A kind of preparation method of pigment functional masterbatch and its product and application

A technology of functional masterbatches and aluminum pigments, which is applied in the preparation of functional masterbatches of effect pigments without flow marks, spray-free high dispersion, and can solve problems such as difficult implementation, poor coloring strength of materials, and failure to meet customer requirements. , achieve high environmental friendliness, reduce application bottlenecks, and be easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

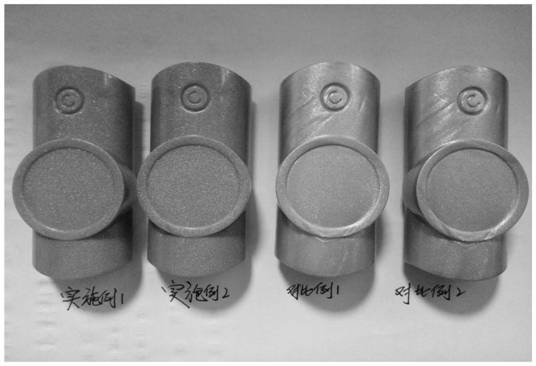

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0024] The invention provides a method for preparing a spray-free effect pigment functional masterbatch, which comprises the following steps:

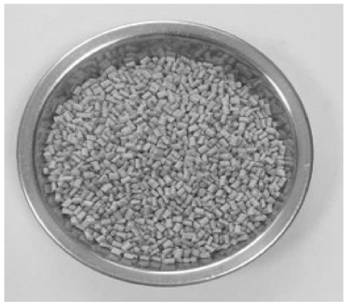

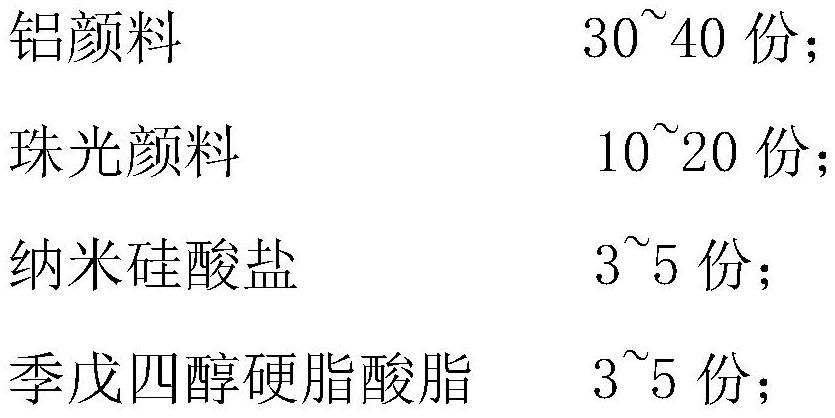

[0025] First add aluminum pigments, pearlescent pigments, pentaerythritol stearate, and nano-silicates into the mixer according to the following parts by mass and mix them evenly at a low speed. act as a package;

[0026]

[0027] Among them, the aluminum pigment has a multi-dimensional three-dimensional structure, and its average particle size is 30-80 microns;

[0028] Pearlescent pigments are glass-coated, with an average particle size of 30-250 mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com