Fiber-enhanced light interlayer composite material and subway cockpit body prepared from same

A composite material and fiber-reinforced technology, applied to railway car bodies, railway car body parts, railway roofs, etc., can solve problems affecting driving safety, poor strength performance, delamination of skin and foam sandwich, etc., and achieve quality Lightweight, good impact resistance and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 4-6 As shown in the structure, the lightweight composite subway cockpit cabin body of the present invention includes a front roof 4 and a bottom plate 5, and the front roof 4 and the bottom plate 5 are connected and fixed by connectors to form a predetermined cabin structure. The front roof 4 is also provided with a window 6 and a light hole 7 penetrating through the front roof 4 along the thickness direction.

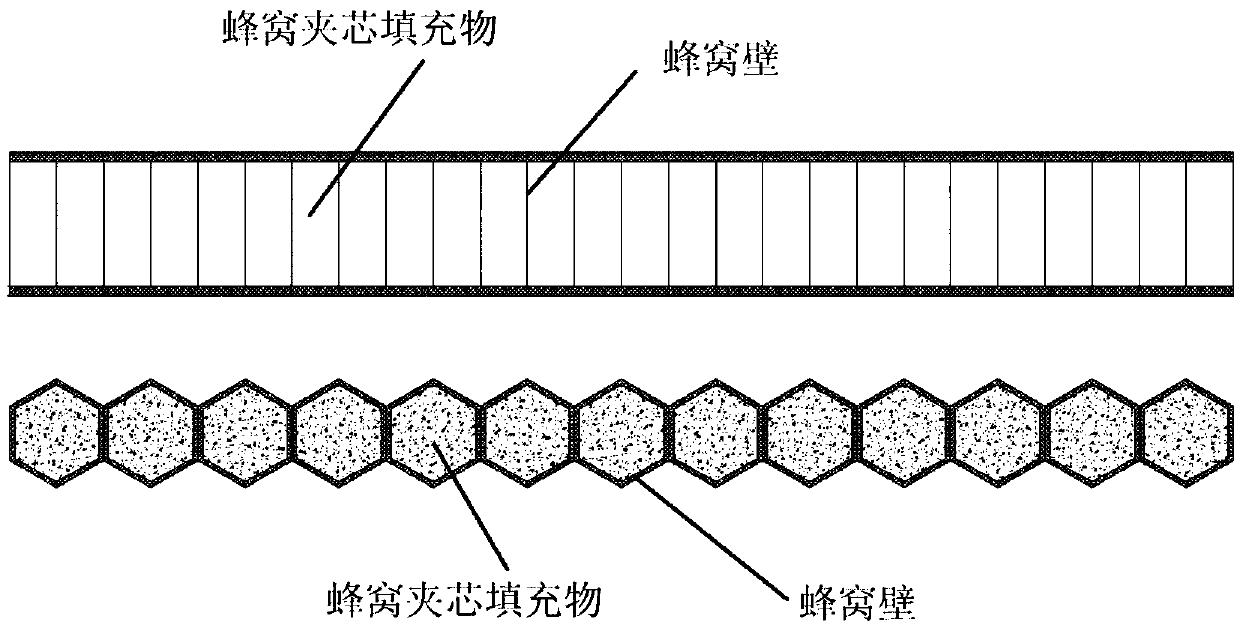

[0044] In the cabin structure, the front roof 4 and the bottom plate 5 are all made of fiber-reinforced lightweight sandwich composite materials, such as figure 1 As shown, the fiber-reinforced lightweight sandwich composite material includes an upper skin 1, a lower skin 2, and a sandwich layer 3 placed between the upper skin 1 and the lower skin 2, forming the upper skin The material of the skin 1 and the lower skin 2 is a fiber-reinforced resin-based composite material made of fiber material and resin, and the sandwich material forming the sa...

Embodiment 2

[0056] Such as Figure 4-6 As shown in the structure, the lightweight composite subway cockpit cabin body of the present invention includes a front roof 4 and a bottom plate 5, and the front roof 4 and the bottom plate 5 are connected and fixed by connectors to form a predetermined cabin structure. The front roof 4 is also provided with a window 6 and a light hole 7 penetrating through the front roof 4 along the thickness direction.

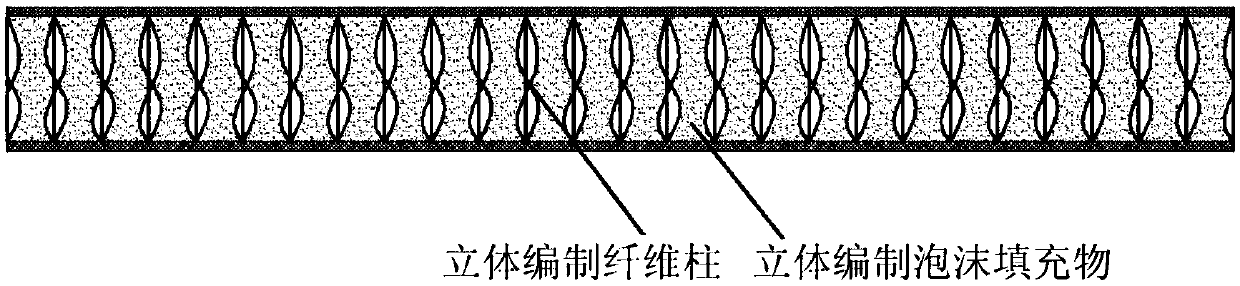

[0057] In the cabin structure, the front roof 4 and the bottom plate 5 are all made of fiber-reinforced lightweight sandwich composite materials, such as figure 2 As shown, the fiber-reinforced lightweight sandwich composite material includes an upper skin 1, a lower skin 2, and a sandwich layer 3 placed between the upper skin 1 and the lower skin 2, forming the upper skin The material of the skin 1 and the lower skin 2 is a fiber-reinforced resin-based composite material made of fiber material and resin, and the sandwich material forming the s...

Embodiment 3

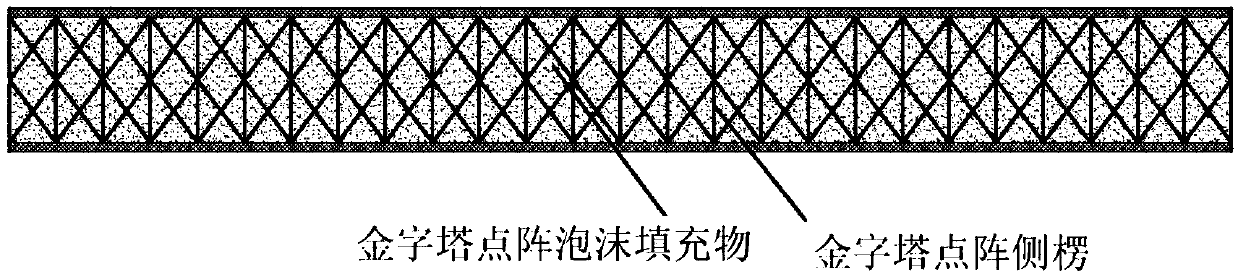

[0069] Such as Figure 4-6 As shown in the structure, the lightweight composite subway cockpit cabin body of the present invention includes a front roof 4 and a bottom plate 5, and the front roof 4 and the bottom plate 5 are connected and fixed by connectors to form a predetermined cabin structure. The front roof 4 is also provided with a window 6 and a light hole 7 penetrating through the front roof 4 along the thickness direction.

[0070] In the cabin structure, the front roof 4 and the bottom plate 5 are all made of fiber-reinforced lightweight sandwich composite material, and the fiber-reinforced lightweight sandwich composite material includes an upper skin 1, a lower skin A skin 2 and a sandwich layer 3 placed between the upper skin 1 and the lower skin 2, the material forming the upper skin 1 and the lower skin 2 is fiber reinforced resin made of fiber material and resin Based composite material, the sandwich material forming the sandwich layer 3 is a sandwich materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com