Harmless sludge-treatment method

A harmless sludge treatment technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of high water content and hinder the development of sludge incineration treatment technology , environmental secondary pollution and other issues, to achieve the effect of enhancing heat exchange capacity, avoiding harm to the human body and the environment, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

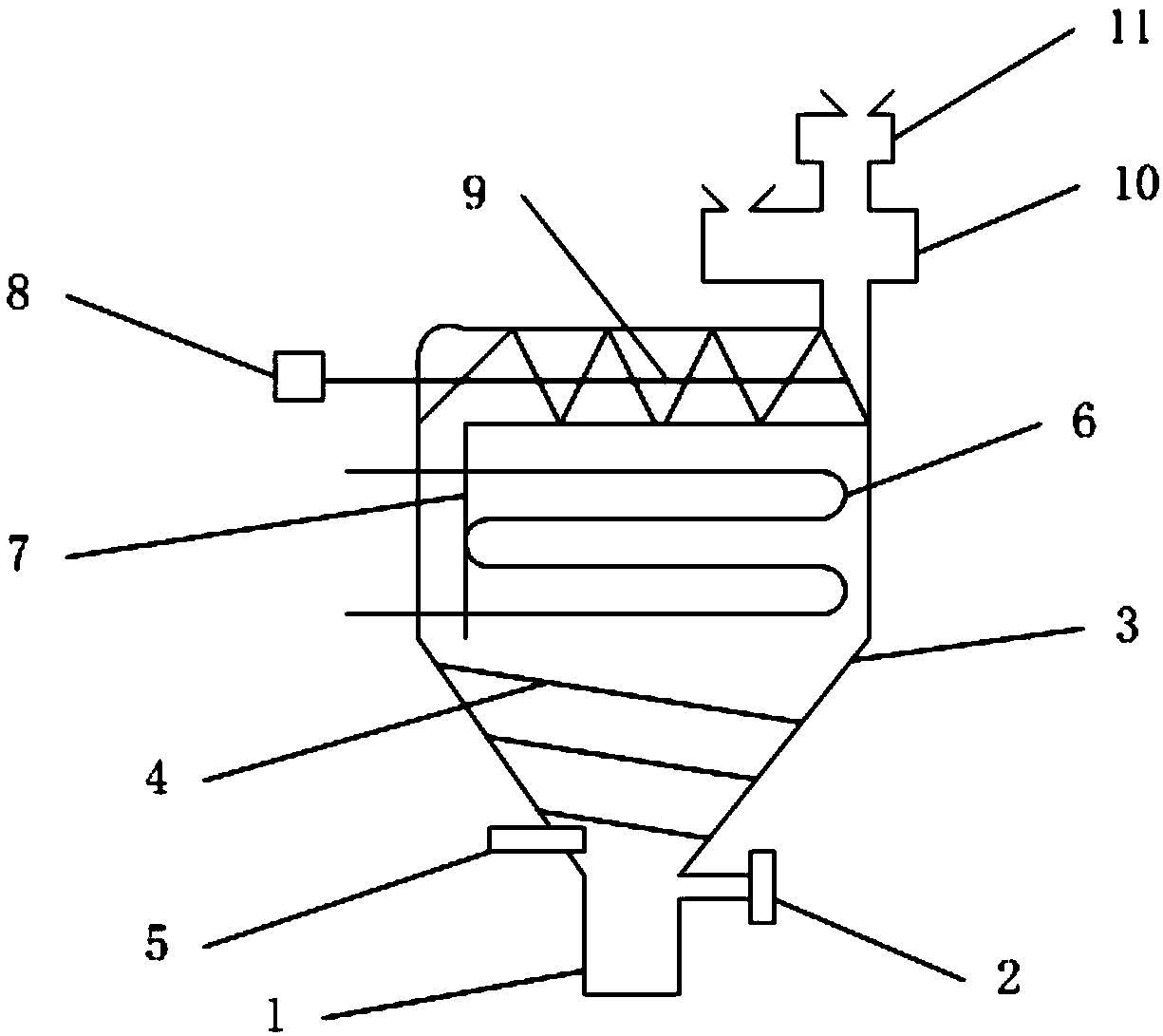

[0024] Such as figure 1 Shown, a kind of sludge harmless treatment method, it comprises the following steps:

[0025] 1) Construction of a sludge incineration device, the sludge incineration device includes a sludge dehydration device 11, a mixing device 10, a drying device, a combustion device, a water circulation device 6 and a combustion barrel 5, and the sludge dehydration device 11 is provided with a dehydration outlet feed port and dehydration feed port, the mixing device 10 is provided with a mixing feed port and a mixing discharge port, the dehydration discharge port is connected with the mixing feed port, and the drying device includes a box body, an auger 9 and a driving device 8, the auger 9 is arranged in the box, the driving device 8 is connected with the auger 9 to drive the auger 9 to rotate, and one end of the box is provided with a box body The other end of the box is provided with a box outlet, and the box inlet is connected to the mixing outlet. The combust...

Embodiment 2

[0030] Such as figure 1 Shown, a kind of sludge harmless treatment method, it comprises the following steps:

[0031]1) Construction of a sludge incineration device, the sludge incineration device includes a sludge dehydration device 11, a mixing device 10, a drying device, a combustion device, a water circulation device 6 and a combustion barrel 5, and the sludge dehydration device 11 is provided with a dehydration outlet feed port and dehydration feed port, the mixing device 10 is provided with a mixing feed port and a mixing discharge port, the dehydration discharge port is connected with the mixing feed port, and the drying device includes a box body, an auger 9 and a driving device 8, the auger 9 is arranged in the box, the driving device 8 is connected with the auger 9 to drive the auger 9 to rotate, and one end of the box is provided with a box body The other end of the box is provided with a box outlet, and the box inlet is connected to the mixing outlet. The combusti...

Embodiment 3

[0036] Such as figure 1 Shown, a kind of sludge harmless treatment method, it comprises the following steps:

[0037] 1) Construction of a sludge incineration device, the sludge incineration device includes a sludge dehydration device 11, a mixing device 10, a drying device, a combustion device, a water circulation device 6 and a combustion barrel 5, and the sludge dehydration device 11 is provided with a dehydration outlet feed port and dehydration feed port, the mixing device 10 is provided with a mixing feed port and a mixing discharge port, the dehydration discharge port is connected with the mixing feed port, and the drying device includes a box body, an auger 9 and a driving device 8, the auger 9 is arranged in the box, the driving device 8 is connected with the auger 9 to drive the auger 9 to rotate, and one end of the box is provided with a box body The other end of the box is provided with a box outlet, and the box inlet is connected to the mixing outlet. The combust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com