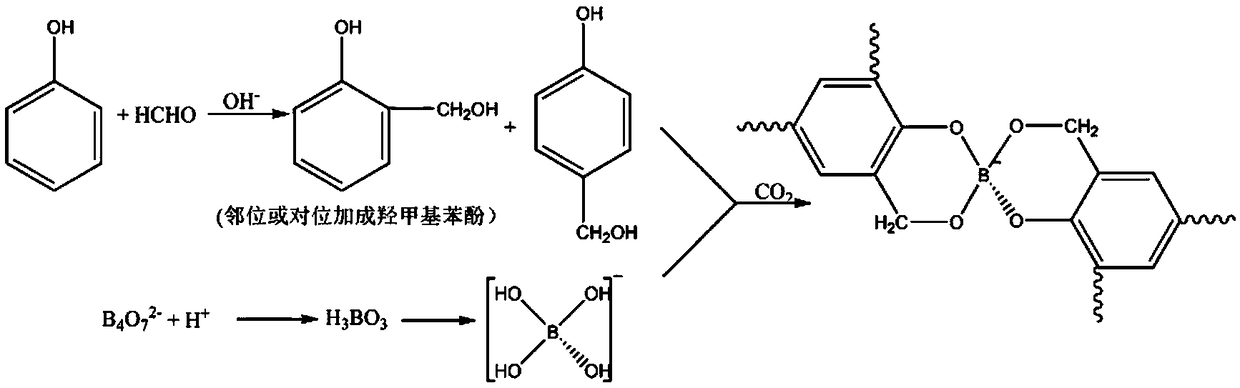

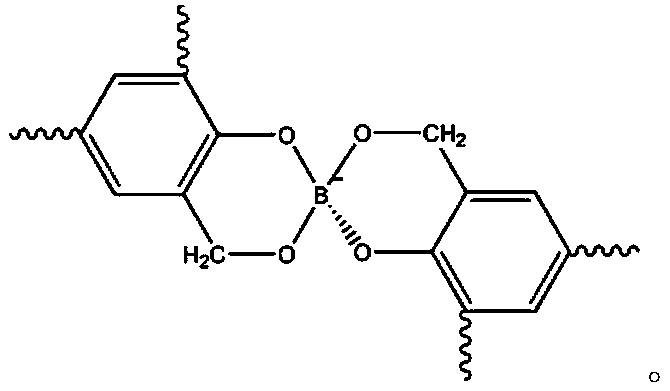

Alkali-resistant boron-modified phenolic resin and preparation method thereof

A phenolic resin, boron modification technology, applied in the field of resin products, can solve problems such as poor alkali resistance, and achieve the effect of improving alkali resistance and expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the embodiment of the present invention, a control CO 2 The time of feeding is obtained boron modified phenolic resin, and its raw material comprises phenol, formaldehyde and borax, wherein adds phenol 0.1mol, formaldehyde 0.16mol and borax 0.75g.

[0021] A CO based control 2 The time of feeding obtains the preparation method of boron modified phenolic resin, and concrete steps are as follows:

[0022] (1) Add phenol and formaldehyde in a three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, and turn on the electric stirrer to stir evenly;

[0023] (2) When the water bath of the reaction device is heated to 90°C, ammonia water is added to adjust the pH to 8.0, and the solution is kept at a temperature of 90-100°C for 2 hours;

[0024] (3) Reflux and condense the insulated three-neck flask with cold water to 50°C, then add a certain amount of borax, and at the same time, feed CO at 50ml / min for 6min. 2 Dehydration under reduc...

Embodiment 2

[0027] In the embodiment of the present invention, a control CO 2 The time of feeding is obtained boron modified phenolic resin, and its raw material comprises phenol, formaldehyde and borax, wherein adds phenol 0.1mol, formaldehyde 0.16mol and borax 0.75g.

[0028] A CO based control 2 The time of feeding obtains the preparation method of boron modified phenolic resin, and concrete steps are as follows:

[0029] (1) Add phenol and formaldehyde in a three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, and turn on the electric stirrer to stir evenly;

[0030] (2) When the water bath of the reaction device is heated to 90°C, ammonia water is added to adjust the pH to 8.0, and the solution is kept at a temperature of 90-100°C for 2 hours;

[0031] (3) Reflux and condense the insulated three-neck flask with cold water to 50°C, then add a certain amount of borax, and at the same time, feed CO at 50ml / min for 7min. 2 Dehydration under reduc...

Embodiment 3

[0034] In the embodiment of the present invention, a control CO 2 The time of feeding is obtained boron modified phenolic resin, and its raw material comprises phenol, formaldehyde and borax, wherein adds phenol 0.1mol, formaldehyde 0.16mol and borax 0.75g.

[0035] A CO based control 2 The time of feeding obtains the preparation method of boron modified phenolic resin, and concrete steps are as follows:

[0036] (1) Add phenol and formaldehyde in a three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, and turn on the electric stirrer to stir evenly;

[0037] (2) When the water bath of the reaction device is heated to 90°C, ammonia water is added to adjust the pH to 8.0, and the solution is kept at a temperature of 90-100°C for 2 hours;

[0038] (3) Reflux and condense the insulated three-neck flask with cold water to 50°C, then add a certain amount of borax, and at the same time, feed CO at a rate of 50ml / min for 8min. 2 Dehydration u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com