Optical Microfluidic Chip Based on Polymer and Multilayer Metal Nanoparticle Modification

A microfluidic chip and nanoparticle technology, applied in scientific instruments, fluorescence/phosphorescence, laboratory containers, etc., can solve the problems of complicated and expensive instruments and equipment, need to drive pumps, and slow detection speed, etc. The effect of detection, elimination of interference, and improvement of detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

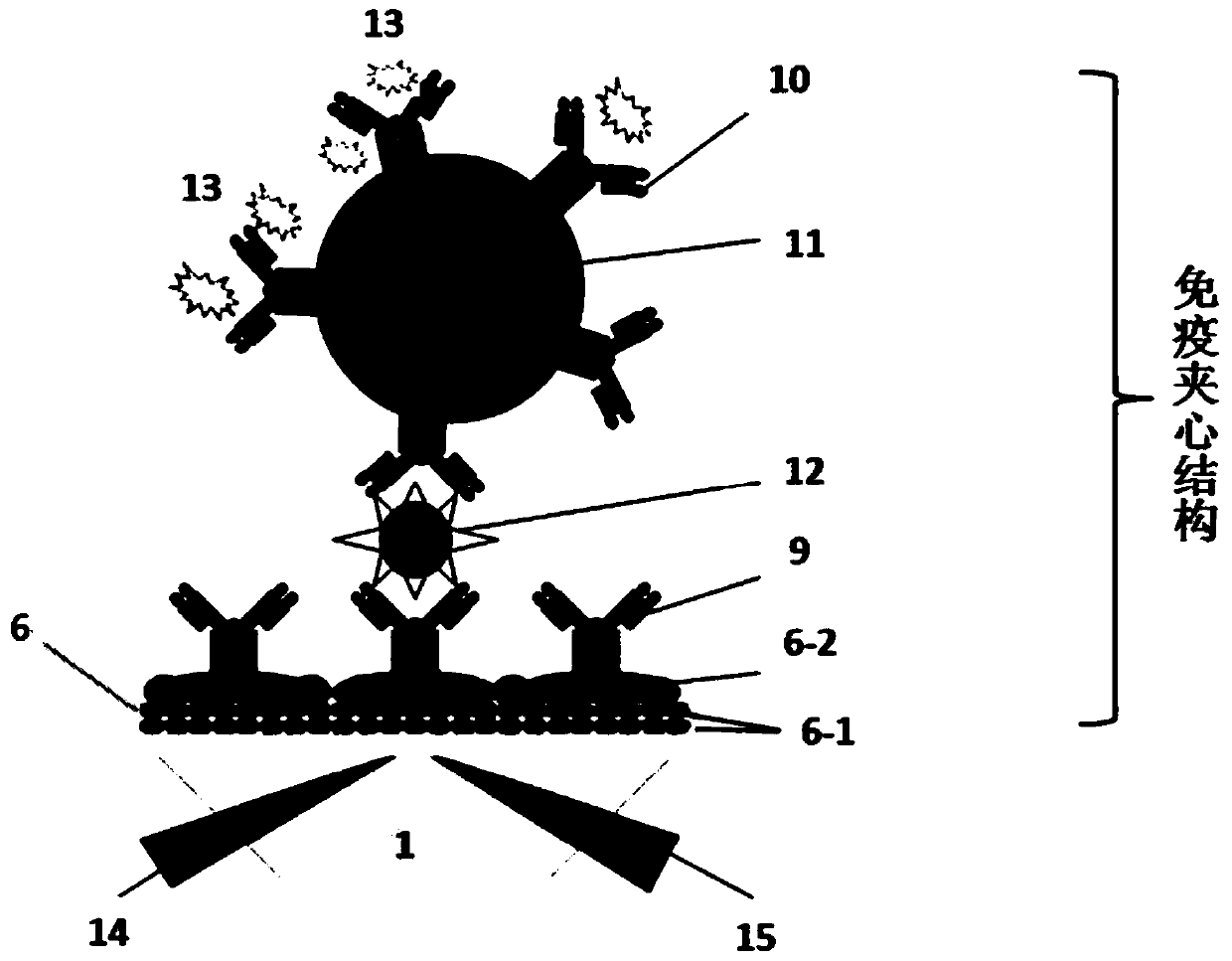

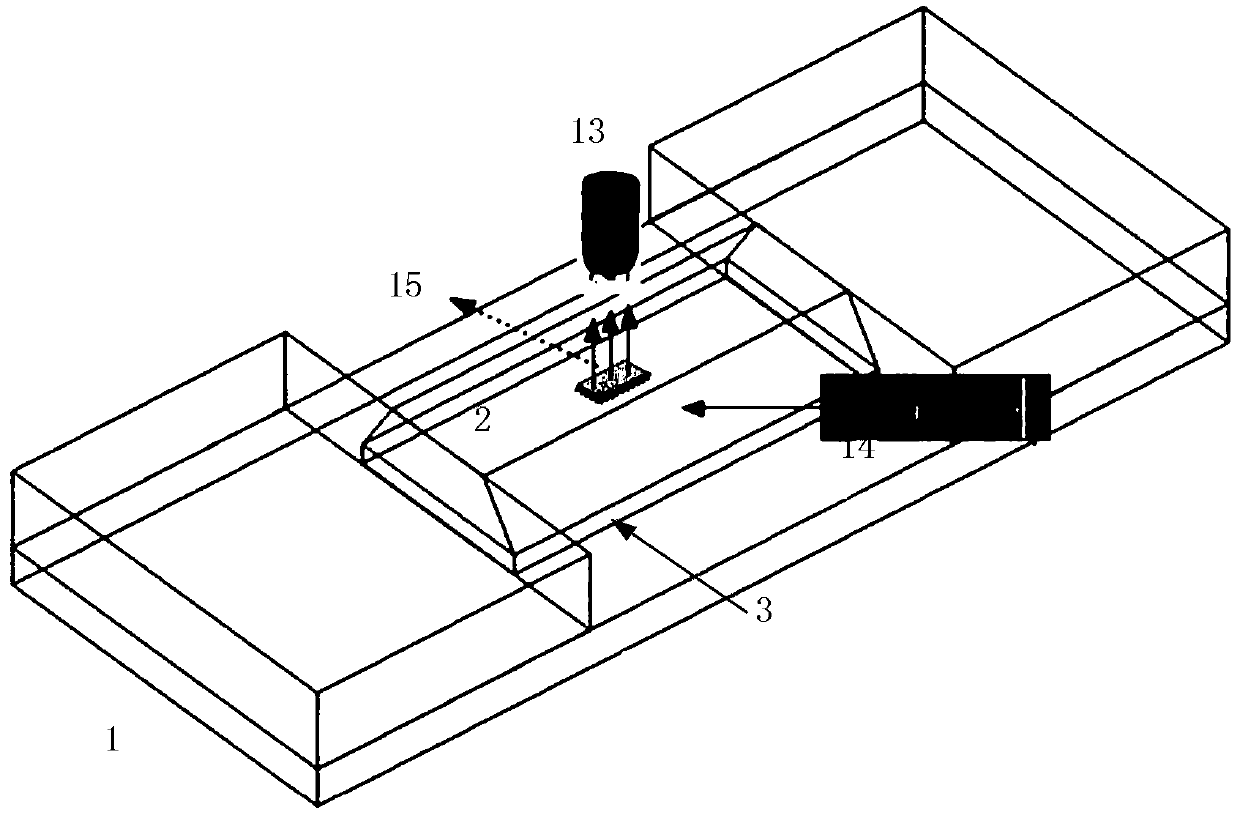

[0061] Embodiment 1 (upper excitation mode)

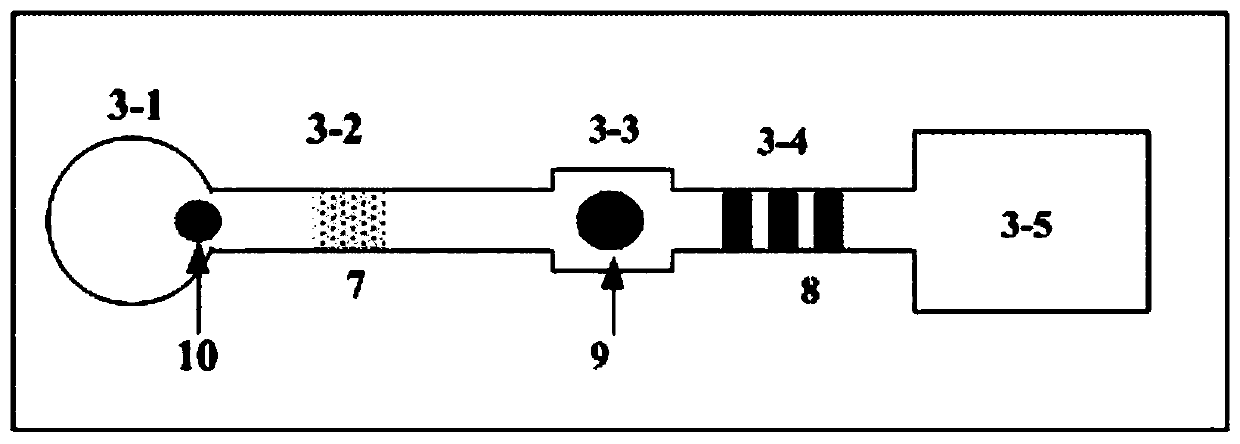

[0062] The chip bottom plate 1 and the chip channel layer 3 are prepared by one-step micro-injection molding. The thickness of the bottom plate is 0.5-10mm. It is preferably made of PET and PMMA high-transparency polymer materials, which have good optical transparency and stability, and the incident light is from the side below Optical surface collimation input. The micro-injection molding technology takes into account the flatness of the optical surface and the micron-level precision requirements of the channel, and realizes the micro-column / micro-disk array structure in the sampling channel area, which is conducive to the miscible reaction of reagents and the control of sampling time. The incident slope has mirror-level smoothness to achieve efficient coupling input and output of incident light. The incident angle of the groove is greater than 40 degrees. The incident light adopts 600nm monochromatic light, which can be polarized...

Embodiment 2

[0069] Embodiment 2 (lower excitation mode)

[0070] The chip bottom plate 1 and the chip channel layer 3 are prepared by one-step micro-injection molding. The thickness of the bottom plate is 0.5-10mm. It is preferably made of PET and PMMA high-transparency polymer materials, which have good optical transparency and stability, and the incident light is from the side below Optical surface collimation input. The micro-injection molding technology takes into account the flatness of the optical surface and the micron-level precision requirements of the channel, and realizes the micro-column / micro-disk array structure in the sampling channel area, which is conducive to the miscible reaction of reagents and the control of sampling time. The incident slope has mirror-level smoothness to achieve efficient coupling input and output of incident light. The incident angle of the groove is greater than 40 degrees. The incident light adopts 600nm monochromatic light, which can be polarized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com