A kind of transparent slurry, wallpaper and preparation method thereof

A wallpaper and paste technology, applied in the field of transparent paste, wallpaper and its preparation, can solve the problems of low adhesion, discoloration of metal powder, easy falling off of gold powder, etc., and achieves high wet tensile strength, excellent scratch resistance, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a method for preparing the above-mentioned transparent slurry, comprising the following steps:

[0059] a) uniformly mixing silicone-modified acrylic resin, alkyd resin, dispersant, leveling agent and solvent to obtain a mixed solution;

[0060] b) Add anhydrous transparent powder and a drying speed modifier to the mixed solution under stirring condition, and after mixing evenly, use a solvent to adjust to the required viscosity to obtain a transparent slurry.

[0061] The components and proportions of the raw materials are the same as above, and will not be repeated here.

[0062] In step a), the uniform mixing is preferably carried out at room temperature.

[0063] In step b), the uniform mixing is preferably carried out at room temperature.

[0064] The transparent slurry layer prepared by the transparent slurry provided by the present invention has better transparency, stronger adhesion, and better wear resistance, and can be we...

Embodiment 1

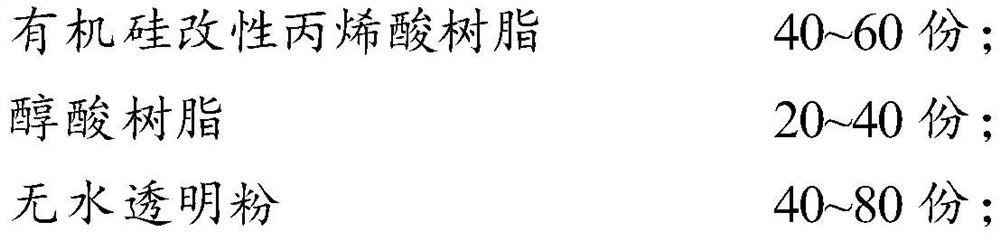

[0102] 40 parts by weight of acrylic modified phenyl silicone resin DY-AB301 (Shandong Dayi Chemical Co., Ltd.), 20 parts by weight of alkyd resin 3370D, 40 parts by weight of anhydrous transparent powder XK-W507 (Shenzhen Anmisi Kexin Materials Co., Ltd.), 1 part by weight of dispersant (ammonium perfluorooctanoate and sodium lauryl sulfate with a mass ratio of 1:1), 1 part by weight of leveling agent (polydimethylsiloxane), 1 1,3-butanediol, 60 parts by weight of isopropanol and 1 part by weight of antistatic agent JWK200 (Switzerland jw import and export company) were mixed to obtain a transparent slurry. The viscosity of the transparent slurry is 3000 cps.

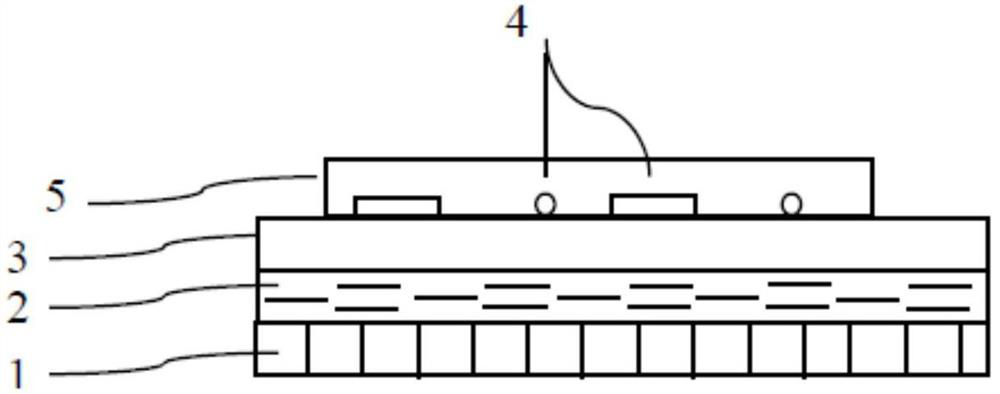

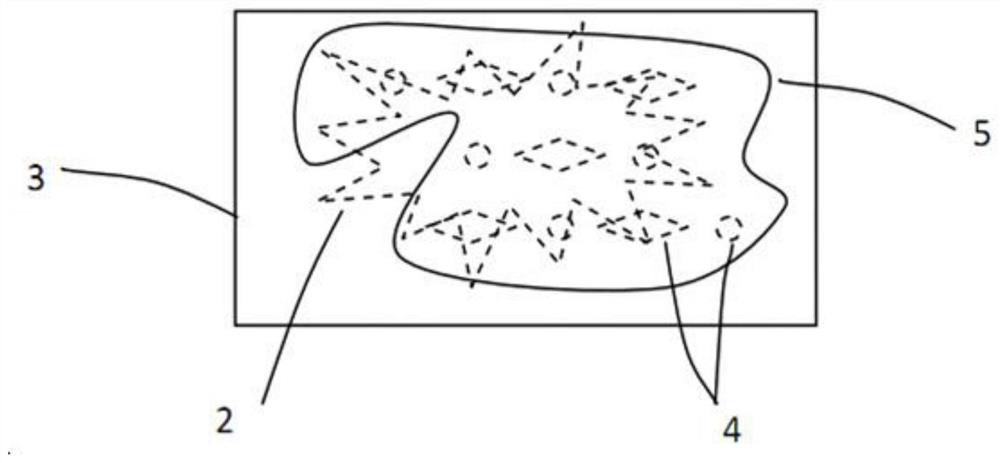

[0103] A patterned textile is laid on the surface of the wood pulp paper to obtain a textile pattern layer. The obtained transparent slurry was coated on the textile pattern layer and dried at 120° C. for 30 seconds to obtain a first transparent layer with a thickness of 0.02 mm. Spray gold powder on the first transp...

Embodiment 2

[0107] 45 parts by weight of acrylic modified phenyl silicone resin DY-AB301 (Shandong Dayi Chemical Co., Ltd.), 24 parts by weight of alkyd resin SM3106-X-70-3, 50 parts by weight of anhydrous transparent powder XK-W316 (Shenzhen Anmi Sike New Material Co., Ltd.), 3 parts by weight of dispersant (ammonium perfluorooctanoate and sodium lauryl sulfate with a mass ratio of 1:3), 2 parts by weight of leveling agent (from Moeneng Chemical Industry Co., Ltd. 1153), 1 part by weight of 1,3-butanediol, 70 parts by weight of isopropanol and 2 parts by weight of SanitizedPL21-60 (Clariant) were mixed to obtain a transparent slurry. The viscosity of the transparent slurry is 5500 cps.

[0108]A patterned textile is laid on the surface of the wood pulp paper to obtain a textile pattern layer. The obtained transparent slurry was coated on the textile pattern layer and dried at 130° C. for 20 seconds to obtain a first transparent layer with a thickness of 0.3 mm. Sand grains are sprayed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com