Welding method of pipelines

A welding method and pipeline technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as easy cracks, and achieve the effects of reducing internal stress, ensuring work and life, and cooling uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

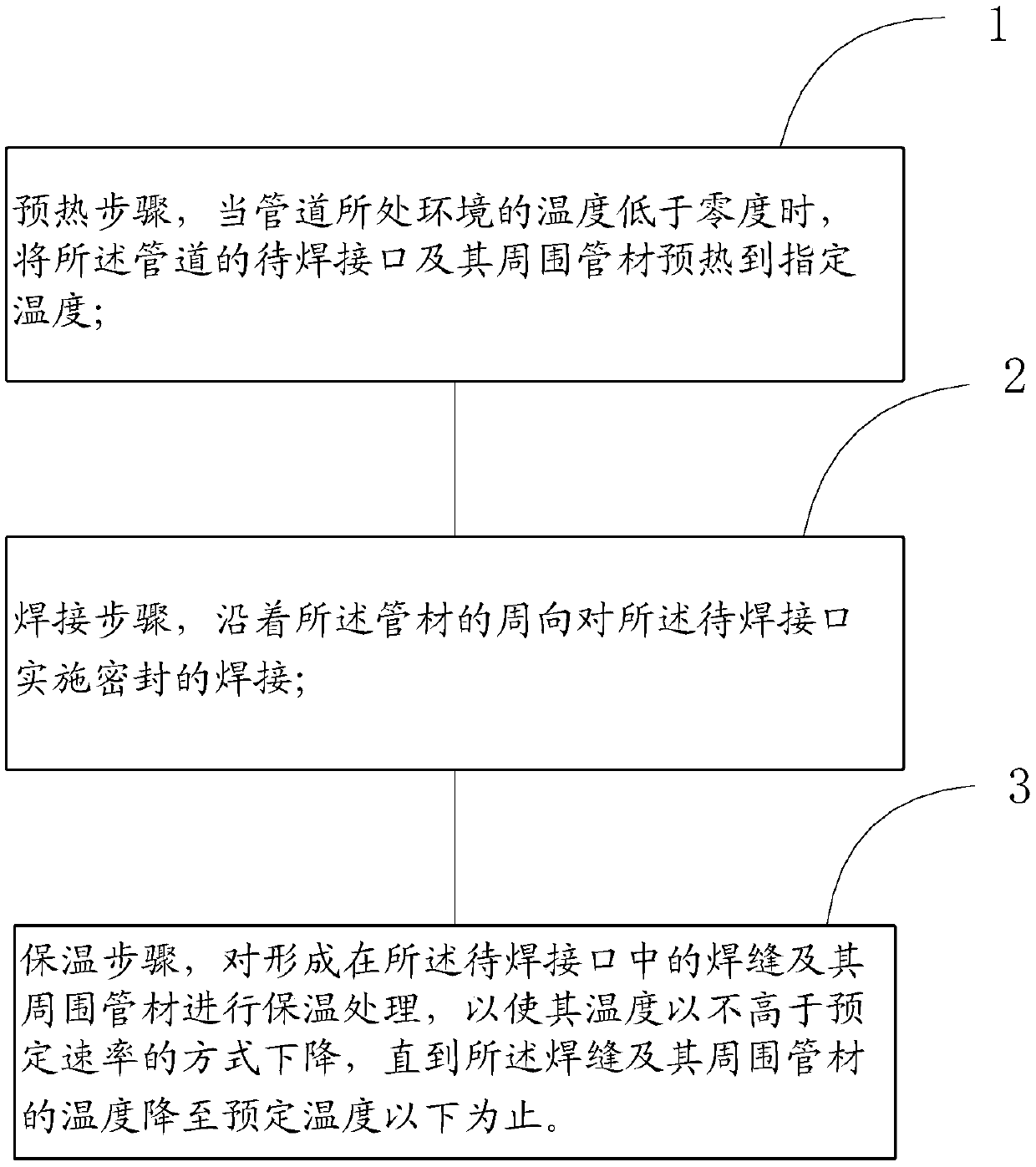

[0020] Such as figure 1 As shown, the welding method 100 of the embodiment of the present invention includes:

[0021] Preheating step 1, when the temperature of the environment where the pipeline is located is below zero, preheat the joint of the pipeline to be welded and the surrounding pipe materials to a specified temperature;

[0022] Specifically, the construction personnel need to determine the specified temperature and preheating range of the pipeline preheating according to the temperature of the environment where the pipeline is located. Generally, the specified temperature is 50-300°C, and the preheatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com