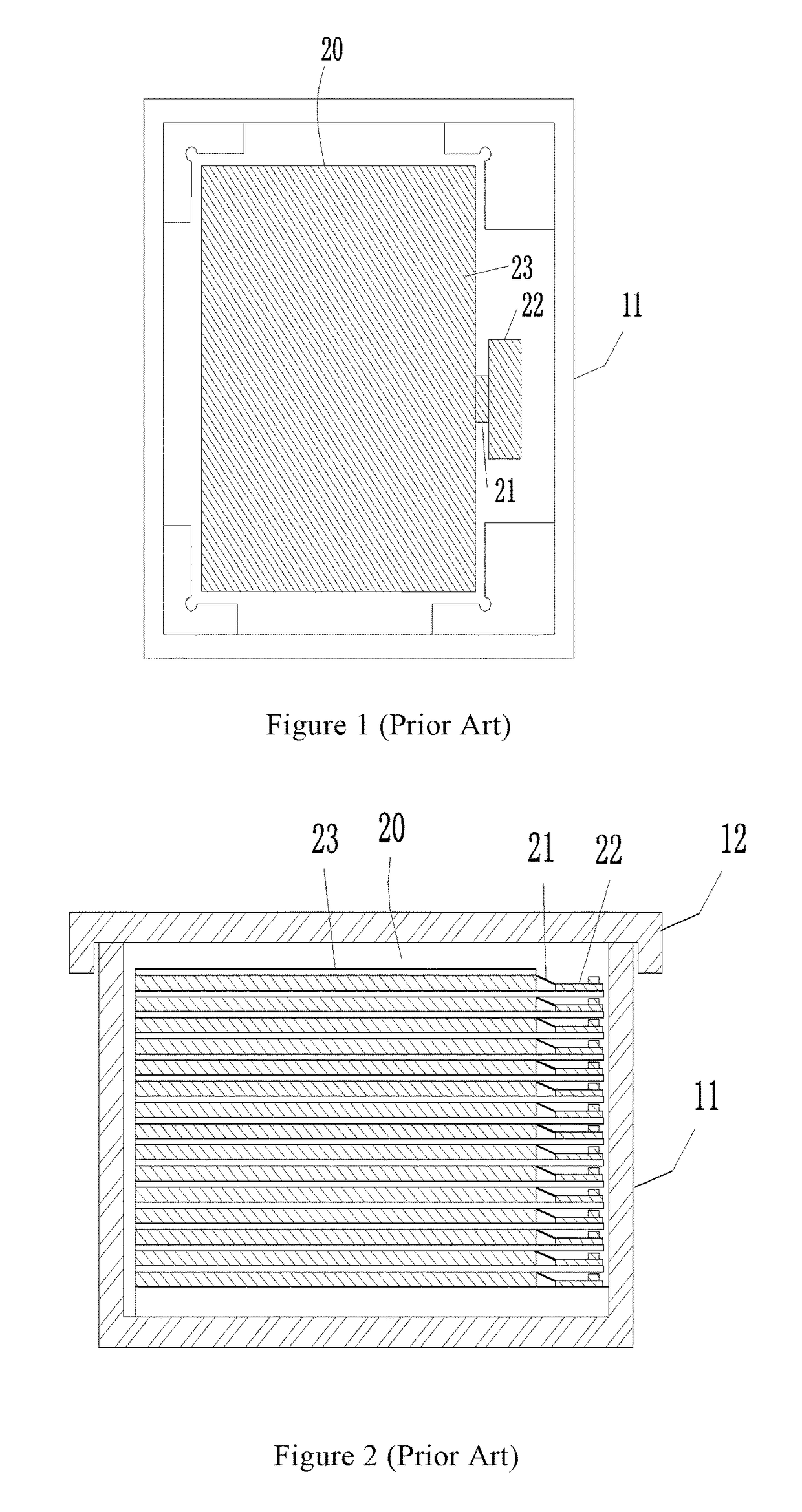

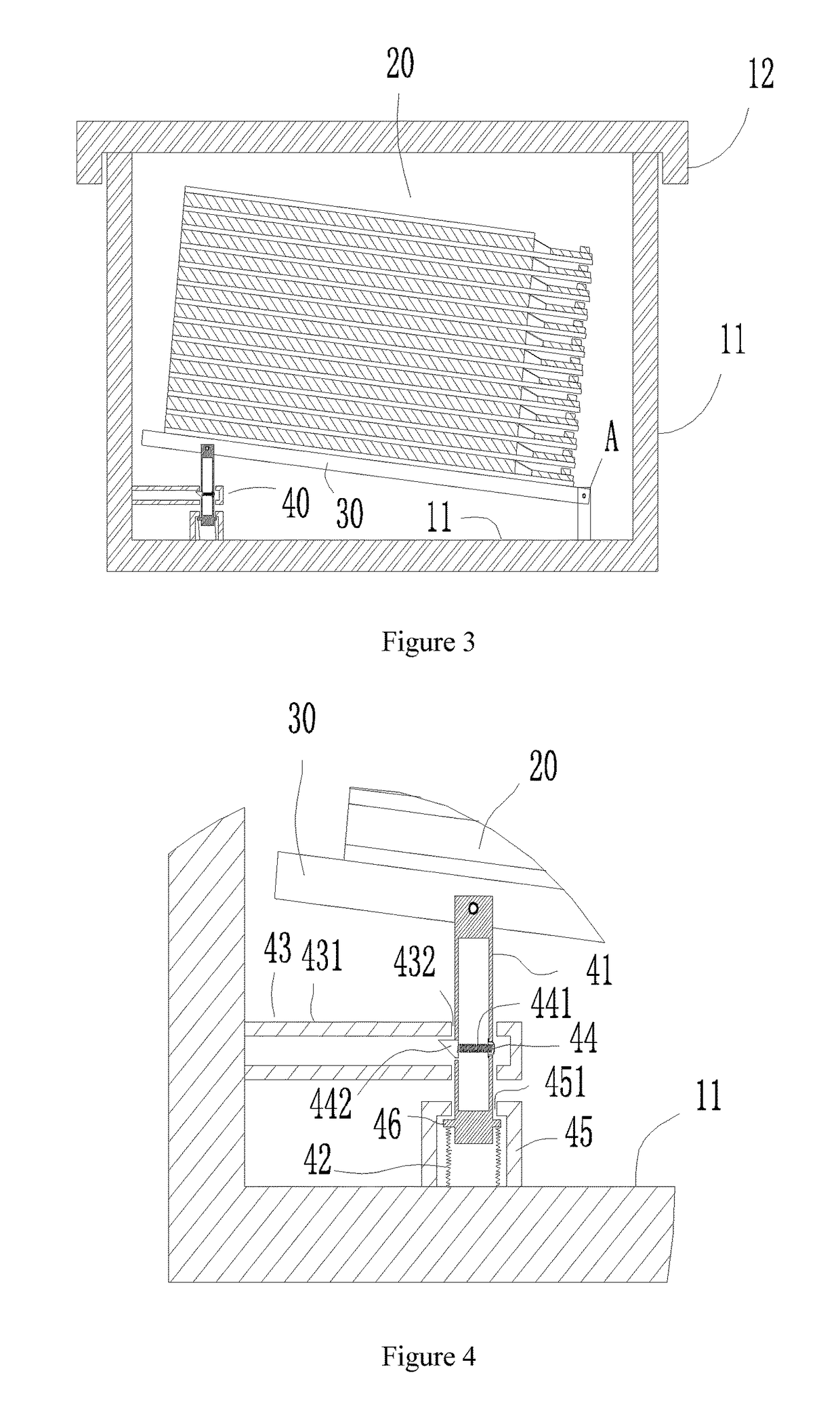

Adjustable tilting packaging box for liquid crystal module

ActiveUS20160355326A1Low yield ratePrevent movementDamagable goods packagingInternal fittingsEngineeringLiquid crystal

The invention provides an adjustable tilting packaging box for liquid crystal module. The first solution includes: box, support rack for carrying liquid crystal module, supporting rack being connected to box bottom through first support element. First support element includes at least a first adjustment mechanism, connected to side of support rack; wherein, first adjustment mechanism including: a first support pillar, a resilient element and a positioning element. First support pillar is retractably connected to box bottom through resilient element; first support pillar is disposed with resilient buckle matching positioning element to realize multi-level rising and lowering of first support pillar. Through tilt angle of support rack making PCB located at lower end of leaning, the weight of PCB prevents PCB from folding up to cause crease in COF or damage to glass during bumpy transportation. The invention uses another means of angle adjustment mechanism to achieve same objective.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Adjustable tilting packaging box for liquid crystal module

ActiveUS9758297B2Low yield ratePrevent movementDamagable goods packagingInternal fittingsEngineeringLiquid crystal

The invention provides an adjustable tilting packaging box for liquid crystal module. The first solution includes: box, support rack for carrying liquid crystal module, supporting rack being connected to box bottom through first support element. First support element includes at least a first adjustment mechanism, connected to side of support rack; wherein, first adjustment mechanism including: a first support pillar, a resilient element and a positioning element. First support pillar is retractably connected to box bottom through resilient element; first support pillar is disposed with resilient buckle matching positioning element to realize multi-level rising and lowering of first support pillar. Through tilt angle of support rack making PCB located at lower end of leaning, the weight of PCB prevents PCB from folding up to cause crease in COF or damage to glass during bumpy transportation. The invention uses another means of angle adjustment mechanism to achieve same objective.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Manufacture method for a surface mounted power LED support and its product

ActiveUS9157610B2Low costEasy to manufactureLighting support devicesPrinted circuit aspectsSingle supportSurface mounting

A manufacture method for a surface mounted power LED support comprises providing a wiring board having both sided metal layers. In addition, the method comprises forming a hole. Further, the method comprises setting a metal layer in the surface of the hole. Still further, the method comprises thickening the metal layer of the wiring board. The method also comprises etching the metal layer of the wiring board. Moreover, the method comprises cutting the wiring board to form single support unit. A surface mounted power LED support comprises a both sided wiring board, a hole formed in the wiring board and wiring layers set on the surface of the wiring board.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD +1

Touch display panel

InactiveUS20160188072A1High yield rateLow fragmentation rateInput/output processes for data processingPolarizerColor gel

A touch display panel is provided herein, which comprises an array substrate, a color filter substrate, and a liquid crystal layer. A touch driving electrode is disposed on the array substrate. A first polarizer is disposed at an outer side of the array substrate. A second polarizer is disposed at an outer side of the color filter substrate. The second polarizer has a touch sensing electrode manufactured on an outer surface thereof. In the present invention, the touch sensing electrode is disposed on the polarizer or the cover plate, thereby avoiding fragmentation of the substrates and further improving the product yield rate of the touch display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Display device

The disclosure provides a display device. The pixel electrode of the display device includes a first pixel electrode and a second pixel electrode having the same electric potential. The first interlayer is formed between the first substrate and the first pixel electrode. Adjacent two of the first strip-shaped branches of the first interlayer form a first gap to expose part of the first substrate. The common electrode layer is disposed over the second substrate. The pixel electrode is positioned between the first substrate and the display medium layer. The first pixel electrode extends to cover the first gap. A difference between a maximum distance between the first pixel electrode and the common electrode layer and a maximum distance between the second pixel electrode and the common electrode layer is 0.1 μm to 0.4 μm.

Owner:INNOLUX CORP

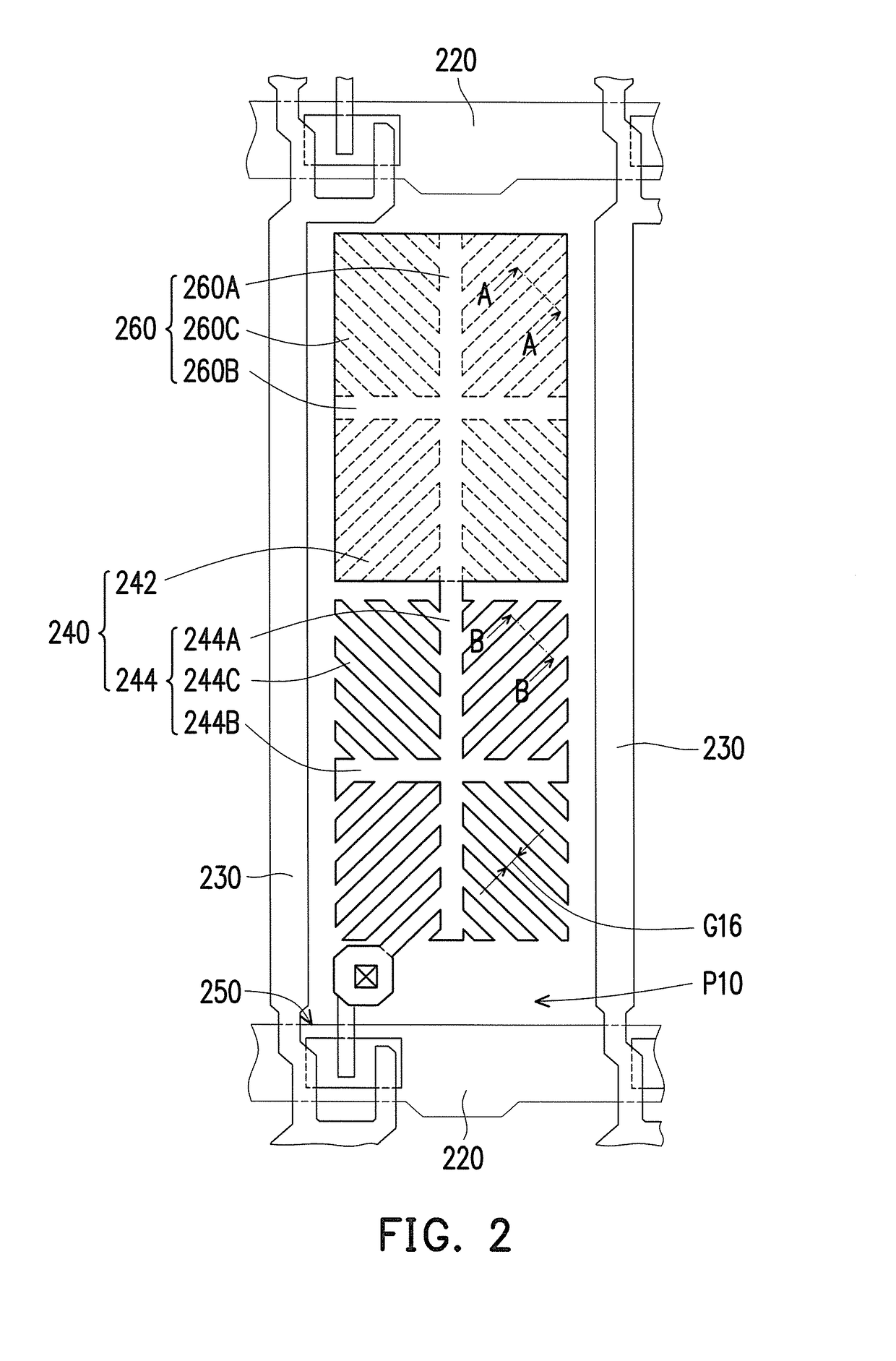

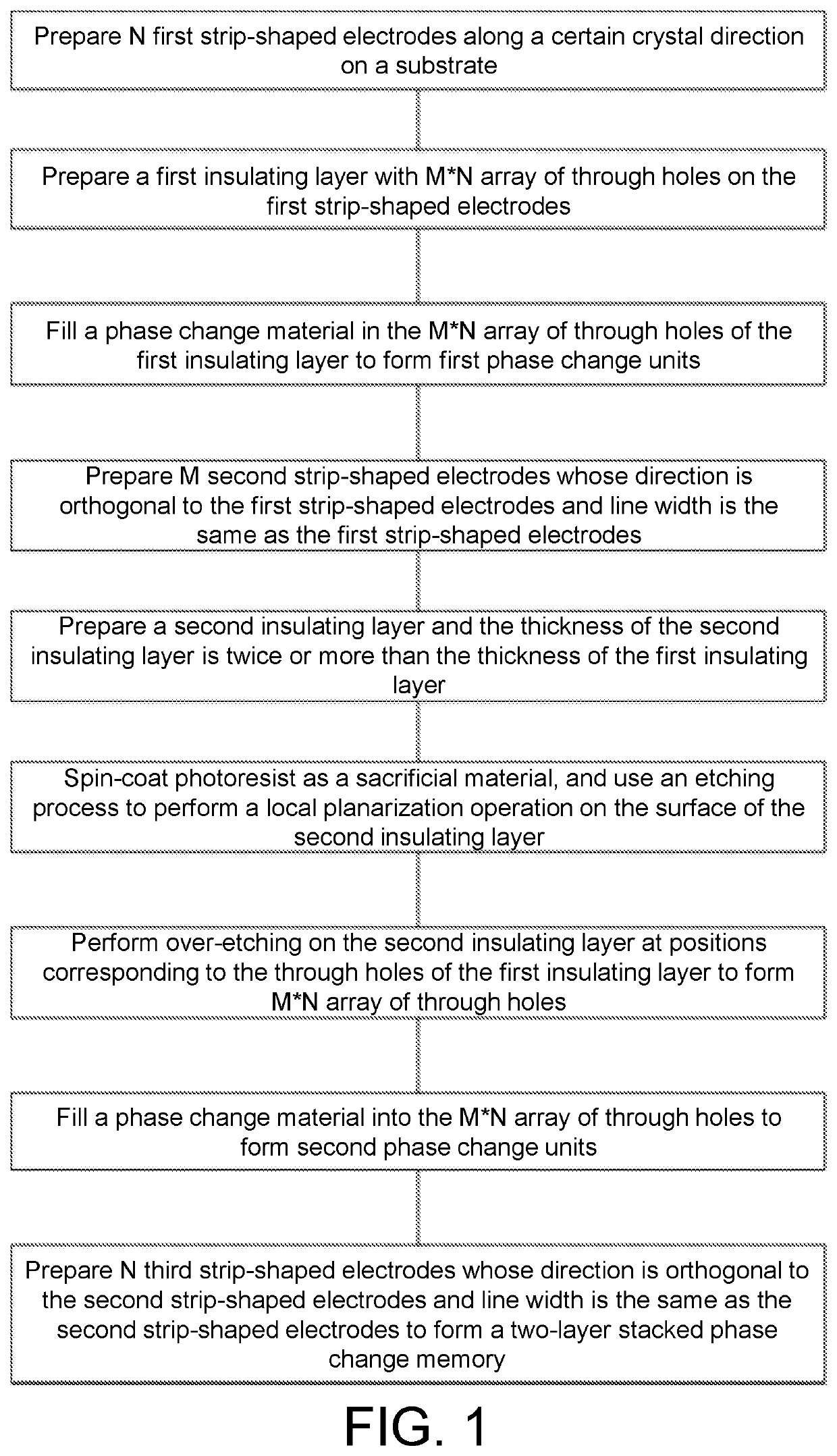

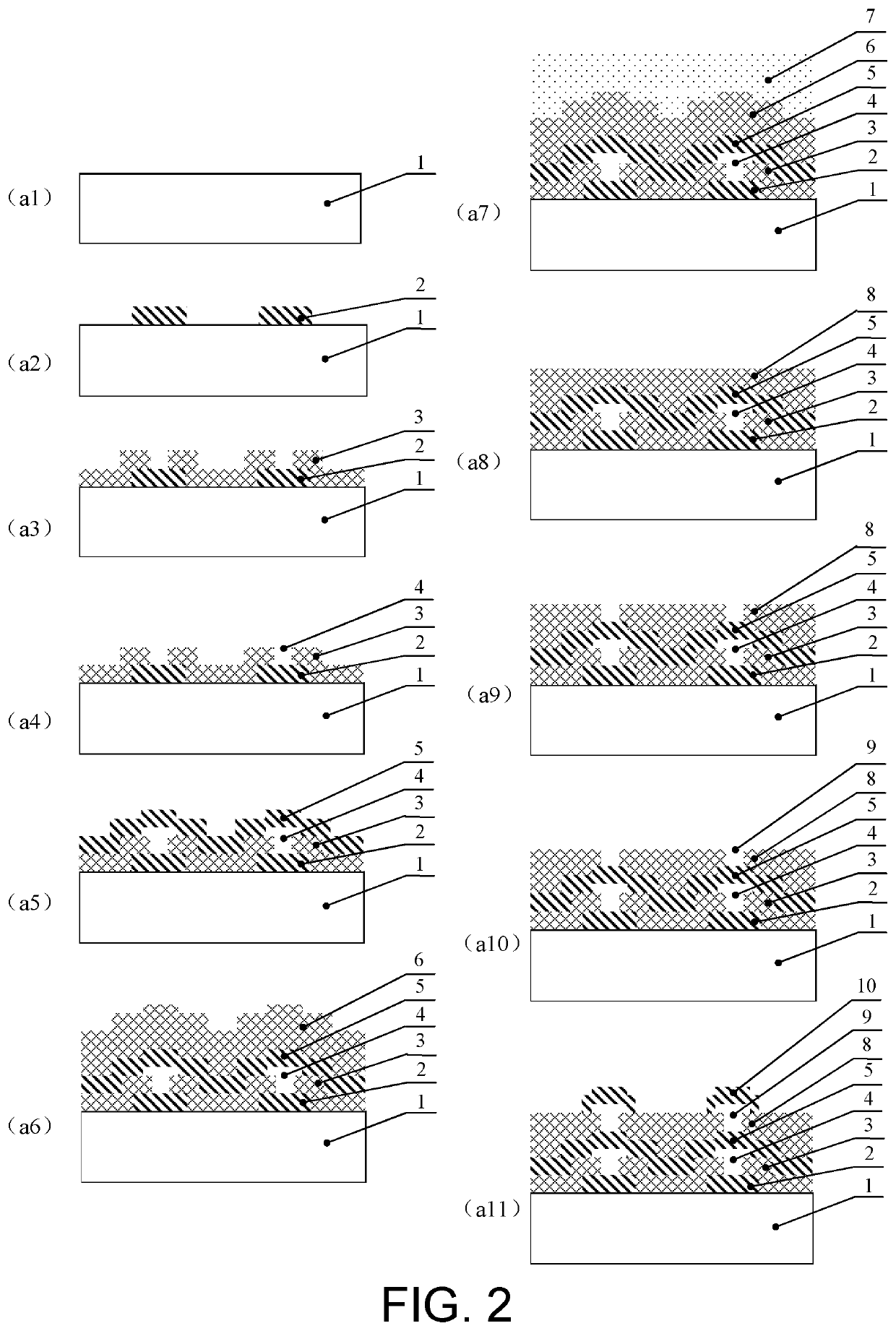

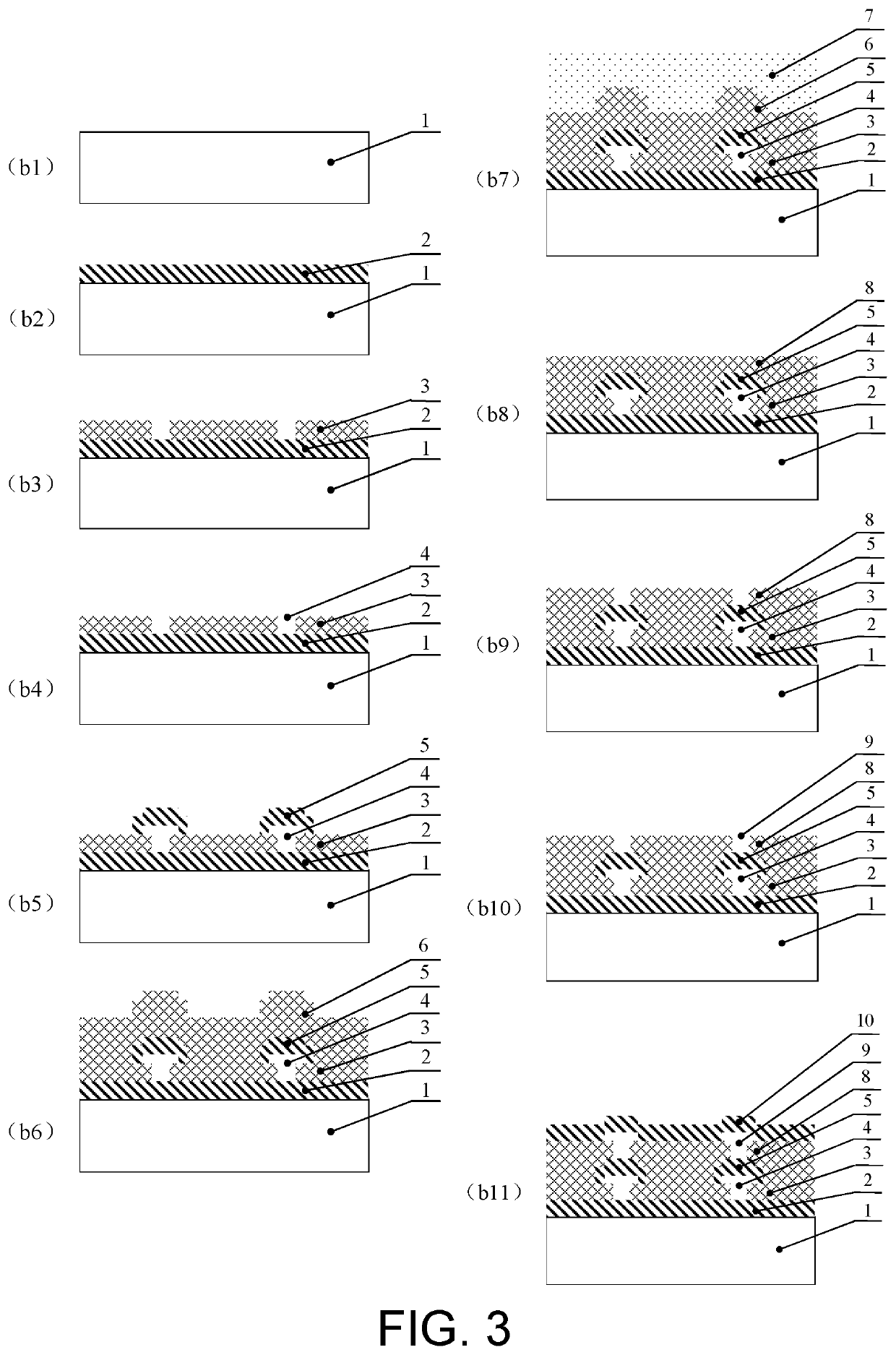

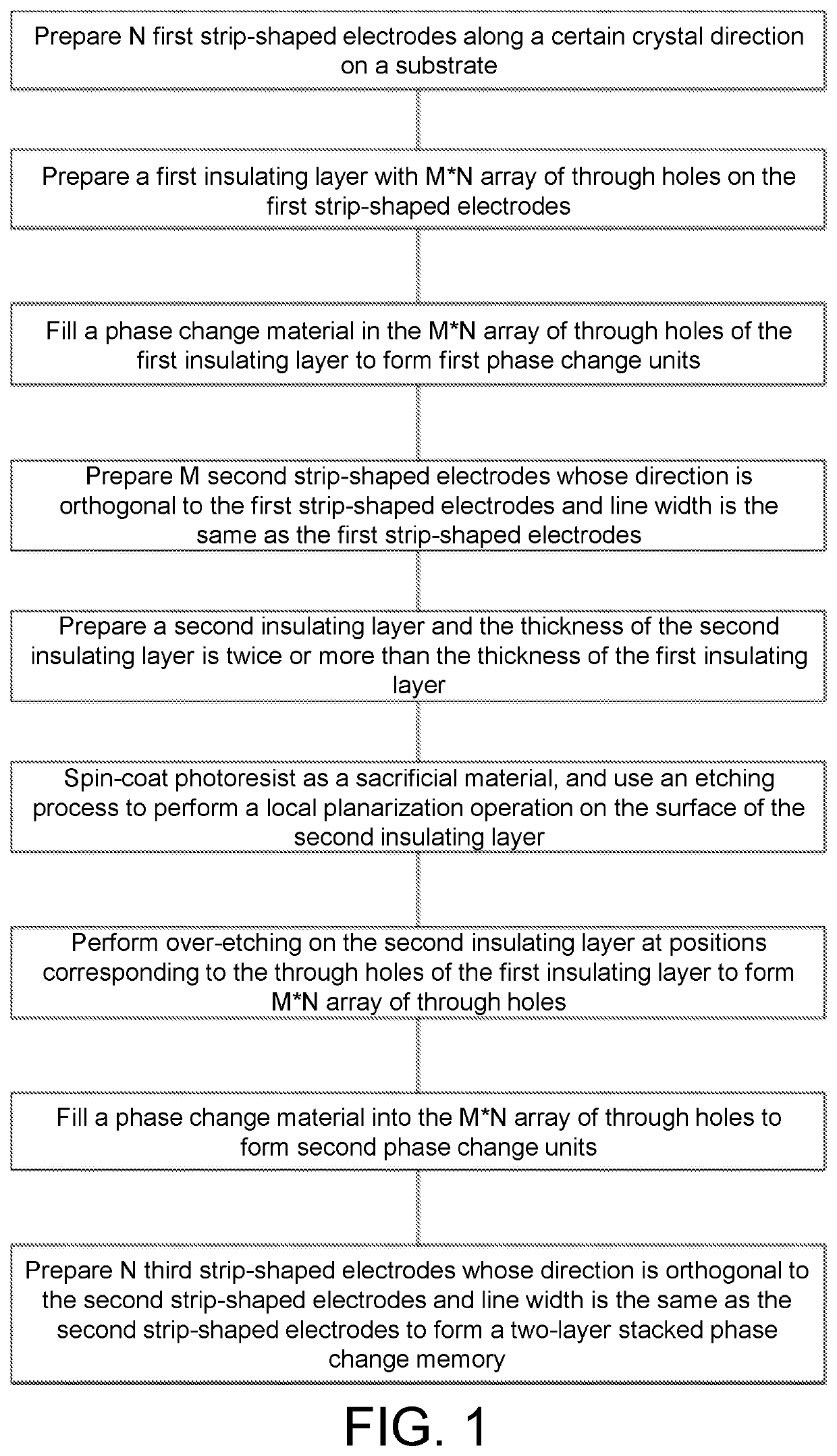

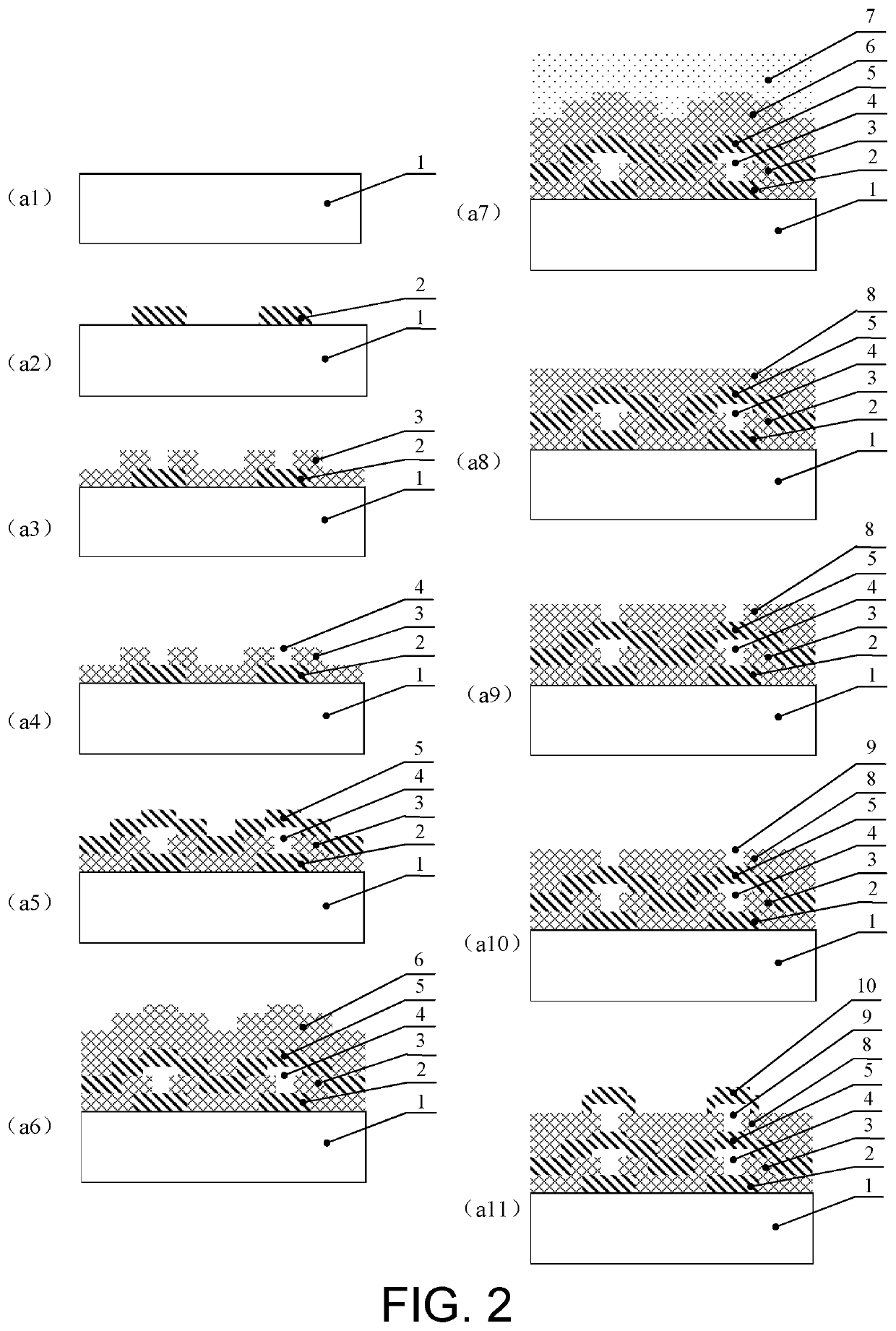

Three-dimensional stacked memory and preparation method thereof

ActiveUS20210104670A1Simple structureLow implementation difficultySolid-state devicesSemiconductor devicesPhase-change memoryEngineering

The disclosure discloses a three-dimensional stacked memory and a preparation method thereof. The storage unit adopts a constrained structure phase change storage unit, and uses a crossbar storage array structure to build a large-capacity storage array. The preparation method includes: preparing N first strip-shaped electrodes along a crystal direction on a substrate; preparing a first insulating layer with M*N array of through holes; filling the M*N array of through holes of the first insulating layer with a phase change material to form first phase change units; preparing M second strip-shaped electrodes; preparing a second insulating layer, using spin-coated photoresist as a sacrificial material, performing a local planarization on the surface of the second insulating layer; forming M*N array of through holes on the second insulating layer; filling a phase change material to form second phase change units; preparing N third strip-shaped electrodes to form a two-layer stacked phase change memory.

Owner:HUAZHONG UNIV OF SCI & TECH

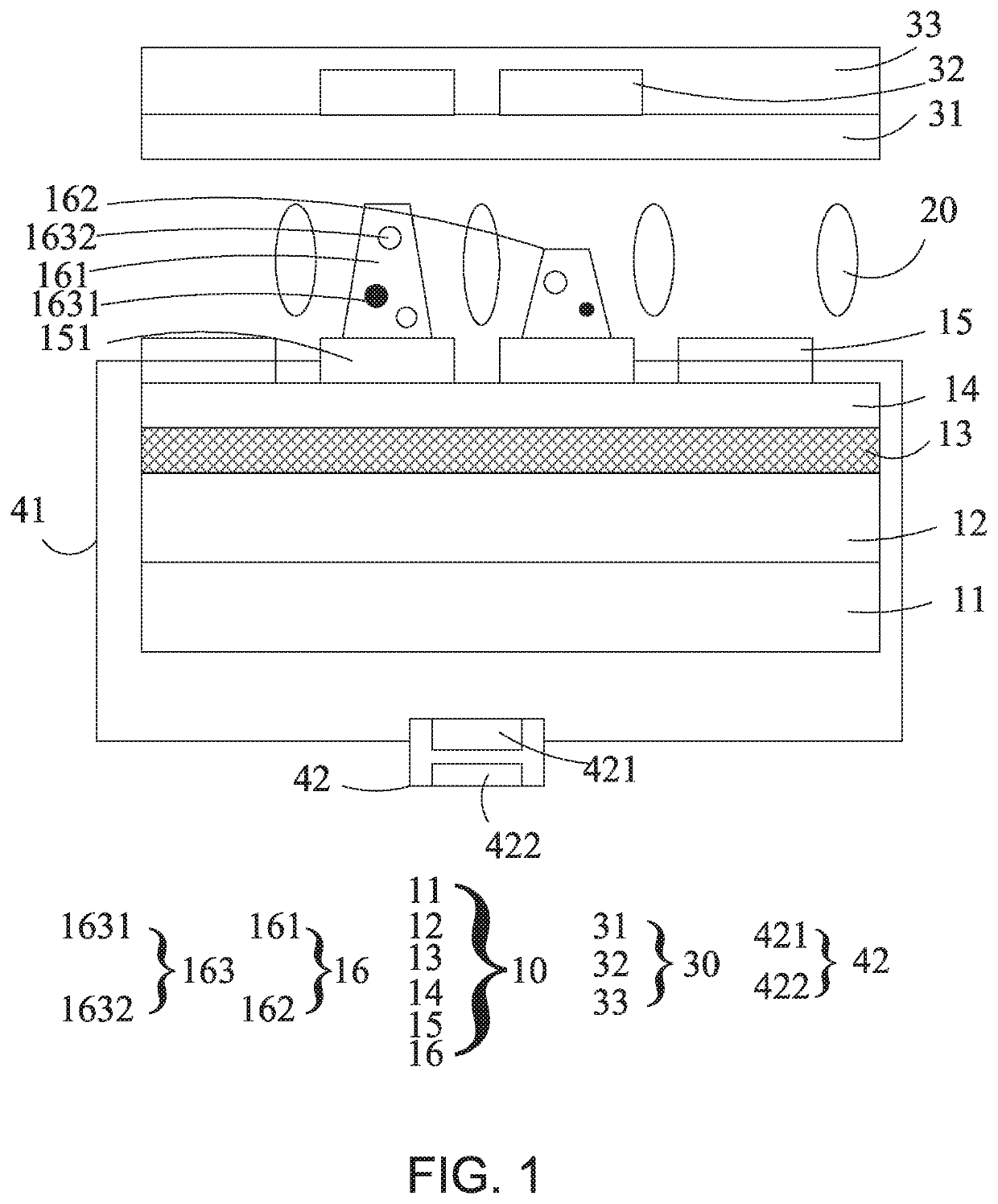

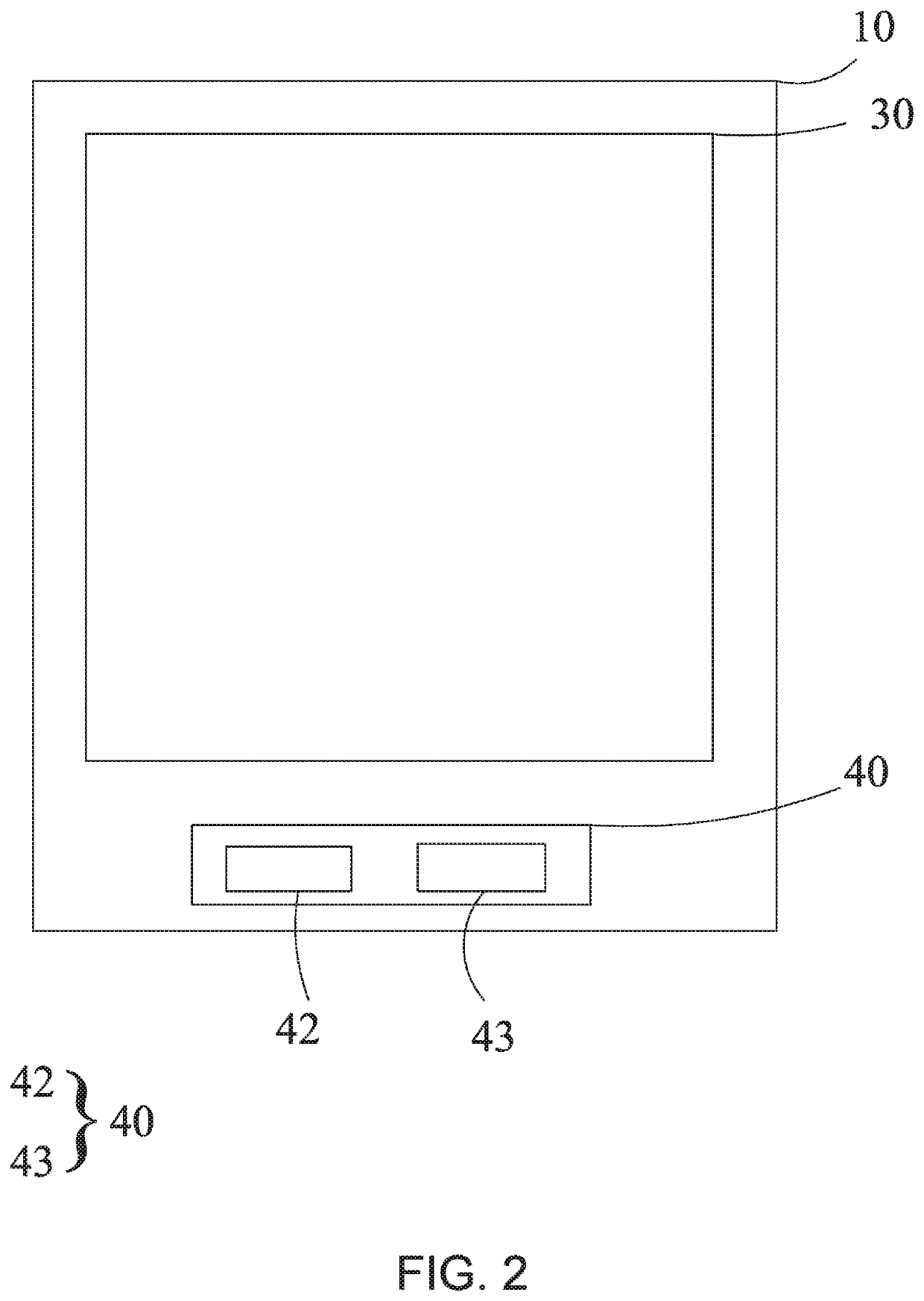

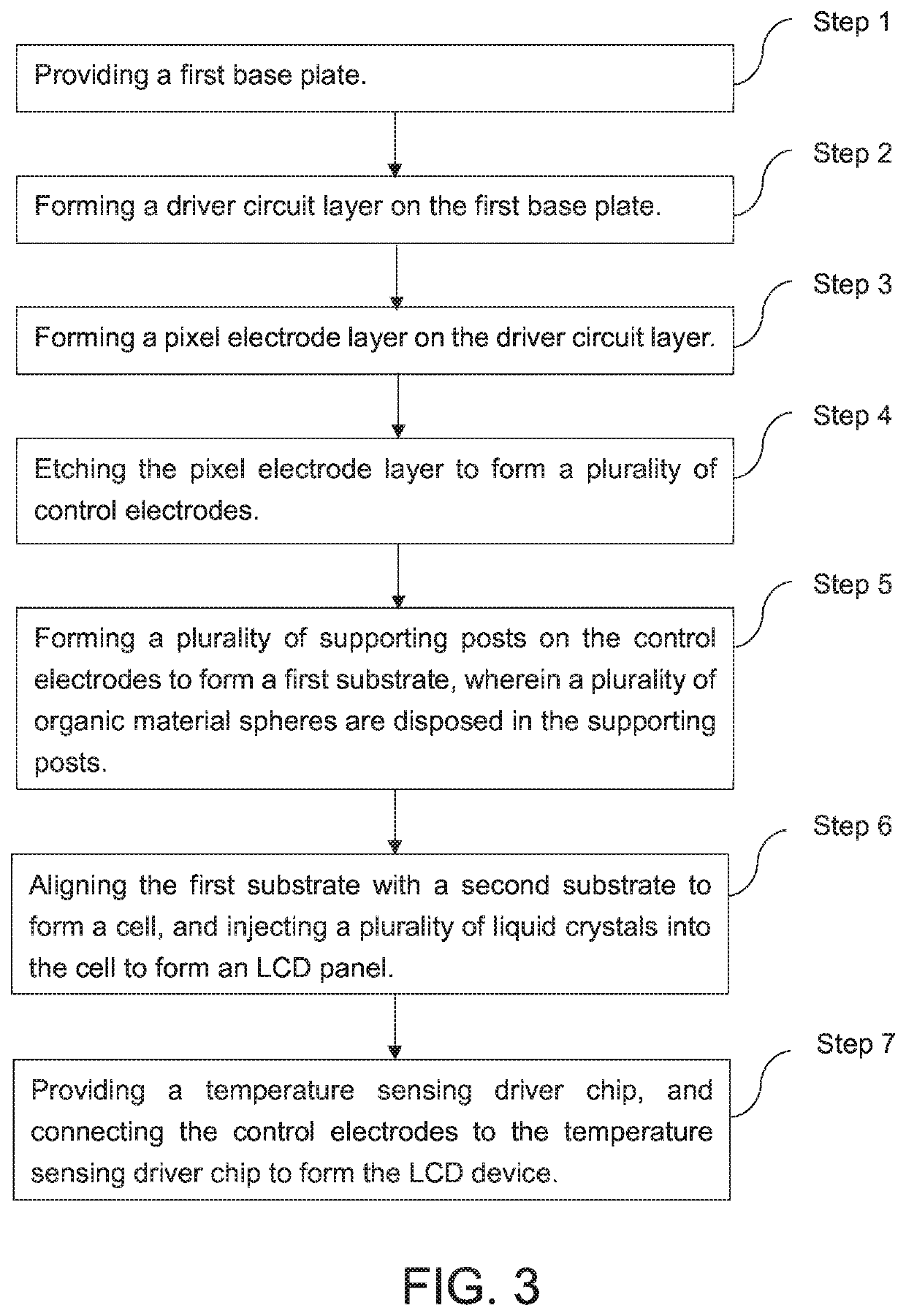

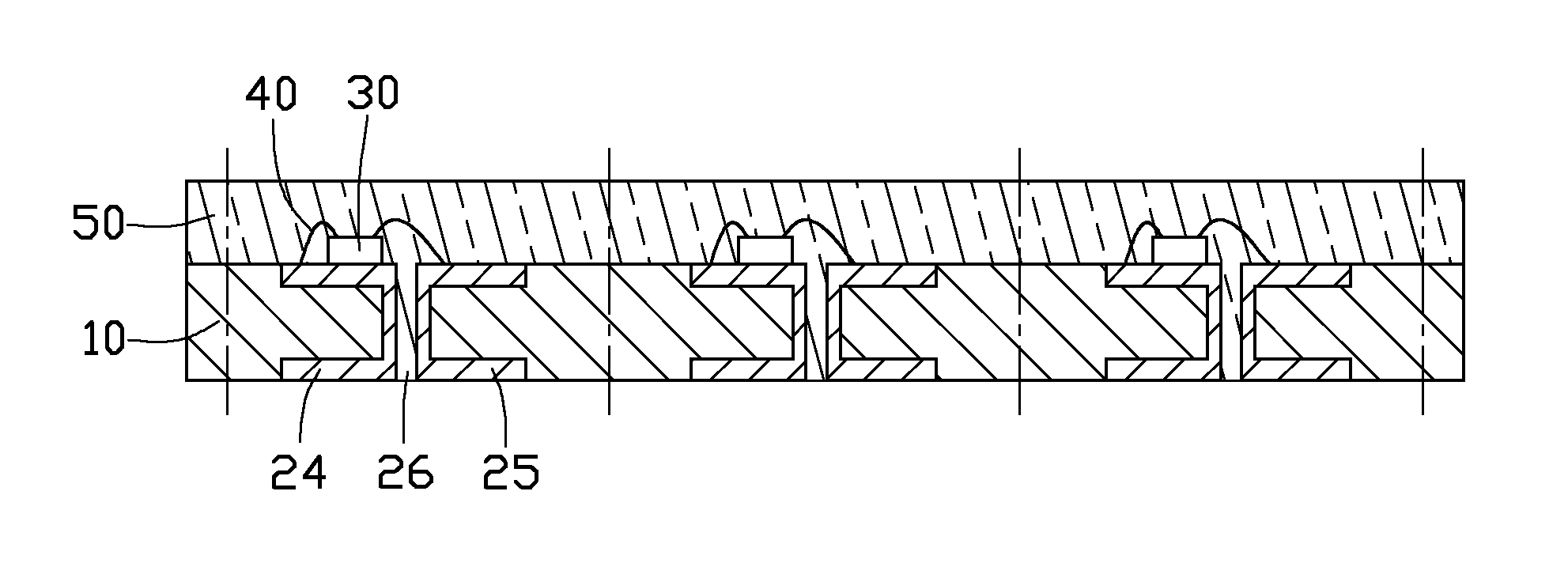

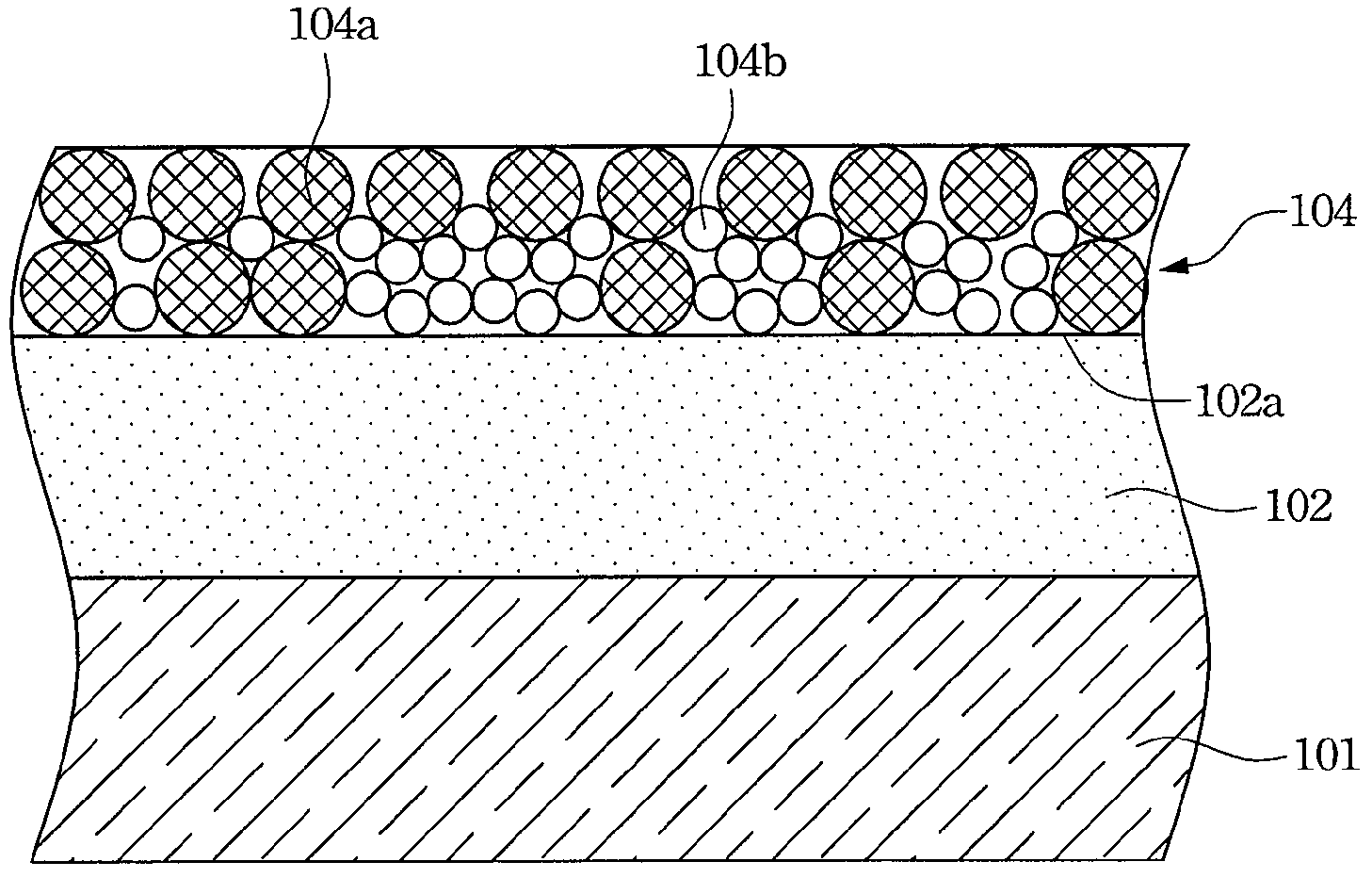

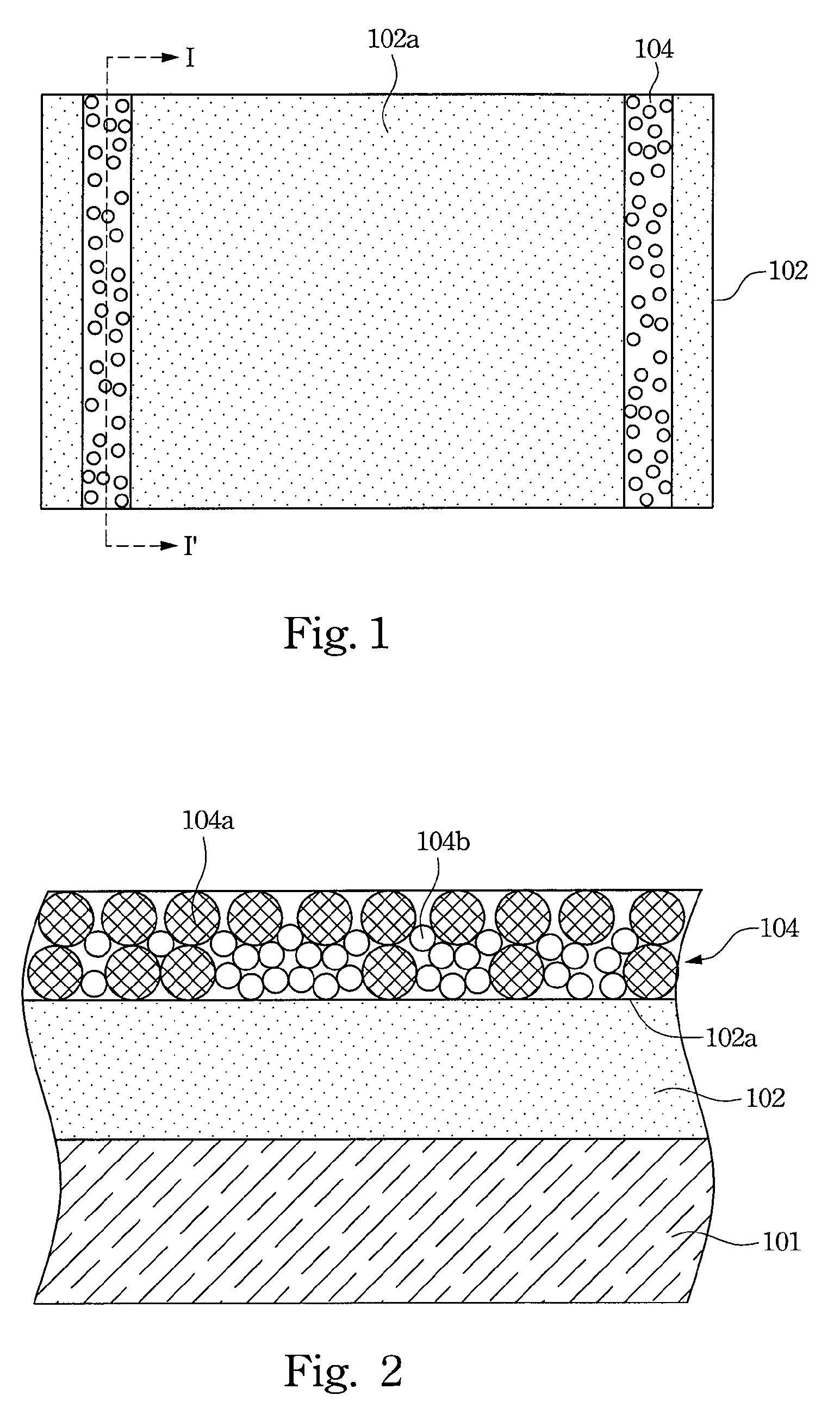

LCD device and manufacturing method thereof

The disclosure provides a liquid crystal display (LCD) device and a manufacturing method thereof. A temperature sensing driver chip is disposed in the LCD device and can output a voltage signal to a control electrode according to changes in temperature. Therefore, an electric field is formed between the control electrode and a common electrode. Heights of a plurality of supporting posts can be changed by the electric field to control stretching and shrinking of the control electrode, thereby improving performance of the supporting posts. Thus, a plurality of organic material spheres disposed in the supporting posts can improve stress tolerance of the supporting posts, thereby further improving performance of the supporting posts.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

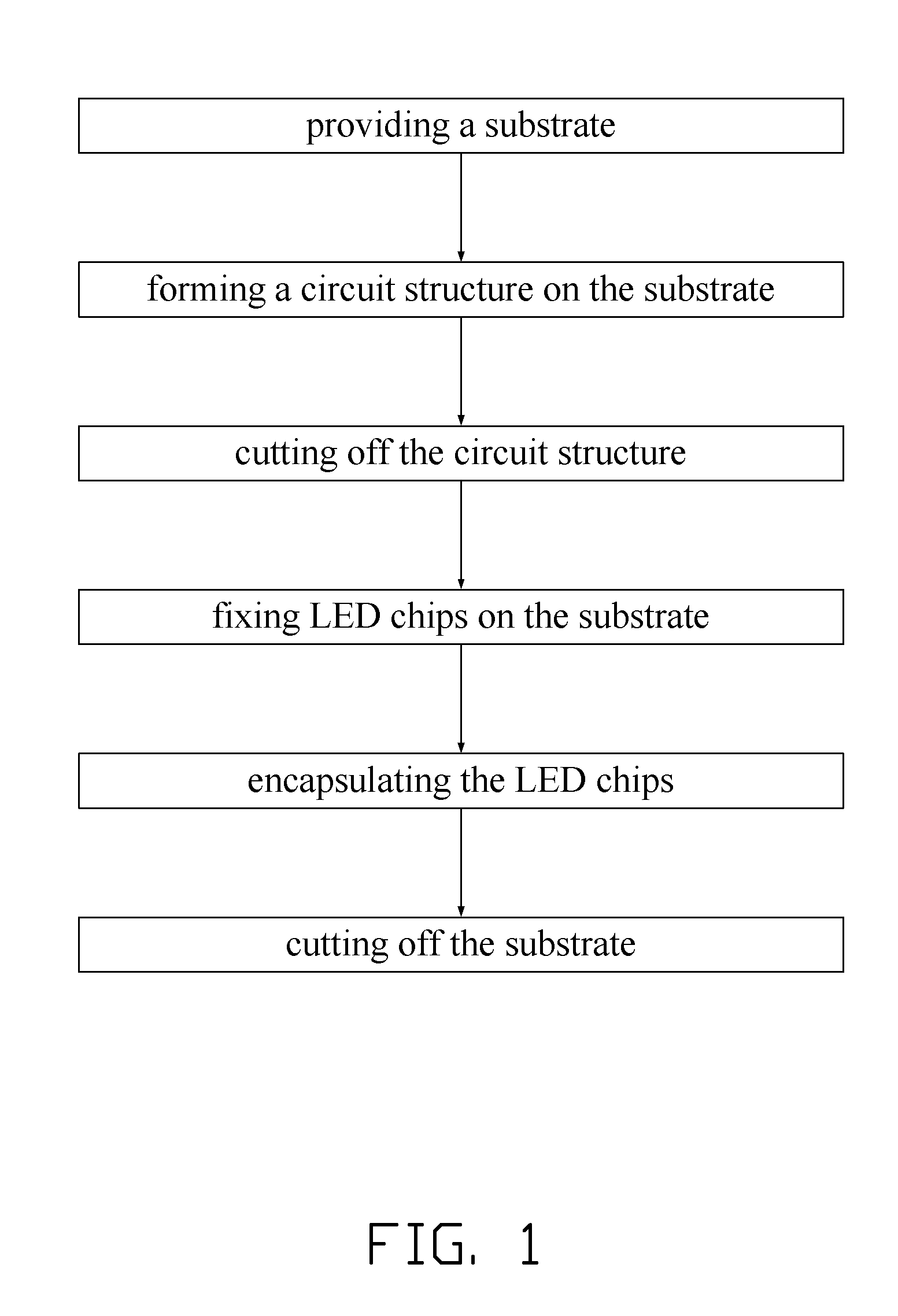

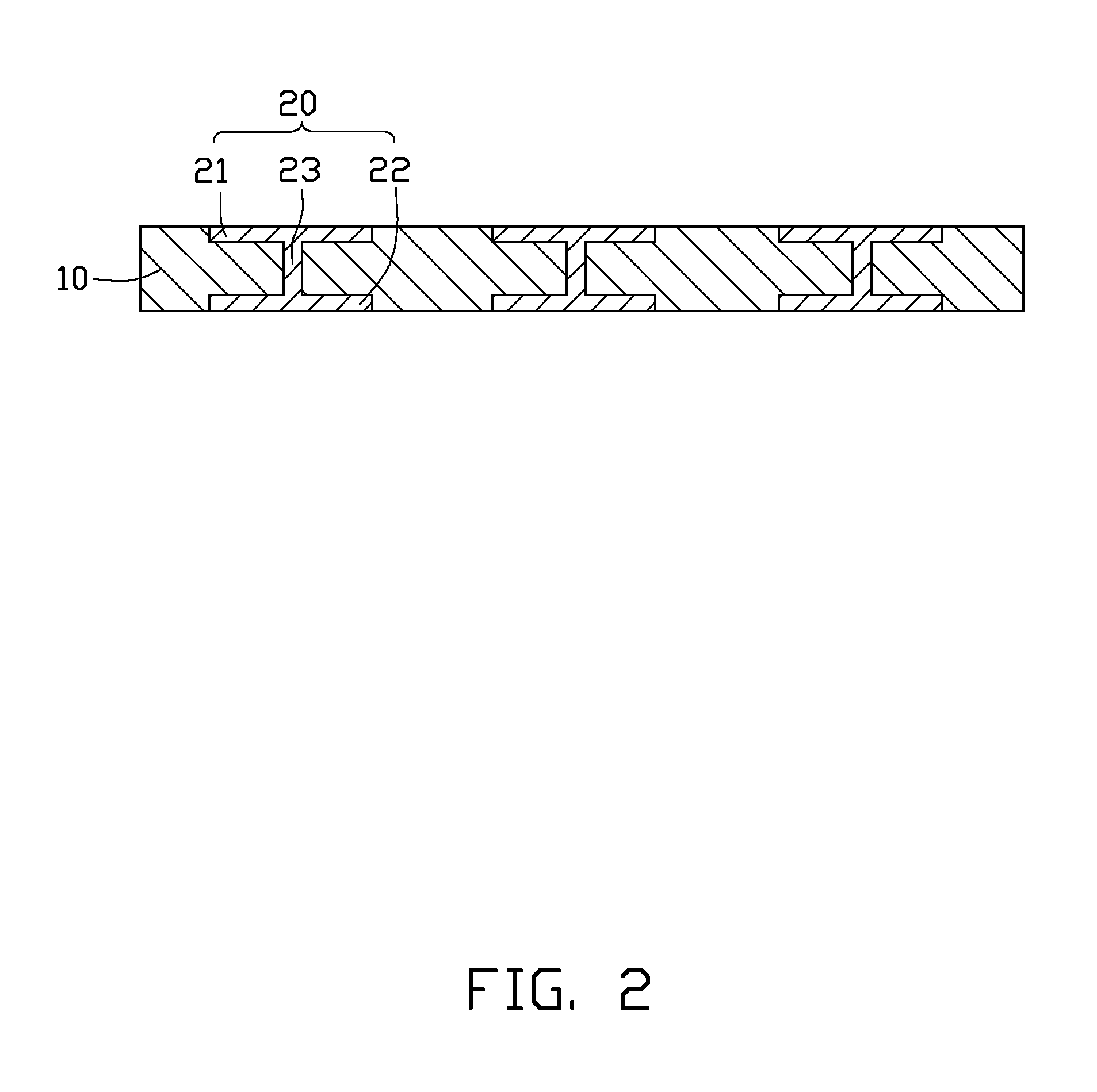

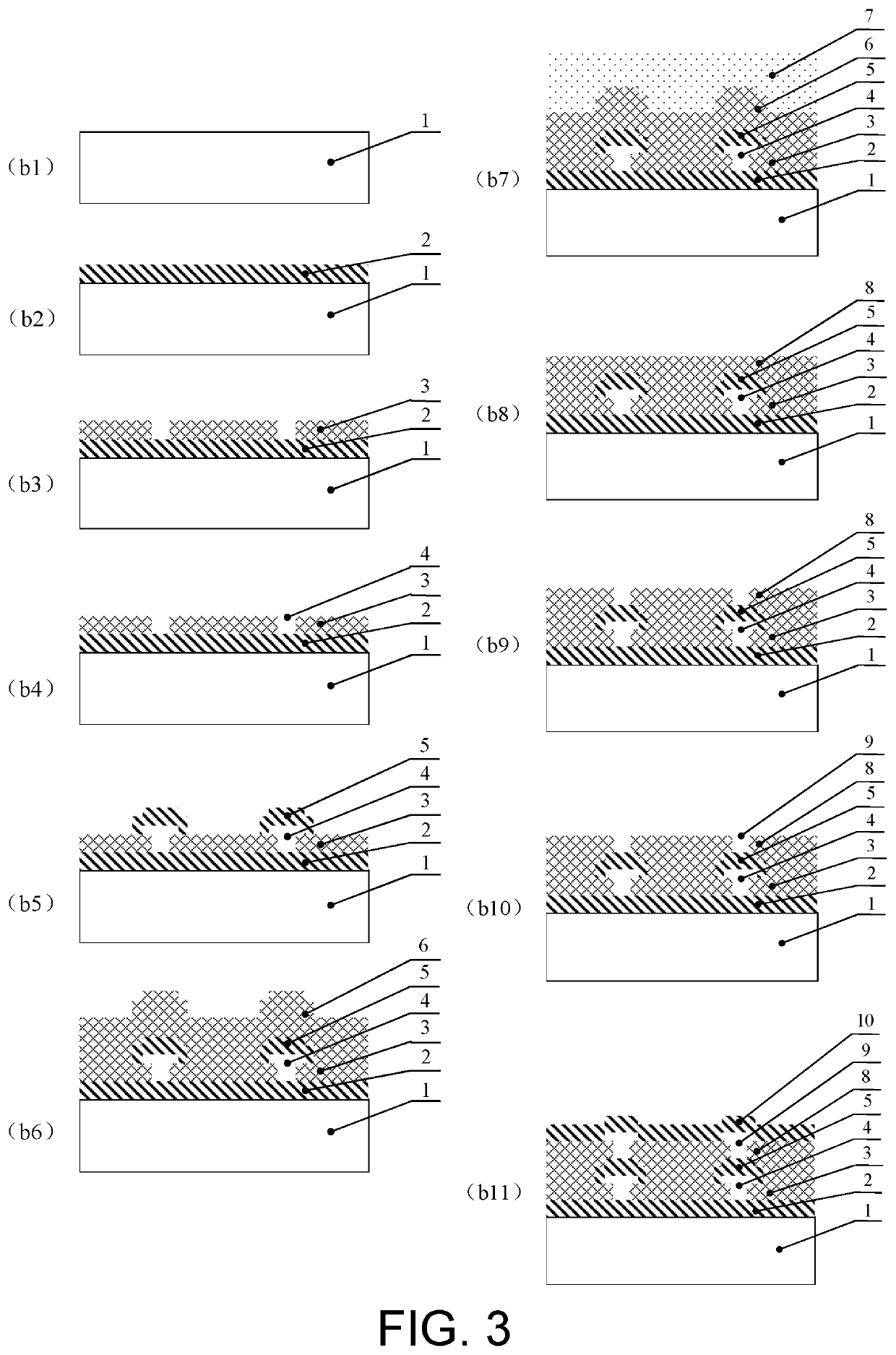

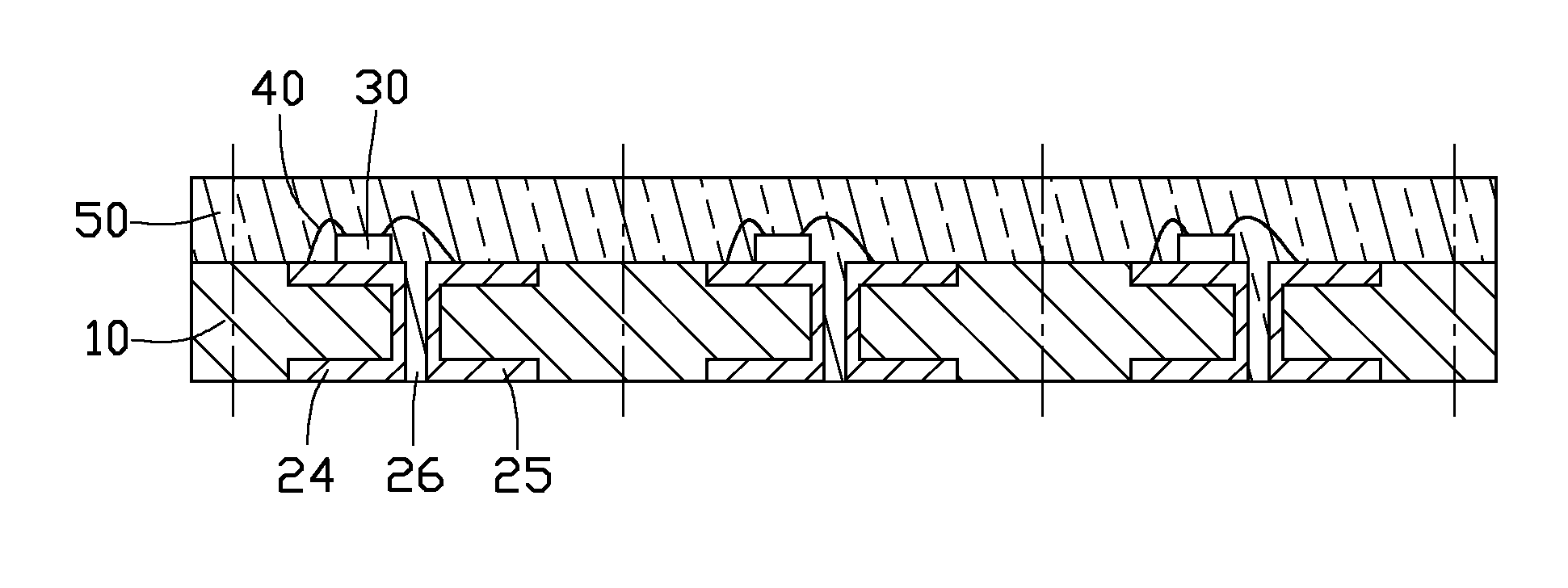

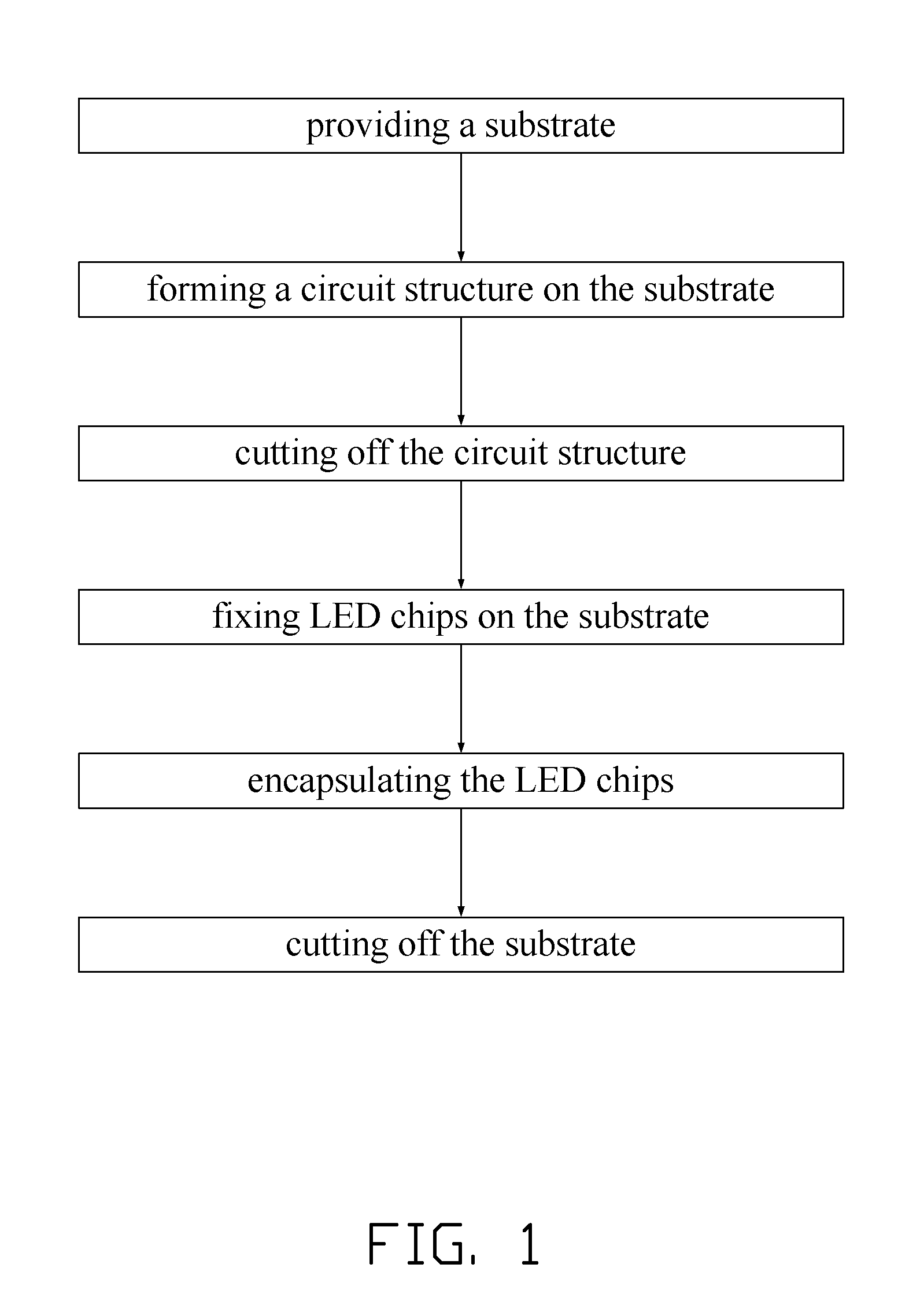

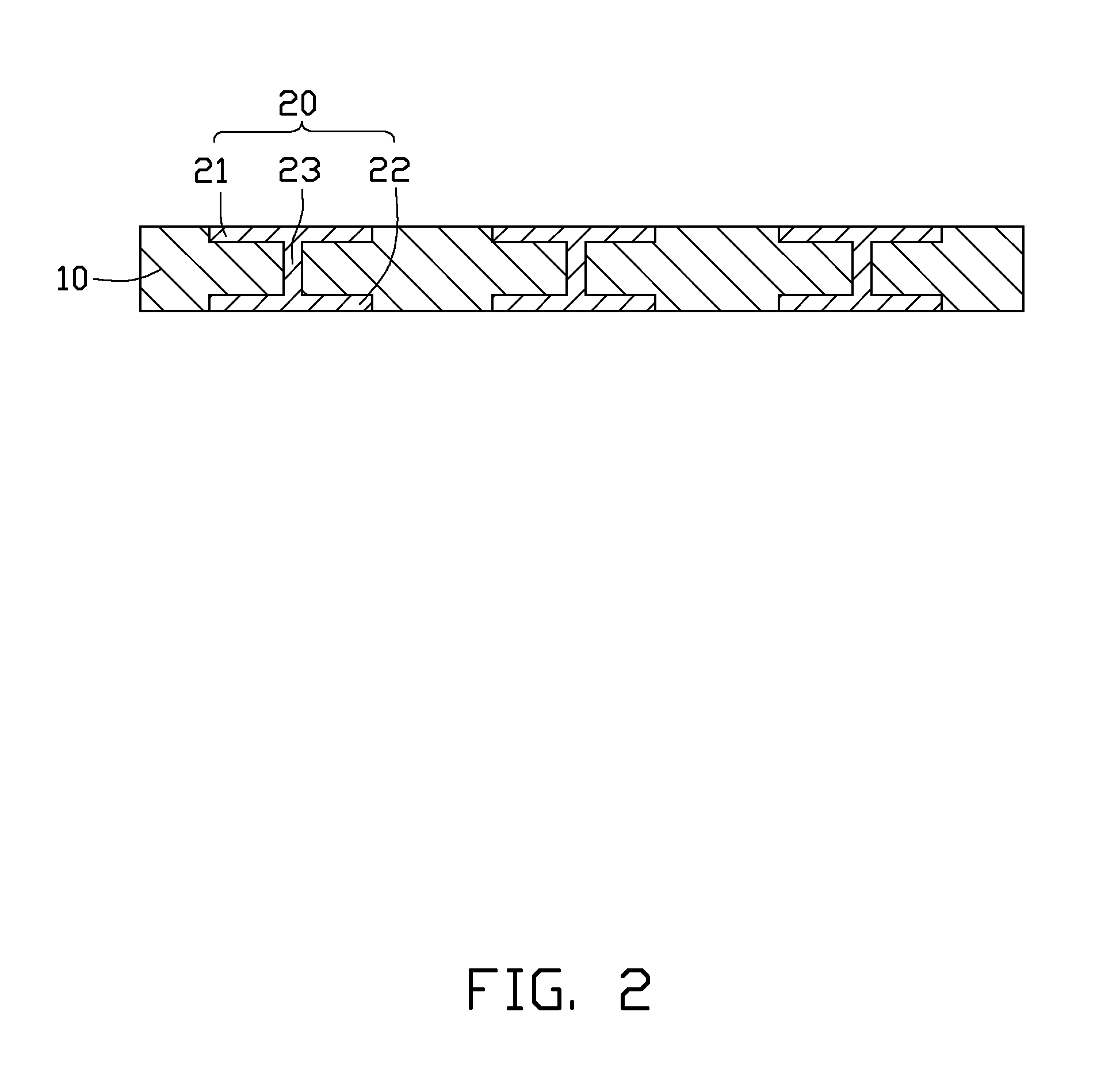

Method for manufacturing light emitting diodes and light emitting diodes obtained thereby

ActiveUS20120273829A1Avoid missing wasteReduce yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

A method for manufacturing LEDs includes following steps: forming circuit structures on a substrate, each circuit structure having a first metal layer and a second metal layer formed on opposite surfaces of the substrate and a connecting section interconnecting the first and second metal layers; cutting through each circuit structure along a middle of the connecting section to form first and second electrical connecting portions insulated from each other via a gap therebetween; arranging LED chips on the substrate and electrically connecting the LED chips to the first and second electrical connecting portions; forming an encapsulation on the substrate to cover the LED chips; and cutting through the substrate and the encapsulation between the first and second electrical connecting portions of neighboring circuit structures to obtain the LEDs.

Owner:ADVANCED OPTOELECTRONICS TECH

Three-dimensional stacked memory and preparation method thereof

ActiveUS11233198B2Increase the difficultyLow yield rateSolid-state devicesSemiconductor devicesPhase-change memoryPhotoresist

The disclosure discloses a three-dimensional stacked memory and a preparation method thereof. The storage unit adopts a constrained structure phase change storage unit, and uses a crossbar storage array structure to build a large-capacity storage array. The preparation method includes: preparing N first strip-shaped electrodes along a crystal direction on a substrate; preparing a first insulating layer with M*N array of through holes; filling the M*N array of through holes of the first insulating layer with a phase change material to form first phase change units; preparing M second strip-shaped electrodes; preparing a second insulating layer, using spin-coated photoresist as a sacrificial material, performing a local planarization on the surface of the second insulating layer; forming M*N array of through holes on the second insulating layer; filling a phase change material to form second phase change units; preparing N third strip-shaped electrodes to form a two-layer stacked phase change memory.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for manufacturing light emitting diodes including forming circuit structures with a connecting section

ActiveUS8642388B2Avoid missing wasteReduce yieldSemiconductor/solid-state device detailsSolid-state devicesElectricityLight-emitting diode

Owner:ADVANCED OPTOELECTRONICS TECH

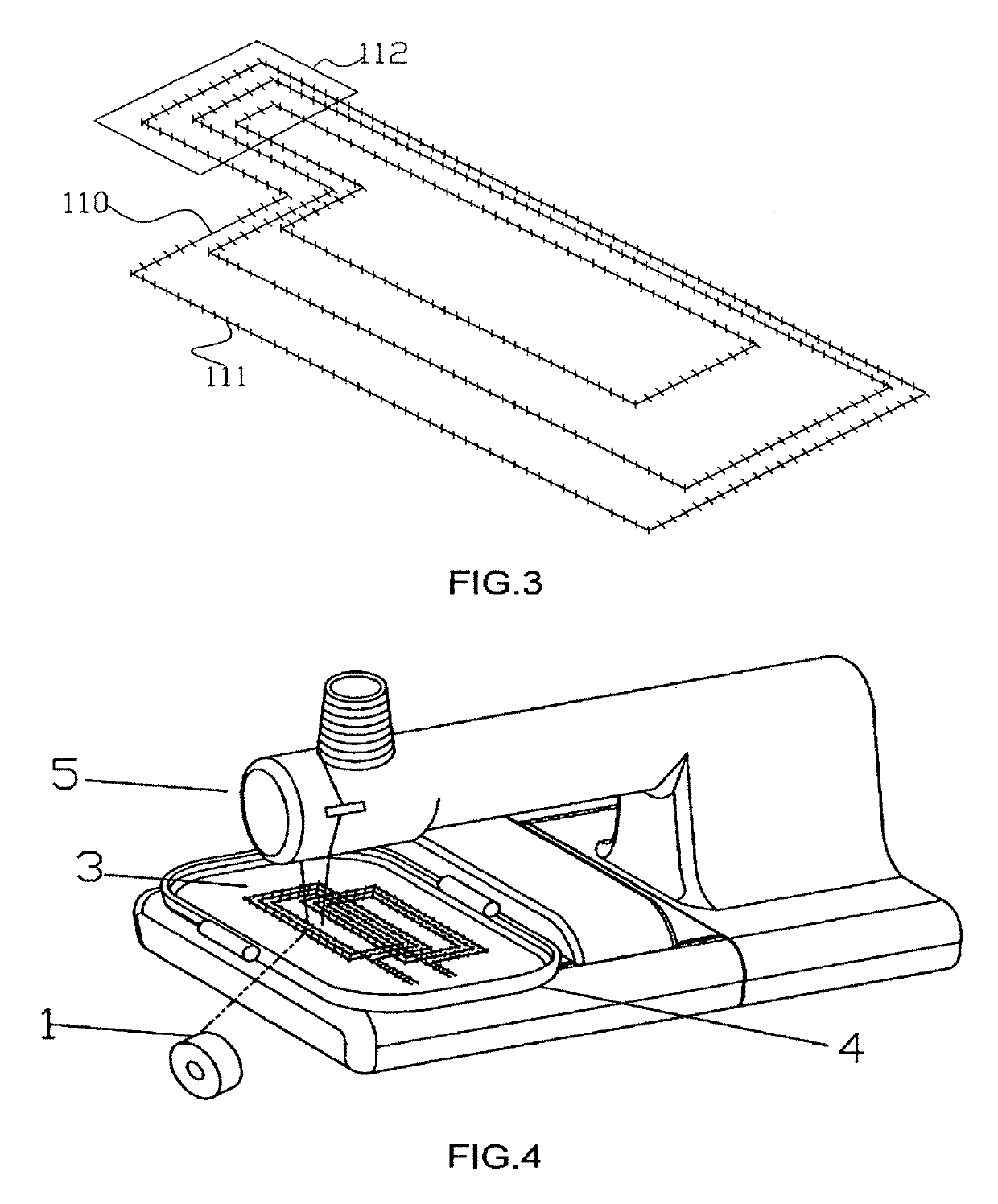

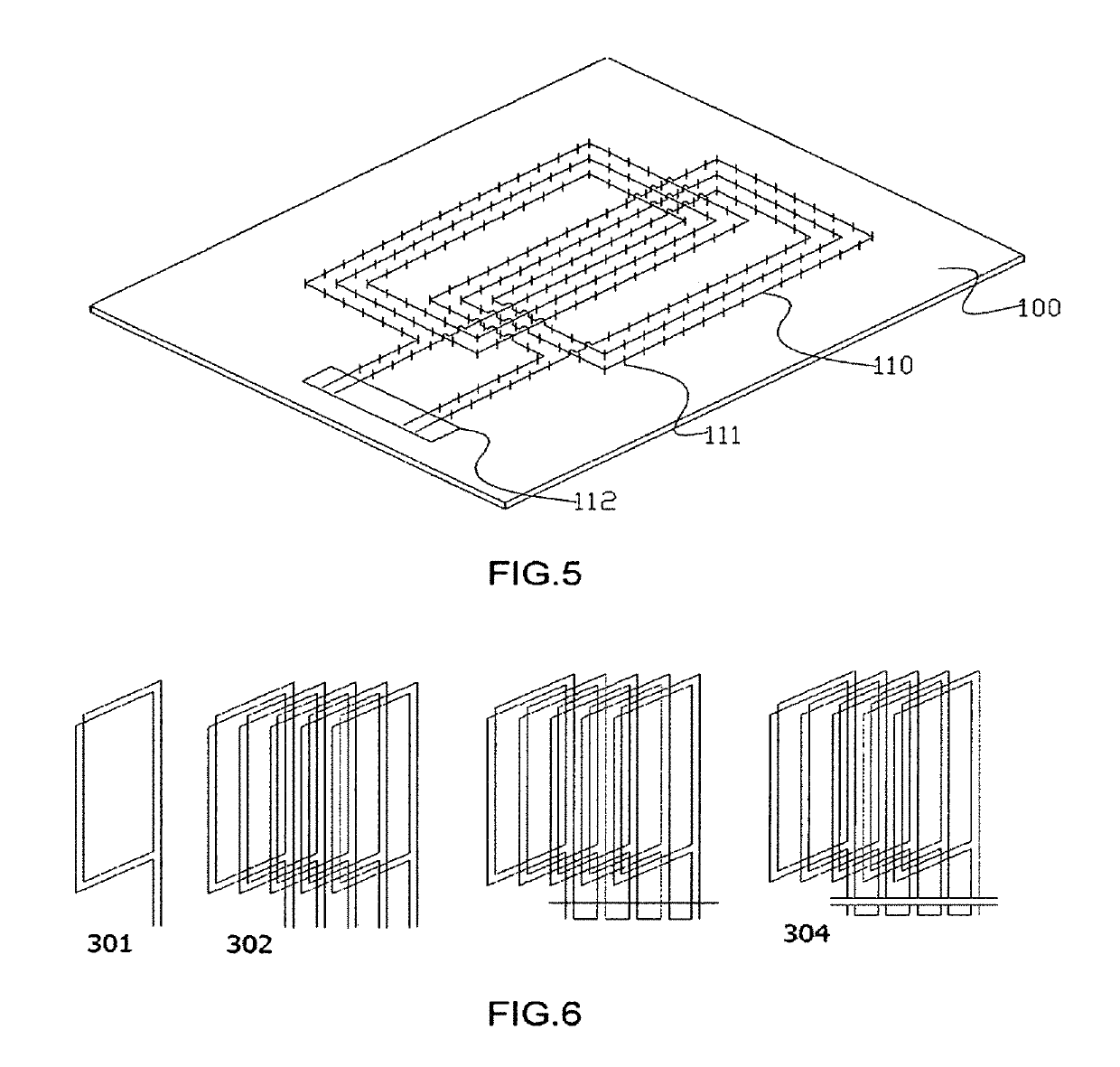

Method for fabricating an electromagnetic induction digitizer antenna board

ActiveUS10276935B2Low yield rateHigh production costNear-field transmissionLoop antennasEngineeringEm induction

Owner:WU YINGCHAO +2

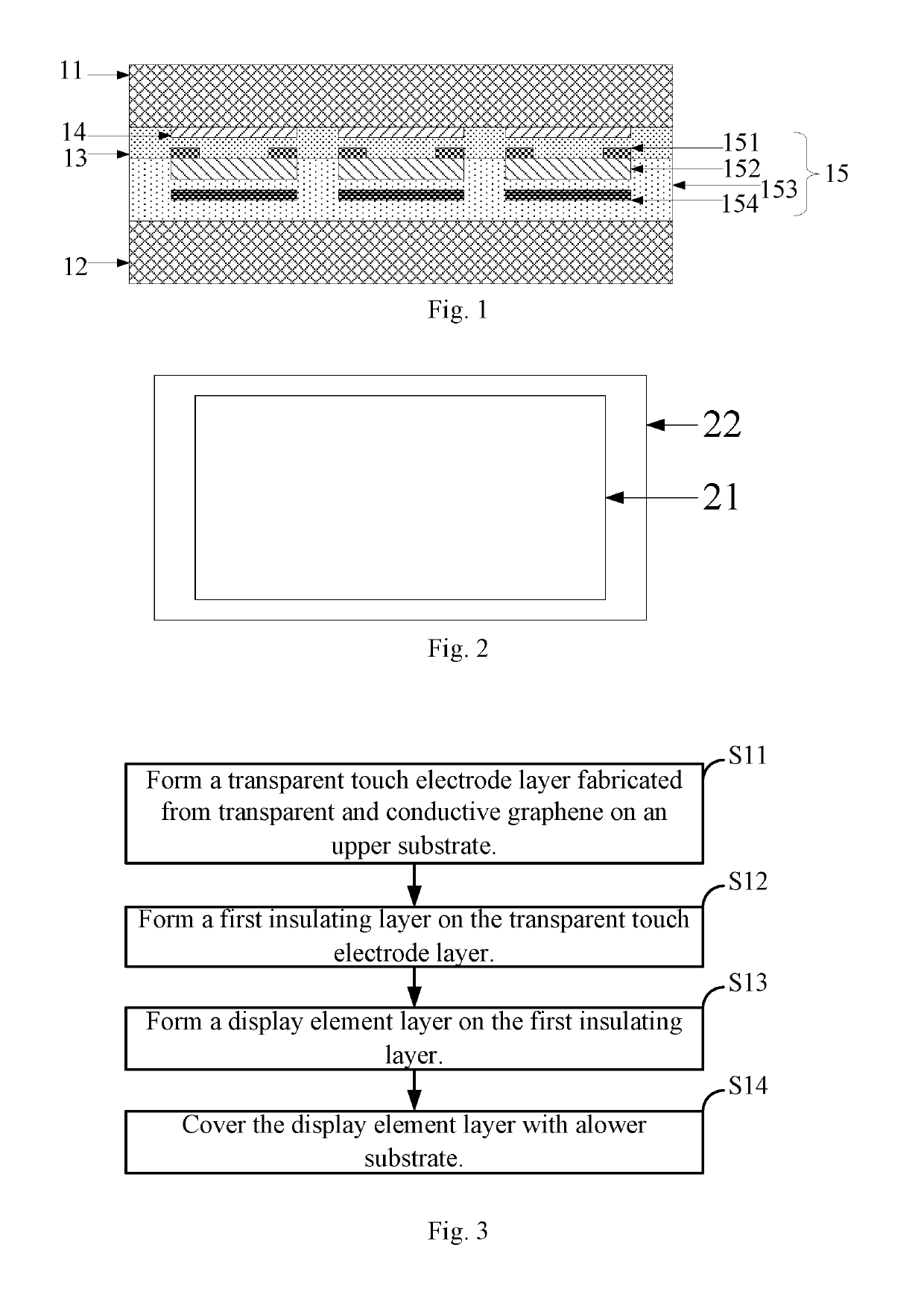

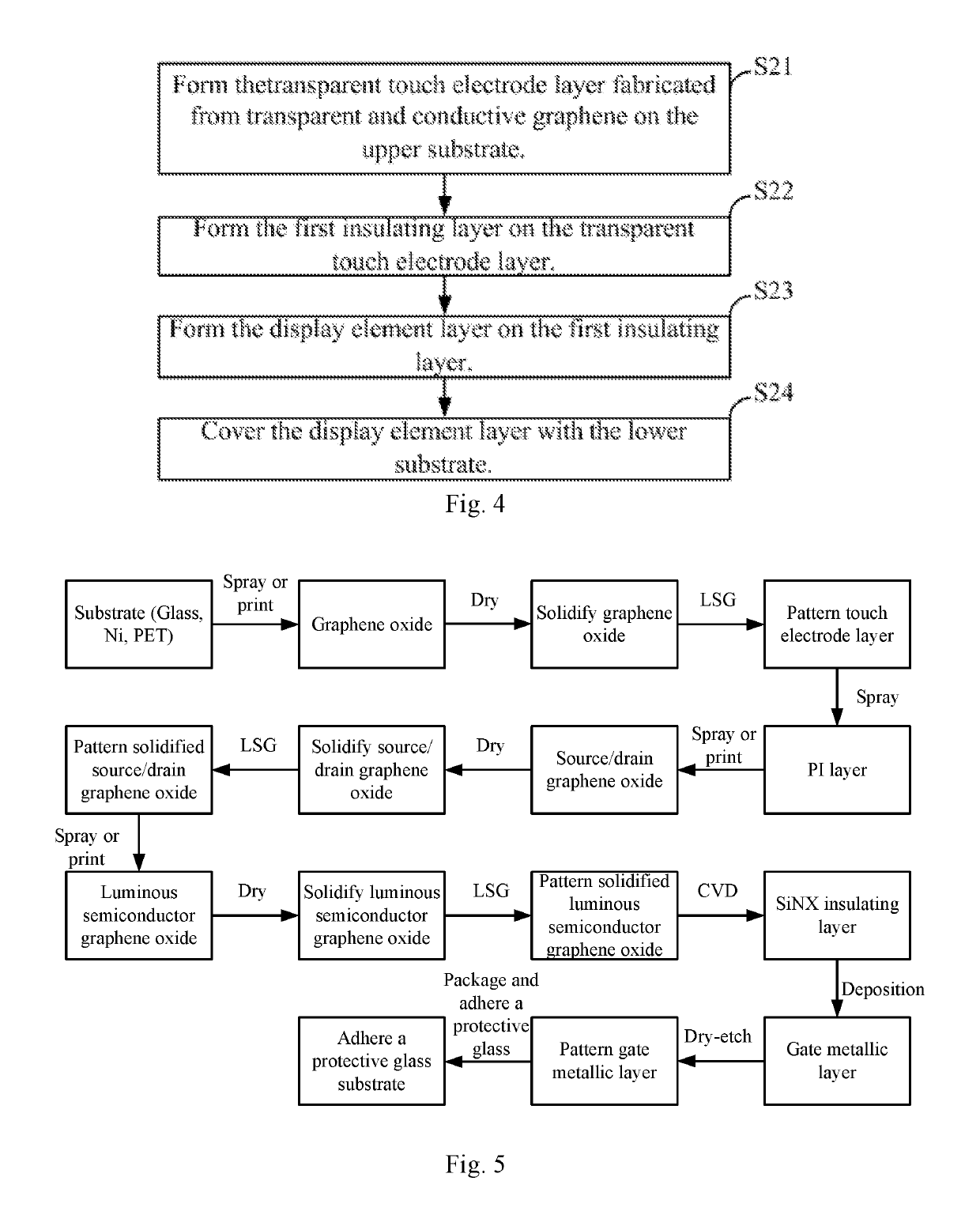

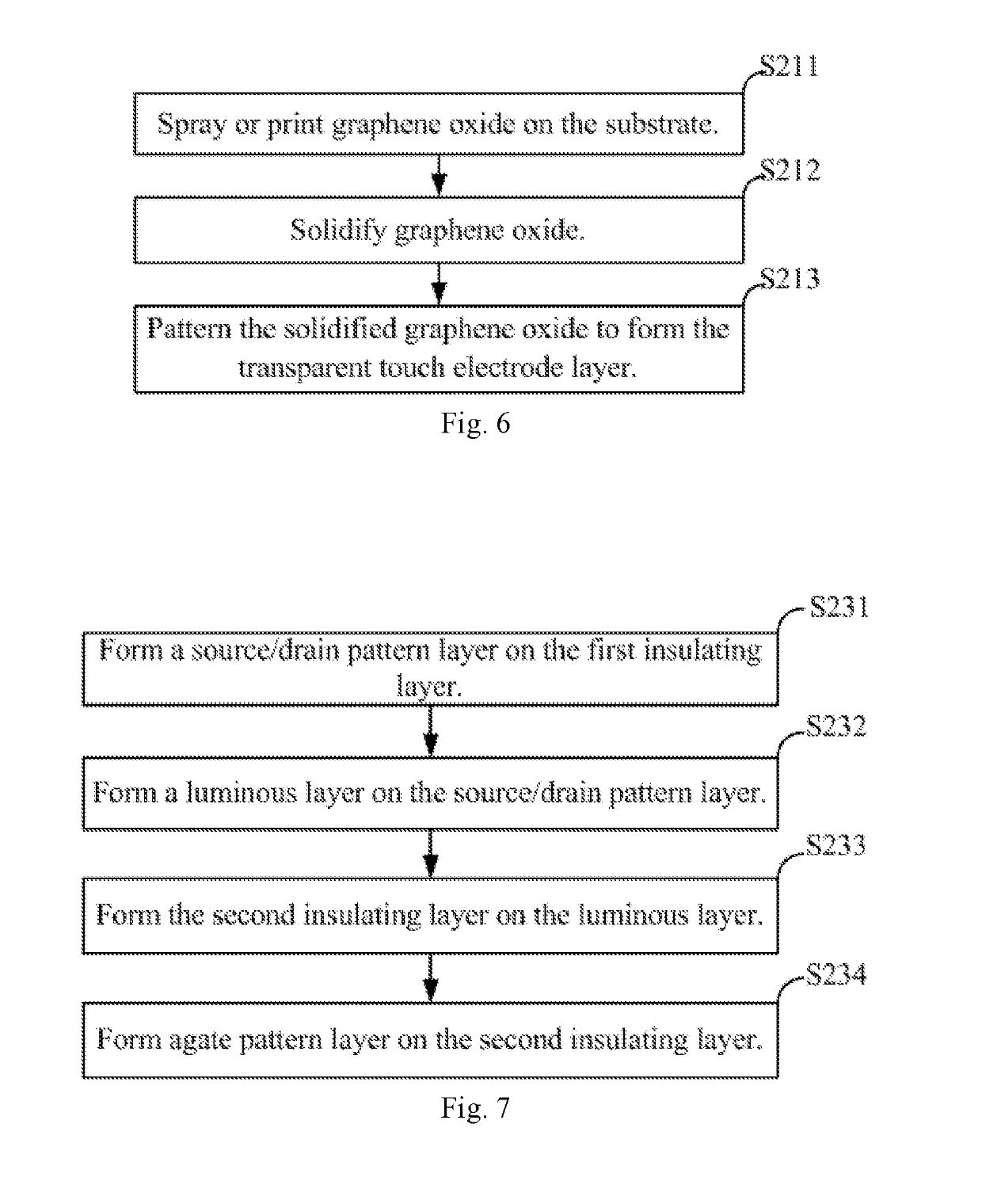

Touch display panel, method for manufacturing touch display panel, and touch panel display

InactiveUS10275060B2Reducing the graphene oxideDecrease in visible light transparencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceGraphene

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Conductive composition and applications thereof

ActiveUS7605528B2Low yield rateSimple manufacturing processDischarge tube luminescnet screensElectroluminescent light sourcesMetal powderElectrode

A conductive composition and applications thereof are provided. The conductive composition comprises metal powder and glass powder. The diameter of metal powder ranges from 1 μm to 3 μm. The diameter of glass powder ranges from 0.5 μm to 1 μm. Weight percentage of the metal powder is from 60% to 98%. The conductive composition could be applied to manufacture the electrodes of a flat lamp.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com