Preparation method of nylon powder material for selective laser sintering

A nylon powder and laser sintering technology, which is applied in the field of additive manufacturing, can solve the problems of waste of powder, pollute the environment, increase costs, etc., and achieve the effects of reducing pollution, good surface quality, and low usage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of nylon powder material preparation method for selective laser sintering provided by the invention comprises the following steps:

[0034] (1) Add nylon raw material, end-capping agent, deionized water and antioxidant into the polymerization kettle to undergo polymerization reaction, and then discharge and pelletize through water-cooled drawing strips to obtain nylon pellets, wherein, nylon raw material, end-capping agent And the mass percent of antioxidant is 96~97.5%: 0.5~3.8%: 0.2~0.5%;

[0035] (2) Nylon granules and solvent are mixed and stirred, powder is prepared by solvent method, and nylon powder is obtained by centrifugal filtration, drying and sieving;

[0036] (3) Mix and stir the nylon powder, flow aid and end-capping agent evenly, and then sieve, the average particle size is 40-110 μm, and a nylon powder material for selective laser sintering is prepared.

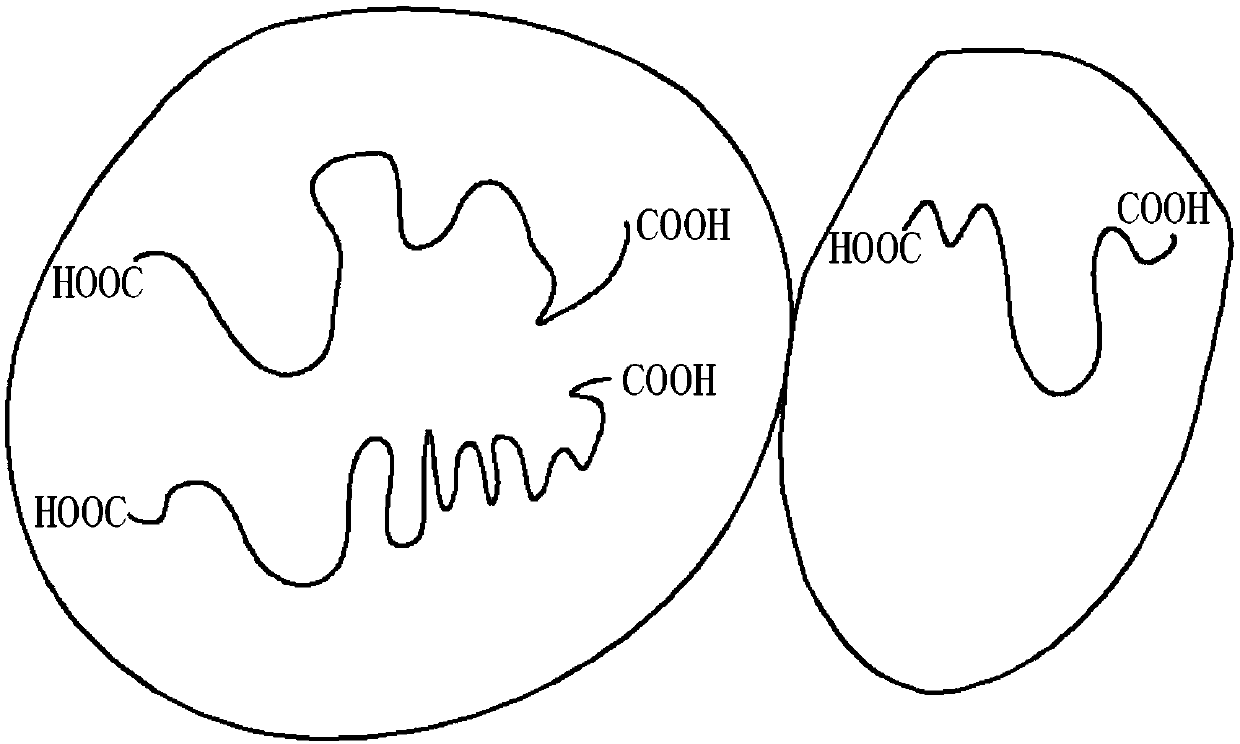

[0037] By adding an end-capping agent, the nylon pellets with controllable molecular weight...

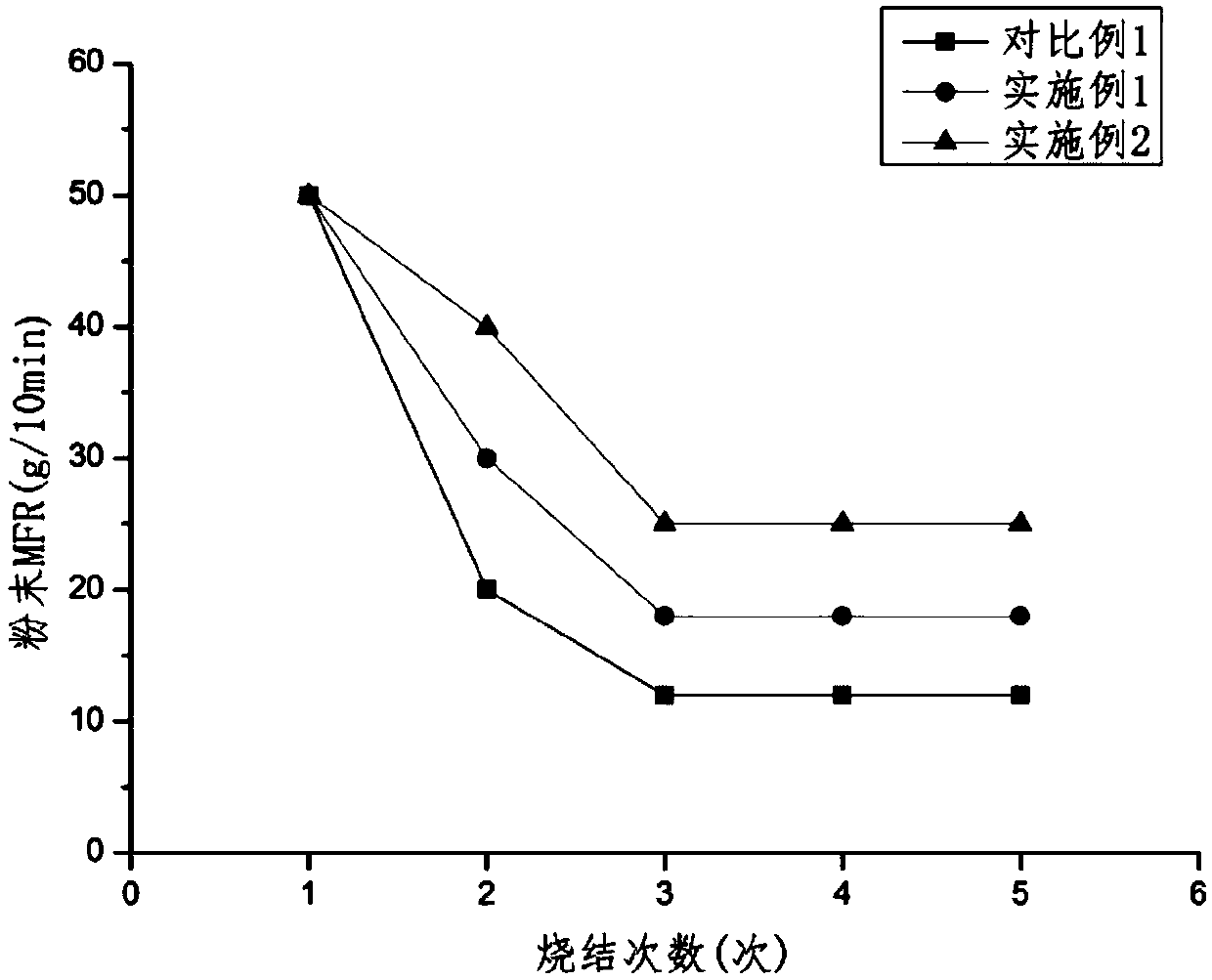

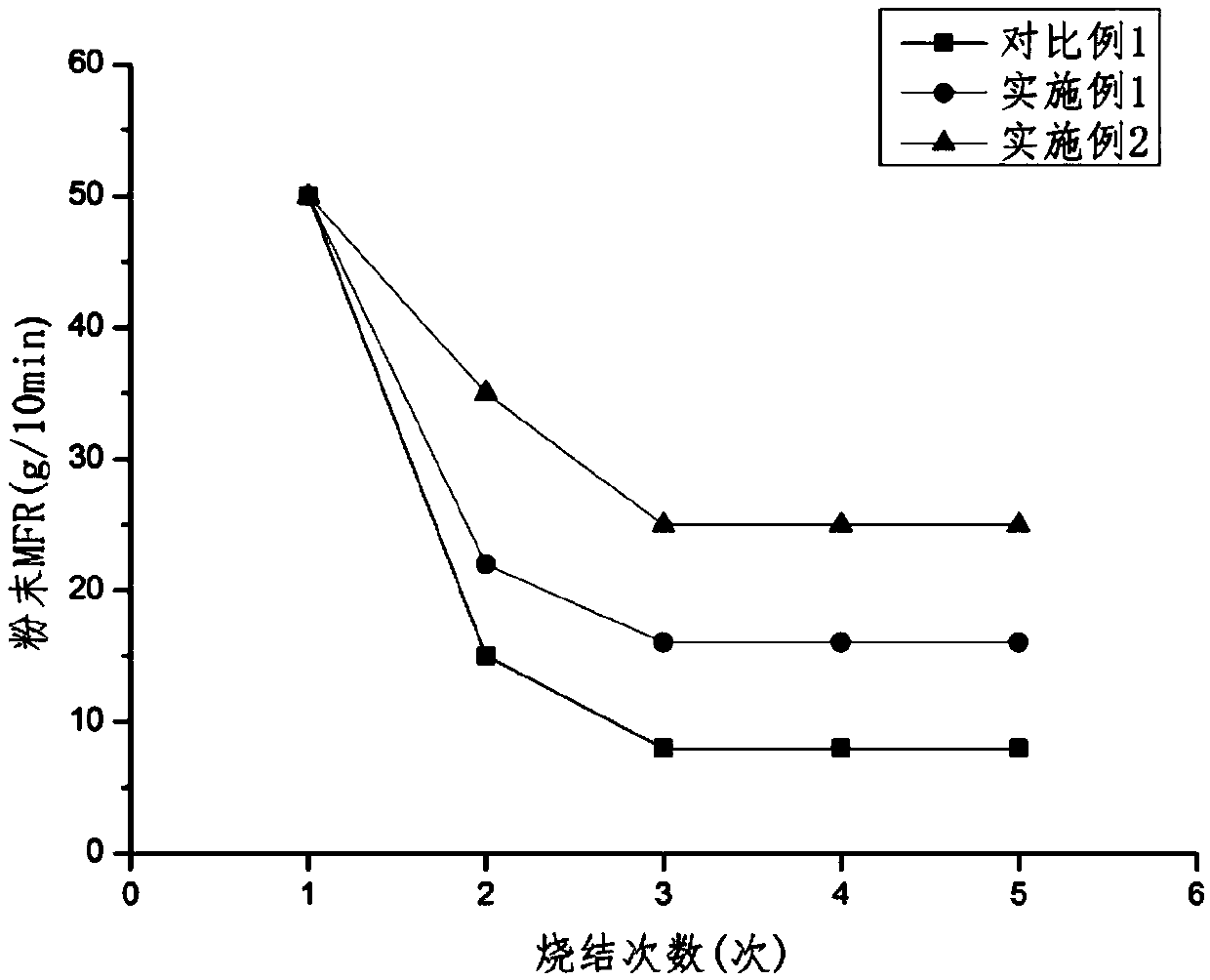

Embodiment 1

[0060] (1), the mass fraction is 96% nylon 1010 salt, the mass fraction is 3.8% sebacic acid and the mass fraction is 0.2% anti-oxidant, deionized water is added in the polymerization kettle, the reactor is airtight, vacuumized, Then feed inert gas until the pressure inside the reactor is 0.10Mpa, raise the temperature to 220°C, the pressure inside the reactor reaches 1.8MPa, and keep the pressure for 1h; The pressure rate is 0.015Mpa / min, and the temperature is raised to 240°C. In the second stage, the pressure is released to 0.4Mpa, and the pressure release rate is 0.01Mpa / min, and the temperature is raised to 250°C. In the third stage, the pressure is released to normal pressure, and the pressure release rate is The temperature is 0.005Mpa / min, and the temperature is raised to 265°C. After the pressure is released to normal pressure, keep the reaction for 2.5 hours, stop heating and discharge through water-cooled rods, and pelletize to obtain nylon 1010 pellets.

[0061] (...

Embodiment 2

[0064] (1), the mass fraction is 96% nylon 1010 salt, the mass fraction is 3.8% sebacic acid and the mass fraction is 0.2% anti-oxidant, deionized water is added in the polymerization kettle, the reactor is airtight, vacuumized, Then feed inert gas until the pressure inside the reactor is 0.10Mpa, raise the temperature to 220°C, the pressure inside the reactor reaches 1.8MPa, and keep the pressure for 1h; The pressure rate is 0.015Mpa / min, and the temperature is raised to 240°C. In the second stage, the pressure is released to 0.4Mpa, and the pressure release rate is 0.01Mpa / min, and the temperature is raised to 250°C. In the third stage, the pressure is released to normal pressure, and the pressure release rate is The temperature is 0.005Mpa / min, and the temperature is raised to 265°C. After the pressure is released to normal pressure, keep the reaction for 2.5 hours, stop heating and discharge through water-cooled rods, and pelletize to obtain nylon 1010 pellets.

[0065] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com