Deforming control method of pre-formed composite forming process and application of control method

A molding process and composite material technology, used in ceramic molding machines, manufacturing tools, etc., can solve problems such as shape deviation, easy deformation, and inability to prepare products of predetermined shapes, achieve comprehensive deformation control, improve product molding rate, processing Good uniformity and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

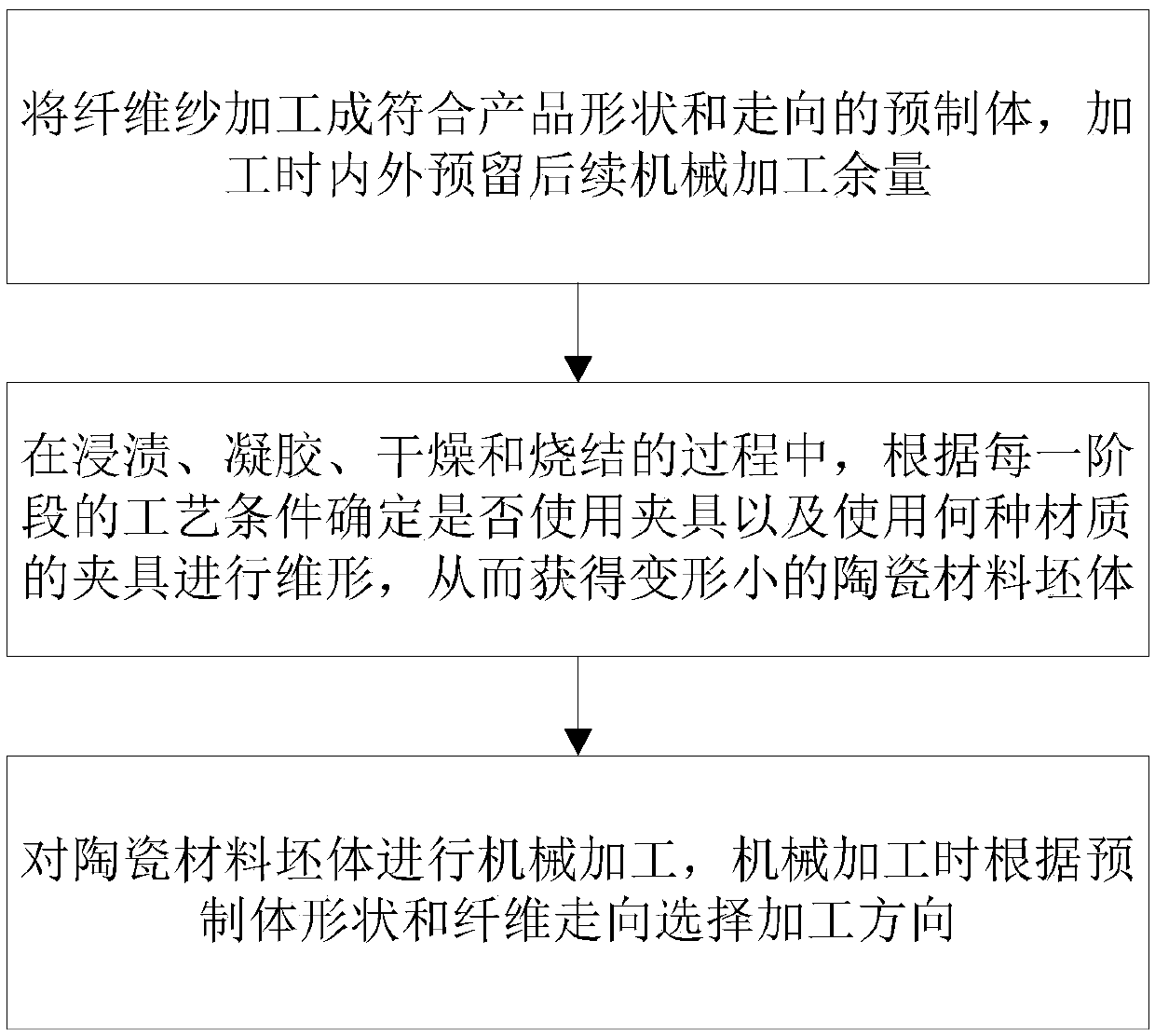

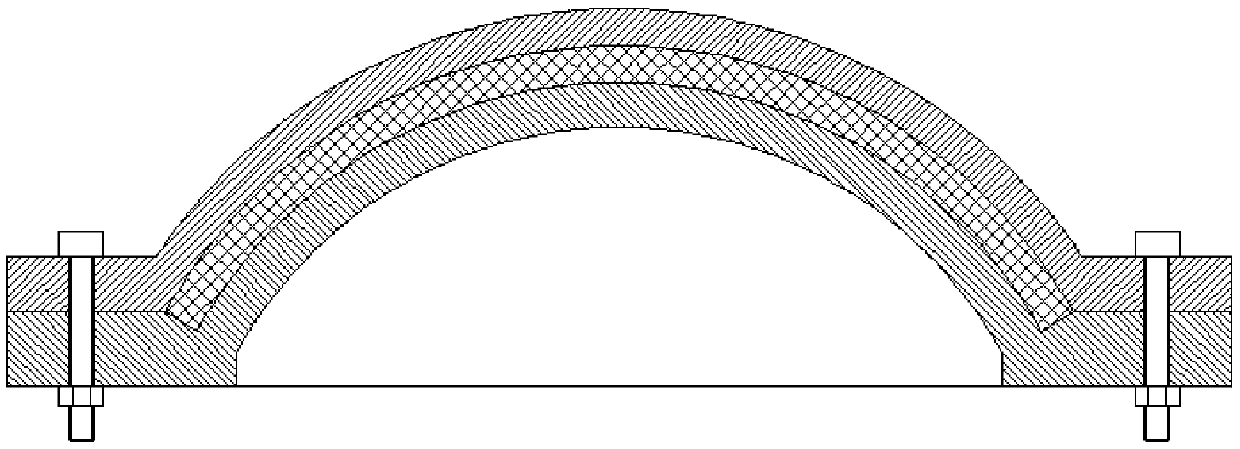

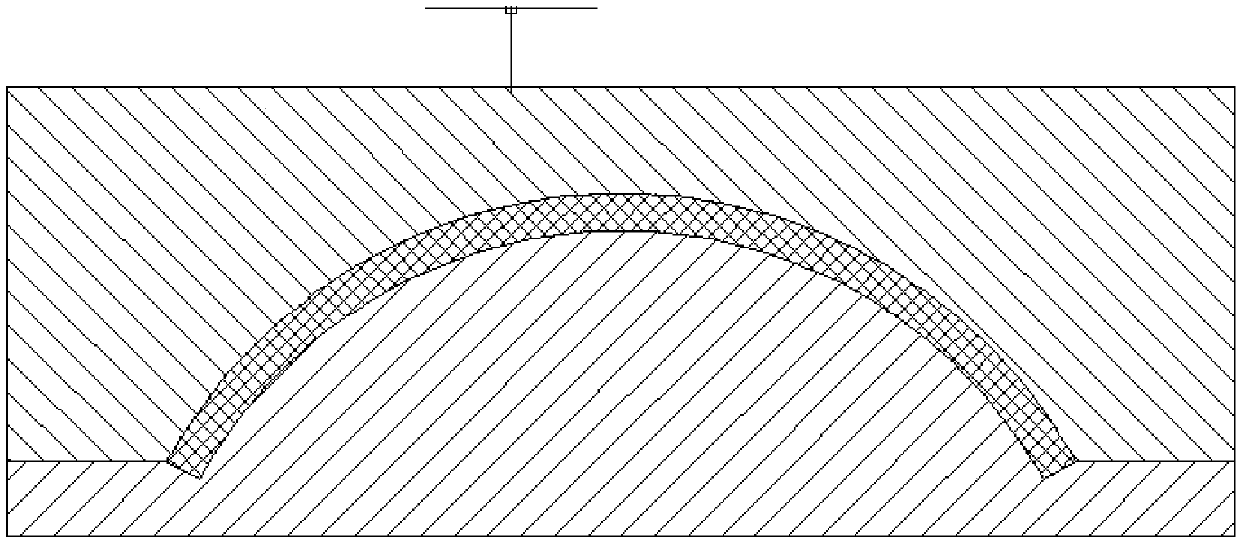

[0052] First of all, the fiber yarn is mechanically needled, and 15% of the processing allowance is reserved for the inside and outside to prepare a preform that conforms to the shape and direction of the product. The structure of the preform is as follows: figure 2 As shown, the prefabricated body is an open structure.

[0053] During the impregnation and gel stages, use aluminum metal fixtures (such as figure 2 Shown) hold the preform and impregnate once, and the solid content of the glue is 40%. After the impregnation is completed, perform gel treatment on the preform (the preform refers to the preform after the impregnation stage), and continue to use aluminum metal clamps to hold the preform during the gel process (the preform refers to the Preforms treated in the impregnation stage) for dimensioning.

[0054] After the gel is completed, the gel-treated preform is dried. In the drying stage, the preform (the preform refers to the preform processed in the coagulation s...

Embodiment 2

[0058] First of all, the fiber yarn is mechanically needled, and 15% of the processing allowance is reserved for the inside and outside to prepare a preform that conforms to the shape and direction of the product. The structure of the preform is as follows: figure 2 As shown, the prefabricated body is an open structure.

[0059] During the impregnation and gel stages, use aluminum metal fixtures (such as figure 2 Shown) hold the preform and impregnate once, and the solid content of the glue is 40%. After the impregnation is completed, perform gel treatment on the preform (the preform refers to the preform after the impregnation stage), and continue to use aluminum metal clamps to hold the preform during the gel process (the preform refers to the Preforms treated in the impregnation stage) for dimensioning.

[0060] After the gel is completed, the gel-treated preform is dried. In the drying stage, the preform (the preform refers to the preform processed in the coagulation s...

Embodiment 3

[0064] First of all, the fiber yarn is mechanically needled, and 15% of the processing allowance is reserved for the inside and outside to prepare a preform that conforms to the shape and direction of the product. The structure of the preform is as follows: figure 2 As shown, the prefabricated body is an open structure.

[0065] During the impregnation and gel stages, use aluminum metal fixtures (such as figure 2 Shown) hold the preform and impregnate once, and the solid content of the glue is 40%. After the impregnation is completed, perform gel treatment on the preform (the preform refers to the preform after the impregnation stage), and continue to use aluminum metal clamps to hold the preform during the gel process (the preform refers to the Preforms treated in the impregnation stage) for dimensioning.

[0066] After the gel is completed, the gel-treated preform is dried. In the drying stage, the preform (the preform refers to the preform processed in the coagulation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com